704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1686 Results Found

704-841-2001

CAM-WOOD FSM-460AX Finger Joint ShaperSingle Finger joint Shaper with 8" min. and unlimited max. block length; 4" max. block thickness, maximum timber height to feed into assembly press is 3"; 18" max. block width (horizontal joint only); 18" table working width.Equipped with: -- Shaper spindle powered by 10 HP belt drive motor with 50 mm dia. spindle turning at 5,500 RPM; 160 mm (6.3") max. dia. cutter. -- Trim-saw powered by 5 HP direct drive motor at 2,850 RPM and a 1" dia. saw spindle; swings 180 mm (7") max. blade dia. -- Table cycles 2 to 4 per Min via the hydraulic system with a 2 HP hydraulic power unit. Includes 5" dia. dust outlet.Features: -- Manual Fingerjointer performs end trimming and shaping functions on right and left end of blocks. -- Air-operated clamp holding blocks firmly in place. After the workpiece is clamped, the table feeds past the saw and shaper spindles to perform trimming and finger-joint operations; trim saw cuts blocks exactly 90° ends. -- Shaper spindle is precision-constructed for cutting fingers accurately; swings up to 6" dia. tooling. -- Spindle height adjustment is displayed on the dial readout for easy adjustment. -- Table travels on a precision linear guide for stability; table traverse driven by hydraulic power system smooth and accurate block feeding. -- Variable feed speed permits proper feed for hard or soft wood. -- Cast iron frame and table for durability.

CAM-WOOD FJ-17 (FM) 6" X 16' Long Semi-Automatic Finger Jointer System(4) Version possible on this model. Choose the one that suits your needsTechnical Specifications:Incoming Block Requirements: -- Incoming block lengths No Limit (Manual Loaded). Blocks must be at least 50% longer than their width. -- Block thickness from 1/2” to 3" -- Block width from 1” to 6" -- Assembled lengths from 8’ to maximum 16’ or (20’ Options Add Extra ...$4,900.00) or 24’ (Options Add Extra ...$9,900.00) -- For use with PVAC adhesives Glue pump is not included -- Works equally well with soft and hardwood Blocks. Moisture content from 8 to 12% -- Blocks to be surfaced (4) sides through a Moulder or 4-sided Planer to ±0.2mm with 90° right angle cornersThis semi-automatic system is offered in (4) different versionsVersion 1: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) The price: $82,900.001. Semi-Auto Finger Shaper Process the finger at one side 2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual blush applied the glue,4. Semi-Automatic finger jointer press The price: $82,900.00Version2: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Manual Gluer (FSH-150) + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual Glue Spreader applied the glue,4. Semi-Automatic finger jointer pressThe price: $92,990Version 3: -- Finger Shaper with Gluer (FSM-621) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Automatic Glue Spreader applied the glue at the second finger process,4. Semi-Automatic finger jointer press The price: ...$104,900Version 4:Finger Shaper (FSM-460A) + RO-62 x 3 + Finger Shaper with Gluer (FSM-621) + Assembly Press (FJ-500A)1. Semi-Auto Finger Shaper Process the finger at one side.2. Push to the next (2nd) Semi-automatic finger shaper with Auto Glue Spreader and applied the glue at the other side,3. Semi-Automatic finger jointer pressThe price: ...$ 143.900Description of Each Unit:FSM-460A Semi-auto finger shaper (Air-hydraulic type) -- Working timber width (Horizontal Direction); 1” to 6” -- Maximum timber total width fit on working table 18” -- Maximum working height (Vertical direction); 4” -- Maximum timber thickness (Height feed into assembly press); 3” -- Working timber length; No Limit (Timber length must be at least 50% longer than the timber width to be processed.) -- Trim saw/Hogging blade 180 mm x 50T x 5 mm x 1 pcs. Trim/Hogging saw speed; 2,850 RPM -- Trim/Hogging saw motor 5 HP x 1 -- Finger shaper motor; 10 HP x 1 . Finger spindle Speed; 5,500 RPM. Spindle size; 50 mm, OD of finger cutter; OD160 mm -- Table movement by pneumatic–hy

$32,500

CAM-WOOD M5412-SC Tenoner & End Matching MachineTenoning/Coping machine for straight or miter material. Great machine for miter door production or stile and rail stock. Equipped with: -- 6" High stackable spindle by pneumatic up & down with (3) different stops; easily and accurately setup for each cutter position.One shaper head at each side of the table. -- Table moves from right to left by variable speed Pneumatic-Hydraulic power to achieve the full cutting power. -- Twin table moves in and out separated for tongue and groove, end-match application. -- Twin heavy-duty pneumatic pistons hold down the work pieces tightly to the table during the cutting process.Features: -- Rigid construction on the heavy sheet metal frame, cast iron table & base for durability usage. -- Heavy duty industrial motor is suitable for heavy-duty cutting under full load. -- Linear guide rails and bearings let the operator move the table smoothly. -- Cast iron fence locks in the table groove to finish 45° cut easily. -- Automatic cycle function, just place the material against the stops, the machine will automatically clamp, move in for shaping/tenoning, come out and release the hold down.

Call for Price

CAM-WOOD HSTC-62 HIGH SPEED LONG BOARD VERTICAL FINGER JOINTER with the following Specifications: HSTC-62A Infeed Belt Conveyor: -- Working dimension: 24” wide x 16’ long -- Speed at 110 FPM -- One 3 HP Inverter Drive Motor SHAPER #1: DFSR-62I - Left Side Heavy Duty Finger Joint Shaper -- Working dimension: 24” wide x 1” to 10” high x 8” to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7” diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12” diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4” -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Table cycle speed from (1) to (4) cycles per minute (depends on work)HSTC-62A HEAVY SINGLE TABLE OUTFEED TRANSFER CONVEYOR -- Working dimension: 24” wide X 16’ long -- Speed at 110 FPM -- One 3 HP Inverter DriveHSTC-62A SINGLE TABLE INFEED TRANSFER CONVEYOR -- Working dimension: 24” wide X 16' long -- Speed at 110 FPM -- One 3 HP Inverter DriveSHAPER #2: DFSR-62I - RIGHT SIDE HEAVY DUTY FINGER JOINT SHAPER WITH GLUE APPLICATOR -- Working dimension: 24” wide x 1” to 10” high x 8” to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7” diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12” diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4” -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Injection type adhesive spreader with standard glue height of 10” -- Glue system included is for PVAC. -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra price -- Deduct ...$5,200 if provided without a Glue SystemHSTC-62B OUTFEED CONVEYOR WITH BELT CLEANER -- Working dimension 24” long X 16’ wide -- Speed at 115 FPM -- (1) 3 HP Inverter Drive -- (1) 1/2 HP motor for conveyor cleaning device HSCB-62 TIPPING CONVEYOR W/NARROW CONVEYOR -- Flips boards from vertical to horizontal for automatic feed to the Press -- Working dimensions: -- (1) Conveyor at 24” wide x 16’ long -- (1) Conveyor at 8” wide x 16’ long -- Speed 110 FPM -- 3 HP Inverter Drive UFJ-600 FINGER JOINT CONTINOUS ASSEMBLY MACHINE FOR INFINITE LENGTHS -- Working dimension 1-3/8” to 10’ wide X 1” to 4” thick by unlimited lengths -- In-feed speed from 100 to 165 FPM -- Cut-Off Saw: 7-1/2 HP -- Cut-Off Saw

CAM-WOOD IAT 620-100HX INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6" X 16.5 feet long medium capacity Finger Jointing SystemIncoming Block Specifications: -- Incoming block lengths from 6” to 31.5” -- Blocks must be at least 50% longer than their width. -- Block thickness from 1/2” to 3" -- Block width from 1” to 6" -- Assembled lengths from 10’ to 16’ (Options 20’ or 24’) -- For use with PVAC adhesives (glue pump and nozzle not included) -- Works equally well with soft and hardwoods. -- Moisture content from 8 to 12% -- Blocks to be surfaced on (4) sides through a Moulder or 4-sided Planer to ± 0.2 mm with 90° right angle corners.Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. The conveyor is controlled by the operating system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width -- 1/2" to 3" thickness -- Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3” (160 mm) maximum shaper cutterhead diameter (cutter head not included) -- 5 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyor powered by 1/2 HP motor. -- Table movement is inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles per minute. Motor senses load and varies travel as needed. TC-62 Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width. -- 1/2" to 4" thickness -- A 20 HP motor drives shaper spindle. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3" (160 mm) Maximum shaper cutterhead diameter (cutter head not included). -- 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP motor scoring saw, running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyer powered by 1/2 HP motor. -- Table movement is Inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses the load and varies travel as needed. Speed is controlled by system criteria. Included Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without a messy runoff. 4" Comb height is standard. -- Finger pitch 4 mm, 10 - 12 mm finger

Call for Price

CAM-WOOD IAT 620-150HX INVERTER DRIVEN FINGER JOINT SYSTEM Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. The conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4” maximum shaper cutterhead diameter - without knives. -- 5 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyor powered by 1/2 HP motor. -- Table movement is inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles per minute. Motor senses load and varies travel as needed. TC-62 Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" Maximum shaper cutterhead diameter - without knives. -- 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and vary travel as needed. Speed is controlled by system criteria. Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without a messy runoff. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (198") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6” wide x 1/2" to 3" high x and from 6' to 16-1/2' long. motor powers the upper and lower pre-assembly driven by (2) 2 HP motor . -- 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. -- 5 HP - 2,850 RPM Cutoff saw accepts 14" dia. x 120 tooth x 4 mm kerf blade. Cu

Call for Price

CAM-WOOD IAT 620-150H INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6":Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. Conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" wide x up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4” maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria STC-62A Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without the messy runoff associated with glue rollers. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (198") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6” wide x 1/2" to 3" high x and from 6' to 16-1/2' long. A 2 HP motor powers the upper and a 2nd 2 HP motor powers lower pre-assembly/crowder rolls. With 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. 5

CAM-WOOD HIAT-620-205 WITH 3” HIGH X 8” WIDE X 20’ LONG WORKING CAPACITIESTECHNICAL SPECIFICATIONS:Incoming Block Requirements: --Incoming block lengths from 6'' to 39” (optionnal 122") --Blocks must be at least 50% longer than their width. --Block thickness from 1/2” to 3 1/2" --Block width from 1” to 8" - --Assembled lengths from 10’ to 20’ - 24’ Optional --For use with PVAC adhesives --Works equally well with soft & hardwoods. --Moisture content preferred from 8% to 12% --Blocks should be surfaced (4) sides to ± 0.2 mm with 90° right-angle corners. To be supplied by the customer: --Electric power supply to electrical cabinet --Constant voltage with deviations of 5% or less --Temperature range for computer control should not exceed 95°F. --Maximum humidity for computer control system under 65% --Hydraulic oil --Skilled operating and maintenance personnel --Motor Control Center with under-voltage and overload protection; includes UL and CSA approved electrical components. Electric parts only, not the complete machine. --Total electricity demand: 63.75 KW, 85 HP --30 HP Compressor with a 50-to-60-gallon Air Receiver PRODUCTION CAPACITIES:Shaper Capacity: --Shift = 480 minutes --Finger length to buyer’s requirement --As an example: 1-1/2” X 5/1/2” X 24” average finished block size at the Shapers --Shaper max. speed of (3) table strokes per minute --Table cycles will change as block widths become “wider” or “taller” at the Shapers --Table accepts up to (16) blocks when vertical finger jointing 1-1/2” X 5/1/2” example blocks. --Table accepts up to (4) blocks when horizontal finger jointing 5-1/2” x 1-1/2” example blocks.Press Capacity: --Assembly Press w/2 operators: -- (4) Table loads per min. x 20’ lengths x 480 min. per shift x 0.8 rate of utilization = 30,720 lineal feet per shift OR 36,864 lineal feet per shift with 24’ Press)Production Calculations: --VERTICAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 1-1/2” x 5-1/2” x 2’ long blocks: (3) tables stroke per minute X 16-blocks per table load X 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 36,864 lineal feet per shift (63.34 M³) --HORIZONTAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 5-1/2” x 1-1/2” x 2’ long blocks: (3) table strokes per minute X 4 blocks per table load x 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 9,216 lineal feet per shift (19.46 M³) NOTE: Capacity is maximum a

Call for Price

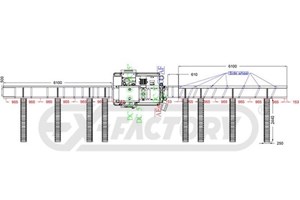

CAM-WOOD INFEED AND OUTFEED PLANER TRANSFER LINE: 20” Wide X 20’ Long Roller Conveyors and Consisting of the following: IDLE INFEED RIGHT ANGLE ROLLER TRANSFER CONVEYORS -- (4) Conveyor Sections, each 8” Wide X 5’ Long (SEE DRAWING). -- 2-11/64” Roller Diameter -- Rolls on 3” Centers to Handle 2” x 4” and Wider -- Supports up to 3,500 Lbs.POWERED INFEED CANTED ROLLER CONVEYOR -- With VFD Drive -- 20” Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32” Roll Diameter -- Rolls on 36” Centers -- Back Side Adjustable Fence -- Includes (4) Sections of Pneumatically Jumped Skate Rolls --Heavy Duty Type, Sections are 6” Wide X 20” LongPOWERED OUTFEED STRAIGHT ROLLER CONVEYOR -- With VFD Drive -- 20” Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32” Roll Diameter -- Rolls on 36” Centers -- Includes (4) Sections of Pneumatically Jumped Skate Rolls -- Heavy Duty Type, Sections are 6” Wide X 20” LongIDLE OUTFEED RIGHT ANGLE TRANSFER ROLLER CONVEYORS (SEE DRAWING) -- (4) Conveyor Sections, each 20” Wide X 5’ Long. -- 2-11/64” Roller Diameter. -- Rolls on 3” Centers to Handle 2” x 4” and Wider -- Supports up to 3,500 Lbs. -- Each Section with Pneumatic Pop-Up Stops

$18,990

CAM-WOOD PL-12SX 12" Wide Top & Bottom Straightening PlanerFEATURES: -- With Spiral Insert Cutterheads (DEDUCT $3,000 FOR STRAIGHT KNIFE HSS CUTTERHEADS) -- Standard equipped with Automatic Thickness Controller, easy and quick setting for the cutting thickness -- Top & bottom carbide cutter heads for accurate and powerful two-sided planing in one pass. -- Auto digital thickness control for quick and accurate setup. -- The worktable surface was precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain. -- A heavy-duty feed conveyor with metal spikes firmly holds stock securely to the worktable and feeds positively giving a smooth finish for rough or final planing. -- Variable speed control by inverter for smooth adjustment of feed rate depending on the material hardness, depth of cut & width to provide the best finish surface and fast cutting performance. -- The in-feed conveyor is fitted with numerous pressure pins so the feeding process can be firmly stabilized. It will moderately press the stock, and then an accurate planing surface can be performed to prevent jumping during the processing of narrow or bent material. -- The (4) power feed rollers are driven with a geared transmission box linked with a heavy-duty drive chain and gears to provide a smooth even feeding during rough or finish planing. -- A twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload SPECIFICATIONS: -- 7-1/2 HP Top Head Motor -- 5 HP Bottom Head Motor -- 12-1/2” Max. Working Width -- 4-3/4” Max. Working Thickness -- 19/32” Min. Working Thickness -- 13” Min. Working Length -- 1/4” Max. Cutting Depth per Head -- 2 HP Feed Motor -- Feed Speed (Inverter drive) from 15 to 52 FPM -- 5,000 RPM Cutter Head Speed -- 1/2 HP Elevation Motor -- With (2) 6" diameter dust outlets -- Spiral Insert Cutterheads with (45) 12 x 30 x 1.5 mm carbide insert knives with (2) cutting edges. Allows for fast, accurate insert changes and minimum downtime -- If required, change of electrics, will be quoted separately

$30,990

CAM-WOOD PL-18 18" Wide Top & Bottom Straightening Planer. -- 18" Planer with straight knife heads with HSS knives for accurate and powerful two-sided planning in one pass.ADD for Spiral Heads with Carbide Insert Knives... $4,000.00Replacement Knives:CT-SCH-14T 14 mm wide x 2.0 mm thick Spiral Knives - $2.90 EACHCT-SCH-15T 15 mm wide x 2.5 mm thick Spiral Knives - $3.60 EACHSpecifications: -- 17-3/4” Max. Planning Width. -- 3/8 to 8" Max. Planning Thickness. -- 1/4” Max. Cutting Depth. -- 10” Min. Planning Length. -- 15 to 70 FPM Feeding Speed (Inverter Driven). -- 4,200 RPM Cutter Straight Knife Head Speed. (6,000 RPM for Spiral Cutter Head). -- (4) Knife Cutterheads. -- 15 HP Upper Motor. -- 10 HP Bottom Motor. -- 2 HP Feed Motor. -- 1/2 HP Elevation Motor. -- Table Size (L x W) 88" x 16". -- N.W. 6,500 Lbs.Features: -- Standard equipped with automatic thickness controller, easy, accurate and quick setting for the cutting thickness. -- Upper & lower straight knives or spiral cutterheads for accurate and powerful two-sided planing in one pass. -- The worktable surface is precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain. -- A heavy-duty feed conveyor with metal spikes firmly holds stock securely to the worktable and feeds positively giving a smooth finish for rough or final planning. -- Stepless variable speed control for smooth adjustment of feed rate depending on the material hardness, depth of cut & width to provide the best finish surface and fast cutting performance. -- The infeed conveyor is fitted with numerous pressure pins so the feeding process can be firmly stabilized. It will moderately press the stock, and then accurate planing of the surface can be performed to prevent jumping during processing of narrow or bent material. -- The (4) power feed rollers are driven with a geared transmission box linked with heavy-duty drive chains and gears to provide a smooth even feeding during rough or finish planning. -- A twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload. -- The heavy-duty rigid cast iron frame supports the worktable, helps dampen vibration and ensures years of dependable service. -- Powerful industrial motor for maximum cutting capacity. -- All precision sealed long-life bearing for durability -- A swivel stand is designed for convenient knife changing on the bottom cutterhead. -- Changing the knife on the upper cutterhead only requires removal of the upper dust chute. -- The optional spiral insert head design allows for fast, accurate insert changes and minimum down time. -- Setup time is minimized to set cutterhead height using the auto material thickness device. -- The top and bottom cutterheads are precision balanced to provide consiste

$34,990

CAM-WOOD PL-24 TOP & BOTTOM STRAIGHTENING PLANER8" x 24" Capacity Planer for accurate and powerful two-sided planing in one pass.Includes (1) set of Spiral Insert Cutterheads with (1) set of 15 x 15 x 2.5 mm Carbide Knives with (4) Cutting EdgesReplacement Knives: CT-SCH-15T 15 x 15 x 2.5 mm Spiral Knives - $3.60 EACHDeduction for HSS Knives in lieu of Carbide Insert Spiral Heads - Deduct $3,000 Specifications: -- 25” Max. Planning Width, 3/8" to 8” Max. Planning Thickness. -- 1/4”Max. Cutting Depth. -- 12” Min. Planning Length. -- 15 to 70 FPM Feed Speeds (Variable). -- 4,200 RPM Cutter Head Speed. -- Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm carbide insert knives with (4) cutting edges -- 25 HP Top Head Motor. -- 20 HP Bottom Head Motor. -- 5 HP Feed Motor and 1/2 HP Elevation Motor. -- Net weight 7,200 Lbs. Equipped with: -- Standard equipment includes Automatic Thickness Controller for quick, accurate thickness adjustments. -- Top and bottom Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm Insert Knives for accurate and powerful two-sided planing in a single pass. -- The Planer’s table surface is precision ground then chrome-plated and polished to a mirror finish; wear resistance, easy to clean and maintain.Feed System: -- Heavy-duty upper feed carpet (conveyor) with spring-loaded steel “fingers” holds stock firmly against the Planer’s table; prevents stock splitting while providing positive feed and smooth finish for rough and finish planing. -- The conveyor (carpet) is fitted with numerous pressure pins, or fingers, which firmly holds and stabilizes stock during the planing process. Fingers apply moderate pressure to the stock and provides accurate planing while preventing wide cupped boards from splitting and feeding problems while planing narrow material. -- (4) Powered feed rolls are driven via a gearbox linked to heavy-duty chains and sprockets; provides smooth even feeding during rough and finish planing. -- Stepless variable speed control (Inverter driven) for smooth adjustment of feed speed depending on the material hardness, depth of cut & width; allows for the best finish and feed speed. -- Anti-kickback device provides safety and is designed to work in unison with a conveyor stop. Safeguards mechanical parts in case of overload situations.Features: -- The heavy-duty CAST IRON frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial motors for maximum cutting capacity. -- All precision sealed-for-life bearings for long and durable use. -- A built in cutterhead stand is designed for convenient knife changing at the bottom cutterhead. -- Changing knives on the upper cutter head only requires removal of the upper dust chute. -- Setup time is minimized to set cutter head height using the auto material thickness device. -- The top and bottom cutter heads are precision balanced to pr

$77,990

CAM-WOOD PL-38 TOP & BOTTOM STRAIGHTENING PLANERIncludes (1) set of Spiral Insert Cutterheads with (1) set of 15 x 15 x 2.5 mm Insert Carbide Knives with (4) Cutting EdgesReplacement Knives: CT-SCH-15T 15 x 15 x 2.5 mm Spiral Knives - $3.60 EACHDeduction for HSS Knives in lieu of Carbide Insert Spiral Heads - Deduct $8,000Specifications: -- 3" to 38” Max. Planning Width -- 3/8" to 7” Max. Planning Thickness. -- 1/4” Max. Cutting Depth. -- 12” Min. Planning Length. -- 15 to 52 FPM Feed Speeds (Variable). -- 4,000 RPM Cutter Head Speed. -- Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm carbide insert knives with (4) cutting edges 40 HP Top Head Motor. -- 20 HP Bottom Head Motor. -- 5 HP Feed Motor -- 2 HP Elevation Motor. -- Net weight 9,800 Lbs. Equipped with: -- Standard equipment includes Automatic Thickness Controller for quick, accurate thickness adjustments. -- Top and bottom Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm Insert Knives for accurate and powerful two-sided planing in a single pass. -- The Planer’s table surface is precision ground then chrome-plated and polished to a mirror finish; wear resistance, easy to clean and maintain.Feed System: -- Heavy-duty upper feed carpet (conveyor) with spring-loaded steel “fingers” holds stock firmly against the Planer’s table; prevents stock splitting while providing positive feed and smooth finish for rough and finish planing. -- The conveyor (carpet) is fitted with numerous pressure pins, or fingers, which firmly holds and stabilizes stock during the planing process. Fingers apply moderate pressure to the stock and provides accurate planing while preventing wide cupped boards from splitting and feeding problems while planing narrow material. -- (4) Powered feed rolls are driven via a gearbox linked to heavy-duty chains and sprockets; provides smooth even feeding during rough and finish planing. -- Stepless variable speed control (Inverter driven) for smooth adjustment of feed speed depending on the material hardness, depth of cut & width; allows for the best finish and feed speed. -- Anti-kickback device provides safety and is designed to work in unison with a conveyor stop. Safeguards mechanical parts in case of overload situations.Features: -- The heavy-duty CAST IRON frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial motors for maximum cutting capacity. -- All precision sealed-for-life bearings for long and durable use. -- A built in cutterhead stand is designed for convenient knife changing at the bottom cutterhead. -- Changing knives on the upper cutter head only requires removal of the upper dust chute. -- Setup time is minimized to set cutter head height using the auto material thickness device. -- The top and bottom cutter heads are precision balanced to provide smooth, chatter-free planing regardless of the feed rate or har

$142,200

CAM-WOOD MODEL PL-40-SH 40" TOP AND BOTTOM SURFACER with Spiral CutterSPECIFICATIONS: -- 40” Maximum Working Width. -- 12-1/4” Maximum Working Thickness. -- 2” Minimum Working Thickness. -- 1/2” Max. Depth of cut (Per Side). -- 4,500 RPM Cutter Head Speed. -- 6-1/4” Cutter Head Diameter. -- 15 x 15 x 2.5mm Spiral Cutter Head Carbide Insert Knives. -- 30 HP Top Cutter Head Motor -- 20 HP Bottom Cutter Head Motor -- 2 HP Elevation Motor -- (2) 5 HP Feed Motors -- Feed Speed (Variable by Invertor drive) from 12 to 55 FPM -- 5-3/4 Feed Roll Diameter. -- Universal Joint & Shaft Drive System. -- Machine Weight, 11,600 Lbs. -- Machine Size (L x W x H) 81" x 106" x 63". FEATURES: -- Roll feed eliminates slipping when running green and heavy wood. -- Universal Joint and Shaft Driven Feed Rolls ensure adequate feeding power for wet, rough lumber as well as warped, cupped and bowed material and provides needed power transmission against heavy cutting depths. -- Top and bottom feed rolls are direct driven by universal joints and drive shafts for full power transmission. -- Movable control box provides additional convenience in operation and setup. -- Standard equipment includes automatic thickness control to aid in easy and quick setting for the thickness to be planed. -- Worktable surface is precision ground and electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain and promotes good feeding of all types of wood. -- Stepless variable speed control (VFD) for smooth adjustment of feed rate depending on the material hardness, depth of cut & width. Used to provide the best finish surface and fast feed performance. -- Twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload. -- Heavy, rigid cast iron frame supports the worktable, helps dampen vibration and ensures years of dependable service. -- Powerful industrial-duty motors for maximum power transmission. -- All precision sealed, long-life bearings for durability. -- A swivel stand is designed for convenient knife changing on the bottom cutterhead. -- Setup time is minimized to set cutterhead height using the auto material thickness device. -- The top and bottom cutterheads are precision balanced to provide consistently smooth, chatter-free planing regardless of the feed rate or hardness of material being planed.

$67,500

COSTA - KK CC-CCC 1350, ...5-Head Top & Bottom Wide Belt Sander.53" Width capacity; (2) Bottom drums, (3) Top drums.Bottom Machine: -- Constant pass line height: 1,000 mm (39"). -- Motorized infeed conveyor. -- Motorized infeed pressure rollers. -- Sectioned infeed pressure beam.1st Head: -- Rubber covered cylinder ,16" dia., 35 kW motor. -- Intermediate pressure shoe with lips and rubber covered rollers.2nd & 3rd Heads: -- Rubber covered cylinder, 16" dia. (2nd head), 52 kW motor (3rd head), 88 kW. -- Outfeed pressure shoe with lip and rubber covered rollers. -- Vacuum Feed Table: 10 HP (7.5 kW) motor. -- Vacuum set pneumatic for (2) levels of vacuum pull control.Top Machine: -- Infeed roller. -- Motorized infeed pressure rollers. -- Sectioned infeed pressure beam.1st Head: -- Rubber covered cylinder, 16" dia., 35 kW motor. -- Intermediate pressure shoe with lips and rubber covered rollers.2nd & 3rd Heads: -- Rubber covered cylinder, 16" dia. (2nd head), 52 kW motor (3rd head), 88 kW -- Outfeed pressure shoe with lip and rubber covered rollers. -- Vacuum Feed Table - 10 HP (7.5 kW). -- Vacuum set pneumatic for (2) levels of vacuum pull control..Equipped with and Features: -- All drives are equipped with disc brakes. -- Each Sander with vacuum feed belt with fans..

$24,700

COSTA - ACCT1350, ...3-Head Wide Belt Sander 53" Width cap.; Drum, Drum, and Platen.Head Configuration:1st Head: Rubber covered contact roll, 9.8" dia., 30 HP motor.2nd Head: Rubber covered contact roll, 9.8" dia., 25HP motor.3rd Head: Polishing platen "jump type"; pneumatically controlled with timers to eliminate any dubbing of leading or trailing edges on panels; 20 HP motor.Specifications -- Contact rolls with pneumatic "grit-set" thickness control with a 4-position turret actuated from the control panel (this adjusts the contact roll for varying thickness of abrasive belts). -- 53" x 103" Abrasive belt length with electronic tracking; --Motorized part thickness opening on conveyor bed, 1/8" - 6 max. thickness opening. --2-Speed conveyor belt feed from 16 - 33 FPM --Vacuum conveyor bed assemblyEquipped with & Features --Thin veneer" sanding package with floating or rigid bed with infeed & outfeed spring loaded holddown shoes. --Oscillating sanding belt cleaners with timed entry -- All motors with Y-Delta starters, motor load meters --Infeed & outfeed conveyor extension tables with rollers, and (3) 6" OD. dust outlets.

$49,500

COSTA - AKF-CT-1350, 2-Head Wide Belt (Veneer) Sander52" Width cap.; drum & segmented platen.Head Configuration:1st Head: Rubber covered contact roll.2nd Head: Electronically controlled segmented platen with (42) segments on 32 mm increments.Specifications: -- 1st Head: Rubber covered contact roll 75 shore, 30 HP motor; features 4-position revolving turret for abrasive grit size setting. -- 2nd Head: Electronically controlled segmented platen with (42) segments, powered by 20 HP motor and variable speed by electronic inverter control; with reverse rotation. -- Abrasive belts: 1,380 mm x 3,250 mm (54" x 128"). -- Air blast abrasive belt cleaning. -- Pneumatic belt tensioning with electronic tracking.Equipped with & Features: -- PLC Processor Control. -- Floating feed table + Quick Set. -- Vacuum assist holddown. -- Variable feed speed belt conveyor, powered by 5.5 HP (4 kW) motor. -- Infeed & outfeed spring-loaded holddown shoes on all heads. -- Powered raise & lower conveyor bed with LED readout. -- In- & outfeed roller table extensions and motor load meters.

COSTA - KBH CCCT 1350 & KH2 CCCT 1350, ...Top & Bottom Sander Line.Head Configuration:Machine #1 - "KBH CCCT" 4-Head Bottom Sander. Bottom Head #1: ~10" Dia. grooved Steel Drum, 47 HP motor. Bottom Head #2: ~10" Dia. grooved rubber covered contact drum, 47 HP motor. Bottom Head #3: ~10" Dia. grooved rubber covered contact drum, 32 HP motor. Bottom Head #4: Finishing platen, 23 HP motor.Machine #2 - "KH2 CCCT 1350" 4r-Head Top Wide Belt Sander. Top Head #1: ~10" Diameter Grooved Steel Drum, 47 HP - 460 V motor. Top Head #2: ~10" Grooved rubber covered contact drum, 47 HP motor. Top Head #3: ~10" Grooved rubber covered contact drum, 32 HP motor. Top Head #4: Finishing platen, 23 HP motor.Specifications: -- PC User interface for each machine. -- Sanding belt size: 53" x 103". -- 96" Belt conveyor in between machines. -- 20 HP Vacuum Blower for each machine's vacuum bed.

$67,365

COSTA KH2 CCCT 1350 Wide Belt Sander (4) Heads52" Width cap. Drum, Drum, Drum, PlatenHead Configuration:1st Head: Steel contact roll, 9-7/8" dia. , 45 HP motor;2nd Head: Rubber covered contact roll, 9-7/8" dia., 45 HP motor.3rd Head: Rubber covered contact roll, 9-7/8" dia. 60 shore, 30 HP motor.4th Head: Finishing Platen, 23 HPSpecifications -- 53" x 103" abrasive belts, air blast abrasive belt cleaning, pneumatic belt tensioning with electronic tracking. -- Controls with PLC processor, -- Pneumatic grit compensation with 4-position stops. -- Variable feed speed conveyor with inverter control 16 - 82 FPM.Equipped with & Features -- Vacuum conveyor bed assembly with 5.5 HP suction fan and motor. -- Infeed & outfeed spring loaded hold down shoes on all heads. -- Powered raise & lower conveyor bed with LED readout and motor load meters.

$135,000

Costa S6 XUT 1350 3 Top Head Wide Belt Sander53" Width cap, Crossbelt, Combination Head, PlatenHead Configuration1st Head :Transverse Belt Unit -- Transverse Belt Width: 5.9” (150mm) -- Transverse Belt Motor: 14.75 HP (2nd Head: Combination Roller-Rad, Steel Roller3rd Head :Segmented Pad Unit with Superfinishing Belt, Motor Power: 20 HP (15 kW)Specifications -- Max. Sanding Width: 53.15” -- Sanding Belt Width: 54” (1380mm) -- Min. Sanding Thickness: 0.12” -- Max. Sanding Thickness: 6.3” -- Vacuum belt with fixed pass height -- Feed Belt Speed: variable up to 82 ft/min. -- Feed Belt Motor: 3 HP (2.2 kW)Equipped with & Features -- Top brush on the outfeed -- Single 3kW fan for vacuum feed belt -- Machine Programming Software: LOGIC A -- Total Installed Power: 112 HP (83 kW)