Select For Sale

9730 Results Found

Call for Price

2023 HULTDINS SG360S (SN: 027-25226) BLADE 8-WHEEL, 15 TON FORWARDER CAB 710/45-26.5 TIRES

$ 280,000

2019 Rottne F15D -7500 hours -Tight and dry -Serviced every 500 hours -Two sets of ECO tracks and front chains Ready to work!!!!! Low Hours!!!!!!

Call for Price

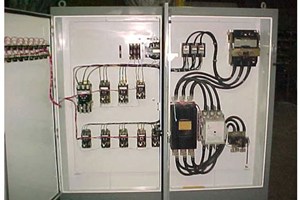

If you run an industrial business, you likely need numerous pieces of specialized equipment that can be difficult to find in a hurry. Row Electrical Equipment, Inc., stocks a vast inventory of industrial motors, motor starters, transformers, and other electrical equipment that is used in a wide variety of industries. We try to minimize down-time by having available a variety of equipment that is always important in a "need it now" situation.

Call for Price

MOTORS - MOTOR STARTERS - TRANSFORMERS - MISC ELECTRICAL EQUIPMENT - PHASE CONVERTERS

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6s ROWLEY & HERMANCE Sash Sticking Machine Specifications: Table size 5” x 46”. Equipped with: 3 HP - 1,750 RPM Motor. (2) 2” Dia. x 2” W Serrated upper feed rollers.

RT 3rd Man Nailer with Stacker- 50x48. Fairly new, Lightly used machine, stored indoors. No guns. All air operated. Located in Minnesota. #C967

Call for Price

Call for Price

Technical specifications[Opening width](https://wtp.hoechsmann.com/en/lexikon/20472/opening_width)1.200 mm Veneer thickness min0,4 mm Veneer thickness max1,5 mm Strip width min45 mm Strip width max1.200 mm Feedrate max50 m/min Continuously variable feed Cooling device Gluing aggregate Edge gluing JointOnly edge gluing Material of the feeding chainStainless steel Declaration of CE-conformity Conformity marking[CE mark](https://wtp.hoechsmann.com/en/lexikon/50233/ce_mark) Total connection9 kW Weight1.500 kg

Call for Price

Call for Price

Call for Price

RUVO Model 2200 Stair Router Sale includes: (2) Working machines and (1) parts machine!

Call for Price

// This item is up for Auction at exfactoryauctions.com // https://bit.ly/40zDLa2 RUVO Door Lite Cutout machine Model 9715W Specifications: 7' Max. door height x 3' max. door width; max. lite sizes in 3' door 30" x 60", 24" x 64", or 20" x 66"; lock sizes 1-1/2", 1-5/8" and 2-1/8". Deadbolt sizes 1-1/2", 1-5/8" and 2-1/8"; corner radius 1/4" for both lite and faceplates; backset switch selectable for 2-3/8" or 2-3/4". "Broken Arm" design for lite cut outs in wooden doors. Machines wood or steel doors (to 16 ga.) with 3 HP cutter head, 2-speed operation with 2,400 or 4,700 RPM; (2) horizontal stations, features door length adj. and end clamps. Equipped with: Boring for lock, deadbolt, and latch, (2) Back fences, steel hole template locating pin, template clamp, end clamp cylinders, flip stop assembly on the back fence. The 9700 control box provides the operator with exceptional versatility allowing independent operations for special house orders Recommended cutter head ONSRUD 15-05 cutting bit with reverse flute (interchangeable with EKSTROM-CARLSON bit 088-1680). Ruvo's 9700 Door Lite Cutter series machines are manufactured to last under heavy use and are the finest available to steel and wood door suppliers. The heavy-duty, easily operated cantilever cutting arm is key to the model's speed and efficiency. After the lite template and door are pneumatically clamped, its arm follows the template edge as a 1/2" cutter bores through the door.

Call for Price

RUVO 2260 Wedge Cutter. -- General Data: Wedge and glue-block cutter. Allows for 1" X and 2" X material in the same hopper. Cuts (2) wedges out of 1" X material and (1) wedge out of 2" X stock. -- Self diagnostic system, walk-away, hands free operation. -- If not reloaded, the machine has an auto-shut-off feature at the end of the stack to prevent the machine from cycling endlessly. --With capability to cut glue-blocks. -- Ports for dust collection.

$ 94,500

RUVO 505, ...Prehung Door Machine.Handles a wide range of door, jamb, and hinge sizes. - Bevels doors and door hinges. - Designed for efficient handling and operation. - Fast, accurate hinge and lock backset adjustment. - Residential, Commercial, Architectural, and Labeled Fire Doors.Features: Heavy duty powered 3° beveler/sizer. Routers to ease door edges. Accurate target scales. The 4-hinge and jamb route location changes fast and precisely. A similar system for the backset on hinges & locks. Provision for single and double-belled doors. Controls interlocked by a PLC. Auto door sizing is fast to adjust the lifter bar by digital input and servo control. Reliable, long-lasting non-contact sensors. Fast push-pull controls with a friendly touchscreen HMI. Hinge screw gun and pre-drill included.Technical Details: Max Door Height: 6’ - 9’ or ADA Specs 6’ - 8’. -- Door Width: 1'-6"’ to 4’. -- Door Thickness: 1-3/8"; to 2-1/4. -- Jamb Size and Styles: Up to 1-1/4"; x 10";, all styles. -- Number of hinges: Up to (4); Hinge Size: 3-1/2" to 5";; Hinge Radius 1/4" to 5/8". -- Hinge Backset: Scaled as required -- Lock Bore Sizes: 2-1/8"; Standard. -- Lock bore Backset: Scaled to 5";. -- Lock Bore Latch plate: Up to 1-1/4"; x 8";.Machine Size: 18’ x 3’ x 7’; Approx. Machine Weight: 3,200 Lbs; Electrical: 4-Wire, 230/3/60 and draws 25 Amps. Requires a 1/2" airline using 40 CFM @ 90 PSI.Options Include: -- Built-In Power Beveler Vacuum System......$ Please call. -- Screw Driver............................................... Included. -- Pre-Drill Kit.................................................. Included -- Digital Readout ..........................................$ Please call.RUVO 512, ...Heavy Duty Strike Jamb Mortising Machine.For Jam Sizes up to 1-1/4"; x 9"; x 10";. Strike Plate mortise to 6";. Compliments Jamb Preparation of the RUVO 505 and 405. Operated by one worker.Unit Includes: -- Adjustable Jamb Stops. -- Heavy Duty Construction. -- Foot Pedal Actuated Clamp. -- 120 Volt, 1-Phase, 20 Amps. -- 1/2" Airline needs 0.5 CFM @ 100 PSI. -- 1.5 HP Router.@ 23,000 RPM. Additional Cost for the RUVO 512 above ...$Please call.Material Handling for the Line:Loading Device..........................................$ Please call.Unloading Device.......................................$ Please call.

Call for Price

RUVO 2200 Stair Stringer Router, Top/Bottom, Semi-automatic. -- Size capacity (nominal): 2" Thick x 12" - 15-3/4" wide stringer size; semi-automatic operation. -- (2) 5 HP, 25,000 RPM Router motors for top & bottom heads. T & B heads are arranged to jump in & out to facilitate open plan stairs; automatic pneumatic clamping of stringers, spring loaded side pressure to keep stringers against the fence. -- Mirror-image routing on (1) pair of stringers at one time, graduated template automatically sets up to stated tread & rise, cuts standard wedge taper for both treads and risers. -- Includes: Clamp and feed system & safety covers. -- NOTE 1: Stair Router rebuilt in 2022 by BUILDERS AUTOMATION. Replaced 3HP with new 5HP routers. Reconditioned air cylinder pistons, air-over oil booster, replaced air lines, etc.. Painted from green to Blue.

$ 17,500

2021 RYANS FIXED GRAPPLE LESS THEN 25 HOURS ON IT PERFECT FOR MINI EXCAVATOR TAKEUCHI PIN GRABBER HEAD CAN BE ADDED TO ANY MACHINE WITH YOUR CONNECTOR LIKE NEW CONDITION SHIPPED TO YOU FOR EXTRA PRICE FINANCING AVAILABLE WITH NO MONEY DOWN 3 MONTHS NO PAYMENTS WITH GOOD CREDIT GRANITEHE.COM

Call for Price

Call for Price

--In auction: https://exfactoryauctions.com/Detail/SA-231010/event/A122024$1 --No Reserve!-- RYE R 72 2-Spindle Automatic Rotary Copy Shaper Specifications: Cutting circle cap. 24" - 80", Max. square cap. 56", Max. rectangular shape cap. 71" x 35-1/2", & Max. length capacity 50". Table size 68" Dia. x 40-1/2" H. Table speeds 0.3 - 3 RPM. Spindle speed 9,000 RPM. Equipped with: (2) 1-1/8” Dia. High frequency floating spindles, with Frequency changer. 6-1/2” Dia. Center clamp plate.

$ 139,500

S&W Model 700 Sawmill 4500 hours 1600bf per day Capacity 26' long x 52" Heavy duty mill Believed to be a 1994

.gif)

.jpg?width=300&height=200&mode=pad)