Misc For Sale

Category

Misc

98 Results Found

Timber Treatment Solutions designs and manufactures turnkey low pressure wood treatment plants of any size which are suitable for use with any of the existing treatment chemicals on the market, whether they are water based or solvent based. These plants generally include: – - Autoclave or rectangular vessel with quick closing door(s) - One or several tanks to store the treatment chemical - Process skid, with all necessary pumps, valves, and pipes - Timber pack handling system, from completely manual to fully automated - Mixing / Dosing System - PC or HMI based control system with our latest plant operating system There are lots of possible configurations of low pressure plant, and our teams will be able to advise the most suitable for you, according to your needs and budget. Plants can be designed for any of the processes usually required by wood impregnation industry, such as Double Vacuum & Envelope WHEN TO USE LOW PRESSURE TREATMENT? Low pressure treatment is widely used, whenever light impregnation of wood by a preservative is required (also called surface treatment or envelope treatment): - To impregnate timber for Use Class 1, such as timbers that will remain dry (e.g. upper floor joists, truss rafters) - To impregnate timber for Use Class 2, such as timbers that are exposed to a slight risk of wetting or damp (e.g. tile battens, CLS framing) - To impregnate construction timber with fire retardant chemical

Timber Treatment Solutions impregnation plants can all be fitted with one of our automated timber handling systems. An automated wood handling and storage system is the best option for treating large volumes of timber in a short space of time due to minimising charge changeover times. This makes annual impregnation volumes of over 100,000m3 on a single plant easily achievable. The automated handling system can consist of anything from a transfer car which changes over one charge automatically to a multi-lane multi-level fully automatic system which only requires operator input once per day. Timber Treatment Solutions are the only manufacturer able to offer the patent pending multi-level timber handling and storage system, which can half or even third the building space required for an automated wood package handling system. There are lots of possible configurations and our teams will be able to advise the most suitable for you, according to your needs and budget.

Call for Price

$ 5,000

splitter saw, designed to split cants, boards, etc., 50hp electric drive, 81x chain, 40" dia inserted tooth blade, hyd drive on feed, good working condition

$ 3,500

$ 8,500

Call for Price

Call for Price

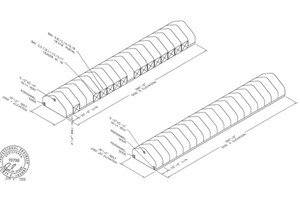

380’ x 70’ x 32’ Free Span Building, Brand New In Containers, Can Be Split Into Multiple Buildings

Call for Price

Call for Price

Call for Price

This wood was all removed from an old mill on South Carolina. It is ready to be loaded out.

$ 3,200

Call for Price

Complete chip mill operation. All machinery will need to be moved from the current facility. System includes: - 29'x11' Log Deck - Emergency log Deck - 50' Log Infeed Conveyor - 57' Incline Bark Conveyor - 60' Deal Processor w/ Recycle Return Conveyor - Log Outfeed - 112' Log Recycle Conveyor - Log Outfeed - Metal Detector - Control Room - Chipper infeed - Carthage 104" 15 Pocket Chipper with 1250 HP Motor (CEM Lite Knife Hardware) - Refurbished Chipper Disc and 1250 HP Motor - Log Peel Bin - (1) 8'x16' Progress Chip Screens with 80' Chip Stacker - #1 Chip Conveyor: 500' - #2 Chip Conveyor: 1000'

Call for Price

Call for Price

Call for Price

The seller has confirmed that this Unscrambler deck is in good working/running condition. It is ready to load! - Unscrambler deck - (8) chains

.gif)