Planers For Sale

Category

Planers

127 Results Found

$ 21,500

(3) Baker Wood Wizzes 6x, variable speed 5.5 HP motors, 480 volt with 6X cutter heads available, The Wood Wizz is a machine that is designed to surface and finish slabs, burls, tabletops and even recycled timber with a lower labor input. The machine is ideal for woodworkers who want to add value to their material and produce a perfect finish without any tearing, ridging, or burn marks. The Wood Wizz runs on a X, Y and Z axis. It includes a large 6" cutter, 10 square cutter inserts, speed controller, two inverters, sanding disk with pads & sand paper, dust tower, dust hosing and fittings. Also includes an edging/joining cutter to combine two or more pieces of material flawlessly. 3 machines very lightly used and in perfect shape. 6x wood wizz footprint is 7’7” wide x 19” 6” long, processing area is 6’ wide x 17” 10” long adjustable leveling legs, welded steel frame. $20,500, 21,000 and 21,500 each. Machines all have about the same hours and are approximately 4 to 6 years old. Contact Michael at [email protected] 828 779 7102 Machinery located in Jacksonville Fl.

Selling a complete Planermill Line -Infeed, tilthoist, landing table, pineapple feed and transfer. -Stetson Ross 6-10-A1 Planer/Moulder c/w assortment of changeable 12 knife side heads can dress up to 6” thick, 8 knife top/bottom heads, 12” wide. Moulder heads with plenty of attachments. -Outfeed Belt, Slowdown Belt, accumulation transfer, lug loader, board turner, Canadian Trimmer with an assortment of trim length stops, trim block belts, green chain and stacking carts. Great planermill, ran 120,000fbm per shift when in production. 600V, 3phase, 60Hz system. Call/text for more details

$ 6,000

Call for Price

Call for Price

$ 10,200

BUSS - DL 30" x 8", ...Heavy-Duty Wood Planer with GrinderModel "DL" bed capacity: 30" W x 65" L x 8" H,Specifications -- (2) Large steel support rollers on bed; upper area: (1) Steel roller. -- (1) Cutterhead with: (4) Knives; (1) grip through roller. -- Heavy-Duty spring tension adjustment on top of machine. -- (2) 15 HP - 3 PH motors; one connected to 20-ratio gear reducer, variable feed speed drive; the other connected to the cutterhead system. -- Upper cross frame attachment for Knife Grinder System (comes with the Grinder).Equipped with & Features -- Oil cup & grease fitting lube system. -- Power raising and lowering of the Planer bed.

$ 6,950

BUSS M 4L 30" STRAIGHT KNIFE PLANER30" X 8" Cap., 20 HP direct drive top motor, 1.5 - 2 HP for dual feed speed, 4-knife round top cutterhead, sectional infeed rolls and chipbreaker. Complete with: Shaving hood, magnetic starters.

Call for Price

$ 189,900

CAM-WOOD WP-4 S2C-500-12 4-SIDED PLANEROutstanding Performance - Quality Components 4 sided with 6 heads as: top and bottom, left and right, (2) chamfer units -- Floating bottom infeed rolls for smooth, positive feeding -- PLC controls with touch-screen interface for ease of operation -- Variable feed speeds by VFD. Controlled from touch screen -- Drive shaft and universal joint feed roll transmission for each feed roll -- Power elevation of overhead mechanism via touch screen control -- Thickness settings from touch screen control -- With cutterheads and carbide knives for straight knife work -- With spindles for easing top edges -- Tables, fences, etc. are precision ground and hard chromed to provide long life and smooth feeding -- Overhead mechanism travels up/down and is support by (6) hard chromed posts -- Motor Control Center with under voltage and overload protection; includes UL and CSA approved electrical componentsWorking Capacities: -- 19 3/4" wide x 12"; high (500 mm X 305 mm) -- Min. thickness: 3/4"; -- Min. width 2-3/4"; -- Max. depth of cut: 1/4"; all heads -- Max. length: Unlimited -- Min. length: 70"; for feed-thru; butt-feed down to 40". (40"; to 70"; may have minor inaccuracies at edge due the hold-down restrictions) -- Feed speeds from 20 to 66 FPMCutterhead Motors: -- 25 HP Top and Bottom (see optional equipment for larger motors) -- 20 HP Right & Left Side Heads (see optional equipment for larger motors) -- Includes Right & Left Spindles for eased edge at top of board; consists of (2) 1 HP floating spindles to accurately ease top edges. Profile knives in primary side heads ease bottom edges. -- Chamfer motor 1/2 HP Feed Works: -- (2) 5 HP VFD’s -- (1) motor drives top set and (1) motor drives the bottom set of feed rolls -- Boards synchronize top and bottom feed roll speed and torque --Cutterheads and Spindles: -- Top and bottom spindles with 60mm (2.362";) spindle dia. Other diameters on request. -- Includes a set of (2) 4-knife x 20"; long x 5-1/2"; dia. spiral carbide cutterheads. -- Side heads with 40mm spindle dia. Other diameters on request -- Includes a set of (2) 4-knife x 12"; long spiral carbide heads -- Includes (1) set per head: 15 x 15 x 3mm carbide knives with (4) cutting edges -- All spindles with hydro-lock outboard bearings -- Left & Right Side Heads can be used for profile work with owner provided tooling -- Eased Edge Spindles: 30mm"; dia. -- Eased Edge Cutting Circle: 4.9"; -- Powered side pressure device at infeed Dust hoods: -- 6"; dia top and bottom head hoods; 6"; dia. side head hoodsOptional Equipment: -- Optional HP on Top & Bottom Heads, up to 40 HP, -- Optional HP on Right & Left, up to 30 HP, -- Electric Brakes for side spindles, -- Power raise/lower and auto-setting for side spindles, Machine Dimensions and Weight: -- 110" long x 86" wide x 94" high x 15200 Lbs.

$ 198,900

CAM-WOOD WP-16L- V5HX 4 Sided 5 Heads High Speed Planer Designed for furniture, cabinet, flooring, intermittent planning mill work, and other industrial uses. Perfect Planer for S2S and S4S planning, tongue & groove flooring, wall paneling, etc. up to approximately 180 FPM depending on depth of cuts and dimensions of partsSpecifications: -- Width: ¾"; to 16"; -- Height: 3/8"; to 4"; -- Length: Maximum Unlimited, Minimum 70";. -- Maximum Cutting Depth; 8 mm -- Feed Rate 40 to 180 fpmFeatures:Horizontal Top & Bottom with Slip-On Spiral Head or Optional Profile cutter head, Tooling Information. -- Standard supply with Slip-On HAR Series Profile / Spiral Cutter head, Profile Knives combined with Carbide Insert 15 x 15 x 2,5 mm. Max depth of cut 8 mm each side (Standard 7"; O.D. Shaft 46 mm): Vertical with Helical or Optional Profile cutter heads -- Left & Right Side/ Standard HAR Series Vertical profile heads. -- Max depth of cut 8mm, 7"; OD, Spindle arbor diameter: 40 mm, -- Left & Right-side Heads can be profile work with owner provided tooling. Fifth head for moulding or sawing -- 15 HP Top Saw Head, raise/lower power digital by HMIQuality Features: -- Simple touch screen with Digital Positioning Controllers for width, thickness adjustment and variable feed speed. -- Hard Chrome plated table for long life -- Automatic top spindle – cutter head height adjustments entered via HMI touch screen control with PLC. -- Floating bottom infeed rolls for smooth, positive feeding -- Variable feed speeds by VFD. Controlled from touch screen. -- Heavy-duty spindle assemblies for durability & smooth finishes. -- Overhead assembly travels up/down and positions via touch screen control, Assembly is support by (4) hard chromed, polished posts and precision screws. -- Tables, fences, etc. are precision ground, polished and hard chromed to provide long life and smooth feeding. -- Massive, heavy-duty sheet metal frame for vibration absorbing finishes and extra-long bearing life. Compact construction with exclusive see-through top guard. -- Motor Control Center with under voltage and overload protection. UL and CSA labeled electric components.Motor Sizes and Feed Works: -- Top and Bottom Cutter Heads Motors each: 30 HP, 5,000 RPM -- Right & Left Side Cutter Motors each: 25 HP, 5,000 RPM -- Second top head for Top saw head, raised and lowered motorized digitally by HMI, drive motor 15 HP -- Variable Feed speeds from 40 to 180 FPM by VFD (invertor) -- Feed is powered by (2) each 5 HP VFD feed motors, (1) motor drives the top infeed and (1) Motor drives the top outfeed feed rolls. Top powered feed rolls are air cylinder loaded / Floating. (4) idle bottom infeed feed rolls and (4) idle bottom outfeed rolls.Overall dimensions: 167" X 71" X 73".

$ 64,500

CAM-WOOD INFEED AND OUTFEED PLANER TRANSFER LINE: 20"; Wide X 20’ Long Roller Conveyors with 6,000 lbs capacity and Consisting of the following: NON POWERED IDLE INFEED RIGHT ANGLE ROLLER TRANSFER CONVEYORS -- (4) Conveyor Sections, each 14"; Wide X 8’ Long (SEE DRAWING). -- 2-11/64"; Roller Diameter -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 6,000 lbsPOWERED INFEED CANTED ROLLER CONVEYOR -- With VFD Drive with speed feed 18' to 70 FPM -- 22"; Wide X 20’ Long -- Heavy Duty 3-11/32"; Roll Diameter -- (9) Rolls on 36"; Centers -- (5) Pneumatic jumped transfer roll -- Back Side Adjustable FencePOWERED OUTFEED STRAIGHT ROLLER CONVEYOR -- With VFD Drive with speed feed 18' to 70 FPM -- 22"; Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32"; Roll Diameter -- Rolls on 36"; Centers -- Includes (4) Sections of Pneumatically Jumped Skate Rolls -- Heavy Duty Type, Sections are 6"; Wide X 20"; Long NON POWERED IDLE OUTFEED RIGHT ANGLE TRANSFER ROLLER CONVEYORS (SEE DRAWING) -- (4) Conveyor Sections, each 14"; Wide X 8’ Long. -- 2-11/64"; Roller Diameter. -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 6,000 Lbs.

$ 67,990

CAM-WOOD SM-324D 4-Sided Planer for L-Shape MouldingSpecial Design for “L"; Shape Mouldings; One set of Cutter heads IncludedSpecifications: -- Maximum Working Width 12";, Max. Thickness 4"; -- Hard chrome-plated table for maximum wear resistance. -- Anti-impact plate for over-width and over-thickness protection. -- Oversized top and bottom rollers run synchronized, ensuring smooth feeding. -- FRP plastic steel safety guard provides maximum durability and impact resistance. -- The three independent sections; pneumatic pressures for the infeed rollers, in-process rollers, and outfeed rollers can be set with individual pressure allowing for consistent feeding and outstanding results. -- The smooth initial feeding of the stock is achieved by the independently powered infeed rollers. -- Specifically designed template inserted pressure plate suits various stock thicknesses and profile variations. -- A special pressure plate based on the table feeding roller design provides smooth and precise cutting of dry and wet wood, reducing the possibility of material jams.Features: -- The base is machined by CNC machine equipment to ensure the utmost working accuracy. -- The first bottom horizontal spindle can be fitted with a trimming cutter for trimming a groove on the workpiece side to achieve perfect straightness. -- The specially designed short stock feeding mechanism combined with auxiliary pressure wheels permits the machine to perform machining on extra short stocks. -- All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy. -- Each spindle is equipped with a mechanical digital readout giving accurate adjustment. -- Every cutter spindle can be adjusted "up and down" and "in and out" for quick setup. -- Industrial full-power motors for maximum cutting capacity.Capacity and Heads: -- Max. Working Width 12"; -- Max. Working Thickness 4-3/4" -- Min. Working Length 9½" -- Vertical stroke of side head 30 mm (1.18") -- 1st Spindle Horsepower 10 HP -- 2nd, 3rd, 4th Spindle Horsepower 10, 10, 10 HP -- Feed Motor 7½ HP -- Elevation motor 1 HP -- Spindle arbor Diameter 40 mm -- Cutter Speeds (RPM) 6,500 -- Variable Feed Speeds (FPM) 16 ~ 82Cutterhead Diameter -- 1st Bottom Head 6"; Dia x 12"; L -- 2nd & 3rd Vertical Head 6"; Dia x 3"; L -- Top Head 6"; Dia x 12"; L -- Pneumatic Air 90 PSI (CFM) 5 -- Dust Outlets Diameter 5" x 4 outlets -- N.W. (Lbs) 9800Option: -- Sound enclosure Add ...$10,900

$ 36,900

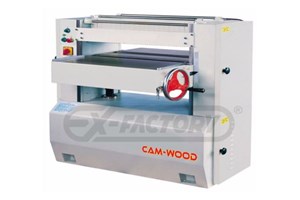

CAM-WOOD PL-24 TOP & BOTTOM STRAIGHTENING PLANER8" x 24" Capacity Planer for accurate and powerful two-sided planing in one pass.Includes (1) set of Spiral Insert Cutterheads with (1) set of 15 x 15 x 2.5 mm Carbide Knives with (4) Cutting EdgesReplacement Knives: CT-SCH-15T 15 x 15 x 2.5 mm Spiral Knives - $3.60 EACHDeduction for HSS Knives in lieu of Carbide Insert Spiral Heads - Deduct $3,000 Specifications: -- 25"; Max. Planning Width, 3/8" to 8"; Max. Planning Thickness. -- 1/4";Max. Cutting Depth. -- 12"; Min. Planning Length. -- 15 to 70 FPM Feed Speeds (Variable). -- 4,200 RPM Cutter Head Speed. -- Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm carbide insert knives with (4) cutting edges -- 25 HP Top Head Motor. -- 20 HP Bottom Head Motor. -- 5 HP Feed Motor and 1/2 HP Elevation Motor. -- Net weight 7,200 Lbs. Equipped with: -- Standard equipment includes Automatic Thickness Controller for quick, accurate thickness adjustments. -- Top and bottom Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm Insert Knives for accurate and powerful two-sided planing in a single pass. -- The Planer’s table surface is precision ground then chrome-plated and polished to a mirror finish; wear resistance, easy to clean and maintain.Feed System: -- Heavy-duty upper feed carpet (conveyor) with spring-loaded steel “fingers"; holds stock firmly against the Planer’s table; prevents stock splitting while providing positive feed and smooth finish for rough and finish planing. -- The conveyor (carpet) is fitted with numerous pressure pins, or fingers, which firmly holds and stabilizes stock during the planing process. Fingers apply moderate pressure to the stock and provides accurate planing while preventing wide cupped boards from splitting and feeding problems while planing narrow material. -- (4) Powered feed rolls are driven via a gearbox linked to heavy-duty chains and sprockets; provides smooth even feeding during rough and finish planing. -- Stepless variable speed control (Inverter driven) for smooth adjustment of feed speed depending on the material hardness, depth of cut & width; allows for the best finish and feed speed. -- Anti-kickback device provides safety and is designed to work in unison with a conveyor stop. Safeguards mechanical parts in case of overload situations.Features: -- The heavy-duty CAST IRON frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial motors for maximum cutting capacity. -- All precision sealed-for-life bearings for long and durable use. -- A built in cutterhead stand is designed for convenient knife changing at the bottom cutterhead. -- Changing knives on the upper cutter head only requires removal of the upper dust chute. -- Setup time is minimized to set cutter head height using the auto material thickness device. -- The top and bottom cutter heads are precision balanced to provide smooth, chatter-fre

$ 30,990

CAM-WOOD PL-18 18" Wide Top & Bottom Straightening Planer. -- 18" Planer with straight knife heads with HSS knives for accurate and powerful two-sided planning in one pass.ADD for Spiral Heads with Carbide Insert Knives... $4,000.00Specifications: -- 17-3/4"; Max. Planning Width. -- 3/8 to 8" Max. Planning Thickness. -- 1/4"; Max. Cutting Depth. -- 10"; Min. Planning Length. -- 15 to 70 FPM Feeding Speed (Inverter Driven). -- 4,200 RPM Cutter Straight Knife Head Speed. (6,000 RPM for Spiral Cutter Head). -- (4) Knife Cutterheads. -- 15 HP Upper Motor. -- 10 HP Bottom Motor. -- 2 HP Feed Motor. -- 1/2 HP Elevation Motor. -- Table Size (L x W) 88" x 16". -- N.W. 6,500 Lbs.Features: -- Standard equipped with automatic thickness controller, easy, accurate and quick setting for the cutting thickness. -- Upper & lower straight knives or spiral cutterheads for accurate and powerful two-sided planing in one pass. -- The worktable surface is precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain. -- A heavy-duty feed conveyor with metal spikes firmly holds stock securely to the worktable and feeds positively giving a smooth finish for rough or final planning. -- Stepless variable speed control for smooth adjustment of feed rate depending on the material hardness, depth of cut & width to provide the best finish surface and fast cutting performance. -- The infeed conveyor is fitted with numerous pressure pins so the feeding process can be firmly stabilized. It will moderately press the stock, and then accurate planing of the surface can be performed to prevent jumping during processing of narrow or bent material. -- The (4) power feed rollers are driven with a geared transmission box linked with heavy-duty drive chains and gears to provide a smooth even feeding during rough or finish planning. -- A twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload. -- The heavy-duty rigid cast iron frame supports the worktable, helps dampen vibration and ensures years of dependable service. -- Powerful industrial motor for maximum cutting capacity. -- All precision sealed long-life bearing for durability -- A swivel stand is designed for convenient knife changing on the bottom cutterhead. -- Changing the knife on the upper cutterhead only requires removal of the upper dust chute. -- The optional spiral insert head design allows for fast, accurate insert changes and minimum down time. -- Setup time is minimized to set cutterhead height using the auto material thickness device. -- The top and bottom cutterheads are precision balanced to provide consistently smooth chatter-free planing regardless of the feed rate or hardness of material being planed. -- A powerful motor is utilized to make adjustments quickly

$ 77,990

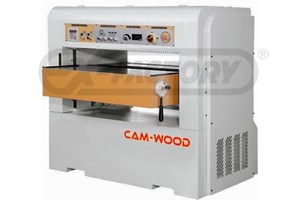

CAM-WOOD PL-38 TOP & BOTTOM STRAIGHTENING PLANERIncludes (1) set of Spiral Insert Cutterheads with (1) set of 15 x 15 x 2.5 mm Insert Carbide Knives with (4) Cutting EdgesReplacement Knives: CT-SCH-15T 15 x 15 x 2.5 mm Spiral Knives - $3.60 EACHDeduction for HSS Knives in lieu of Carbide Insert Spiral Heads - Deduct $8,000Specifications: -- 3" to 38"; Max. Planning Width -- 3/8" to 7"; Max. Planning Thickness. -- 1/4"; Max. Cutting Depth. -- 12"; Min. Planning Length. -- 15 to 52 FPM Feed Speeds (Variable). -- 4,000 RPM Cutter Head Speed. -- Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm carbide insert knives with (4) cutting edges 40 HP Top Head Motor. -- 20 HP Bottom Head Motor. -- 5 HP Feed Motor -- 2 HP Elevation Motor. -- Net weight 9,800 Lbs. Equipped with: -- Standard equipment includes Automatic Thickness Controller for quick, accurate thickness adjustments. -- Top and bottom Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm Insert Knives for accurate and powerful two-sided planing in a single pass. -- The Planer’s table surface is precision ground then chrome-plated and polished to a mirror finish; wear resistance, easy to clean and maintain.Feed System: -- Heavy-duty upper feed carpet (conveyor) with spring-loaded steel “fingers"; holds stock firmly against the Planer’s table; prevents stock splitting while providing positive feed and smooth finish for rough and finish planing. -- The conveyor (carpet) is fitted with numerous pressure pins, or fingers, which firmly holds and stabilizes stock during the planing process. Fingers apply moderate pressure to the stock and provides accurate planing while preventing wide cupped boards from splitting and feeding problems while planing narrow material. -- (4) Powered feed rolls are driven via a gearbox linked to heavy-duty chains and sprockets; provides smooth even feeding during rough and finish planing. -- Stepless variable speed control (Inverter driven) for smooth adjustment of feed speed depending on the material hardness, depth of cut & width; allows for the best finish and feed speed. -- Anti-kickback device provides safety and is designed to work in unison with a conveyor stop. Safeguards mechanical parts in case of overload situations.Features: -- The heavy-duty CAST IRON frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial motors for maximum cutting capacity. -- All precision sealed-for-life bearings for long and durable use. -- A built in cutterhead stand is designed for convenient knife changing at the bottom cutterhead. -- Changing knives on the upper cutter head only requires removal of the upper dust chute. -- Setup time is minimized to set cutter head height using the auto material thickness device. -- The top and bottom cutter heads are precision balanced to provide smooth, chatter-free planing regardless of the feed rate or hardness of planed material.

$ 189,900

CAM-WOOD MODEL WP-4S 650 2C 25" 4-SIDED PLANER WITH MOULDING CAPABILITIES: -- WP-4S2C-650-6 25"; wide x 6"; high 4-Side Planer $189,900 -- WP-4S2C-650-12 25"; wide x 12"; high 4-Side Planer $208,900 -- WP-4S2C-650-16 25"; wide x 16"; high 4-Side Planer $226,900 -- WP-4S2C-650-20 25"; wide x 20"; high 4-Side Planer $238,900Designed for heavy furniture, cabinet, flooring, intermittent planing millwork, and other industrial uses. Perfect Planer for S2S and S4S planing up to 16" high x 25" wide timbers, tongue & groove flooring, wall paneling, etc. up to approximately 75 FPM depending on depth of cuts and dimensions of parts.SPECIFICATIONS: -- Width capacity from 2-3/4"; to 25";. -- Thickness capacity from 3/4"; to 6";. (up to 16"; with O/B Bearings is optional) -- Feed speeds variable from 18 to 65 FPM -- 15 HP Bottom head motor (20 HP optional) -- 20 HP Top head motor (25 HP optional) -- 20 HP Left (outside) spindle motor -- 15 HP Right (inside) spindle motor -- 1/2 HP motors on right & left champhering (top eased edge) spindles -- 10 HP feed motor -- 5"; dia. top and bottom cutterheads -- 5"; or 6"; dia. right & left cutterheads -- 60 mm (2.362";) dia. spindles on top and bottom heads -- 40 mm (1.574";) dia. spindles on top and bottom heads -- 30 mm (1.181") champhering spindles -- 15 x 15 x 2.5 mm insert knives -- (4) Dust outlets, each 6"; diameter -- Planer measurements: 110"; long x 91"; wide x 94"; high -- Planer weighs 19,500 Lbs. FEATURES: -- Compact construction with planing and moulding capabilities; provides flexible performance at an affordable price -- Equipped with a digital controller to set thickness & width automatically -- Rigidly mounted alloy steel spindle with outboard bearing support for accurate, vibration-free planing surfaces on horizontal spindles -- Spindle height adjustment by precision rack & pinion gear sets. -- Bedplates are precision ground, chrome-plated and polished to a mirror finish; provide a smooth, wear-resistant surface -- Variable speed inverter control for smooth feed speed adjustment depending on lumber hardness, depth of cut & width. Speed adjusts to provide the best finish and highest speed for best overall performance. -- Feed rolls are driven by geared transmission boxes and drive shafts with heavy-duty universal joints and drive shafts; provide smooth, even feeding for rough or finish planing -- Heavy fabricated steel plate frame, heated and stress relieved for vibration-free finishes, supports the worktable and helps dampen vibration for a superior finish. Ensures years of dependable service -- Industrial-grade, standard off-the-shelf motors for maximum cutting capacity and ease of service -- Bearings are precision, sealed, long-life bearings for durability and service life -- Removable cutterheads on all spindles, designed for convenient knife changing or rotating, including the bottom head. -- Changing or rotating knives on the top head only requires r

$ 24,900

CAM-WOOD SM-124TAX 4-Sided Planer/Moulder; 11-3/4"; Wide x 4" to 9"; HighCompact construction with moulding & planing capabilities and flexible performance at an attractive price. Designed for furniture, cabinet, and yes, even industrial arts and large hobby shops. The perfect machine for tongue & groove flooring, wall paneling, S4S work, etc. Specifications: -- 2-Sided Planing Capacity: 7/16"; to 9"; thick x 11-5/8"; wide -- 4-Sided Planing Capacity: 7/16"; to 9"; thick x 10-1/4"; wide. -- All cutters run at 7,000 RPM -- Top and bottom heads are 2-27/32"; (72 mm) diameter. -- Right and left side heads are 3-1/2"; (90 mm) diameter -- All spindles powered by 4.1 HP (3 kW) motors -- Top Spindle will profile to a 3/8"; pattern depth and 5/16"; max. stock removal when planing. -- Bottom Spindle will profile to a 3/16"; pattern depth and 3/16"; max. stock removal when planing. -- Right & left side spindles are 4"; long and have a max. moulding depth of 13/16";. -- Machined and hard chromed table is 24"; wide x 40"; long and travels 9"; (230 mm) vertically -- Feed system runs at 11 to 52 FPM and is powered by a 1/2 HP variable speed drive. -- Overall dimensions are 54"; long x 42"; wide x 44"; high and weighs 1,370 Lbs.Features: -- Large 11-5/8"; wide x 9"; thick 2-sided planing capacity or 10-1/4"; wide x 4"; thick 4-sided planing and moulding work. -- Individual motors drive each spindle; 7,000 RPM spindle speeds on all heads. -- Mechanical meter for accurate thickness adjustments. -- Heavy-duty spindle assemblies for durability & run-out free finishes. -- Rigidly mounted alloy steel spindles in precision bearings provide accurate and vibration-free power transfer. -- Spindle height adjustment by precision rack & pinion gear system. -- Compact construction, Heavy-duty welded steel frame and See through top guard. -- Magnetic overload switch for protection. -- Industrial-rated TEFC motors with sealed-for-life ball bearings.

$ 59,900

CAM-WOOD WP-20L8-V4X, 20"; WIDE X 5" HIGH 4-SIDED PLANER/MOULDER, (8" Optional)Planer or Combination Planer/Ripsaw is designed for furniture, cabinet, flooring, intermittent planing millwork, and other industrial applications. The perfect Planer for S2S and S4S planing, planing and ripping, tongue & groove flooring, wall paneling, etc. up to approximately 75 FPM depending on the depth of cuts and dimensions of parts.Working Capacities: -- Width: 3/4"; to 20";. -- Height: 3/8"; to 5", (8"; optional additional $4,900). -- Length: 20"; Minimum, Maximum Unlimited. -- Maximum Cutting Depth: Top & Bottom Heads 1/2";, Side Heads 1";. Included Tooling Is Slip-On Spiral or Profile Cutterheads: -- Standard with Slip-On HAR Series Profile / Spiral Cutter head. Profile Knives combined with 15 x 15 mm x 3° Carbide Insert knives. 1/2"; Max depth of cut. The top and Bottom spindles are 60 mm (2.36";) in diameter. Optional Profile Cutterheads Available. -- Left & Right-Side Spindles with Standard HAR Series Profile Heads. -- Max depth of cut 1";. With 40 mm (1.57";) Spindle Diameter. Cutting Circle from 6" to 7";. -- Left & Right-Side Heads will run profiles with owner-provided tooling. Quality Features = Long and Outstanding Performance -- Simple touch screen with Digital Positioning Controllers for width adjustment, thickness adjustment and variable feed speed. -- Hard Chrome Plated Table for long life and smooth feeding. -- Automatic Top Head Adjustment – cutter head height adjustment entered via HMI touch screen control with PLC. -- Floating Bottom Infeed Rolls for smooth, positive feeding. -- Variable Feed Speeds by VFD Controlled from Touch Screen. -- Heavy-duty Spindle Assemblies for durability & smooth finishes. -- Overhead assembly travels up/down and positions via touch screen control. Assembly is support by (4) hard chromed, polished posts and precision screws. -- Tables, fences, etc. are precision ground, polished and hard chromed to provide long life and smooth feeding. -- Massive, heavy-duty sheet metal frame aids in vibration absorbing finishes and extra-long bearing life. Compact construction with exclusive see-through top guard. -- Motor Control Center with under voltage and overload protection. UL and CSA labeled electric components. Motors and Feed Works: -- Top and Bottom Cutter Heads Motors, each: 15 HP, 5,000 RPM. -- Right & Left Side Cutter Motors, each: 10 HP, 5,000 RPM. -- Variable Feed Speeds from 20 to 65 FPM by VFD (invertor). -- Feed is powered by (2) each 2 HP VFD feed motors. -- (1) motor drives the top infeed and (1) Motor drives the top outfeed feed rolls. Top-powered feed rolls are air cylinder loaded / floating. -- (8) non-powered bottom rolls, (4) infeed and (4) outfeed.Machine Sizes / Dimensions and Weight: -- 76"; Length x 52"; Width x 71"; Height. -- Weight 4,920 LbsOptional Equipment: -- Type MP Carbide Side Head Tooling for profile work. Price on request. -- With a 20" spindle length -- 40 mm arbor diameter

$ 10,990

CAM-WOOD WP-2400S SINGLE SIDED PLANER WITH SPIRAL HEADFeatures & Specifications: -- Self-braking motor 5 HP, Magnetic starter & thermal overload switch. -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws, up to 7" opening. -- Scale & pointer readout for accurate thickness adjustments. Spiral Head & Feed: -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers.Complete with: -- Hinged top for easy access to cutterhead & gear assembly. -- Emergency stop. -- Operations manual, parts list & tool kit.1250 lbs

$ 39,990

CAM-WOOD WP-1010H 40"; Heavy Duty Planer with S.C.H.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- Maximum thickness capacity 8" -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planing with low noise levels. -- With (4) each 4" diameter dust outlets -- 20 HP Main drive motor. -- 3 HP Variable feed speed 10 to 50 FPM. -- Maximum depth of cut 1/4". -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 40" -- Max. Cut Thickness 8" -- Max. Cut Depth ¼" -- Min. Cut Length 9" -- Cutting Speed 3600 RPM -- Table Size (W x L) 43" x 55" -- Main Motor 20 HP, 3 Ph -- Feed Motor 3 HP -- Table Raising Motor 1 HP -- Feed Rate (Variable) FPM 10 ~ 50 -- Net Weight 4,750 Lbs -- Shipping weight 5,500 LbsFOR UPGRADE TO 25 HP ADD ...$900.00

.gif)

.jpg?width=300&height=200&mode=pad)