Northfield For Sale

1968 Results Found

Call for Price

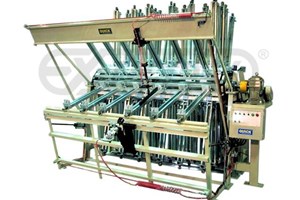

Make an offer - Machine is in an Ex-Factory Liquidation. 4-Station Profile Shaper Specifications: 6" Chain drive with non-marking rubber top pads traveling on a hardened and ground precision dia. 5/8" round rods, Top pressure beam driven, Heavy duty fabricated transporter frame, Forward and reverse mode and block mode for creating sanding tools Precision X & Y axis mounting stands, 60° rotating tilt on mounting stands with positive lock, Independent activation control at each station, Adjustable infeed fence system, All dust hoods and guards, 2 HP AC variable speed gear drive 5 to 60' per min. Workstation 1: 3.5 HP TEFC Saw Arbor Motor, 1" Dia. Spindle, Dust Hoods with 4" outlet, Mounted on precision X & Y slides Workstation 2 & 3 - Belt Sanding Unit: 2 HP AC motor drive, Air belt tension system, Independent belt tracking system, Air activated sanding pad with touch control, 2" sanding belt width, Guards and Dust hoods with 4" outlet Workstation 4 - Wheel Sanding Unit: 3" HP variable speed (0-3,400 RPM) AC TEFC drive motor, 1" or 1.25" arbor 3.5" long, Dust Hood with 4" dia. outlet, Mounted on precision X & Y slides SPECIAL NOTE: Needs New PLC or wire for traditional controls NOTE: Above specs are taken from literature and thought to be accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

$ 13,900

PROFILEMATIC 503 PROFILE SANDER3-Head feed through, sands from top at adjustable angles narrow moulding type parts as well profiled edges on panels.Equipped with: -- (3) Top VPS vibrating air-loaded sanding units, 0.5 HP vibrating motor ea., sanding heads have (2) pneumatic cylinders for sanding pressure control and oscillate with 1/2" stroke on dust-protected round guides, variable vibration speed from 200 - 1,800 RPM; adjustment range of 120ø to conform to profile, equipped with air shower to clean workpiece & sandpaper automatically. -- Part transport is achieved by a 4-1/2" wide linatex coated conveyor belt system, "quick adjustment" holddown wheels & fence system, variable feed speed 0 - 35 FPM powered by a 0.25 HP DC gear drive (forward & reverse feed mode). -- Each sanding head with its own controls for manual raise & lower, pressure control and vibrating speed. Profile width approx. 1/2" min. to 4" max., material feed through thickness up to 5"; support fences for up to 10" moulding width.

$ 5,500

4-Station Profile ShaperSpecifications: -- 6" Chain drive with non-marking rubber top pads traveling on a hardened and ground precision dia. 5/8" round rods, Top pressure beam driven, Heavy duty fabricated transporter frame, Forward and reverse mode and block mode for creating sanding tools -- Precision X & Y axis mounting stands, 60° rotating tilt on mounting stands with positive lock, Independent activation control at each station, Adjustable infeed fence system, All dust hoods and guards, 2 HP AC variable speed gear drive 5 to 60' per min.Workstation 1: 3.5 HP TEFC Saw Arbor Motor, 1" Dia. Spindle, Dust Hoods with 4" outlet, Mounted on precision X & Y slides Workstation 2 & 3 - Belt Sanding Unit: 2 HP AC motor drive, Air belt tension system, Independent belt tracking system, Air activated sanding pad with touch control, 2" sanding belt width, Guards and Dust hoods with 4" outlet Workstation 4 - Wheel Sanding Unit: 3" HP variable speed (0-3,400 RPM) AC TEFC drive motor, 1" or 1.25" arbor 3.5" long, Dust Hood with 4" dia. outlet, Mounted on precision X & Y slidesSPECIAL NOTE: Needs New PLC or wire for traditional controlsNOTE: Above specs are taken from literature and thought to be accurate.

$ 1,550

PROGRESS PMC-264 Stroke SanderSpecifications: -- 8' x 30" Sliding table (on ball bearing steel rollers), 30" table travel; -- Manually operated stroker pad travels on ball bearings; large hand wheel for manual raise-and-lower of table for up to 24" vertical opening -- 5 HP - 1,750 RPM TEFC main motor. -- (2) 10" Dia. pulleys x 6-1/4" face, drive pulley rubber covered; -- 6" Wide x 264" long abrasive belt, abrasive belt speed 4,300 SFPM. -

Call for Price

$ 30,000

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- PURE (PUR & EVA) Hot melt gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers. -- Antistatic & Cooling Spray UnitNOTE: Sold "As Is" Without Warranty!

$ 19,500

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 Knives, Vertical nesting copiers, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters.NOTE: Sold "As Is" Without Warranty!

$ 16,000

CASADEI (PUTSCH-Branded) EBP-950 PMVR Edgebander, New, Never Used, with Pre-Mill & Vertical RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Vertical Rounding End Trim Unit, with Diamond Cutterhead & PLC-selectable front, rear, or complete panel processing. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier.NOTE: Sold "As Is" Without Warranty!

$ 11,000

CASADEI (PUTSCH-Branded) EBP-950 EdgebanderSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters.NOTE: Sold "As Is" Without Warranty!

$ 47,000

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- PURE (PUR & EVA) Hot melt gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

$ 41,500

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- FLEX Interchangeable gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

$ 41,500

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- FLEX Interchangeable gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

$ 95,000

PUTSCH-MENICONI KOPERNIC 4,200 x 2,200 mm CNC Vertical Machining Center, New with Parts Warranty, ATC, & C-AxisSpecifications: -- Working area X-Axis 4,200mm (165.35";), Y-Axis 2,220 mm (86.61";), & Z-Axis 100 mm (3.94";). -- Min. panel size 300 x 300 mm (11.81"; x 11.81";). -- Positioning speed: X-Axis 45 MPM (147 FPM), Y-Axis 30 MPM (98 FPM), & Z-Axis 15 MPM (49 FPM).Equipped with: -- Inclined Bakelite working table, with 20° Angle with respect to vertical, (12) Independently controlled vacuum zones with Solenoid valves with EtherCAT module & Digital vacuum pressure switch, and (10) Horizontal, (1) Left vertical & (1) Right vertical retractable pneumatic stops. -- Rack & pinion drive system on X & Y-Axes, with Automatic guide lubrication. -- Brushless motors, with EtherCAT Bus drives on All axes. -- Air pressure regulator, with digital pressure gauge. Machining: -- HSD 8 kW (10-3/4 HP) - 24,000 RPM ISO30 Air-cooled electro-spindle, with ER32 20 mm (0.79";) Chuck, High frequency inverter, & Variable spindle speeds to 24,000 RPM. -- CNC-Controlled C-Axis with 360° Rotation. -- Pneumatically actuated suction hood. -- 12-Position Automatic tool changer, with Automatic preset zero tool length probe.Control: -- OSAI “OPEN SMART CNC Control, with 21-1/2"; Display, EtherCAT Bus, USB & Ethernet ports, & MICROSOFT “WINDOWS 10"; Operating system. -- Remote pendant control.Complete with: -- Electrical Cabinet Cooling System. -- BECKER 6.6 kW (8.85 HP) 250 m³/h Vacuum Pump, with inverter for vacuum pressure adjustment from control. -- (6) ISO 30 Tool holders & (6) ER32 Clamps. -- 90° Grooving Cutter & HSD Shank for C-Axis Aggregate. -- 80 mm (3.15";) Cutter for shaving spoil board.Options available at additional cost: -- 150 mm (5.91";) Dia. Circular Tools for C-Axis Aggregate. -- 135° V-Grooving Cutter. -- Z48 Saw Blade.

Call for Price

Call for Price

Quick Clamp Carrier Model: SA-CCFP-10.5-14 10.5' Wide 14 Section Clamp: 2.5" high jaw, 38" opening Pneumatic clamp tightener Pneumatic Panel Flattener Electric Drive

QUICK 14-Section Pneumatic Clamp Carrier with 8-1/2' width capacity With (6) Standard zinc plated clamps per section (84 clamps total), 32" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. The automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- 14-Section Clamp will produce 300 panels per shift; 20-Section machine, 500 panels per shift.

QUICK 6-SECTION Clamp Carrier; (6) Sections, (6) clamps per section, and 8-1/2' width capacity. -- (36) Clamps total with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. -- 8 1/2 feet wide with easy to use controls.Equipped with: -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Pneumatic Panel Flattener -- Electric motor drive for Carrier rotation.Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler. -- Hhigh quality Urethane finish coating, and tool box with spare parts & tools. NOTE: -- 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). -- Clamp can be expanded to (14 or 20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.Floor space requirement: 134"w x 142"d x 143"h

QUICK 40-Section HEAVY DUTY HYDRAULIC CLAMP CAFRRIER with 8-1/2' Width cap. -- Clamp Carrier with: (6) Clamps per section, (240) total Heavy Duty zinc plated "Quick-Adj" fast adjusting clamps; 32" opening on clamps; jaw sizes of clamps are 3-1/2" high x 4-3/4" wide, with 1° inward draft. -- Equipped with: Integral pneumatic panel flattener and fully automatic hydraulic clamp tightener with adjustable torque limiter. -- Single-button automatic Heavy Duty electric motor rotation with cycle indexing. -- Automatic Carriage traverse is powered by a hydraulic motor coupled to a rack & pinion drive system, which provides smooth, accurate and very quiet operation. -- Automatic Carriage includes its own control panel for easy operator control at the Carriage; this is particularly helpful during "semi-automatic" operation. -- Operation: The machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. After loading wood into a section of clamps, the operator presses the "Cycle Start" button. -- The hydraulic Automatic Carriage traverses from right-to-left, flattening panels and tightening clamps along the way. -- When the carriage reaches the end of its traverse, the machine performs an automatic rotation cycle, bringing the next section of clamps down to the operator's position. -- The carriage then traverses from left-to-right, loosening clamps on the way back to its starting point. -- Standard features: All structural & mechanical components are manufactured with very Heavy Duty materials, providing many years of reliable service. -- Heavy Duty frame with 3" dia. shafts and 6" I-beam legs. -- Supplied with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools (QUICK Model "A-CCFH-08.5-40").

QUICK 20" Wide Conveyorized Glue Applicator -- 20" wide grooved rubber glue applicator roll with stainless steel doctor blade and glue reservoir. -- Features easy adjustment or removal of doctor blade, 16' overall length, 8' infeed before the glue roller and 8' outfeed conveyor. -- Equipped with: Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. -- Complete with: Foot levelers, Heavy Duty crossbars, chain guard, high quality anti-stick urethane finish, and owner & operator's manuals.

QUICK 30-Section HEAVY DUTY Pneumatic Clamp Carrier with 8-1/2' width cap. -- (6) Heavy Duty zinc plated clamps per section for (180) total clamps, 38" opening on clamp. -- Jaw sizes on clamps are 3-1/2" high x 4-3/4" wide with 1° inward draft.Equipped with: -- Pneumatic overhead panel flattener, -- Pneumatic clamp tightener, -- Electric motor rotation with indexing.Standard features include: -- Foot levelers, coiled air lines where used, and flexible conduit for wires.

.gif)