Woodworking Equipment For Sale

1986 Results Found

Call for Price

Call for Price

Busellato Jet 100 CNC Router 4' x 9' Table 10 HP Spindle Boring Block: (7)X, (5)Y 20 HP Vacuum Pump Custom built offload table 240 V/3PH

Call for Price

Busellato V-Tech CNC Router 400 Volt/50-60 HZ MFG Specs (to be confirmed): BUSELLATO V-TECH Vertical CNC Machining Center with ATC: Working Field "X" Axis 120" (3,050 mm), "Y" axis 51.1" (1,300 mm), Z-axis 70 mm (2.8"). Positioning Speed: "X" axis is 197 FPM (60 MPM), "Y" axis 164 FPM 50 MPM), "Z axis 33 FPM (10 MPM). Worktable Bored "Phenolic table with (10) adjustable vacuum pods; (6) Pneumati

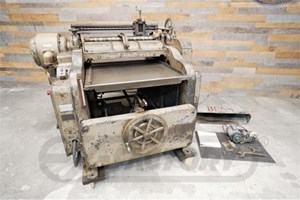

$ 6,950

BUSS M 4L 30" STRAIGHT KNIFE PLANER30" X 8" Cap., 20 HP direct drive top motor, 1.5 - 2 HP for dual feed speed, 4-knife round top cutterhead, sectional infeed rolls and chipbreaker. Complete with: Shaving hood, magnetic starters.

$ 10,200

BUSS - DL 30" x 8", ...Heavy-Duty Wood Planer with GrinderModel "DL" bed capacity: 30" W x 65" L x 8" H,Specifications -- (2) Large steel support rollers on bed; upper area: (1) Steel roller. -- (1) Cutterhead with: (4) Knives; (1) grip through roller. -- Heavy-Duty spring tension adjustment on top of machine. -- (2) 15 HP - 3 PH motors; one connected to 20-ratio gear reducer, variable feed speed drive; the other connected to the cutterhead system. -- Upper cross frame attachment for Knife Grinder System (comes with the Grinder).Equipped with & Features -- Oil cup & grease fitting lube system. -- Power raising and lowering of the Planer bed.

Call for Price

$ 51,450

BÜTFERING SWT 335-RLL 3-Head Wide Belt Sander,53" Width cap. Drum, Drum, Combination HeadHead Configuration1st Head: Steel Profiled Contact Roller 21.5 KW (28.83 HP)2nd Head: Rubber Profiled Contact Roller 17.4 KW (23.37 HP)3rd Head: Combination Head: Contact Roller & Air Cushion Sanding Pad/Platen Head 17.4 KW (23.37 HP)4th station: Panel Cleaning BrushSpecifications -- 1st Head: Steel contact roll, 240 mm (9-1/2") dia., abrasive belt speed 18 m/sec (59 FPS), driven by 22 kW (30 HP) motor. -- 2nd Head: Rubber covered contact roll, 65 Shore hardness, 240 mm (9-1/2") dia., abrasive belt speed 18 m/sec (59 FPS), driven by 15 kW (20 HP) motor. -- 3rd Head: Combination head consisting of Contact roller 55 Shore hardness, 140 mm (5,5") dia. and Air cushioned polishing platen with jump control for leading & trailing edges. Abrasive belt speed 12 MPS (39 FPM), driven by 15 kW (20 HP) motor. -- Outfeed rotary panel cleaning brush. -- All heads use 1,400 x 2,620 mm (54" x 103") abrasive belts. Electronic abrasive belt tracking. Air jet abrasive belt cleaner on head # 2.Feed system: -- Conveyor belt feed with variable feed speed from 2,5 - 13 m/min (8 - 42 FPM). -- Vacuum table with internal suction fan and motor 5,5 kW (7,5 HP). -- Part thickness 3 - 160 mm (1.2" - 6.3").Equipped with & Features -- Motorized thickness adjustment with LED readout. -- Constant pass line of conveyor bed 900 mm (35"). -- Automatic electronic conveyor belt tracking, in & outfeed spring loaded rubberized hold-down rolls. -- Automatic part thickness setting. Complete with: -- Infeed panel "over-thickness" sensor, in & outfeed emergency stops, safety interlocks on all doors. --Telescopic infeed roller conveyor extension, fold away outfeed table 900 mm (35"). -- Motor load meters, and main motor electronic brakes. -- Operator panel with joystick and multi-function readout for thickness, feed speed etc.Full Load Amps: 150 FLA at 460 VoltsCompressed Air: 55 cfm @ 90 PSI RequiredTotal CFM Required 5,365Actual model is BÜTFERING SWT 335-RLL 3-Head Wide Belt Sander

$ 37,500

--MAKE OFFER!--EXCELLENT CONDITION!-- BÜTFERING SWT134/RRC 1100 mm (43.31") 3-Head Wide Belt Sander, with Combination Head Specifications: Suitable for sanding of veneered parts in 1 or 2 passes with segmented pad only & Thickness tolerance compensation up to 1 mm (0.04”), Suitable for sanding of solid wood & wood based materials in single pass with 3 grit sequence. Thickness cap. 3 mm - 160 mm (0.19” - 6.30"). Variable feed speeds 2.5 - 13 MPM (8.5 - 42 FPM). Equipped with: 1st Head: 160 mm (6.30”) Dia. Grooved steel contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. 2nd Head: 160 mm (6.30”) Dia. 85° Shore Grooved rubber-covered contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. 3rd Head: Combination head, with 60 mm (6.30”) Dia. 65° Shore Grooved rubber-covered contact roll, 3-3/4" Dia. Smooth steel contact roll, 3-1/8” W Electronically-controlled segmented pad finishing platen with 35 mm (1.38”) W Segments, & 18 kW (15 HP) Motor with Electric braking. 1-7/8” Dia. Rubber-covered roller & spring-loaded segmented nylon rollers on infeed & 1-7/8” Dia. Rubber-covered spring-loaded hold-down rollers between heads & after 3rd head. 1,120 mm x 1,900 mm (44.09" x 74.80") Abrasive belts, with Electronic oscillation. 43-1/4” W x 5’ L Feed belt, with 1.3 kW (1-3/4 HP) Feed motor with Frequency inverter, 44” W x 8” L 2-Roll Infeed Extension, & Automatic conveyor belt tracking. Power raising of conveyor bed, with Automatic thickness adjustment & Over thickness Protection. LCD Touchscreen control, with 5-1/2” Display, & Motor load meters. Complete with: Original Production Instructions. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

Call for Price

Manufacturer’s Specification Single belt max. passage height : 150 mm max. working width : 1100 mm combination unit design roller/electronic shoe electronic single links segment width 50 mm Dedusting brush Sanding belt length 1900 mm Sanding belt width 1120 mm Motor. KW 10 Feed speed 4 and 8 m/min Unvfu3R3Ap Weight approx. : 1900 kg Dimension : 2000 x 2000 x 2600 mm

$ 37,500

BÜTFERING SWT134/RRC 1100 mm (43.31") 3-Head Wide Belt Sander, with Combination HeadSpecifications: -- Suitable for sanding of veneered parts in 1 or 2 passes with segmented pad only & Thickness tolerance compensation up to 1 mm (0.04";), Suitable for sanding of solid wood & wood based materials in single pass with 3 grit sequence. -- Thickness cap. 3 mm - 160 mm (0.19"; - 6.30"). -- Variable feed speeds 2.5 - 13 MPM (8.5 - 42 FPM).Equipped with: -- 1st Head: 160 mm (6.30";) Dia. Grooved steel contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. -- 2nd Head: 160 mm (6.30";) Dia. 85° Shore Grooved rubber-covered contact roll, with Grit size compensation, Automatic positioning for calibrating, & 15 kW (20 HP) - 2,930 RPM Motor with Electric braking. -- 3rd Head: Combination head, with 60 mm (6.30";) Dia. 65° Shore Grooved rubber-covered contact roll, 3-3/4" Dia. Smooth steel contact roll, 3-1/8"; W Electronically-controlled segmented pad finishing platen with 35 mm (1.38";) W Segments, & 18 kW (15 HP) Motor with Electric braking. -- 1-7/8"; Dia. Rubber-covered roller & spring-loaded segmented nylon rollers on infeed & 1-7/8"; Dia. Rubber-covered spring-loaded hold-down rollers between heads & after 3rd head. -- 1,120 mm x 1,900 mm (44.09" x 74.80") Abrasive belts, with Electronic oscillation. -- 43-1/4"; W x 5’ L Feed belt, with 1.3 kW (1-3/4 HP) Feed motor with Frequency inverter, 44"; W x 8"; L 2-Roll Infeed Extension, & Automatic conveyor belt tracking. -- Power raising of conveyor bed, with Automatic thickness adjustment & Over thickness Protection. -- LCD Touchscreen control, with 5-1/2"; Display, & Motor load meters.Complete with: -- Original Production Instructions.

$ 27,500

Bütfering SWT 124 RC Wide Belt Sander (2) Heads43" Width cap. Drum, Combination HeadBütfering SWT 124 RL Features: --Touch Screen display and control. -- Capacity of (125) programs. -- Conveyor speed is controlled within the program. -- Controls the number of sanding heads activated. -- Controls use of sanding pad or contact roller on combination heads. -- Controls thickness of work piece. -- Controls air jet belt cleaning on or off ( only on models with this feature). -- Error message display including safety functions. -- Displays in mm or decimal inches. -- Hour meter display. -- Conveyor table mounted on four heavy duty jack screws. -- Automatic conveyor belt tracking. -- Electronic belt oscillation system. -- Electronic motor braking system. -- Over thickness protection system. -- Safety interlocks on all access doors. -- In feed roller table. -- Emergency stops at in feed and out-feed locations.Head Configuration:1st Head: Contact roller head located in position #1 includes:160 mm diameter steel profile contact roller. -- Automatic height positioning -- Grit compensation -- 20 HP motor -- Cutting speed is 60 FPS.2nd Head: Combination head located in position #2 includes: -- 65 shore profiled rubber contact drum --Automatic height positioning -- Air cushion sanding pad with rise and fall timing -- 18 HP motor -- Cutting speed is 60 FPSSpecifications: -- Working width 1,100 mm (43";) -- Abrasive Belt width 1120 mm (44";) -- Abrasive Belt length 1,900 mm (75";) -- Work piece thickness min. 3 mm ( 1/8"; ) -- Work piece thickness max. 160 mm (6-3/8";) -- Variable conveyor speed 8 - 42 FPM; Feed motor 1 HP -- Contact Roller - Head #1 20 HP, 60 FPS belt speed. -- Combination- Head #2 18 HP, 60 FPS belt speed.Utilities: -- Total power required 28 kW. -- Dust collection requirements 1500 CFM; -- Dust outlet – head #1 160 mm ( 6.25 "; ) -- Dust outlet – head #2 160 mm ( 6.25 "; ). -- Compressed air requirements 90 PSI; Air consumption per cycle 4 CFM; Machine net weight 3960 Lbs.

$ 26,500

BÜTFERING SGO 211 RK Wide Belt Sander, 2-Head,(43") Working width, equipped with (1) Contact Roller and (1) Combination Head consisting of Contact Roller & Finishing Platen.Head Configuration;1st Head: Rubber contact roller 160 mm (6.3") with 15 kW (20 HP) motor.2nd Head: Combination head with rubber covered contact roller and finishing platen, not segmented, 11 kW (15 HP) motor.Specifications: -- Both heads use 1,120 x 1,900 mm (43" x 75") abrasive belts with electronic abrasive belt tracking. -- Feed system: Conveyor belt feed with variable feed speed 2,6 - 13 m/min (8,5 - 42 FPM), 1,1 kW (1.5 HP) feed drive, auto belt tracking. Part thickness 3 - 160 mm (0.1 - 6.3"). Automatic motorized part thickness adjustment with 0,1 mm LED readout.Equipped with and Features -- Electronic emergency brakes on sanding head motors. -- Infeed emergency stop. -- Motor load meters for supervision of stock removal. -- Roller table extension at infeed. -- Emergency stops at in & outfeed end—automatic star/delta starters.

Call for Price

53" 3-head sander 1st head - Drum 2nd head - Combo head 3rd head - polishing head outlet rotary cleaning brush belts 54" x 103" Feed variable 8-43 FPM Controller with color screen Manuals available

Call for Price

$ 174,000

Homag Sander Butfering W300 SWT345/QCUH (4) Heads wide belt sander53" Width cap. Cross belt , Combi head Electronic platen, Universal oscillating brushing cups, Chevron super-finish head Electronic platen, Cleaning brushHead Configuration1st Head: processing unit Cross belt Electronic platen2nd Head: Processing unit Combi head Electronic platen3rd Head: Processing unit Universal oscillating brushing cups (includes additional brass wire 300mm drum and 300mm Tynex Drum in carts never used4th Head: Processing unit Chevron super-finish head Electronic platen5th Station Head cleaning brushSpecifications -- Air jet blowers -- Integrated vacuum -- Bed width 53"; -- Includes AC unit -- Digital calliper -- About 30 belts different grit sizes -- All heads are program controlled5’ out feed table with interoll rubber rollersEquipped with & Features -- Custom metal fencing -- 6 custom metal belt racks -- Voltage 460 -- Machine commissioned June 2021 -- Sellerwill include preparing the machine for shipping and loading NOTE Reason for sale. Changes in manufacturing process.

$ 499,000

C.R ONSRUD MODEL 615DG24H8 "Dual Gantry Series" CNC router with ATC Multi spindles:5' X 51' working table with Multi spindles and Dual Gantry aluminum non-vacuum table. -- Features:Dual Gantry each with (4) spindles, each gantry has its own 12 position hide away tool changer. -- Thermal Heat Treated:Stress Relieved, & Normalized One-Piece, Steel Frame Base, & Thermal Heat Treated, Stress Relieved, & Normalized Steel Bridge; Dual Support, Dual Drive, Moving Gantry, Fixed Table Design with standard 2,500"; per minute machining speed, full 3-D capability, precision ball screw drives for Z & Y axis, case-hardened, precision ground, helical rack & pinion drives for X axis with forced-air continuous rack cleansing system & anti-contamination shielding, precision linear profile guide ways, centralized manual lubrication system, 11-inches of Z stroke - 14"; under bridge clearance & 11"; Z axis stroke.. -- Spindles:Total of (8), (4) per gantry, 18kW, 24HP "QTC" – 24,000 RPM Liquid cooled Long Nose Spindle w/ HSK-63F Spindle Taper, fully programmable & reversible, variable speed, liquid-cooled, quick-change spindle, capable of routing, drilling and ridged tapping, programmable feed rates w/override capability supported with a 12 hideaway tool changer on each gantry total of 24, Automatic Oil Mist Lubricator for each spindle. -- Spindle adjustments:Servo Adjustment of Spindle Center Distance. -- Controls:(2) FANUC 31i-B5 Machine Controller With Integrated PC Interface one for each gantry Fanuc 31i-B5 is Industrial CNC Machine Controller with Fanuc Panel-i HMI w/High Res touch screen. Includes: Network capability, adds Larger FANUC Digital Drives & Servos. Includes Full remote diagnostic troubleshooting capabilities. -- Complete with:Assorted tool holders, centralized grease lubrication on Multi-Head, 63kVA Isolation Transformer, FANUC MPG Handheld Remote Jog Pendant, and manuals. -- Machine floor space required 64' by 14' 5"

Call for Price

CALPE TH5-1600 Heavy-Duty High-Production, Fully Automatic CNC Lathe: General Description: -- Multi-Spindle cutting simultaneously, (5) spindles using V-type gouge knives. -- 63" (1,600 mm) Max. distance between centers; 5-1/2" (140 mm) max. swing diameter between spindles. -- CNC Controlled with 2.95" (75 mm) travel for depth of cut. Motors/Speeds: -- Servo controlled CNC drives: -- CNC controlled electronic variable speed head drives the movement of the (5) gouge tools. -- CNC controlled feed speed carriage, variable up to 50 FPM (15 MPM). -- (1) Head stock variable speed drive for the (5) spindles, up to 6,000 RPM, approx 10 HP. -- Fast return travel of up to 590 IPM (15,000 mm/Min). 2 HP approx hydraulic drive -- Loading device & tail stock powered by hydraulic pump with 2 HP - 1,750 RPM motor; No. 5 Morse taper on main spindle shaft. Features: -- Automatic loading & unloading device; carriage mounted with linear guides providing high precision movement. -- Full CNC controller with on-screen CAD programming for all products.Matching CALPE L6-1600, record number LC-010996 spindle sander is available at additional cost at same facility.

Call for Price

CALPE L6-1600 Spindle Sander with Hopper Feed. -- (6) Spindles, semi-automatic sanding machine; distance between centers 63", 6-3/16" max sanding diameter, capable of sanding 1800 spindles per hour. -- 4 HP - 1,800 RPM head motor, (5) sandpaper holders, each for different grits, 4000-3200-2200-850 RPM head spindle speeds. Copier unit that follows all contours. -- Oscillating sanding units & stationary pick up of part. -- NOTE: This sander was running with lathe on our record number LC-010811 and owner prefers to sell at the same time.

Call for Price

CAM-WOOD IAT 620-150H INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6":Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. Conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" wide x up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4"; maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria STC-62A Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without the messy runoff associated with glue rollers. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (198") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6"; wide x 1/2" to 3" high x and from 6' to 16-1/2' long. A 2 HP motor powers the upper and a 2nd 2 HP motor powers lower pre-assembly/crowder rolls. With 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. 5 HP - 2,85

CAM-WOOD FSM-460AX Finger Joint ShaperSingle Finger joint Shaper with 8" min. and unlimited max. block length; 4" max. block thickness, maximum timber height to feed into assembly press is 3"; 18" max. block width (horizontal joint only); 18" table working width.Equipped with: -- Shaper spindle powered by 10 HP belt drive motor with 50 mm dia. spindle turning at 5,500 RPM; 160 mm (6.3") max. dia. cutter. -- Trim-saw powered by 5 HP direct drive motor at 2,850 RPM and a 1" dia. saw spindle; swings 180 mm (7") max. blade dia. -- Table cycles 2 to 4 per Min via the hydraulic system with a 2 HP hydraulic power unit. Includes 5" dia. dust outlet.Features: -- Manual Fingerjointer performs end trimming and shaping functions on right and left end of blocks. -- Air-operated clamp holding blocks firmly in place. After the workpiece is clamped, the table feeds past the saw and shaper spindles to perform trimming and finger-joint operations; trim saw cuts blocks exactly 90° ends. -- Shaper spindle is precision-constructed for cutting fingers accurately; swings up to 6" dia. tooling. -- Spindle height adjustment is displayed on the dial readout for easy adjustment. -- Table travels on a precision linear guide for stability; table traverse driven by hydraulic power system smooth and accurate block feeding. -- Variable feed speed permits proper feed for hard or soft wood. -- Cast iron frame and table for durability.

.gif)