Equipment For Sale

10092 Results Found

Call for Price

Description Mattison "55-F" Turning Lathe - Back Knife 30" Cap. in length and 4" x 4" cap. dia. - Pneumatic feed; rear arbor with cutter-head driven by a 10 HP V-belt motor. Work piece rotation is belt driven by main motor with variable speed gear box, double end drive, mechanical feed of work piece into cutter head. Rear dust shroud with collection outlet.

Call for Price

Call for Price

Mattison 404 Rip Saw Seller was using until they upgraded to a gang rip. Ready to ship.

Call for Price

MATTISON - 404, ...Straight Line Rip SawSpecifications: approx.20HP - 3,600 RPM Direct drive arbor motor; 14" dia. max. saw blade cap. (9" smallest dia.), 1-1/2" dia. arbor; 4" thickness capy. -- Table size: 65" x 77" Long. -- 30" Distance from saw to left edge of table. -- 24-1/4" Between saw & column and 24" rip distance to right of gauge. -- Top roller holddown with 7-1/2" shortest stock handled under (1) roll, 15" under (2) rolls.Equipped with & Features: -- Overhead cutting design with single cast chain links. -- Chain with automatic oil lubrication. -- 2 HP Feed motor with (2) feed speeds of 50 & 100 FPM

$ 36,000

Heat treated and dynamically balanced 36" aluminum disc. -- Commercial duty 5 HP motor base mounted with multiple drive belts. -- Heavy cast iron 16" x 46" table w/miter gauge slot. -- Easy precise tilting of the work table with 45° forward and 30° back. -- Rack and pinion adjustment of the table rise & fall and rack and pinion tilting of the table. -- Sanding station is mounted to (4) 3-1/2" heavy columns. -- Heavy bolt-down cast iron base. -- Optional: Motorized table elevation add.....$16, Motorized table elevation with limit switches add....., Electric brake add....., Circular attachment add....., Miter gauge add..... Hoist (chain drive lift for heavy parts) add..... JIL package (oil/dust proof switch components) add.. OPTIONS QUOTED UPON REQUEST.

$ 7,920

Heat treated and dynamically balanced 18" aluminum disc. -- Commercial duty 1.5 HP direct drive motor. -- Heavy cast iron 10-1/2" x 24" table w/miter gauge slot. -- Easy precise tilting of the work table with 45° forward and 30° back. -- Rack and pinion adjustment of the table rise & fall and manual tilting of the table. -- Sanding station is mounted to a heavy column. -- Heavy bolt-down cast iron base. -- Optional: Upgrade to a 2 HP motor add.....$240, Miter gauge add.....$270, Rack and pinion movement of the tilt add....$400, Single Phase 1.5 HP motor add.....$120.

$ 9,995

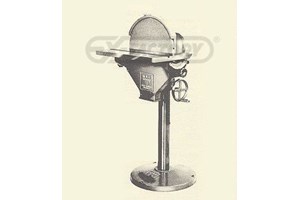

MAX Spindle Sander VSI Made is USAOscillating Spindle Sander constructed for rugged use. -- 1 HP Motor drives and is connected through a flexible coupling, and can be installed or removed without disturbing the drive mechanism. -- Spindle speed 1,725 RPM, Oscillation speed 75 Cy/Min with 1-1/2" stroke length. -- Spindle quill runs in precision ball bearings, oscillated by a heavy duty worm & gear mechanism running in a bath of oil. -- (10) spindle sizes provided: 1/4 x 5", 3/8 x 6", 1/2 x 6", 5/8 x 6", 3/4 x 9", 1 x 9", 1 1/2 x 9", 2 x 9", 3 x 9" and 4 x 9"; 100 grit abrasive sanding sleeve with each spindle. -- Large 24" x 24" precision ground cast iron table mounted on large trunnions that can be tilted 45° down and 30° up by use of a convenient handwheel. -- Complete with: Pedestal style stand.

MAX-PAK - HOE-2850-308AR, ...Horizontal Open-End Auto-Tie BalerSpecifications: -- Bale size: 30″ x 42″ x 72″ (variable) -- Bale weight: Up to 1,400 Lbs -- Cycle time: 15.23 Seconds -- Motor: 30 HP -- Cylinder bore: 8″ -- Rod: 5-1/2″ -- Stroke: 70" -- System pressure: 3,000 PSI -- Platen force: 143,256 Lbs - 120.49 PSIFeatures: -- Automatic Wire Tie System -- Heavy wall tubular steel frame -- AR 400 floor and platen -- Hydraulic regenerative circuit and air/oil cooler -- NEMA 12 Electrical panel and Control System -- Conforms to: OSHA &ANSI Z245.5 Standards

Call for Price

MAXPAK HCE60-FE-8 HORIZONTAL CLOSED DOOR BALER -- 8" Main Cylinder -- 30 HP Motor -- Full Eject -- Includes Infeed

Call for Price

Call for Price

MAYER PS 80P FRONT LOAD, AUTOMATIC PANEL SAW -- Specifications:125.9" (3,200 mm) Cutting length & 122" (3,100 mm) pull back, 3.14" (80 mm) max. saw blade projection,12 HP (9 kW) main saw motor, 320 mm main saw blade (3,800 RPM), 30 mm bore dia.; 1.5 HP (1.1 kW) score blade, 150 mm (8,680 RPM), 30 mm bore.Electronically controlled saw blade height adjustment, electronically controlled scoring blade horizontal (side-to-side) adjustment; "QUICK CHANGE" main & scoring blade system. -- Saw Carriage:Infinitely variable forward cutting speed from 5 - 262 FPM (1.5 - 80 MPM), constant return speed of 262 FPM (80 MPM);Automatic cutting length adjustment, rack & pinion drive (not chain), AC Servo motor drives on the saw carriage with rack & pinion on hardened & ground guideways -- Pusher Fence:Electronically controlled overhead program fence, forward speed from 0 - 82 FPM (0 - 25 MPM), return speed of 196 FPM (60 MPM); fence retracts 122" (3,100 mm) behind cutting line, AC Servo motor drives on the pusher fence with rack & pinion on hardened & ground guideways.(6) Material gripper clamps open up to 80 mm (3.1"), of which (3) are closely spaced in cross-cut area and the other (3) are at equal distance in rip cut area. -- Operator Interface:Mayer "PC 5400" + Windows operating system with "REAL TIME" graphic display, 14" color monitor mounted in a pivoting console;3-COM Network interface 10/100 MBs with RF45 (TP) connection; (2) serial & (1) parallel interfaces & SVGA graphics adapter, data input by keyboard or downloading from office PC is possible.PC 5400 Control system features automatic cutting length (material is scanned by sensor underneath the packet on the saw bed), electronically controlled automatic cutting height adjustment (also can be used for grooving by entering depth and width of groove at control)Automatic trim calculation, constant display of remaining material in both axis during programming (eliminates need for operator calculations during programming). -- Complete With:Left angle crosscut fence 78.7" (1,999 mm) long, automatic cross-cut aligner from .75" - 47.2" (19 - 1,199 mm) with automatic presetting)Rear slotted pressure beam to minimize offcut, (3) front mounted air flotation tables 79" x 24" (2,000 x 600 mm), segmented transparent plastic safety guards on front of pressure beam & wire mesh screen enclosure around rear machine table. -- Actual model is MAYER PS/80P/3200

$ 88,000

2008 McCloskey 412 -2500 hours -New brushes -Fluids been flushed -New coat of paint -Swivel Conveyor -Smaller job trommel

$ 72,500

1995 McCloskey 833 Trommel -9000 hours -Meter might be faulty -Engine runs strong -Needs -Drum chain -Feed conveyor drive chain -Batteries

$ 225,000

$ 325,000

2019 McCloskey I34R -1500 hours -950 crushing hours -Track machine -Tight and dry Turn Key unit !!!!

$ 235,000

2013 McCloskey J50 Jaw Crushers -10,780 hours -Cat engine -New main belt -Recent replaced tail pulley, rollers -Hopper has been relined Ready to work!!!!!!

$ 72,500

1995 McCloskey 621 Trommel Screen -6634 Hours -Tight and dry -Belts are good -Hoses are good -1/2 inch screens Only was used for leaf and compost

.gif)