Woodworking Equipment For Sale

1779 Results Found

$ 14,900

BUSELLATO B1CNC CNC MACHINING CENTER (UNIVERSAL): -- Specifications: Design Type: Cantilever Style, 49" x 120" universal phenolic machine table, multizone "Universal" vacuum table for use with pods. -- Equipped with:(1) 10 HP ISO 30 Type ATC spindle; variable speed from 3,000 - 18,000 RPM; (7) position side tool magazine; (1) Multispindle boring block (7-vertical, 4-horizontal) with an X-axis grooving Saw. -- PC-Based ControlWith "Windows 2000 Professional", GENESIS EVOLUTION programming software, Rail plan for pod location software, Autolink DXF conversion software, Autobar labeling software, Gencode barcode reading software. -- Complete with:(1) 80 Cubic meter rotary vane Vacuum Pump; assorted tooling; documentation; manuals and applicable software media.NOTE: This machine has very low usage and was used more like a Hobby/R+D CNC Machining Center by the owner.INCLUDES: -- CORAL - CA/3C Dust Collector; (3) canvas filter Bags; (3) HD plastic Collection Bags; 10" dia. intake flange; 3,105 CFM; 5.5 HP motor, 3/220/440 Volt; complete with on/off starter.

$ 19,800

BUSELLATO JET 2 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working field: "X" Axis 120" (3,050 mm); "Y" axis 49.2" (1,250 mm); "Z" axis stroke 6.7" (170 mm); max. material thickness 4.7" (120 mm). -- Positioning Speeds:"X" Axis 197 FPM (60 MPM); "Y" axis 197 FPM (60 MPM); "Z" axis 66 FPM (20 MPM).Motion system utilizes Rack & Pinion and precision ball screws driven by AC Servo motors.The working head travels on high precision profile Guide Rail & Way Bearing System. -- Worktable:(6) Support rails with (4) panel lifters for heavy panels; (2) adjustable vacuum pods per rail. -- Boring Unit: 3 HP (2.2 kW) - 4,000 RPM motor; (12) independent vertical spindles: 7-Spindles in "X" axis, 5-spindles in "Y" axis.(6) Horizontal spindles: (2 + 2) Spindles in "X", (1 + 1) spindle in "Y". (1) "X" Axis grooving saw for max 120 mm dia. blade. -- Machining:(1) 10 HP (7.5 kW) Electro spindle with ISO 30 adaptor; variable spindle speed from 1,000 - 18,000 RPM. (1) 8-Position ATC tool plate for "on the fly ATC".(1) Additional 3 HP (2.2 kW) horizontal router mounted in "Y" axis. -- Operator & Machine Control:"PC" Front-End with: "TPA Genesis Evolution 2.2" + Windows 2000 Operating system; 32-bit INTEL Pentium III Processor - 1,000 MHz, 10 GB hard drive.15" Color monitor, international keyboard, soft touch keypad, & industrial mouse; (4) serial ports, (1) parallel port, (2) USB ports, (1) 1.44 MB floppy & (1) CD ROM disk drives. "Genesis Evolution" is a real-time multitask Processing System with data & error diagnostics; programs can be transferred via diskette or possible downloading by wire. -- Complete with:(1) 100 cbm/Hr BUSCH Vacuum Pump; scrap conveyor; safety mats; safety hood; all backup disk, documents, & manuals associated with this machine. -- Actual Model is: BUSELLATO JET 2.

Call for Price

BUSELLATO JET 4002 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working capacity: "X" Axis of 145.7" (3,700 mm); "Y" axis of 47.2" (1,200 mm); "Z" axis stroke 9.8" (250 mm); 6.8" (175 mm) max. material thickness. -- Positioning speed:"X" Axis at 230 FPM (70 MPM); "Y" axis at 197 FPM (60 MPM); "Z" axis 49 FPM (15 MPM). -- Worktable:(8) Pneumatic locking panel supports, (2) vacuum pods per support & LED digital readouts; (8) pneumatic backstops, (2) pneumatic side stops & (2) pneumatic central stops; (2) independent working zones. -- Boring Head:(1) 4 HP (3 kW) - 4,000 RPM Motor: (17) Vertical spindles; (8) horizontal spindles with (3 + 3) in "X" axis & (1 + 1) in "Y" axis. -- Machining:(1) Vertically mounted 10 HP (7.5 kW) electro spindle with ISO-30 adaptor (0 - 18,000 RPM) with RH or LH rotation; Router is driven by an 11 kW digital inverter.(1) 6-Position Automatic Tool Changer. -- Operator & Machine Control:PC Front-End with: "GENESIS EVOLUTION" 2.2.1 + Windows "NT" Operating System; 15" color monitor; 1.44 MB floppy & 32X CD ROM drives; 8.4 GB hard disk; 64 MB RAM; (2) RS 232 serial ports; integrated modem; Ethernet card; all built into a protective cabinet enclosure.GENESIS Software is continuously online providing real-time information on tool position & error messages, visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups.Software features: Automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single program. -- Complete with:Front safety mats that will instantly place machine in "Pause Cycle" when Operator steps onto the mats. -- Actual Model is BUSELLATO Jet 4002.

Call for Price

BUSELLATO JET 4002 XL CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working Field "X" Axis of 168.1" (4,270 mm); "Y" axis of 47.2" (1,200 mm); "Z" axis stroke 9.8" (250 mm); 6.8" (175 mm) max. material thickness. -- Positioning Speed:"X" Axis at 230 FPM (70 MPM); "Y" axis at 197 FPM (60 MPM); "Z" axis 49 FPM (15 MPM). -- Worktable:(8) Pneumatic locking panel supports, (3) vacuum pods per support.(8) Pneumatic backstops, (2) pneumatic side stops & (2) pneumatic central stops.(4) Independent working zones; jig locking device on (2) work areas. -- Boring Head:(1) 4 HP (3 kW) Motor - 4,000 RPM; (20) vertical spindles with: (12) Spindles in "X" axis & (8) spindles in "Y" axis. -- Machining:(1) Vertically mounted 10 HP (7.5 kW) electro spindle with: ISO-30 Adaptor (0 - 18,000 RPM) with RH or LH rotation; (1) 6-position automatic tool changer.(1) Additional 5 HP (3.8 kW) vertical router; routers are driven by an 11 kW Digital Inverter -- Operator & Machine Control:PC Front-End with: "GENESIS EVOLUTION" 2.2.1 + Windows "NT" Operating System; 15" color monitor; 1.44 MB floppy & 32X CD ROM drives; 8.4 GB hard disk; 64 MB RAM; (2) RS 232 serial ports; integrated modem; Ethernet card, all built into a protective cabinet enclosure.GENESIS Software is continuously online providing real-time information on tool position & error messages, visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups.Software features: Automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single program. -- Complete with:Front safety mats that will instantly place machine in "Pause Cycle" when operator steps onto the mats. Safety Perimeter Fencing. Transformer for 480 V. -- Actual Model is: Busellato Jet 4002 XL.

$ 23,700

BUSELLATO JET 2 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working field: "X" Axis 120" (3,050 mm); "Y" axis 49.2" (1,250 mm); "Z" axis stroke 6.7" (170 mm); max. material thickness is 4.72" (120 mm). -- Positioning Speeds:"X" Axis 197 FPM (60 MPM); "Y" axis 197 FPM (60 MPM); "Z" axis 66 FPM (20 MPM).Motion system utilizes rack & pinion and precision ball screws driven by AC Servo motors.The working head travels on high precision profile guide rail & way bearing system. -- Worktable:(6) Support rails with: (4) Panel lifters for heavy panels; (2) adjustable vacuum pods per rail. -- Boring Unit: 3 HP (2.2 kW) - 4,000 RPM motor; (12) independent vertical spindles: (7) Spindles in "X" axis, 5-spindles in "Y" axis; (6) horizontal spindles: (2 + 2) Spindles in "X", (1 + 1) spindle in "Y". (1) "X" Axis grooving saw for max 120 mm dia. blade. -- Machining:(1) 10 HP (7.5 kW) electrospindle with: ISO 30 Adaptor; variable spindle speed from 1,000 - 18,000 RPM. (1) 8-Position ATC tool plate for "on the fly ATC". -- Operator & Machine Control:PC Front-End with: "Genesis Evolution" + MS/Windows 2000 Operating System; 32-bit INTEL PENTIUM III Processor - 1,000 MHz; 10 GB hard drive.15" Color monitor, international keyboard, soft touch keypad & industrial mouse; (4) serial ports, (1) parallel port, (2) USB ports; (1) 1.44 MB floppy & (1) CD ROM disk drives. "Genesis Evolution" is a real-time multitask Processing System with data & error diagnostics; programs can be transferred via diskette or possible downloading by wire. -- Complete with:(1) 100 cbm/Hr "BUSCH" Vacuum Pump; scrap conveyor; safety mats; safety hood; all backup disk, documents, & manuals associated with this machine. -- Actual model is: BUSELLATO JET 2.

Call for Price

BUSELLATO JET 4002 XL CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working Field "X" Axis of 168.1" (4,270 mm); "Y" axis of 47.2" (1,200 mm); "Z" axis stroke 9.8" (250 mm); 6.8" (175 mm) max. material thickness. -- Positioning Speed:"X" Axis at 230 FPM (70 MPM); "Y" axis at 197 FPM (60 MPM); "Z" axis 49 FPM (15 MPM). -- Worktable:(8) Pneumatic locking panel supports, (3) vacuum pods per support.(8) Pneumatic backstops, (2) pneumatic side stops & (2) pneumatic central stops.(4) Independent working zones; jig locking device on (2) work areas. -- Boring Head:(1) 4 HP (3 kW) Motor - 4,000 RPM; (20) vertical spindles with: (12) Spindles in "X" axis & (8) spindles in "Y" axis. -- Machining:(1) Vertically mounted 10 HP (7.5 kW) electro spindle with: ISO-30 Adaptor (0 - 18,000 RPM) with RH or LH rotation; (1) 6-position automatic tool changer.(1) Additional 5 HP (3.8 kW) vertical router; routers are driven by an 11 kW Digital Inverter -- Operator & Machine Control:PC Front-End with: "GENESIS EVOLUTION" 2.2.1 + Windows "NT" Operating System; 15" color monitor; 1.44 MB floppy & 32X CD ROM drives; 8.4 GB hard disk; 64 MB RAM; (2) RS 232 serial ports; integrated modem; Ethernet card, all built into a protective cabinet enclosure.GENESIS Software is continuously online providing real-time information on tool position & error messages, visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups.Software features: Automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single program. -- Complete with:Front safety mats that will instantly place machine in "Pause Cycle" when operator steps onto the mats. Safety Perimeter Fencing. Transformer for 480 V. -- Actual Model is: Busellato Jet 4002 XL.

Call for Price

BUSELLATO JET 4002 XL CNC MACHINING CENTER (W/ATC/BORING): -- Specifications Working Field "X" Axis of 168.1" (4,270 mm); "Y" axis of 47.2" (1,200 mm); "Z" axis stroke 9.8" (250 mm); 6.8" (175 mm) max. material thickness. -- Positioning Speed"X" Axis at 230 FPM (70 MPM); "Y" axis at 197 FPM (60 MPM); "Z" axis 49 FPM (15 MPM). -- Worktable(8) Pneumatic locking panel supports; (2) vacuum pods per support.(8) Pneumatic backstops; (2) pneumatic side stops & (2) pneumatic central stops.(4) Independent working zones; jig locking device on (2) work areas. -- Boring Head(1) 4 HP (3 kW) Motor - 4,000 RPM; (20) vertical spindles with (12) spindles in "X" axis & (8) spindles in "Y" axis. -- Machining(1) Vertically mounted 10 HP (7.5 kW) electro spindle with ISO-30 adaptor (0 - 18,000 RPM) with RH or LH rotation; (1) 6-position automatic tool changer.(1) Additional 5 HP (3.8 kW) vertical Routers; Routers are driven by an 11 kW digital Inverter. -- Operator & Machine ControlPC Front-End with: "GENESIS EVOLUTION" 2.2.1 + Windows "NT" Operating System; 15" color monitor; 1.44 MB floppy & 32X CD ROM drives; 8.4 GB hard disk; 64 MB RAM; (2) RS 232 serial ports; integrated modem; Ethernet card, all built into a protective cabinet enclosure.GENESIS Software is continuously online providing real-time information on tool position & error messages; visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups.Software Features: Automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single program. -- Complete with:Front safety mats that will instantly place machine in "Pause Cycle" when operator steps onto the mats. -- Actual Model is BUSELLATO- Jet 4002 XL.

Call for Price

Call for Price

Busellato Jet 100 CNC Router 4' x 9' Table 10 HP Spindle Boring Block: (7)X, (5)Y 20 HP Vacuum Pump Custom built offload table 240 V/3PH

Call for Price

Busellato V-Tech CNC Router 400 Volt/50-60 HZ MFG Specs (to be confirmed): BUSELLATO V-TECH Vertical CNC Machining Center with ATC: Working Field "X" Axis 120" (3,050 mm), "Y" axis 51.1" (1,300 mm), Z-axis 70 mm (2.8"). Positioning Speed: "X" axis is 197 FPM (60 MPM), "Y" axis 164 FPM 50 MPM), "Z axis 33 FPM (10 MPM). Worktable Bored "Phenolic table with (10) adjustable vacuum pods; (6) Pneumati

Call for Price

Busellato Easy Jet CNC Router 5x12 Table 9 HP Spindle 7-Spindle Boring Block 8-Position Parallel Tool Changer

Call for Price

BUSELLATO JET 4000 CNC MACHINING CENTER W/ATC: -- Specifications: Working Cap. "X" Axis 126"(3,200 mm), "Y" axis 56.6"(1,440 mm), "Z" axis stroke is 11.8" (300 mm), max. material thickness 5.9" (150 mm). -- Positioning Speed:"X" axis is 377 FPM (115 MPM), "Y" axis 246 FPM (75 MPM), "Z" axis 98 FPM (30 MPM) -- Worktable:(8) Pneumatically locking panel supports, (4) lifter rails for heavy panels, (4) "MATRIX" vacuum pods per support; (8) Pneumatic backstops, (8) Pneumatic central stops, (4) pneumatic side stops & (4) pneumatic central stops; (4) independent work areas. -- Boring unit:3 HP (2.2 kW) - 4,000 RPM motor; Boring head with (15) independent vertical spindles (9) spindles in "X" axis & (6) spindles in "Y" axis.(4) Horizontal boring units with (1+1) in "X" axis & (1+1) in "Y" axis. -- Machining Units:(1) 14 HP (10.4 kW) Electro spindle router with HSK F63 adaptor, (1,000 - 18,000 RPM); (1) 10-Position rotary tool changer mounted to the head for "on the fly" ATC.(1) Additional 9.5 HP (7 kW) router with RH rotation & ER32 adaptor. -- Operator & Machine Control:PC front end with "Genesis" + Windows operating system; 15" Color monitor, 1.44 MB floppy & 8.4 GB hard disk system, 32x CD ROM, 64 MB RAM, (2) I/F serial ports, integrated modem, Ethernet card."GENESIS" Software is continuously online providing real-time information on tool position & error messages, visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups."GENESIS" Software features automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single-program; all built into a protective cabinet enclosure -- Complete with: (1) 100 m³/Hr Vacuum Pump; safety mats, auto lubrication system, air-conditioned control cabinet. -- Actual Model is Busellato JET 4000

Call for Price

BUSELLATO JET 100 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working field: "X" Axis 120" (3,048 mm); "Y" axis 49" (1,244 mm); "Z" axis 3.9" (100 mm). -- Positioning Speed:"X & Y" Axes 328 FPM (100 MPM) each; "Z" axis 98 FPM (30 MPM); sll units ride on precision guides & ways."X" Axis uses a helical rack-and-pinion system; "Y & Z" axes use ball screws; all axes are driven by digital, brushless AC Servo motors. -- Worktable:(6) Panel supports with: (4) Lifting bars & digital readouts for manual rail & pod locations according to the program. (4) Vacuum pods per support rail; (2) independent working areas. -- Boring Unit:TF 20 Boring head with (14) vertical spindles: (8) Spindles in "X" axis & (6) spindles in "Y" axis.(4) Horizontal spindles with: (1 + 1) in "X" & (1 + 1) in "Y"; (1) "X" axis grooving saw for max 120 mm blade. -- Machining:(1) ISO-30 Spindle(1) 15-Position ATC tool changer mounted at the rear of the machine. -- Operator & Machine Control:PC-Based control with "GENESIS" + Windows "2000" Operating System.Includes Color CRT monitor, full keyboard & mouse; 256 MB RAM, 10 GB hard disk, CD ROM (52X), 1.44 MB floppy drive; (4) serial ports, (1) parallel port, (2) USB ports. "GENESIS" Operating System with: Large onboard program storage, ethernet connection, specific function controls, and internet troubleshooting capabilities. -- Complete with:(1) 100 m³/Hr Vacuum Pump, Bar Code Scanner, Belt Conveyor for scrap removal. -- Actual Model is BUSELLATO JET 100

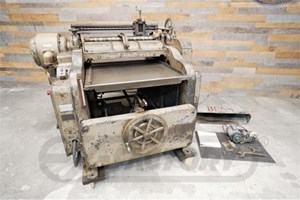

$ 10,200

BUSS DL 30" X 8" Heavy Duty Wood Planer with GrinderModel DL, , Bed Capacity 30" W x 65" L x 8" H ,Specifications: -- (2) Large steel support rollers on bed, upper area: (1) steel roller -- One (1) cutter-head with (4) knives, one (1) grip-thru roller. -- Heavy duty spring tension adjustment on top of machine. -- Two (2) 15 HP, 3-PH motors; one connected to 20-ratio gear reducer variable feed speed drive and the other connected to the cutter head system. -- Upper cross frame attachment for knife grinder system ( Comes with grinder )Equipped with & Features -- Oil cup & grease fitting lube system. -- Power Raising and lowering of the Planer bed.

$ 7,200

BUSS - 44, 26" PLANERSpecifications: -- 25" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$ 18,200

BUSS DL TYPE Heavy Duty 50" x 8" Single Sided Wood Planer:Specifications: -- Belt-Driven 50" Straight Knife Cutter Head. -- 25Hp Cutter Head Motor. -- Dust hood with 12" Port. -- Chip Breakers -- Grooved Feed Rolls -- Smooth Pressure Roll After Cutter HeadEquipped with & Features -- Top Mounted Grinding Bar -- Manual Height Adjustment -- Leeson SpeedMaster - Adjustable Feed Speed Controller -- Push Button Controls -- Safety Guards

$ 19,750

BUSS 44-40 STRAIGHT KNIFE PLANER40" x 8" Cap., 30 HP - 3,600 RPM direct drive single top head,Specificatioins: -- 4-knife cutterhead w/high speed steel knives, top sectional -- infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. material thickness. Manual opening with indicator. -- Min. stock length 14" and 4" butted, manual table raise-and-lower; variable speed infeed 28 - 85 FPM. via REEVES power transmission -- Complete with: Knife grinding/jointing equipment, pressure lubricator, push button magnetic control & shaving hood.

$ 8,750

BUSS - 44, ...36" PlanerSpecifications: -- 36" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Knife Grinding/Jointing equipment. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

Call for Price

2007 BUTFERING OPTIMAT SC0213 DIAMOND CE WIDE BELT SANDER - 53'' - 460 VOLT - WITH ROLLING CONVEYOR, S/N: 0411200029 - Includes: Boxes of new misc belts

$ 26,950

BUTFERING - STO 211 RL, ...2-Head Wide Belt Sander.43" Width cap.; Drum & Combination Head.Head Configuration:1st Head: Grooved Steel Contact Drum, ~8"; dia. and 25 HP motor.2nd Head: Combination style, w/grooved rubber covered drum & platen, 20 HP motor.Specifications: -- 43" x 75" Abrasive belts, both heads with grit compensation. -- Electronic abrasive belt tracking. -- Conveyor belt feed with 2-speed control at 14 & 28 FPM. -- Automatic conveyor belt tracking. -- Infeed & outfeed spring-loaded rubber covered holddown rolls.Equipped with & Features: -- Automatic part thickness setup with index control. -- 1/8" - 5-1/2" Motorized thickness adjustment with joystick control and LED readout. -- Panel "over-thickness" sensor at infeed. -- Infeed & outfeed emergency stops, safety interlocks on all doors. -- Roller infeed conveyor extension. -- Motor load meters and main motor electronic brakes.

.gif)