Equipment For Sale

9663 Results Found

Call for Price

Call for Price

$ 5,250

Call for Price

This mill is ready to be removed from the current location. - 4 Roll Cases 24’’ 2 center 6.5 Diameter 45’ 56’ 62’ 70’HMC All motor controls included - 7 Lumber Decks Flat Chains 10’ 12’ 16’ 20’ 24’ 40’ 82’ 5 Chains WIDC All motor controls included - 2 Log Decks - 28’ Long 12’wide 3 chains stop loader - 14’ long 12’ wide 4 chains stop loader - All motor controls included - Newman Trimmer, drop saws, scrap belt chain 100’x 24’ - Unscrambler 16’wide x 5’high 8 chains - Air Compressor Model SSREP100 HP - Air Dryer storage tank - HMC Model mm10 4 heah block carriage 49’ - HMC Saw Booth - HMC Feed Works - HMC Husk 54’ bottom saw 36’ top saw - 200 HP motor - HMC Log Turner - HMC Drop Belt Live Off Barrer - 10 Headrig saws inserted tooth 54” - Roof Top Chain 10ft 5 Chain - Blower system - Tie-Cant Deck 62’Lx13’ W 4 chain all motors & Controls - Roof Top Lumber Deck 30’L x 13’W 5 chains all motors & Controls

Call for Price

HOCKER POLYTECHNIK - MultiStar Series: Pulse Jet Baghouse 33,000 CFM (56,000 cbm/Hr) based on 5.2 to 1 Air-to-cloth ratio (FPM: Average air velocity thru filter media) with: 6,345 Square feet of filter area. -- Filtration: Filters are automatically cleaned by Pulse-Jet system based on supply of: 1" Dia. dried clean compressed air line from Plant. Cleaning automatically controlled via timed cycles or by the Delta P, which is the differential pressure across the filter bags. -- Supplied with: (4) HOCKER DER - 040/45022 Radial BI fan; each directly driven by: 30 HP - TEFC 3,600 RPM High efficiency motors; mounted on the clean air side. Rated for a total of: 33,000 CFM at 16" SP (4,000 Pa). Fan inlets are: 18" (450 mm) Dia. each. Non-return flap camper on the outlet side. -- Includes Electrical panel with: PLC Controls; explosion relief panels; sprinkler heads in the clean air plenum; ATEX approved construction with 11-gauge electroplated galvanized steel shell with: Clean air outlet not returned to plant. -- Equipped with: (1) HP Rotary Air Lock. -- Control - SIEMENS - SIMATIC TPI200. PLC Controller housed in a floor-mounted central control panel with: Modem module for allowing HOCKER online access to assist in program changes; 12" TFT color, touchscreen display.All starters & contacts for included motors.Pictorial guided navigation and fault messages are displayed in text.Graphic images, curves, bar diagrams, parameter adjustment settings, and fault report.FI MF 22.0 kW SPS Ctrl.: Allows startup of several fans, one after the other. -- VFD Drives on each motor with: Automatic motor tuning; automatic startup; min./max. speed limits; DC brakes; operating hours meter. -- Includes: Access ladder to upper catwalk and exterior pipe; Heavy-Duty galvanized for outdoor operation. -- Professional dismantling & transportation available upon request.

Call for Price

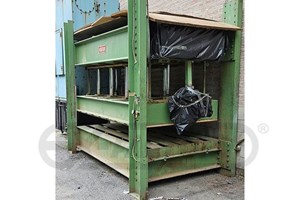

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.

Call for Price

Call for Price

HOFFMANN PU 2 DOVETAIL ROUTER (SINGLE SPINDLE) Pneumatic Dovetail Routing Machine - Dovetail routing machine for use with HOFFMAN dovetail butterfly connectors. - Maximum routing height 4", Max. workpiece height 5-3/4" - Table size 15-1/2” x 27-1/2” x 36-1/2” H - Production speed: Approx. 16 SPM (2 Complete rectangular frames) - (1) HOFFMANN "UAD 33 F" 33,000 RPM 1,000 W Router motor - 45° Fence, Accurately positions material with guide in table keyway, Quick adjustments made by adjusting fence plate - Pneumatic hold-down, Pneumatic foot pedal Includes: - Extra HOFFMANN "UAD 33 F" 33,000 RPM 1000 W Router Motor - 2007 HOFFMANN "FM1000" 35,000 RPM 1,000 W Router Motor - (2) 16” x 48” x 35” H Left-Hand & Right-Hand Aluminum Frame Tables, with 3/4” Thick Top, & 2” x 2” Aluminum frame - Palletized Dimensions: 42” x 42” x 60” H

$ 165,000

Hogzilla TC 1464 Tub Grinder -700HP KTTA19 Cummins -3-Stage Twin Disk Torque Converter -Roughly 6500 hours -Tires are good -Belts in good shape On the job working

Call for Price

$ 14,600

HOLTEC Lumber Trimmer. Manually trims bundles of lumber. Trims one end only. Manual setting of lumber bundles required. Bar & guard replaced; hydraulics tested; support frame, including steps, sand blasted and painted; electric motor drive checked; air cylinder and up-down of bar tested; manually operated saw assembly moves about 12". Offered as-is/where is. Price $14,600.00

Call for Price

Call for Price

$ 14,800

Holytek 37DA Wide Belt Sander (2) Heads37" Width cap Drum, Combination Head1st Head: 7" Dia. spiral grooved rubber covered contact roller, 20 HP motor;2nd Head: Combination sanding head with 5" dia. spiral grooved rubber covered contact roll & 2" wide polishing platen, 15 HP motor.Specifications -- Abrasive belt size of 37" x 60" -- Pneumatic belt tensioning and electronic abrasive belt tracking -- 12" min. working length. -- 2 HP Conveyor belt motor, -- Variable feed speed from 13 - 52 FPM,Equipped with & Features -- Infeed & outfeed rubber covered holddown rolls; -- 0" - 4" motorized thickness adjustment by 0.5 HP motor. -- Safety stop bar, emergency rail stop across the front of conveyor -- Motor load meters.

$ 8,500

HOLYTEK - GES 920 RK: Wide Belt Sander(2) Heads; drum and combination head. -- 2-Head; 36" width cap. -- 1st Head: Heavy-Duty rubber covered contact drum; 15 HP motor. -- 2nd Head: Combination head with 6" dia. contact roll; 20 HP motor. -- 2 HP Feed motor; 16 - 55 FPM variable feed speed. -- 37" x 75" Abrasive belts; electronic oscillating belt system. -- Motorized table elevation with: 0.25 HP Motor; max. height: 125 mm (4.9").Equipped with: -- Digital readout and infeed & outfeed spring loaded holddown rolls.

$ 9,250

HOLYTEK - YRT 100: Round End Tenoner -- Twin positioning tables with: Traversing single cutterhead design; fully automatic work cycle; tables alternate into the cutting cycle for continuous operation; rotational movement of cutterhead is externally adjusted. Capacity: -- Width of tenon: 0" - 3.9" Plus both radii; thickness of tenon: 1/8" - 1-3/16"; depth of tenon: 3/8" - 1-3/4"; 1/4" - 3-1/2" with special tooling. Specifications: -- Belt driven cutterhead, 3 HP - 6,000 RPM spindle; 1 HP motor with variable rotational movement of cutterhead; straight, simple or compound angles are easily adjusted with tables. -- (2) 14" x 9" Tilting tables: 0° - 15° Up, 0° - 30° down, and 0° - 20° to the side; each table with: Pivoting fences & miter gauges, vertical height adjustment. -- Overhead pneumatic holddowns. -- Production rate approx.: (13) Pieces per Min.

$ 4,950

HOLYTEK SS-512 TS Shaper with Tilting Spindle, and Power FeederSpecifications: -- 1-1/4" Interchangeable spindle, 7.5 HP motor with (5) spindle speed settings of 3,000 - 4,000 - 6,000 - 8,000, & 10,000 RPM. -- Approx. 6" max. cap. under nut, 31" x 39" cast iron table. -- Insert ring diameters 2.8", 4/3", 6" and 8". -- Tilting spindle +10° and -45° -- Vertical movement of the spindle 7" -- sliding tableComplete with: -- Reverse rotation switch, adjustable fence assembly, and dust hood. -- 3-Roll Power Feeder

HOLYTEK - HRS-12TK, ...Straight Line Rip SawSpecifications: -- Overhead saw arbor, 15 HP motor belt driven, 4,500 RPM arbor. -- 12" Dia. max. saw blade. -- 3-3/8" Max. depth of cut. -- 18" Max. throat depth. -- 2 HP Stepped feed speeds of 50 - 65 - 83 - 100. -- Automatic lubrication of chain. -- Magnetic controls. -- Saw is glue line rated.Equipped with & Features: -- Overhead holddown rolls. -- Double-row of antikickback fingers. -- (6) Pressure rollers. -- Infeed adjustable fence line. -- Cast Iron table with rip fence.

HOLYTEK - HRS-12TK, ...Straight Line Rip SawSpecifications: -- Overhead saw arbor, 15 HP motor belt driven, 4,500 RPM arbor. -- 12" Dia. max. saw blade. -- 3-3/8" Max. depth of cut. -- 18" Max. throat depth. -- 2 HP Stepped feed speeds of 50 - 65 - 83 - 100. -- Automatic lubrication of chain. -- Magnetic controls. -- Saw is glue line rated.Equipped with & Features: -- Overhead holddown rolls. -- Double-row of antikickback fingers. -- (6) Pressure rollers. -- Infeed adjustable fence line. -- Cast Iron table with rip fence.

$ 16,800

HOLYTEK HP-11P Horizontal Resaw -- Hydraulic Feeding conveyor, hydraulic pump with 3 HP motor -- Main saw motor 20 hp. Specifications: -- Working width capacity 12“ (300 mm) -- Variable Feed Speed 0- 17 m/min (0 to 55 FPM) -- Thickness capacity 4mm to 125 mm (.11/8" to 4.92") -- Conveyor tilting 0 ° to 7° -- Electroni display of cutting height -- Blade Capacity 4270 X 25 X 0.89 mm. -- Wheels Diameter 725 mm -- Return conveyor on machine top

.gif)