704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

Category

Tennoners

30 Results Found

704-841-2001

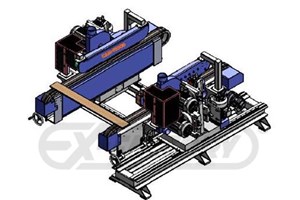

CAM-WOOD SET-410-SHJJA 50" Double End Tenoner with Sanding(10) Heads Double End TenonerFeatures: -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 66 FPM. -- Suitable for mass production in woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most universally satisfying machines for bulk production in lumber-processing factories. -- The specially designed numeric controller allows quick setting of length sizes for tolerance within 0.004". -- Variable speed, through feed, wide rubber pad, spring-loaded dogs at 16" center conveyor for the best finish selections. -- Heavy-duty powered pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting and sanding process. -- Shaper head can be moved up & down, forward & backward. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Two sanding heads can use brush, flap wheel or profile disc for fine finish with one pass. -- Trim saws and sanding heads can be tilted for different angular setup. -- Heavy cast iron base for durability usage.SPECIFICATIONS: -- Material Thickness: ½" to 4". -- Material Length: 10" to 50". -- Scoring Saw Blade: 12" x 1" Dia. -- Hogging Saw Blade: 8" x 40 mm dia. arbor. -- Shaper Cutter: 6" - 10" x 40 mm dia. arbor. -- Feed Speed: 20' - 66' Variable, Motor 3 PH, 220/440 V. -- Trim Saw 5 HP x 2. -- Hogging saw blade 10 HP x 2. -- Jump Shaper 15 HP x 2. -- Jump Shaper 15 HP x 2. -- Brush/Disc Sanding 2 HP x 2 with inverter for variable RPM. -- Feed Drive 3 HP x 1. -- Width Setting 1HP x 1. Option: -- Sound enclosure $ 8,900 -- Hopper feed magazine $ 3,900 -- 42" extend infeed conveyor before top hold down $ 4,900

CAM-WOOD SET-46TS 6 Heads 48" Double End Tenoner: Soring, trimming and shapingCapacity: -- Max. 48" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Motorized opening with LED indicator; -- Single-post machine, single "dual-track" base, right side fixed, left side movable.Each side equipped -- Front of post: Bottom scoring unit, 2 HP - 3,600 RPM motor, 1" dia. arbor & up to 10" blade; -- Top trim head, 3 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade; -- Back of post: Vertical shaping head, 5 HP - 7,200 RPM motor, 5-7/8" (150 mm) long & 1" dia. arbor, 8" max. dia. cutter-head. -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads and dogs at 6" center, --Spring loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Cross transfer system with transfer line 4' X 8' transfer table with rollers (additional $29,600) -- Hopper feed magazine (additional $3,990) -- Pneumatic jump control on scoring or shaping unit -- Same machine with 8' opening

CAM-WOOD - SET-48TS-CHX, ... Double End Tenoner for Chevron & Herringbone FlooringSpecial design Servo Control for Chevron & Herringbone Double End TenonerFeatures: -- Servo Control for +45° or –45° and 90° cutting. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 12 - 52 FPM. -- Feed chain with dogs at 10" center distance. -- Suitable for mass production of woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- Possibility for: Scoring Saw, Trim Saw, Jump Coping, Shaper, Coping. -- Total (4) stations at each side. -- Reversed direction cutting jump shaper head with sensor for automatic move in and out for perfect cutting to prevent tearing at end edge. -- HMI Plus PLC controller for user-friendly easy setting and operation. -- Powerful machine is great for heavy-duty production. In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of sizes for tolerance within 0.004”. -- Variable speed, through feed, wide rubber pad, and spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of wide width Conveyor to hold the material tight to prevent sliding during the cutting process. -- The Shaper head can be moved up & down, forward & backward. -- Equipped with: Industrial motors for full power cutting capacity. Specifications: -- Max. working thickness: 2”. -- Max. working length: 45° is 49”. -- Max. working length: 90° is 48". -- Min. working length: 45° is 18". -- Min. working length: 90° is 13-3/4". -- Scoring/Main saw blade (dia.): 10" x 1". -- Shaper cutter (dia.): 6" - 8" x 1" -- Feed speed 12' - 52', variable power 3 PH - 220/440 Volt. -- V-Scoring saw: 3 HP x 2. -- Trim saw: 3 HP x 2. -- Jump Shaper: 5 HP x 2 Stationary. -- Shaper: 5 HP x 2. -- Feed motor by Servo: 1 kW x 1; Width setting by Servo 0.75 kW x 1.Available Options: -- Total sound enclosure cover: Add ...$7,900. -- Infeed Hopper Magazine: Add ...$4,990.

CAM-WOOD SET-49DET CKX Double End Tenoner for Click SystemFeatures: -- (9) Heads total as Scoring, Trim Saw, Jump shaper X 3, plus free space -- Configured for click lock System application -- Special design for Click Lock System project with 31” extra Outfeed Conveyor Space. -- HMI / Touch Screen Plus PLC controller for easy and quick setting -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 ~ 76 FPM. -- Suitable for mass production processing of double-end cutting, tenoning, grooving, moulding, and sanding. -- Powerful machine great for heavy-duty production. • In addition to the double-end cutting, all other settings and processes can also be executed with high accuracy. -- Since the machine is so versatile, we believe it should be one of the highest pay-back investments for lumber-processing factories' with volume production. -- The specially designed numeric controller allows quick setting of sizes, for tolerance within 0.004”. -- Variable speed through feed, wide rubber pad, and spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty powered pressure rolls at top of wide-width conveyor to hold the material tight to prevent sliding during the cutting process. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Trim saw heads can be tilted for different angular setups. -- Heavy cast iron base for durability and heavy-duty usage.Specifications: -- Maximum working thickness 2 1/4" -- Maximum working length 50" (optional for 96") -- Minimum working length: 9" -- (2) Scoring Saw motors, 7.5 HP each -- (2) Trim/hogging saw, motors 7.5 HP each -- (5) Shaper motors with jump servo controlled, 7.5 HP rotation 6,200 RPM, arbor 40 mm dia., spindle tilting 0 - 90° -- Feed speed 20 to 72 FPM, servo drive motor 7.5 HP -- Motorized opening with 1 HP motor -- Control with color touchscreenAvailable option: -- SET-2TRAN two-stage transfer line Additional: ...$86,900 -- Hopper feed magazine additional ...$86,900 -- Sound enclosure additional ...$14,900 -- Infeed extension 48" additional ...$12,600

CAM-WOOD SET-52SAT 6-Head Double End Tenoner (Not Feed Through)Capacity: -- Length of cut: 12" to 60" (opening). -- Max. width of cut: 24" (cross cut). -- Max. clamping thickness: 4-1/2". -- Saw blade dia. 8" to 12"; saw arbor dia. 1"; saw blade speed 3,400 RPM; saw head swivels 180 degrees. -- Moulder (Shaper) spindle: 1" Dia. x 5" long; spindle speed 6,000 RPM; spindle swivels 180 degrees. -- Vertical travel: 17" vertical. -- Carriage (table) travel (front/back): 24".Equipped with: -- Saw motors: (4), each 2 HP motors (1 top & bottom each side). -- Shaper spindles: (2), each 2 HP motors (1 each side). -- Out Feed Conveyor drive: 1 HP motor (not this model!). -- Powered length setting: 1/2 HP motor (machine opening).Features: -- With the double end miter saw set-up, you can cut-off stock faster or consider a double end miter saw combined with moulding (shaper) head. It lets you cut and machine stock and moulding pattern in a single feed, saves time, space and cost. -- Air-operated vertical clamps hold sticks firmly in place. After the work piece is clamped, table start to feed, performs trimming and shaping operations. -- Trim saw allows to cut stock accurately with a clean cut. -- Moulding (Shaper) spindle mounted at the rear of saw head enables the machine to perform edge moulding after stock is cut off. -- The entire cutting cycle, cut-off, shaping/tenon or mortise is automatically operated in a single pass of stock feeding. -- The material Clamping table travels on a precision linear motion guide for stability. -- The table traverse is motorized, ensuring very stable, smooth workpiece feeding. -- Material transport thru machine powered by variable speed inverter drive for 10 to 20 Sec per cycle -- Variable feed speed permits proper feed selection for hard or soft wood materials. -- Large hand-wheel to adjust depth of cut. -- All controls are grouped in a control panel. -- Industrial motors for optimal cutting results.Machine Stations: -- 1: Top & Bottom Trim Saws powered by (4) 2 HP saw arbor motors for trimming to length. -- 2: Shaper spindles powered by (2) 2 HP spindle motors for applying tenons and grooves. -- Floor space requirement: 94" X 40" X 54" high. -- Cycle time: 10 to 20 Sec per cycle.Available option at additional cost: -- Auto Outfeed device -- Return conveyor

$18,750

CAM-WOOD - SET-5SA, ...Double End Trim Saw (Tenoner) Capacity: -- Length of cut: 12" to 60". -- Max. width of cut: 24". -- Max. clamping thickness: 4-1/2". -- Saw blade dia.: 8" to 12"; saw arbor dia.: 1"; saw blade speed: 3,400 RPM; saw head swivels: 360°. -- Moulder (Shaper) Spindle: 1" Dia. x 5" long; spindle speed of 6,000 RPM; spindle swivels: 360°. -- Vertical travel: 17". -- Carriage cross travel: 24".Equipped with: -- Saw motors: (2) Each, 3 HP motors. -- Moulder spindles: (2) Each, 3 HP motors. -- Outfeed Conveyor drive: 1 HP Motor. -- Powered length setting: 0.5 HP.Features: -- With the Double End Miter Saw setup, you can cut off stock faster or consider it a Double End Miter Saw combined with moulding head. It cuts off stock & moulding pattern in a single feed that saves time, space, and cost. -- Air-operated Clamp comes down holding sticks firmly in place. After workpiece is clamped, the table starts to feed, perform trims, and shape operations. -- Trim Saw allows cutting stock accurately with a clean-cut. -- Moulding (Shaper) spindle mounted at the rear of saw head enables the machine to perform edge moulding after stock is cut off. -- The entire cutting cycle, cut off, shaping/tenon or mortise is automatically operated at single pass of stock feeding. -- The table travels on a precision linear motion guide for stability. -- The table traverse is driven by power system, ensuring very stable, smooth workpiece feeding. -- Variable feed speed permits proper feed selection for hardwood or softwood materials. -- Big hand wheel adjusts depth of cut. -- All controls are grouped in a Control Panel. -- Industrial motors for optimal cutting results. -- Material transport through machine powered by variable speed inverter drive for (10 - 20) Sec/cycle. Machine Stations: -- 1: Trim Saws powered by: (2) 3 HP Saw arbor motors for trimming to length. -- 2: Shaper Spindles powered by: (2) 3 HP Spindle motors for applying tenons & grooves. -- Floor space requirement: 94" x 40" x 54" high. -- Cycle time: (10 - 20) Sec/Cy.Options Included: -- Auto. Outfeed device. -- CSA Electrics.

$165,500

CAM-WOOD SET-812 SCCWW, Double End Tenoner with Sanding12-Head Double End Tenoner, suitable for mass production in a woodworking factory, processing double end cutting, tenoning, grooving, moulding, and sanding.Features: -- Automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 75 FPM. -- In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of length sizes for tolerance within 0.004". -- The numeric control system provides highly accurate settings, and a special memory retains all settings, even if there is a power failure. -- Variable speed, through feed, wide rubber pads with spring-loaded dogs located at 16" center distance with conveyor speed for the best finish selections. -- Heavy-duty powered pressure rolls at top of the wide width conveyor holds the material tight to prevent sliding during the cutting and sanding process. -- Shaper head can be moved up & down, forward & backward. -- Workstations are powered by industrial motors for full power cutting and utilizing the entire sanding capacity range. -- Two sanding heads can use brush, flap wheel or profile disc for fine finish with one pass. -- Trim saws and sanding heads can be tilted for different angular setup. -- Heavy cast iron base for durability and heavy duty usage.Specifications: -- Thickness: ½" to 4" -- Length: 10" to 96" -- Miter Saw Blade: 10" x 30 mm Dia. -- Grooving Saw Blade: 8" x 1" Dia. -- Shaper Cutter: 6" - 10" x 30 mm Dia. -- Feed Speed: Variable, 20 ~ 75 FPM -- Trim Saw 3 HP x 2, 3,450 RPM -- Hogging Saw 10 HP x 2, 3,450 RPM -- Jump Shaper 10 HP x 2, 4,500 to 7,000 RPM -- Shaper 10 HP x 2 4,500 to 7,000 RPM -- Belt Sanding 3 HP x 2, 0-1500 RPM -- Brush Sanding 3 HP x 2 with 30 mm arbor 0-1500 RPM -- Feeding 3 HP x 1 -- Width (Opening) Setting 1 HP x 1 Option: -- Sound enclosure ...$ 7800

CAM-WOOD SET-84 -TS - SH Double End Tenoner, (4) Heads4-Head machine (two on each side) with Scoring/Cutting and HoggingCapacity & Style: -- Max. 98" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Single-post machine, single "dual-track" base, right side fixed, left side movable. -- Motorized opening with LED indicator.Each side equipped with: -- Scoring head, 3 HP - 3,600 RPM motor, and 1" dia. arbor for up to 10" blade. -- Hogging/cutting unit 5 HP - 3,600 RPM motor, 1" dia. arbor, 10" max. dia. cutter-head. -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads, and dogs at 6" center. -- Spring loaded overhead hold-down beams with endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Cross transfer system with transfer line 4' X 8' transfer table with rollers (additional $38,900). -- Hopper feed magazine (additional $3,990). -- 42" Infeed extension (additional $4,500) -- Sound enclosure ...$6,900 -- Electric motor brake -- Central supportNote: Pictures are showing the machine with several options included

CAM-WOOD SET-86TSX SJC Double End Tenoner, 6 HeadsCapacity & Style: -- Max. 98" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Single-post machine, single "dual-track" base, right side fixed, left side movable. -- Motorized opening with LED indicator.Each side equipped with: -- Top trim head, 10 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade. -- Jump cope shaping head, 7.5 HP - 7,200 RPM motor, 5-7/8" (150 mm) long & 1" dia. arbor, 8" max. dia. cutter-head. -- Cope shaping head, 7.5 HP - 7,200 RPM motor, (150 mm) 5 7/8" long X 1" diameter arbor, 6" to 8" max. dia. cutter head -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads, and dogs at 6" center. -- Spring-loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Cross-transfer system with transfer line 4' X 8' transfer table with rollers (additional $38,900). -- Hopper feed magazine (additional $3,990). -- 42" Infeed extension (additional $4,500) -- Pneumatic jump control on scoring or shaping unit. -- Sound enclosure (additional $ 6,900) -- Electric motor brake -- Central supportNote: Pictures are showing the machine with several options included

$259,900

CAM-WOOD SET-88-DET CKX Double End Tenoner for "Click System"Features: -- (9) Heads total as Scoring, Trim Saw, Jump Shaper X 5, and Free Space -- Configured for click-lock System application -- Special design for Click Lock System project with 31” extra Outfeed Conveyor Space. -- HMI / Touch Screen Plus PLC controller for easy and quick setting -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20~76 FPM. -- Suitable for mass production of woodworking factory for processing of double-end cutting, tenoning, grooving, moulding, and sanding. -- It is a powerful machine great for heavy-duty production. • In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it should be one of the most satisfactory equipment for volume production lumber-processing factories. -- The specially designed numeric controller allows quick setting of sizes, for tolerance within 0.004”. -- Variable speed, through feed, wide rubber pad, and feed chain with spring-loaded dogs for the best finish selections. -- Heavy-duty powered pressure rolls at the top of the wide-width conveyor to hold the material tight to prevent sliding during the cutting process. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Trim saw heads can be tilted for different angular setups. -- Heavy cast iron base for durability usage.Specifications: -- Maximum working thickness 2-1/4" -- Maximum working length 98" -- Minimum working length: 9" -- (2) Scoring Saw motors, 7.5 HP each -- (2) Trim/hogging saw, motors 7.5 HP each -- (5) Shaper motor with jump servo-controlled 7.5 HP at 6,200 RPM, arbor 40 mm diameter, spindle tilting 0 - 90° -- the (2) shaper head on the 4th station will have a special motor with 90-degree spindles for the toe notch -- Feed speed 20 to 72 FPM, servo drive motor 7.5 HP -- Motorized opening with 1 HP motor -- Control with a color touchscreenAvailable options: -- SET-2TRAN two-stage transfer line Additional: ...$86,900 -- Hopper feed magazine additional ...$86,900 -- Sound enclosure additional ...$14,900 -- Infeed extension 48" additional ...$12,600

CAM-WOOD SET-88DET-SHJCJC 8-Head, 96" Double End Tenoner -- Suitable for mass production of woodworking task for double-end cutting, tenoning, grooving, profiling and sanding -- Scoring, Hogger/Saw, Jump Shaper, Jump Shaper: Total (4) stations on both sides. -- A solid, powerful machine great for Heavy-Duty production.Capacity: -- The specially designed numeric controller allows quick setting of sizes, for the tolerance within 0.004”. -- Variable speed, through feed, wide rubber pad chain, spring-loaded dogs at 8" center conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting process. -- Shaper heads can be moved up & down, forward & backward. -- Max. 96" working capacity, min. 12"; max. 3-1/8" opening, 24" load area in front of hold-downs. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 66 FPM. -- Motorized opening with LED indicator.Each side equipped -- Top Scoring saw unit , 2 HP - 3,600 RPM motor, 1" dia. arbor & up to 8" blade -- Hogging/ Trim saw tiltable unit, 5 HP - 3,600 RPM motor, 1" arbor and up to 10" blade. -- Jump Shape/coping head unit, 7.5. HP - 4,500-7,000 RPM motor, 40mm dia. arbor for 6" to 8" cutter head. -- Jump Shape/coping head unit, 7.5 HP - 4,500-7,000 RPM motor, 40 mm dia. arbor for 6" to 8" cutter head -- Variable feed speed from 20 - 66 FPM, 2 HP motor, steel feed chains with plastic anti-slip pads and dogs at 16" center. -- Spring-loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Not Included -- Hopper feed magazine $3,960) -- Extended infeed 42" in front of hold-down belt $4,900) -- Sound enclosure $ 8,900Floor space : 8.5' X 9' X 6', weight 10,500 Lbs

CAM-WOOD SET-88TS-SHJC 96" 10 Heads Double End Tenoner: -- 96" Double end tenoner with Scoring, Hogging, Jump coping, coping and belt sandingCapacity: -- Max. 96" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Motorized opening with LED indicator; -- Single-post machine, single "dual-track" base, right side fixed, left side movable.Each side equipped -- Head 1: Bottom scoring unit, 3 HP - 3,600 RPM motor, 1" dia. arbor & up to 10" blade; -- Head 2:Top Hoging/triming head, 3 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade; -- Head 3 Vertical Jump shaping head, 5 HP - 7,200 RPM motor, 6" to 8" tool capacity & 1 1/4" dia. arbor, -- Head 4: Universal shaping head, 5 HP - 7,200 RPM motor, 6" to 8" tool capacity & 1 1/4" dia. arbor, -- Head 5: Belt sanding unit with 2 HP motor, belt sanding speed 300-1,200 RPM -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads and dogs at 6" center, --Spring loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Hopper feed magazine (additional $4,990) -- Extended infeed 42" ( additional$4,600) -- Sound enclosure ( additional $ 8,900) -- Auto transfer line (4' X 8') with transfer table ( additional$ 38,900)

CAM-WOOD SET-88TSX SHJC Double End Tenoner, 8 HeadsCapacity & Style:Double end Tenoner with Scoring, Hogging/sawing, Jump cope, Cope -- Max. 98" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Double-post machine, single "dual-track" base, right side fixed, left side movable. -- Motorized opening with LED indicator.Each side equipped with: -- Scroring saw with 2 HP motor- 3,600 RPM -- Top trim head, 3 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade. -- Jump cope shaping head, 5 HP - 7,200 RPM motor, 5-7/8" (150 mm) long & 1" dia. arbor, 8" max. dia. cutter-head. -- Cope shaping head, 5 HP - 7,200 RPM motor, (150 mm) 5 7/8" long X 1" diameter arbor, 6" to 8" max. dia. cutter head -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads, and dogs at 6" center. -- Spring-loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Cross-transfer system with transfer line 4' X 8' transfer table with rollers (additional $38,900). -- Hopper feed magazine (additional $3,990). -- 42" Infeed extension (additional $4,500) -- Pneumatic jump control on scoring or shaping unit. -- Sound enclosure (additional $ 6,900) -- Electric motor brake -- Central support -- Automatic return conveyor from bottom of the machine Add $18,950Note: Pictures are showing the machine with several options included

$28,900

FRIULMAC - Dual-Feed, ...Double End Cut-Off SawFor squaring workpieces and for transportation to a Planer or Moulder with a straightening table.Specifications: -- 79" Max. (2,000 mm) opening from Saw to Saw. Motorized opening with LED readout on the control panel; left-hand fixed with left-hand fence line. -- Hopper Magazine - material capacity: Min. length: 7.87" (200 mm), max.: 79" (2,000 mm); width: 1-1/8" (30 mm) to 6-3/4" (170 mm); and thickness: 0.59" (15 mm) min. up to 2-3/8" (60 mm) max.; hopper stack height: 23-1/2" (600 mm).Each side is equipped with: -- (2) Trim saw motors, 5.36 HP each; saw blade dia. 9.84" (250 mm). -- Hydraulic feed drive unit: 4 HP (3 kW) motor. -- Trimming & throughput capacity: Up to (55) pieces/Min.NOTE: Voltage transformer for 600 Volts available with the machine

FRIULMAC Quadramat Single End TenonerSingle end tenoner with (4) heads with Jump cope, cope, disc sanding and disc sandingSpecifications: -- Workpiece Length: 125 - 1500mm -- Workpiece Width: 125-1500mm -- Workpiece Thickness: 13 - 40mm -- Configuration: Jump-Cope, Cope, Wheel-Sanding, Wheel-Sanding -- First Station: 7.4 HP Jump-Cope/Profiling Unit with 40mm Diameter Shaft, 6000 RPM Rotation -- Second Station: 7.4 HP Cope/Profiling with 40mm Diameter Shaft, 6000 RPM Rotation -- Thirds Station: 4.7 HP Sanding Wheel -- Fourth Station: 4.7 HP Sanding Wheel -- Variable Speed Control of Sanding Stations from 750 - 1400 RPM -- Feed Speed: 13 - 98 FPM

$19,800

GABBIANI S.Q.V. Double End Tenoner ● Double sided with Scoring, hogging, top/bottom cope, shaping, belt sanding, belt sanding ● 2,500 mm (102") Max. width and 235 mm (9-1/2") min., programmable motorized opening with LED readout.Specifications: -- 112 mm (4.72") max. part thickness. -- 900 mm (36") Load area in front of holddowns driven upper holddowns caterpillar type -- 235 mm (9-1/4") min. length, left side fixed right side moveable.Each side equipped with: -- 1st Station: Jump scoring, 2.4 Kw (3.2 HP) motor. -- 2nd Station: Hog/trim saw, 7.5 Kw (10HP) motor. -- 3rd station: Cope unit Top,5.5 Kw (7.5 HP) motor -- 4th Station:Cope unit bottom 5.5 Kw (7.5 HP) motor. -- 5th Station: Cope unit, 8 Kw (10.8 HP) motor -- 6th Station: Belt sanding unit with pneumatic 7.5ontrols. -- 7th Station: Belt sanding unit with pneumatic controls. -- Variable feed speed 0 - 36 m/Min (120 FPM), 7.5 HP feed drive, -- Feed chains with disappearing dogs, platform feed chain with rubber faced track pads and separate control panel with controler, contactors and overloads. - -- Full sound enclosures.

$5,950

GRIGGIO - "GT-4", Single End Tenoner4-Head Tenoner with: Sliding Table & Holddown. -- 1st Head: Trim saw, 10" dia. -- 2nd/3rd Head: Top & bottom tenon heads; 6.6 HP motor belt drives saw & tenons; 4" max. tenon length and 3/16" - 2-1/8" thickness. -- 4th Head: Cope head; 4.6 HP motor; 9-7/8" - 11-7/8" max. cope cutting circle; 3-15/16" max. tool length. -- Equipped with: 15" Long x 6" wide sliding table, travels 63" & tilts 0° - 30°; overhead holddown with tilting fence line. Also Included: -- Cutterhead for top/bottom tenon. -- Cutterhead for coping.

HOLYTEK - YRT 100, ...Round End Tenoner -- Twin positioning tables with: Traversing single cutterhead design; fully automatic work cycle; tables alternate into the cutting cycle for continuous operation; rotational movement of cutterhead is externally adjusted. Capacity: -- Width of tenon: 0" - 3.9" Plus both radii; thickness of tenon: 1/8" - 1-3/16"; depth of tenon: 3/8" - 1-3/4"; 1/4" - 3-1/2" with special tooling. Specifications: -- Belt driven cutterhead, 3 HP - 6,000 RPM spindle; 1 HP motor with variable rotational movement of cutterhead; straight, simple or compound angles are easily adjusted with tables. -- (2) 14" x 9" Tilting tables: 0° - 15° up, 0° - 30° down, and 0° - 20° to the side; each table with: Pivoting fences & miter gauges, vertical height adjustment . -- Overhead pneumatic holddowns. -- Production rate approx.: (13) Pieces per Min.

PMK C 1203 Single End Coping/Tenoning Machine -- With the C-1203 Coping Machine you can run stiles first or cope first, this machine using a 5 HP motor has counter rotating spindles to insure chip free coping of either square, single profiled or double profiled parts. -- Since we are only coping one end at a time the length doesn't matter. We can also cope more than one part at a time up to 9.5" wide on the C-1203. -- (2) Counter rotating spindles 1.25" diameter. -- Spindle Speed 7,000 RPM; cycle time approx. (4) seconds. -- Side Pressure Clamp to insure proper alignment with fence. -- Cutter Heads totally enclosed for Safety!

PMK C 1205 Single End Coping Machine -- With the C-1205 Coping Machine you can run your Styles first or run your cope first, this machine using a 7.5 HP motor has counter rotating spindles to insure Chip free coping of either square. -- Single profiled or double profiled parts. Since we are only coping one end at a time the length doesn't matter. We can also cope more than one part at a time up to 13.5" wide on the C-1205. -- Two counter-rotating spindles 1.25" in Diameter. -- Capacity of maximum (2) cutters on stack tooling -- Spindle Speed 7,000 RPM; cycle time approx. (4) Seconds. -- Side Pressure Clamp to insure proper alignment with a fence. -- Cutter Heads totally enclosed for Safety!