Woodworking Equipment For Sale

1771 Results Found

Call for Price

BUSELLATO JET 4002 XL CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working Field "X" Axis of 168.1" (4,270 mm); "Y" axis of 47.2" (1,200 mm); "Z" axis stroke 9.8" (250 mm); 6.8" (175 mm) max. material thickness. -- Positioning Speed:"X" Axis at 230 FPM (70 MPM); "Y" axis at 197 FPM (60 MPM); "Z" axis 49 FPM (15 MPM). -- Worktable:(8) Pneumatic locking panel supports, (3) vacuum pods per support.(8) Pneumatic backstops, (2) pneumatic side stops & (2) pneumatic central stops.(4) Independent working zones; jig locking device on (2) work areas. -- Boring Head:(1) 4 HP (3 kW) Motor - 4,000 RPM; (20) vertical spindles with: (12) Spindles in "X" axis & (8) spindles in "Y" axis. -- Machining:(1) Vertically mounted 10 HP (7.5 kW) electro spindle with: ISO-30 Adaptor (0 - 18,000 RPM) with RH or LH rotation; (1) 6-position automatic tool changer.(1) Additional 5 HP (3.8 kW) vertical router; routers are driven by an 11 kW Digital Inverter -- Operator & Machine Control:PC Front-End with: "GENESIS EVOLUTION" 2.2.1 + Windows "NT" Operating System; 15" color monitor; 1.44 MB floppy & 32X CD ROM drives; 8.4 GB hard disk; 64 MB RAM; (2) RS 232 serial ports; integrated modem; Ethernet card, all built into a protective cabinet enclosure.GENESIS Software is continuously online providing real-time information on tool position & error messages, visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups.Software features: Automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single program. -- Complete with:Front safety mats that will instantly place machine in "Pause Cycle" when operator steps onto the mats. Safety Perimeter Fencing. Transformer for 480 V. -- Actual Model is: Busellato Jet 4002 XL.

Call for Price

Call for Price

Busellato Jet 100 CNC Router 4' x 9' Table 10 HP Spindle Boring Block: (7)X, (5)Y 20 HP Vacuum Pump Custom built offload table 240 V/3PH

Call for Price

Busellato V-Tech CNC Router 400 Volt/50-60 HZ MFG Specs (to be confirmed): BUSELLATO V-TECH Vertical CNC Machining Center with ATC: Working Field "X" Axis 120" (3,050 mm), "Y" axis 51.1" (1,300 mm), Z-axis 70 mm (2.8"). Positioning Speed: "X" axis is 197 FPM (60 MPM), "Y" axis 164 FPM 50 MPM), "Z axis 33 FPM (10 MPM). Worktable Bored "Phenolic table with (10) adjustable vacuum pods; (6) Pneumati

Call for Price

Busellato Easy Jet CNC Router 5x12 Table 9 HP Spindle 7-Spindle Boring Block 8-Position Parallel Tool Changer

Call for Price

BUSELLATO JET 100 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working field: "X" Axis 120" (3,048 mm); "Y" axis 49" (1,244 mm); "Z" axis 3.9" (100 mm). -- Positioning Speed:"X & Y" Axes 328 FPM (100 MPM) each; "Z" axis 98 FPM (30 MPM); sll units ride on precision guides & ways."X" Axis uses a helical rack-and-pinion system; "Y & Z" axes use ball screws; all axes are driven by digital, brushless AC Servo motors. -- Worktable:(6) Panel supports with: (4) Lifting bars & digital readouts for manual rail & pod locations according to the program. (4) Vacuum pods per support rail; (2) independent working areas. -- Boring Unit:TF 20 Boring head with (14) vertical spindles: (8) Spindles in "X" axis & (6) spindles in "Y" axis.(4) Horizontal spindles with: (1 + 1) in "X" & (1 + 1) in "Y"; (1) "X" axis grooving saw for max 120 mm blade. -- Machining:(1) ISO-30 Spindle(1) 15-Position ATC tool changer mounted at the rear of the machine. -- Operator & Machine Control:PC-Based control with "GENESIS" + Windows "2000" Operating System.Includes Color CRT monitor, full keyboard & mouse; 256 MB RAM, 10 GB hard disk, CD ROM (52X), 1.44 MB floppy drive; (4) serial ports, (1) parallel port, (2) USB ports. "GENESIS" Operating System with: Large onboard program storage, ethernet connection, specific function controls, and internet troubleshooting capabilities. -- Complete with:(1) 100 m³/Hr Vacuum Pump, Bar Code Scanner, Belt Conveyor for scrap removal. -- Actual Model is BUSELLATO JET 100

Call for Price

BUSELLATO JET 4000 CNC MACHINING CENTER W/ATC: -- Specifications: Working Cap. "X" Axis 126"(3,200 mm), "Y" axis 56.6"(1,440 mm), "Z" axis stroke is 11.8" (300 mm), max. material thickness 5.9" (150 mm). -- Positioning Speed:"X" axis is 377 FPM (115 MPM), "Y" axis 246 FPM (75 MPM), "Z" axis 98 FPM (30 MPM) -- Worktable:(8) Pneumatically locking panel supports, (4) lifter rails for heavy panels, (4) "MATRIX" vacuum pods per support; (8) Pneumatic backstops, (8) Pneumatic central stops, (4) pneumatic side stops & (4) pneumatic central stops; (4) independent work areas. -- Boring unit:3 HP (2.2 kW) - 4,000 RPM motor; Boring head with (15) independent vertical spindles (9) spindles in "X" axis & (6) spindles in "Y" axis.(4) Horizontal boring units with (1+1) in "X" axis & (1+1) in "Y" axis. -- Machining Units:(1) 14 HP (10.4 kW) Electro spindle router with HSK F63 adaptor, (1,000 - 18,000 RPM); (1) 10-Position rotary tool changer mounted to the head for "on the fly" ATC.(1) Additional 9.5 HP (7 kW) router with RH rotation & ER32 adaptor. -- Operator & Machine Control:PC front end with "Genesis" + Windows operating system; 15" Color monitor, 1.44 MB floppy & 8.4 GB hard disk system, 32x CD ROM, 64 MB RAM, (2) I/F serial ports, integrated modem, Ethernet card."GENESIS" Software is continuously online providing real-time information on tool position & error messages, visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups."GENESIS" Software features automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single-program; all built into a protective cabinet enclosure -- Complete with: (1) 100 m³/Hr Vacuum Pump; safety mats, auto lubrication system, air-conditioned control cabinet. -- Actual Model is Busellato JET 4000

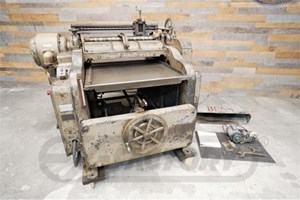

$ 8,750

BUSS - 44, ...36" PlanerSpecifications: -- 36" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Knife Grinding/Jointing equipment. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$ 10,200

BUSS DL 30" X 8" Heavy Duty Wood Planer with GrinderModel DL, , Bed Capacity 30" W x 65" L x 8" H ,Specifications: -- (2) Large steel support rollers on bed, upper area: (1) steel roller -- One (1) cutter-head with (4) knives, one (1) grip-thru roller. -- Heavy duty spring tension adjustment on top of machine. -- Two (2) 15 HP, 3-PH motors; one connected to 20-ratio gear reducer variable feed speed drive and the other connected to the cutter head system. -- Upper cross frame attachment for knife grinder system ( Comes with grinder )Equipped with & Features -- Oil cup & grease fitting lube system. -- Power Raising and lowering of the Planer bed.

$ 7,200

BUSS - 44, 26" PLANERSpecifications: -- 25" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$ 18,200

BUSS DL TYPE Heavy Duty 50" x 8" Single Sided Wood Planer:Specifications: -- Belt-Driven 50" Straight Knife Cutter Head. -- 25Hp Cutter Head Motor. -- Dust hood with 12" Port. -- Chip Breakers -- Grooved Feed Rolls -- Smooth Pressure Roll After Cutter HeadEquipped with & Features -- Top Mounted Grinding Bar -- Manual Height Adjustment -- Leeson SpeedMaster - Adjustable Feed Speed Controller -- Push Button Controls -- Safety Guards

$ 19,750

BUSS 44-40 STRAIGHT KNIFE PLANER40" x 8" Cap., 30 HP - 3,600 RPM direct drive single top head,Specificatioins: -- 4-knife cutterhead w/high speed steel knives, top sectional -- infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. material thickness. Manual opening with indicator. -- Min. stock length 14" and 4" butted, manual table raise-and-lower; variable speed infeed 28 - 85 FPM. via REEVES power transmission -- Complete with: Knife grinding/jointing equipment, pressure lubricator, push button magnetic control & shaving hood.

$ 37,950

BUTFERING - OPTIMAT STO 311 RRL, ...3-Head Wide Belt Sander43" Width cap., Drum, Drum, and Platen.Head Configuration:1st Head: 7" Steel spiral contact drum, 29.5 HP motor.2nd Head: 7" Rubber covered drum, 25 HP motor.3rd Head: Combination Style Head with Grooved Rubber-Covered Drum and Air-Cushion Pad; 3rd Head Motor: 16.7/21.5 HP.Specifications: -- 43" x 75" Abrasive belts, electronic abrasive belt tracking. -- Conveyor belt feed with variable feed speed from 8 - 43 FPM. -- Automatic conveyor belt tracking. -- Infeed & outfeed spring-loaded rubberized holddown rolls. Equipped With & Features: -- 1/8" - 5-1/2" Motorized thickness adjustment, "quick-set" automatic thickness adjustment with LED readout. -- Infeed panel "over-thickness" sensor. -- Outfeed rotary panel cleaning brush Infeed & outfeed emergency stops. -- Safety interlocks on all doors. -- Roller infeed conveyor extension, -- Motor load meters and main motor electronic brakes.

$ 86,135

BÜTFERING SWT 325 QX - 2-Head Wide Belt Sander for lacquer, veneer & solid wood sanding.1,350 mm (53") working width, equipped with (1) Cross belt "Q", (1) BÜTFERING patented Combination Head "X" Roller/Pad with inner chevron belt.This configuration allows for high-quality sanding of various surfaces, like: ● Fine sanding & calibrating of solid woods ● Lacquer sanding with grit sizes P 120 - 800 ● Preparation for high-gloss surfaces1,350 mm (53") working width, equipped with (1) Cross belt "Q", (1) BÜTFERING patented Combination Head "X" Roller/Pad with inner chevron belt.Head Configuration: 1st Head: Cross belt sanding unit "Q". With inner chevron belt. Infinitely variable abrasive belt speed 2 - 16 m/Sec (7 - 53 FPS). Segmented fine sanding pad, electro-pneumatically controlled by BÜTFERING EPS system, with 54 segments, each 25 mm (1") wide. Abrasive belt size 150 x 4,700 (5.9"- 185"). Driven by 13,5 kW (18 HP) motor.2nd Head: BÜTFERING patented Combination Head "X" Roller/Pad with inner chevron belt. Consisting of Contact Roller, rubberized, spirally grooved, and Segmented fine sanding polishing platen with inner chevon belt. With 54 segments, each 25 mm (1") wide, electro-magnetically controlled. Infinitely variable abrasive belt speed 2 - 12 m/Sec (7 - 40 FPS). Abrasive belt size 1,370 x 2,620 mm (54" x 103"). Driven by 20 kW (27 HP) motor.Equipped with BÜTFERING MPS - Magnetic Pad System with 3 sensors per segment. Dynamic sanding pressure control ensures that equal sanding pressure is applied on the entire workpiece, with compensation on the leading & trailing edges. This sytem will allow up to 2 mm (1/16") in thickness variations.Total repeatability. High-precision machined segments are wear- & maintenance-free. For very intricate sanding tasks the sanding pressure of every segment can be individually controlled with the BÜTFERING IAC - Individual Actuator Control system.Both heads equipped with: Electronic abrasive belt tracking. Pneumatic abrasive belt tension. Air jet belt cleaner, activated by part size. Feed system: -- Constant pass line 900 mm (35.4"). -- Vacuum conveyor bed assembly. Divided in two sections, on each section the vacuum power can be adjusted. -- Conveyor belt feed speeds 2,5 - 13 m/Min (8 - 43 FPM). Driven by 0,55 kW (0,75 HP) motor. -- Part thickness 3 - 160 mm (1.2" - 6.3"). -- Motorized thickness adjustment driven by 0,25 kW (0,35 HP) motor. -- Automatic thickness adjustment. -- Automatic electronic conveyor belt tracking. -- Extractable support table with idle rollers at infeed. -- Support roller and support table at outfeed of the machine.Machine management system: VSE Control System with Color Touch Screen for all major machine operations, programming of parameters and storage of 1,000 sanding programs, supervision of major machine functions. Visual display of the work process. Error diagnosis. Fully automatic start sequence of the main motors. Recor

$ 37,500

BUTFERING E-LINE 213RL (2) Head Wide Belt Sander53" Width cap. Drum, Combinbation HeadHead Configuration1st Head : Steel calibrating contact roll 200mm Dia. 20 HP2nd Head : Combination Head 20 HP. ( Comes with (2) slide in platens, one for veneer, one for solid wood ) Rubber contact roll 140mm Dia. Specifications -- 53" x 75" Abrasive belts, -- Electronic abrasive belt tracking -- Conveyor belt feed with 2-speed motor, 18/ms, 2.3 HP motor, infeed & outfeed spring loaded holddown rolls, -- 1/8" - 5-3/4" motorized part thickness adjustment with LED readout.Equipped With & Features -- Infeed panel "over-thickness" sensor -- Brakes on both sanding head motors, -- Infeed emergency stop, -- Roller infeed conveyor extension -- motor load meters.

$ 14,950

BUTFERING SKO-113-C WIDE BELT SANDER53" Width cap. Combination Head. Combination sanding head with steel contact roll & electronically controlled segmented platen.Specifications: -- Contact roll height position with programmable control. -- Platen consists of 35 mm wide segments designed to conform to part size to minimize sand throughs. -- 53" Wide vacuum bed with 3 kW vacuum pump motor assembly. -- 53" x 75" Abrasive belt with air tensioning and electronic abrasive belt tracking,Equipped with & Features: -- Out-feed rotary panel cleaning brush. -- Touch screen program control with storage up to (125) programs. -- Conveyor belt feed 2 HP motor, Variable feed drive from 8 - 43 FPM. -- Vacuum conveyor bed assembly with suction fan and motor assembly. -- Infeed & outfeed rubber-covered hold-down rolls. -- Programmable part thickness opening 1/8" - 5-7/8", automatic conveyor belt tracking -- Infeed roller extension, electric brake on abrasive belt, -- Emergency stop button, -- Motor load meter, and magnetic controls.

$ 25,000

BUTFERING - Profiline SUR 313 RRR, ...Bottom Wide Belt Sander with Powered Infeed & Connect to Top Sander (...see SX-012684 - OPTIMAT SCO 413 RRRR, ...Top Head Wide Belt) Bottom 3-Head, 53" Width Capacity Wide Belt Sander.Head Configuration: -- 1st Head: Steel Contact Roll, 240 mm (9-1/2") dia., 22 kW (30 HP) motor. -- 2nd Head: Rubber covered Contact Roll, 65 Shore, 320 mm (12-1/2") dia., 22 kW (30 HP) motor; Rotation with or against feed direction. -- 3rd Head: Rubber covered Contact Roll, 55 Shore, 320 mm (12-1/2") dia., 18.5 kW (25 HP) motor; Rotation with or against feed direction.Features & Specifications: -- Outfeed Rotary Panel cleaning brush with: Abrasive grit, 5.5 kW (7.5 HP) motor. -- 950 mm (37") Section of free-standing power driven infeed roller track. -- 54" x 103" Abrasive belts, electronic abrasive belt tracking, and all heads with Servo driven grit compensation and motorized positioning. Abrasive belt Air Jet blowers on all heads. -- Vacuum conveyor belt feed with: Variable feed speed 5 - 25 MPM (16-1/2 - 82 FPM); automatic conveyor belt tracking; infeed & outfeed spring loaded rubberized holddown rollers; outfeed extension for linking to transfer conveyor, connecting Bottom head to Top head Sander. -- Constant pass line of 900 mm (35-1/2") by adjustment upper machine frame via (4) large dia. threaded spindles. -- Tie In conveyor: To connect to Top Head Sander; 1,500 mm (59"), 5 - 25 MPM (16-1/2" - 82 FPM), synchronized with machine bed conveyor speed. -- Color touch screen control with: (1,000) Programs, 1/8" - 5-1/2" motorized thickness adjustment; "quick-set" automatic thickness adjustment with LED readout; infeed panel "over-thickness" sensor.Complete with: -- Infeed & outfeed emergency stops; safety interlocks on all doors; roller infeed conveyor extension; motor load meters and electronic brakes for all sanding head motors. -- Operator and Maintenance manuals (in Spanish); spare parts drawings, spare parts list, and wiring diagram.NOTE: -- BUTFERING - PROFILINE SUR, ...Bottom Sander and OPTIMAT SCO, ...Top Sander are being offered as a "Complete System/Line" with Infeed & Transfer Connect; (1) Common Control for both machines to operate as a Line. Copy of original quote with detailed specifications is available upon request.Asking Price with this "SX-012681" listing is for the Bottom Head Sander only - Open to reasonable offers.

$ 25,000

BUTFERING - OPTIMAT SCO 413 RRRR, ...Top Head Wide Belt Sander (...part of line with SX-012681 Profiline 3-Head Bottom Sander)Top 4-Head, 53" Width Capacity Wide Belt Sander with (4) Drums (Rollers).Head Configuration: -- 1st Head: Steel Contact Roll, 240 mm (9-1/2") dia., 22 kW (30 HP) motor. -- 2nd Head: Rubber covered Contact Roll, 85 Shore, 240 mm (9-1/2") dia., 22 kW (30 HP) motor. -- 3rd Head: Rubber covered Contact Roll, 65 Shore, 320 mm (12-1/2") dia., 22 kW (30 HP) motor; Rotation with or against feed direction. -- 4th Head: Rubber covered Contact Roll, 35 Shore, 320 mm (12-1/2") dia., 18.5 kW (25 HP) motor. -- All Heads with servo positioning of Contact Roller via precision motor to 1/100 mm, with possibility to store different values in the Terminal.Features & Specifications: -- Outfeed Rotary Panel cleaning brush with abrasive grit, 5.5 kW (7.5 HP) motor; 950 mm (37") Section of free-standing power driven infeed roller track; 54" x 103" Abrasive belts and electronic abrasive belt tracking; all heads with Servo driven grit compensation and motorized positioning; Abrasive belt air-jet blowers on all heads; Automatic head locking for fast abrasive belt change. -- Vacuum Conveyor belt feed with variable feed speed 5 - 25 MPM (16-1/2 - 82 FPM); automatic conveyor belt tracking, infeed & outfeed spring loaded rubberized holddown rollers. -- Constant passline of 900 mm (35-1/2") by adjustment upper machine frame via (4) large dia. threaded spindles. -- Color touchscreen control with (1,000) programs, 1/8" - 5-1/2" motorized thickness adjustment, "quick-set" automatic thickness adjustment with LED readout; infeed panel "overthickness" sensor.Complete with: -- Infeed & outfeed emergency stops, safety interlocks on all doors, roller infeed Conveyor extension, motor load meters, and electronic brakes for all sanding head motors. -- Operator and Maintenance manuals (in Spanish); spare parts drawings, spare parts list, and wiring diagram.NOTE: -- BUTFERING "PROFILINE SUR" Bottom Sander and "OPTIMAT SCO" Top Sander [SX-012681] are: Offered as a Complete System/Line with Infeed & Transfer Connect; one common Control for both machines to operate as line. - Copy of original quote with detailed specifications is available upon request.Asking Price with this "SX-012684" listing is for the Top Head Sander only - Open to reasonable offers.

Call for Price

53" 3-head sander 1st head - Drum 2nd head - Combo head 3rd head - polishing head outlet rotary cleaning brush belts 54" x 103" Feed variable 8-43 FPM Controller with color screen Manuals available

.gif)