Woodworking Equipment For Sale

1987 Results Found

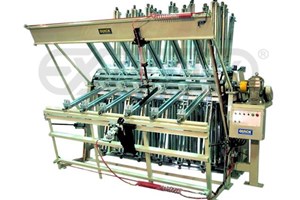

QUICK 30-Section HEAVY DUTY Pneumatic Clamp Carrier with 8-1/2' width cap. -- (6) Heavy Duty zinc plated clamps per section for (180) total clamps, 38" opening on clamp. -- Jaw sizes on clamps are 3-1/2" high x 4-3/4" wide with 1° inward draft.Equipped with: -- Pneumatic overhead panel flattener, -- Pneumatic clamp tightener, -- Electric motor rotation with indexing.Standard features include: -- Foot levelers, coiled air lines where used, and flexible conduit for wires.

QUICK 6-Section Clamp Carrier with 16-1/2' width capacity6-Section Pneumatic Clamp Carrier with 16-1/2' width cap. -- (12) Heavy Duty zinc plated clamps per section (72 clamps total); 52" opening on clamps. -- Jaw size of clamps are 3-1/2" high x 4-3/4" wide, with 1° inward draft.Equipped with: -- Pneumatic overhead panel flattener 16-1/2' wide. -- Pneumatic clamp tightener -- Semi-automatic rotation via electric motor drive; -- Separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In. -- Flexible conduit for electric wires.Features & Includes: -- Automatic air line oiler; -- High quality urethane finish coating. -- Toolbox with spare parts & tools.Floor space requirement: 236" W X 131"D X 148" H

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. -- NOTE: Clamp Carrier can be expanded to (14) or (20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

Call for Price

QUICK 20 Section Automatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 32" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Pneumatic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 16-1/2' width capacity and Glue applicatorWith (15) Standard zinc plated clamps per section (210 clamps total), 48" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment (2) Panel Flattener with easy to use controls.(2) Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.14-Section Clamp will produce 300 panels

$ 21,600

QUICKWOOD CD2-300 Moulding & Profile Sander or Denibber;4-Head Brush Loading Sander, 12" width and 4" height cap., for 3-sided sanding & denibbing. Head Configuration: -- (2) "BH300" Overhead rotating abrasive/brush heads, both arbors equipped with a combination of abrasive and brush loadings, 12" long arbors, 12" max. dia. sanding discs. -- 0.75 HP Motor drives each arbor with inverter for 200 - 1,200 RPM arbor rotation speed. -- Right & Left ("BH-140" & "BH-100" respectively) side mounted rotating abrasive/brush heads. -- Tilting heads and adjustable in-and-out, 6" long arbor, 8" dia. sanding discs, 0.5 HP motor each head. -- 0" - 4" Max. manual part height adjustment via hand wheel; 57-1/2" long roller conveyor with PVC covered rollers, variable feed speed 10 - 60 FPM. -- Infeed & outfeed overhead holddown rolls and (1) between the top heads. Includes centralized control panel, hubs, abrasive, & brush. -- Can also be ordered with just (2) top heads or (3) heads, ie. Left or Right. Call for separate prices.

Call for Price

Call for Price

Call for Price

8 or more brushes arranged at 360 ° with respect to the work pieces Adjustable inclination for the profile step QRC module for the super finishing of the flat parts in view

QUICKWOOD - Denibbing Sander with: (2) Brush Heads2-Head with: 32" max. cap.; 0" - 4" max. part thickness opening. -- Equipped with: (2) Carousel heads; each with (4) rotating arbors mounted on a central rotating drive assembly; carousel rotation: 2 - 20 RPM; 0.75 HP rotation drive. -- Arbor/spindles are: 11.4" Long; 350 - 1,150 RPM spindle speed with: LED Readout on control panel; 2-1/2 HP main motor; each arbor holds: combination of (25) "Quick-Discs" & (12) nylon brush loadings of 13-3/4" max. dia. -- Feed system with: 32" wide vacuum conveyor belt; a 5 HP pump; variable feed speed from: 6 - 36 FPM; 3/4 HP feed drive. - Complete with: Hinge mounted operator panel and (2) 6" dia. dust collection ports.

QUICKWOOD - RO 800-1, ...Denibbing Sander.1-Head with 32" max. cap., 0" - 4" max. part thickness opening. Equipped with: -- (1) Carousel head with: (4) Rotating arbors mounted on a central rotating drive assembly, carousel rotation 2 - 20 RPM, 0.75 HP rotation drive. -- Arbor/spindles are: 11.4" Long; 350 - 1,150 RPM spindle speed with LED readout on control panel; 2.5 HP main motor; each arbor holds a combination of (25) "Quick-Discs" & (12) nylon brush loadings of 13-3/4" max. dia. -- Feed system with: (2) 2-3/8" Wide narrow conveyor belts and side guides (to keep panels from moving side-to-side), motorized width adjustment in-and-out from the center. -- Manual thickness opening 0" to 4". -- Variable feed speed from 6 - 36 FPM, 0.75 HP feed drive. Complete with: -- Control panel and (2) 6" dia. dust collection ports.

QUICKWOOD - ELITE-1400: Denibbing Sander with (8) Abrasive Brush Heads(1) 8-Head carousel with: Brush loadings; 55" max. width; for finish & sealer sanding.Equipped with & Specifications -- (1) Carousel head with: (4) Double arbor; opposing heads consisting of: (8) Counterrotating spindles. -- Heads on each side are: Staggered left/right & center mounted for carousel operation. -- Each double arbor powered by: 2 HP Motor; variable spindle speed from: 300 - 1,150 RPM; inverter powered; controlled from: Operator panel; 21-1/2" long spindles extend out each side of head drive. Features & Brush loadings -- Carousel variable speed from: 3 - 16 RPM; 2 HP drive motor; inverter controlled with: Keypad & LED readout. -- Spindles hold: Approx. (344) discs or a combination of QUICK abrasive discs; nylon brushes or nylon impregnated discs.14" Max. disc dia., brush loadings; mounted on a slight angle to create an oscillating motion. Feed System & Speed -- "Vactronic" Vacuum bed conveyor feed system: (2) 10 HP Vacuum fan assembly; variable feed speed from: 6 to 36 FPM; 2 HP feed drive. -- 0" to 4" Motorized thickness opening inverter; controlled with: Keypad &LED readout. - Features holddown brush plate. Includes -- Full sound enclosure; 11 kW frequency inverter; (6) 5-1/2" dia. dust collection outlets; reversible head rotation; Flexi-heads.Operator Control panel with: Color monitor at eye-level height; swivels on swing arm.

Call for Price

QUINCY QSVB-25ANN2F VACUUM PUMP:25 HP "QSVB Series": 371 CFM, 29.9"HgV rotary screw vacuum; positive lubrication fluid pump; 3″ inlet and 2″ exhaust port. -- Equipped with:Modulating inlet valve; temperature regulating valve; high discharge temperature shutdown system with manual reset. -- Complete with:Control panel; electrical enclosure; gauges; exhaust separation system; spin on fluid filter; (2) magnetic motor starter kits as pictured. GREEN ONE MODEL #PKT; SERIAL #981113937. - GREY ONE MODEL #SK25; SERIAL #0101-2-SK25 KVAR54.NOTE: The Pump only has (6,935) total hours on the meter!

Call for Price

Call for Price

Call for Price

Call for Price

This Rainmann Ripsaw will need to have the blades replaced and other than that, it is in good condition.

Call for Price

Raimann KM310 Rip Saw Per seller: The saw runs material. The variable infeed is stuck on one speed.

Call for Price

RAIMANN Model ASA 1650 II, Veneer Patcher.Specifications: -- 5HP gearmotor, drive conversion wit new clutch and motor. Strip type mechanical plug-feeder mechanism - cap.. of up to (40) Plugs/Min.; -- Thickness of veneer patchable 1/32" - 3/16" (0.8 mm - 4.76 mm). Profile P-34 dies in good condition. -- Table dimensions approx. 39" x 47" -- Throat distance from tool to back column 65" -- Table height 35" -- Tool sequence: Veneer patch is cut by the table die and scrap is ejected into discharge chutes, veneer patch blank is then positioned against the underside of the table die, plug punch cuts replacement veneer patch from underside and patch is inserted into the proper position. -- Reconditioned by experts. -- Overall size: 10' 8" (3,250 mm) Length x 67" (1,700 mm) height; approx. weight 12,000 Lbs (5,450 kG). --Option: Veneer Strip Feeder. Feeds standard strip widths continuously. Venturi vacuum cup strip feed mechanism. All pneumatic operation. 120 Volt/60 Hz controls.please inquire for price extra. --Actual model is RAIMANN Model ASA II 1650.

.gif)