Northfield For Sale

1975 Results Found

Call for Price

Call for Price

54" 3-Head Orbital Sander, For abrasive belt cross-grain scratch removal with (3) Orbital Platen Heads & (1) Rotary Brush Head Configuration: 1st, 2nd, & 3rd Heads: Each with 5" W Platen, Dual orbital action, High-speed orbit on sanding pad with 3 kW (4 HP) Motor, Secondary oscillation with 1-1/2 HP Motor, "Quick-change" abrasive material, Inverter drive; Rotary Brush: 6" Maximum diameter, 3-1/2 HP Motor, Brush loading, Ionization bar for final fine dust collection Vacuum conveyor bed with 10 HP Blower motor, Inverter-controlled variable speed drive with 4 HP Motor & Variable feed speeds 15 - 66 FPM, Automatic conveyor belt tracking, Automatic parts thickness, with 1/8" - 4-5/8" Thickness range & Programmable height adjustment, (4) Screw jacks PC-based control, Windows XP, Touchscreen monitor, Infeed & outfeed spring-loaded hold-down rolls, Infeed hand safety stop, outfeed emergency stop, Digital motor load meters, High-efficiency dust extraction NOTE: Machine is currently in storage.

Call for Price

HEESEMANN LSM-8 C/L Wide Belt Sander, (2) Heads 53" (1,300 mm) Width cap., (1) Segmented cross-belt & (1) longitudinal combination head with segmented platen. Head Configuration: · 1st Head: Segmented cross-belt, 5/8" wide segments (86 total) with "CSD" control, abrasive belt size 5.9" x 244", (5,400 mm X 150 mm ) inside chevron belt 5.9" x 191", sanding belt speed 5-12 m/s with 17 HP motor. (Inverter controlled) · 2nd Head: Combination head, with segmented polishing platen, 5/8" wide segments with CSD control, 17 HP motor, 106" x 53" ( 2,620 mm X 1,350 mm ) abrasive belt size. (Inverter controlled) Equipped with & Features: · HESSEMANN's patented "CSD" magnetic pressure adjustment system, sensors spaced every 5/8" (16 mm) sense part configuration; (2) mm part thickness variation can be sanded without sand through’s, pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if required. · The "CSD" computer control will hold approx. (20) programs or part configurations. · Additional features: Outfeed rotary panel cleaning brush with single end adjustment, 2 HP motor, air blast abrasive belt cleaners on all heads. · Variable feed speed from 13 to 82 FPM via Stober drive, 6.5 HP feed drive, motorized thickness opening 1/4" to 3-5/32" maximum. · Belt condition at 80% good.

--AT AUCTION-- HEESEMANN KSA 8 CSD 80" Lacquer/Sealer Sander This is a Very Special "extra wide" HEESEMANN equipped with: HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 5/8" (16 mm) sense part configuration; pressure for each segment can be preprogrammed to provide less pressure on the outer edges, or more in the center if desired. The "CSD" computer control will hold a max. of (20) programs. Equipped with: Segmented Polishing Platen: Segments are computer controlled to conform to irregular shaped panels; sanding pressure on panel edges is adjustable. Platen will accept panel thickness variation up to 5/64" (2 mm). Dual speed motor: 26 & 31 kW (35 & 42 HP); abrasive belt speed: 10 + 20 MPS (33 + 66 FPM); abrasive belt size: 2,050 mm x 3,250 mm (80.7" x 128"); pneumatic air tension and tracking control. 250 mm Dia. Rotary Panel Cleaning Brush, 5 HP motor, 150 mm Outfeed Rotary Panel Cleaning Brush, and 2 HP motor. Additional Features: Vacuum bed assembly to ensure flatness of parts and feeding of small parts. Computer control and monitor, light indication of panel movement; electronic abrasive belt tracking. Feed System: Variable feed speed from 5 - 15 MPM (16 - 49 FPM); 4 kW (5 HP) feed motor; motorized thickness opening. NOTE: This Sander had a "Brand New" ...$ 17,000 display/control installed shortly before it was taken out of service in 2016. The machine has been in storage since that time.

$ 55,000

HEESEMANN LSM-8/3-OSR Wide Belt Finishing Sander, 52" and (3) Heads; Equipped with: (1) longitudinal segmented platen head. and (2) Orbital Platens -- 1st Head: Longitudinal segmented platen head. Segmented Polishing Platen, 20 & 27 HP dual speed motor. electronically controlled segments to conform to panel size,.2620 x 1350 mm (91.4 x 53.2") Sanding belt. - Equipped with HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 16 mm (5/8") sense part configuration; pressure for each segment, to eliminate sand through, can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. The "CSD" computer control will hold a maximum of (20) programs. -- 2nd & 3rd Heads: OSR Dual orbital action head with (1) high-speed orbit on sanding pad, powered by 3 kW (4.5 HP) motor.Secondary oscillation movement of platens powered by 1.5 HP motor. Upstream and downstream vacuum chutes on each head for dust localized dust pickup.- Platens feature "quick change" abrasive material; Both orbital heads with variable speed inverter drives. -- Outfeed Rotary Brush with cleaning brush loading with single end adjustment , 6" max. dia., 3.4 HP motor. -- Variable feed speed from 13 to 82 FPM, 6.5 HP feed drive. -- Infeed and outfeed Ssissor Lift and Control box shown are not included. -- Motorized thickness opening 1/4" to 3-5/32" max. - -- Power Consumption: 63 KW, 75 Amps. -- Separate display console for CSD control.

$ 14,500

HEESEMANN MFA-8 D Wide Belt Sander (4) Heads; 53" Width cap. Veneer/ Sealer Sanding Wide Belt.Great Lacquer/Sealer sander with: (2) Segmented polishing platen, (2) Orbital heads, (1) De-nibbing/Polishing brush.Head Configuration: Head 1: Segmented polishing platen, 5/8 wide segments CSD Control, Variable speed abrasive belt with inverter RPM control, 15HP motorHead 2: Segmented polishing platen, 5/8 wide segments CSD Control, Variable speed abrasive belt with inverter RPM control, 15HP motorHead 3: Orbital head with composite/dense fiber loading; 5HP motorHead 4: Orbital head with composite/dense fiber loading: 5HP motor(1) Brush Type head for de- nibbing and polishingSpecifications: -- LCD monitor with graphic display and key pad entry, 20 program capacity, -- Pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if required.Equipped with & Features -- Air blast abrasive belt cleaner on heads 1 & 2. -- Variable feed speed from 10 to 49 FPM via 2 HP feed drive. -- Motorized thickness opening 1/4" to 3-5/32" max. -- Rubber covered Infeed and out feed holddown rolls.

Call for Price

MFA 6 3 heads Pad (inverter controlled) Pad (inverter controlled) brush CSD System 480 V 100 A

$ 39,700

HEIAN FP-151-MC-2113 5-Axis CNC MachineFor high speed & precision routing/trimming & sizing wood and composite parts.Equipped With: -- (2100 mm) x (1,300 mm), moving table, fixed bridge style machining center; mahogany vacuum table. -- 3.7 kW, NT 30 Type ATC spindle, variable speed from 2,000 - 18,000 RPM with 8-position tool carousel. -- FANUC "16i CNC Control, 10.4" LCD , RS-232C/PCMCIA (memory card). Features: -- 5-Axis simultaneous motion, M & G code programming, inch or metric operation. -- Working Axes Stroke & Speed: X-Axis (2,600 mm) 60 m/Min; Y-axis (1,600 mm) 40 m/Mn; Z-axis (800 mm) 20 m/Min -- C-axis +/- 270°; B-axis +/- 110°; C-axis travels at 4,000°/Min and B travels at 4,000°/Min. -- Complete with assorted tool holders.

Call for Price

Call for Price

Call for Price

Hemple CL-8 Wood Turning Lathe 20” capacity will turn to 1/4” diameter manyal feed but auto cycle up to 400/hour 220 volt 3- phase

Call for Price

Hemple CL-8 Wood Turning Lathe 20” capacity will turn to 1/4” diameter manyal feed but auto cycle up to 400/hour 220 volt 3- phase

Call for Price

Hemple CL-8 Wood Turning Lathe 20” capacity will turn to 1/4” diameter manyal feed but auto cycle up to 400/hour 220 volt 3- phase

$ 24,900

HENDRICK - PRO-V HP3: Automatic Vertical Panel SawSpecifications & Features -- 96" Cutting length (cuts vertically top to bottom); adjustable depth of cut up to 2-3/8"; 14" blade dia. with: 1" Dia. bore; single blade scoring; 7.5 HP main motor. -- Equipped with: -- Heavy-Duty precision machined squaring fence; Formica laminated back table surface; full length pneumatic holddown bar with: Sensitive safety tape on both sides of holddown; 1 HP drive; 2-speed automatic saw carriage; travels 30 & 60 FPM (saw travel/return adj. to cut length). -- Complete with: -- (5) Adjustable flip stops on: (3) Positioning bars; ready for Dust Collector hookup. Actual model: Pro-V HP3

Call for Price

Single Head Horizontal Band Re-saw System Model : HP-11P-SMART • Single saw head configuration. • Motor powered set works for accurate saw wheel elevation. • Digital position controller permits accurate saw wheel height positioning. • Automatic blade tension is controlled by hydraulic cylinder. • Variable feed speed by hydraulic motor drive. • The big pressure roller is air cylinder loaded to hold wood down firmly. Specifications HP- 11P-SMART 1. Saves Time and labor costs 2. Pneumatic pressure roller infeed 3. Digital position controller permits accurate saw wheel height 4. Easy to operate and set up Feed speed: 4-27m/min (13-90FPM) Max. cutting height: 250mm (10”) Max. cutting width: 300mm (11 3/4”) Min. workpiece length: 400mm; 205mm with extension set Max. workpiece length: 580mm Distance from blade to conveyor: 4-125mm Saw wheel Diameter: 711.5mm (28”) Saw wheel width: 22.7mm (1”) Saw blade size: 4265 x 27mm (168” x 1’) Blade speed: 2816m/min (9240FPM) Saw Motor: 15kW(20HP) Feed unit: 0.75kW(2HP) gearbox motor with frequency converter Cooling system Oil mist Blade tensioning Hydraulic system Motor for blade positioning: 0.18kW(1/4HP) Dust post: Ø4” x 4 Table height: 902.5mm Machine weight: 951kgs Machine dimensions: 2835 x 2052 x 1678mm (LxWxH)

Call for Price

Call for Price

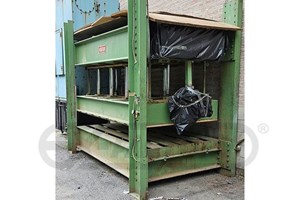

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.

Call for Price

HOFFMANN PU 2 DOVETAIL ROUTER (SINGLE SPINDLE) Pneumatic Dovetail Routing Machine - Dovetail routing machine for use with HOFFMAN dovetail butterfly connectors. - Maximum routing height 4", Max. workpiece height 5-3/4" - Table size 15-1/2” x 27-1/2” x 36-1/2” H - Production speed: Approx. 16 SPM (2 Complete rectangular frames) - (1) HOFFMANN "UAD 33 F" 33,000 RPM 1,000 W Router motor - 45° Fence, Accurately positions material with guide in table keyway, Quick adjustments made by adjusting fence plate - Pneumatic hold-down, Pneumatic foot pedal Includes: - Extra HOFFMANN "UAD 33 F" 33,000 RPM 1000 W Router Motor - 2007 HOFFMANN "FM1000" 35,000 RPM 1,000 W Router Motor - (2) 16” x 48” x 35” H Left-Hand & Right-Hand Aluminum Frame Tables, with 3/4” Thick Top, & 2” x 2” Aluminum frame - Palletized Dimensions: 42” x 42” x 60” H

.gif)