Select For Sale

10017 Results Found

$ 44,000

Universal arch moulder, equipped with two (2) axis spindle adjustment and spindle tilt in order to easily and accurately match the cutter to the moulding profile. -- The spindle adjustment and floating feed make cutting circular, elliptical, and straight casing and crowns a breeze. -- The Floating feed system is user friendly and easy to set up. -- The Spindle can be adjusted from Horizontal to 52° to insure the proper cut on the parts you need!

Call for Price

Call for Price

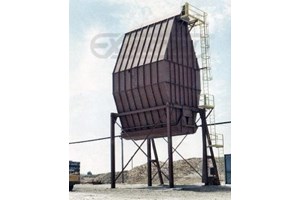

(20) Units cap. Rapid Discharge Bin, prefabricated for nut & bolt erection, exterior constructed of 12 gauge structurally reinforced steel. -- Chips are discharged by (2) hydraulically operated shell clamp type bottom doors for a 78" x 96" free fall opening, opening & closing via (2) 5" dia. double acting cylinders w/stroke of 48", 15 HP hydraulic pump motor with 20-gallon reservoir; braced, wide flange steel beam support structure with 14' truck height clearance. -- Complete with: Weather covers, (1) bin level indicator, embed plates w/detailed foundation plans, operator's platform, upper catwalk w/handrail & (1) caged ladder. - It holds (20) units or the equivalent of 4,000 cu. ft. by volume. - Price includes (1) coat of green primer for exterior & (1) coat of safety yellow for hand railing, ladders & guards. - Price does not include Delivery cost, Foundation, Installation or Starters & Switches for electric motor. -- This is a representative photo - other sizes are available on application.

$ 500

Call for Price

Call for Price

USNR Canter-Sawing Line consisting of: 60' double length infeed section; 10' log rotation section; (ASM sharp chain--NO longer available); 40' infeed section; 6' chipping canter section with 200 HP motors; 7'60" twin band sections with 150 HP motor; 25' outfeed with board off loading; 20' off-feed belt. Price includes removal cost (ready to load); all hydraulic power systems; all Square D motor control centers; Sub-operator's cab with controls included. 2001 model, only operated until 2007. Loaded onto your trucks $245,000 OBO.

Call for Price

Call for Price

This system was removed last year. Controls include: - USNR M6 millexpert computer system for edger. - Installed 2010 and took out December 2022. - (1) Windows 7 analize computer and (1) data acquisition computer. - (17) M6 Dynavision scanner heads - Allen Bradley PLC-5/40E with (5) 1771 input cards and (7) output cards, (4) 1771 linear positioning cards. - (3) TT5RBU0240 24” stroke temposonic wands - (4) 60” stroke TTSRBU0600 wands - (7) Moog model 641F229C valves - (2) Operator panels

Call for Price

Call for Price

V-HOLD - MF-2230, ...Profile Grinder.Technical Specifications MF 2230: -- The max. dia. of the cutterhead is 300 mm. -- Max. profile length: 300 mm. -- Movement of a desktop: 45 mm. -- Sharpening angle: ± 30°. -- Grinding wheel dimensions: 225 x 32 mm. -- Grinding wheel rotation: 2,800 - 4,000 RPM. -- Total power: 1.59 kW. -- Dimensions: 1,260 x 1,250 x 1,830 mm. -- Weight: 560 kG.

Call for Price

Call for Price

VAC-U-CLAMP FT-1000 52" x 123" Dual Shuttle Table Thermofoil Vacuum Press Overall OEM Specifications: Typical cycle time 5.5 - 7 Min. averaging 7 - 8 Cycles/Hr., Approx. conservative production with 18 Parts/Cycle & 126 Parts/Hr., 1,000 Parts/Day, 5,000 Parts/Week. Table Configuration: (2) Shuttle tables (when one table is in press oven, other table is being loaded or unloaded), Table entry & exit completely automatic & powered by CNC-controlled gear-driven stepper motor. Construction: TIG-welded aluminum tubing covered with 18 GA steel covers that have been powder coated for durability, Aluminum platen easily removable for cleaning if necessary, Easy-access table 36" H. Heating: (24) 1000 W Quartz infrared type lamps, Infrared thermocouple for accurate reading film temperature. Features: Automatic film pressure bar opening/closing connected to safety circuit preventing table movement if bar is not completely closed, Automatic high pressure cooling air as tables exit from oven, Tempered glass viewing window with 300 W Interior halogen light. Includes: 45 CFM Vacuum Pump capable of producing near absolute vacuum (14.7 PSI, 29.9 in. Hg.), 30 Gallon ASME-certified vacuum reserve tank for rapid evacuation & decrease of cycle time, Vacuum lines rated for 3,000 PSI. Operator Controls: OMRON PLC Control, with Color touchscreen display, (5) Storage bays for different film type programs, & Remote access through built-in remote wireless modem. Complete with: (2) 61” W 3-tiered double-sided steel roll racks, Each with (2) Locking swivel & (2) Swivel 3-1/4” Dia. x 1” W Casters, Rack dimensions 76" x 32" x 41" H. NOTE: (1) Shuttle Table Not Installed & in Crate. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

Call for Price

Vac-U-Clamp FT800+ Thermofoil Press 52" x 105" Work area Dispenser Rack (3) Vac bags new in boxes still

$ 22,500

ADVANCE MANUFACTURING VACUMIZER M-100 Vacuum CoaterModel M-100 Vacuumizer Continuous Feed Thru Vacuum Finisher, -- 71/2 Hp Vacuum Pump, Capacity : 2" X 6" openingNote: Transformer for 600 volts included

$ 28,500

$ 36,000

Northeast Implement is your resource for VALBY CUSTOM-BUILT DOT LOG TRAILERS & DUMP TRAILERS are strong, light and maneuverable to help you work fast and stay profitable. They are built for Professionals, but they are affordable enough for Semi-professionals and Landowners. VALBY trailers are loaded with standard features and many available options, so you can design YOUR perfect trailer. Our trailers are constructed using superior-quality design & components, like Dexter single-tandem or dual-tandem axles, heavy-grade structural channel for main beams and cross pieces, fully primed and painted frames to withstand northern winters, and radial tires with 8-hole rims for stability. Call us today to get more information - As Low as Only $36,000 - 607-589-6160

Convert your Edgebander from its standard Glue Pot system to PUR Slot Die Extrusion system usingVALCO MELTON'S HOT MELT/PUR EXTRUSION SYSTEM With up to 60 mm wide Glue Line Coverage The "IsoMelt Mini" melting tank is used for this proposal, it will be able to melt and pump around 10 Lbs of adhesive per hour. The IsoMelt Mini has a completely enclosed reservoir, which seals off the PUR from moisture in the atmosphere. To ensure that no moisture enters the reservoir, there is a small PLC program that injects dry air on a timed basis into the reservoir. The external MCP-6 pattern controller will process the photo-eye input and encoder signal measuring the machine speed. The pump will deliver adhesive to the head. A sensor mounted upstream from the applicator head will "see" the edge of the board coming through the system and triggers the valve to fire at the appropriate time and shut off at the appropriate time, ensuring that glue is accurately placed. An encoder is included for the speed feedback necessary for precise pattern placement. The head itself will need to be mounted in place of your current glue pot.Should you decide to go with this solution, we will provide you with drawings of the mount to make sure there are no issues with the fit before we take your machine down for the install.Also to expedite frequent changeover of part thickness and the importance of machine up-time, this proposal includes the motorized part thickness adjustment. It eliminates the need for operators to adjust the coating width on each setup.Components Required:1 946XX052 IsoMelt Mini, 4 cc/rev pump, 53 Lbs (24kG)/Hr, 2 exit NI1201 968XX167 Clearcut 60 edgebanding head (adjustable up to 60 mm wide)1 N/A Motorized option for edgebanding head including. . . 988xx894 controller, 912xx860 cable kit, 912xx027 unit communication cable1 988XM859 Uni-Flow Pneumatic Control for IsoMelt Mini1 913XX876 NV-10A level sensor board1 913XX513 Level sensor M30X1,51 780XX149 Heated hose, 2300/3000 Series,1/2-inch X 16-ft, 240 V1 074XX056 MCP-6 pattern control1 155XX341 1000 Pulse Encoder Kit (rigid encoder bracket)1 029XX511 Encoder splitter, Y-adapter to D series hot melt unit1 030XX632 Encoder cable, 8 m, 8-pin DIN1 280XX256 Fixed-field sensor, 4-inch (100-mm) range, with 581XX484 mounting bracket1 030XX596 Scanner cable, 10 m, flying leads 1 030XX882 Valve cable, 10 m, female reverse key to flying leads1 799XX716 Tank fittings kit, qty 2, straight #8 hose core1 799XX713 Tank fittings kit, qty 2, 45-degree #8 hose core 10 795XX550 InsulationPrice is for all of the items required to convert your Edgebander to an efficient PUR machine. Labor prices not included.

.gif)

.jpg?width=300&height=200&mode=pad)

.jpg?width=300&height=200&mode=pad)

.jpg?width=300&height=200&mode=pad)