Equipment For Sale

10198 Results Found

Call for Price

CAM-WOOD SET-108TS- SHJC Double End Tenoner, (8) HeadsCapacity & Style: -- Max. 120" working capacity, min. 12"; max. 2" opening(thickness), 24" load area in front of hold-downs. -- Single-post machine, single "dual-track" base, right side fixed, left side movable. -- Motorized opening with LED indicator.Each side equipped with: -- Top scoring head, 2 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade. -- Top trim head , 10 HP - 7,200 RPM motor, 5-7/8" (150 mm) long & 1" dia. arbor, 8" max. dia. cutter-head. -- Cope shaping head, 7.5 HP - 7,200 RPM motor, (150 mm) 5-7/8" long x 1" diameter arbor, 6" to 8" max. dia. cutter head -- Jump coping head, 7.5 HP - 7,200 RPM motor, (150 mm) 5 7/8" long X 1" diameter arbor, 6" to 8" maximum dia. cutter head -- Variable feed speed from 12 - 52 FPM, 2 HP motor, steel feed chains with plastic anti-slip pads, and dogs at 6" center. -- Spring-loaded overhead hold-down beams with endless belts. -- Separate electrical control cabinet with operator controls.Options Available: (Pricing to be confirmed at time of order) -- Cross transfer system with transfer line 4' X 8' transfer table with rollers (additional ...$39800). -- Hopper feed magazine (additional ...$3,990). -- 42" Infeed extension (additional ...$4,500) -- Pneumatic jump control on scoring or shaping unit. -- Sound enclosure (...$6,900) -- Electric motor brake -- Central support Included for 10' opening machineNote: Pictures are showing the machine with several options included

$ 189,900

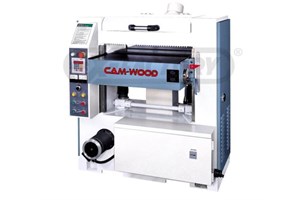

CAM-WOOD WP-4 S2C-500-12 4-SIDED PLANEROutstanding Performance - Quality Components 4 sided with 6 heads as: top and bottom, left and right, (2) chamfer units -- Floating bottom infeed rolls for smooth, positive feeding -- PLC controls with touch-screen interface for ease of operation -- Variable feed speeds by VFD. Controlled from touch screen -- Drive shaft and universal joint feed roll transmission for each feed roll -- Power elevation of overhead mechanism via touch screen control -- Thickness settings from touch screen control -- With cutterheads and carbide knives for straight knife work -- With spindles for easing top edges -- Tables, fences, etc. are precision ground and hard chromed to provide long life and smooth feeding -- Overhead mechanism travels up/down and is support by (6) hard chromed posts -- Motor Control Center with under voltage and overload protection; includes UL and CSA approved electrical componentsWorking Capacities: -- 19 3/4" wide x 12"; high (500 mm X 305 mm) -- Min. thickness: 3/4"; -- Min. width 2-3/4"; -- Max. depth of cut: 1/4"; all heads -- Max. length: Unlimited -- Min. length: 70"; for feed-thru; butt-feed down to 40". (40"; to 70"; may have minor inaccuracies at edge due the hold-down restrictions) -- Feed speeds from 20 to 66 FPMCutterhead Motors: -- 25 HP Top and Bottom (see optional equipment for larger motors) -- 20 HP Right & Left Side Heads (see optional equipment for larger motors) -- Includes Right & Left Spindles for eased edge at top of board; consists of (2) 1 HP floating spindles to accurately ease top edges. Profile knives in primary side heads ease bottom edges. -- Chamfer motor 1/2 HP Feed Works: -- (2) 5 HP VFD’s -- (1) motor drives top set and (1) motor drives the bottom set of feed rolls -- Boards synchronize top and bottom feed roll speed and torque --Cutterheads and Spindles: -- Top and bottom spindles with 60mm (2.362";) spindle dia. Other diameters on request. -- Includes a set of (2) 4-knife x 20"; long x 5-1/2"; dia. spiral carbide cutterheads. -- Side heads with 40mm spindle dia. Other diameters on request -- Includes a set of (2) 4-knife x 12"; long spiral carbide heads -- Includes (1) set per head: 15 x 15 x 3mm carbide knives with (4) cutting edges -- All spindles with hydro-lock outboard bearings -- Left & Right Side Heads can be used for profile work with owner provided tooling -- Eased Edge Spindles: 30mm"; dia. -- Eased Edge Cutting Circle: 4.9"; -- Powered side pressure device at infeed Dust hoods: -- 6"; dia top and bottom head hoods; 6"; dia. side head hoodsOptional Equipment: -- Optional HP on Top & Bottom Heads, up to 40 HP, -- Optional HP on Right & Left, up to 30 HP, -- Electric Brakes for side spindles, -- Power raise/lower and auto-setting for side spindles, Machine Dimensions and Weight: -- 110" long x 86" wide x 94" high x 15200 Lbs.

$ 39,990

CAM-WOOD WP-1010H 40"; Heavy Duty Planer with S.C.H.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- Maximum thickness capacity 8" -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planing with low noise levels. -- With (4) each 4" diameter dust outlets -- 20 HP Main drive motor. -- 3 HP Variable feed speed 10 to 50 FPM. -- Maximum depth of cut 1/4". -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 40" -- Max. Cut Thickness 8" -- Max. Cut Depth ¼" -- Min. Cut Length 9" -- Cutting Speed 3600 RPM -- Table Size (W x L) 43" x 55" -- Main Motor 20 HP, 3 Ph -- Feed Motor 3 HP -- Table Raising Motor 1 HP -- Feed Rate (Variable) FPM 10 ~ 50 -- Net Weight 4,750 Lbs -- Shipping weight 5,500 LbsFOR UPGRADE TO 25 HP ADD ...$900.00

$ 7,990

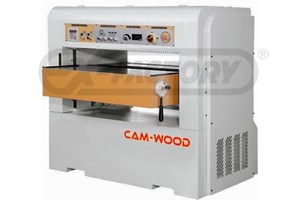

CAM-WOOD WP-2400 Single Sided PlanerFeatures & Specifications: -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- solid steel 3 knife cutter head -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor 5 HP. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit..

$ 13,690

CAM-WOOD WP-610A Single-Sided Planer 10 HP - 24" Cap. Features: -- 24" Spiral cutter head provides precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate setting. -- Motorized worktable raises & lowers by separate motor for more efficient operation. -- Specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the optimal feed rate for planing to a precise smooth finish on both hard or softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker gives the operator greater safety. -- Up to 8"; thickness large cutting capacity. -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base for maintenance-free service.Specifications: -- Table area 25" x 28". -- Max. planing width 24". -- Feed Speed (Var.) 15 ~ 60 FPM. -- Max thickness 8'' and min. Planing Thickness 1/8". -- Elevation Motor 0.5 HP. -- Cutterhead Speed 5,500 RPM. -- Cutter head diameter 4-3/4", Spiral. -- Knife insert dimensions 14 mm x 14 mm. -- Max. Cutting Depth 5/16";. -- Feed Motor 1 HP. -- Cutterhead Motor 10 HP. -- G.W. 1,850 LBS / 2,000 Lbs.

$ 20,990

CAM-WOOD WP-760 15 HP Single Sided 30" Planer Features: -- Spiral cutterhead provides precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate setting. -- Motorized worktable raises & lowers by separate motor for more efficient operation. -- Specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the exact feed rate and allows precision smooth finish planing on both hard or softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provides greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base for maintenance-free serviceSpecifications: -- Table Area 38" x 31" -- Max. Planing Width 30" -- Max. Planing Thickness 8" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5,500 RPM -- Cutterhead Diameter 4-3/4" Spiral -- Knife Dimensions 14 mm x 14 mm -- Feeding Speed (Var.) 15 ~ 75 FPM -- Max. Cutting Depth 5/16" -- Feed Motor 2 HP -- Cutterhead Motor 15 HP, 3 Ph, 230 V -- Table Elevation Motor 1 HP -- Digital Thickness Control Yes -- Dust Hood Outlet 5"G.W. 2450 Lbs

$ 8,389

CAM-WOOD WP-2000S Single Sided Planer20" Planer with solid cast iron construction and Spiral Cutter Head.Features & Specifications: -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- Fixed feed (30 FPM) speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- 3 HP Self-braking motor. -- Magnetic starter & thermal overload switch and Emergency stop. -- Operations manual, parts list & tool kit. Optional: CT-SCH-14T - 14 mm x 14 mm SPIRAL CUTTERHEAD BLADES ...$3.30 each

$ 45,139

CAM-WOOD WP-1400H 52"; Heavy Duty Planer with S.C.H.55" Cap. solid cast iron construction planer with powerful 25 HP motor.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering, manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planning with low noise levels. -- With (4) each 4" diameter dust outlets. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 52". -- Max. Cut Thickness 8". -- Max. Cut Depth ¼". -- Min. Cut Length 9". -- Cutting Speed 3,600 RPM. -- Table Size (W x L) 55" x 55". -- Main Motor 25 HP, 3 Ph. -- Feed Motor 5 HP. -- Table Raising Motor 1 HP. -- Feed Rate (Variable) 0 ~ 50 FPM. -- Shipping weight 7,400 Lbs.

$ 18,990

CAM-WOOD WP-660A Single-Sided 15 HP, 26" PlanerFeatures: -- Spiral cutter-head with inserts provide precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate settings. -- The motorized worktable raises & lowers by a separate motor for more efficient operation. -- The specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the optimal feed rate for planing a precision smooth finish on both hard and softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provide greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes quick adjustable twin bed rollers for rough & finish planning on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision-sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base.Specifications: -- Table Area 35" x 27". -- Max. Planing Width 26". -- Max. Planing Thickness 11-3/4" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5,500 RPM. -- Cutterhead Diameter 4-3/4" Spiral. -- Knife Dimensions 14 mm x 14 mm. -- Feeding Speed (Var.) 15 - 60 FPM. -- Max. Cutting Depth 3/8". -- Feed Motor 1 HP. -- Cutterhead Motor 15 HP, 3 Ph, 230 V. -- Table Elevation Motor 1 HP. -- Digital Thickness Control. -- Dust Hood Outlet 5".

$ 14,990

CAM-WOOD BX-1212BEEX Single Bottom Head Band Resaw.Can be used to cut boards, cants, or reclaim slabs; Specifications: -- Can process up to 12" H x 12" W; 5/16" - 5-1/4" from blade to conveyor. -- 2 HP Electric motor controlled variable speed from 12 - 80 FPM. -- This Model BX-1212BEE is equipped with: -- 20 HP Saw Motor, 28" x 1" band wheels, 168" x 1" band saw blade (not included). Features: -- Hand-wheel blade tensioning; manual elevation adjustment; 2 HP hydraulic system pump motor. Complete with: -- Spring-loaded steel and rubber upper-pressure rolls; 11" X 215" conveyor belt.

CAM-WOOD BX-1212HR-1 Single-Head Band Resaw w/30° Bevel CuttingCan be used to cut boards, cants, or reclaim slabs; Specifications: -- Max. working height up to 12" H under pressure roller x 12" W; 1/4" - 10-5/8" between blade and conveyor; -- VFD controlled variable speed from 0 - 60 FPM. Equipped with: -- 20 HP Saw Motor, 24" x 2" dynamically balanced cast iron band wheels, 184" x 1" to 1-1/2" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Tilting 10-5/8" x 165-1/2" infeed conveyor from 0° - 30° with side support for bevel cutting; 3 HP drive motor; variable feed speed 0 - 60 FPM; return gravity roller conveyor.Complete with: -- Programmable Digital Controller for convenient and accurate thickness setting; -- 1/4 HP Blade elevation motor moves blade and saw head; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. Includes: Operators' & Parts Manual and covered by (1) Year Warranty.

$ 30,990

CAM-WOOD BX-1616HR Single-Head Band Resaw w/Return ConveyorCan be used to cut boards, cants, or reclaim slabs; max. working height up to 16" under pressure roller x 16-1/2" Widths; 1/4" - 12" between blade and conveyor; VFD controlled variable speed from 0 - 60 ft./min.Equipped with: -- 30 HP Saw Motor, 32" x 2" dynamically balanced cast iron band wheels, 230-1/4" x 2" - 4" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- 3 HP Frequency Drive motor; variable feed speed 0 - 60 FPM; return gravity roller conveyor; a side support is applied for safe and stable cutting operations.Complete with: -- Digital controller for convenient and accurate thickness setting; 1/4 HP blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

$ 39,890

CAM-WOOD BX-2410HR Single-Head Band Resaw w/30° Bevel CuttingCan be used to cut boards, cants, or reclaim slabs; max. working height up to 10" H under pressure roller x 24" W; 5/32" - 10" between blade and conveyor; VFD controlled variable speed from 0 - 82 FPM.Equipped with: -- 30 HP Saw Motor, 28" x 2" dynamically balanced cast iron band wheels, 195-1/2" x 2-1/8" x 3/64" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Tilting 23" x 215" infeed conveyor from 0° - 30° with side support for bevel cutting; hydraulic infeed and outfeed conveyor drive motor; variable feed speed 0 - 82 FPM; return gravity roller conveyor. -- Complete with: -- Digital controller for convenient and accurate thickness setting; 1/4 HP blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. -- Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

CAM-WOOD BX-1616HR-TN Two-Head Band Resaw Can be used to cut boards, cants, or reclaim slabs; max. working height up to 16" H under pressure roller x 16" W; 1/4" - 12" between blade and conveyor; VFD controlled variable speed from 0 - 90 FPM.Equipped with: -- 30 HP Saw Motor (each head), 28" x 2" dynamically balanced cast iron band wheels, 201" x 2" - 3" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Automatic moisture cooling system for cooling and lubricating the saw blade for cleaning the blade tooth and longer blade life; Blade guard is easily lifted up, supported by two nitrogen gas cylinders for convenient blade change. Complete with: -- 3 HP Drive motor; variable feed speed 0 - 90 FPM; digital controller for convenient and accurate thickness setting; 1/2 HP blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack.Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

CAM-WOOD BX-1212-HR-TNX Two-Head Band Resaw Can be used to cut boards, cants, or reclaim slabs; max. working height up to 12" H under pressure roller x 12" W; 1/4" - 10-5/8" between blade and conveyor; VFD controlled variable speed from 0 - 90 FPM.Equipped with: -- 20 HP Saw Motor, 28" x 2" dynamically balanced cast iron band wheels, 201" x 2" - 3" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Automatic moisture cooling system for cooling and lubricating the saw blade for cleaning the blade tooth and longer blade life; -- Blade guard is easily lifted up, supported by two nitrogen gas cylinders for convenient blade change. Complete with: -- 3 HP Drive motor; variable feed speed 0 - 90 FPM; digital controller for convenient and accurate thickness setting; -- 1/2 HP Blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by a gear rack.Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

$ 89,990

CAM-WOOD TRS 150F Frame SawCAM-WOOD Frame Saws are engineered and designed to make extremely accurate cuts, cutting products with very tight tolerances up to 0.004" and often eliminating sanding before proceeding to the next step . The unique thin frame saw design accepts different saw frames, blade combinations, and allows multiple saw fence configurations to produce single, double or multiple cuts in a single pass.Specifications: -- 3/4" Min. to 6" max. working width; 1-1/4" min. to 7-3/4" max. working thickness (height); 7-1/2" minimum length; finished material > 0.1094". -- 0.043" to 0.055" Saw blade thickness; runs up to (22) blades at one time at (450) stroke/minute with a 8-1/4" stroke length; accommodates blades 1.575" wide x 19.685" long. -- Saw blade frame is powered by a 15 HP motor. Feed speeds of 1 to 5 FPM by 1 HP motor. -- Features automatic oil lubrication system requiring 90 PSI air pressure. Cooling system via water and air. -- Minimum kerf multi-blade frame saw designed to maximize production and minimize material losses to kerf. -- Machine supplied with PLC controller to allow operator fast, instant set-up changes. -- All controls are centrally located for the operator to easily adjust & control operation. -- Material waste reductions of up to 20% are achievable by use of the thin kerf blades (0.043" ~ 0.055"). -- A special air blast system cools the blade for longer service intervals and removes saw dust from the gullet of the blade to reduce temperature and increase blade life.Note: Frames are available in different configurations.

$ 29,039

CAM-WOOD TRS-3200 SLAT RIPPER - (1) Horizontal Bottom Saw or Moulder Spindle Bottom;The machine can rip extremely narrow parts. Ideal for shutters, louver slats, yardsticks, etc.Features & Equipped with: -- Designed to meet the exacting standards required for high-quality production line use. -- CAM-WOOD’s Slat Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- All of these features combine to show what true value these machines are in today’s highly competitive market. -- Precision fence assures absolute accuracy and is equipped with measuring gauge. -- Double anti-kickback fingers mounted at the infeed end of the machine provided maximum safety protection. -- Heavy-duty industrial TEFC motor ensures full-depth cutting capacity in all materials. -- Ruggedly constructed steel frame for durability and extended machine life. -- The variable speed feed works allow the machine to meet the cutting requirements of different materials. -- Saw head built to precise tolerances assures accuracy for all straight-line ripping operations and provides stellar cut quality. -- Top & bottom powered pneumatically tensioned feed rolls for precise feeding and cutting. -- Saw arbor is manufactured from alloy steel for dependability and anti-fatigue, heat-treated, precision ground, and balanced providing precise cutting performance.Specifications: -- 12"; Max. Cutting Width. -- 4-3/4"; Max. Cutting Depth. -- 10"; Min. Workpiece Length. -- 10"; to 16"; Dia. Sawblade Size. -- 4,000 RPM Spindle Speed. -- 12"; Spindle Length -- 70 mm Arbor Diameter (with 2-keyways). -- 30 HP Rip Saw Motor -- 3 HP Feed Motor. -- 12 to 60 FPM Feed Speed (Variable). -- 1 HP Feed Roll Elevating Motor. -- 1/2 HP Saw Arbor Elevating Motor.Footprint: 81" long x 40" wide x 60" high.

$ 59,500

CAM-WOOD - SM-236AX, ...Moulder Feed Through 6-Head (B-R-L-T-T-B), working cap. 9" x 5-1/4". Specifications: -- Head sequence: Bottom 10 HP, Right 10 HP, Left 10 HP, Top 15 HP, Top 10 HP and Bottom 10 HP motor -- Max. (Min.) Working Thickness 5-1/4" (5/16") -- Min. Working Length 9-1/2 in. -- Feed Motor 4 HP, variable feed speed from 16 - 82 FPM -- Elevation motor 1 HP -- Spindle Dia.: 40 mm with cutterhead speed of 6,500 RPM. -- Mechanical digital readouts for all spindle adjustments, as well as chip breakers and pressure elements. -- Tool cutting circles: First bottom head 5", 2nd & 3rd head 5" to 6-1/4", 4th to 6th head 5" to 7".Feed System: -- Variable Feed Speed from 16 - 82 FPM with LED speed readout. -- Oversized top & bottom rollers run synchronized, ensuring smooth feeding. -- The (3) independent section pneumatic pressures for the infeed rollers, in-process rollers, and outfeed rollers can be set with individual pressure allowing for consistent feeding.Complete with: -- Infeed table: 2M (6'-6") with manual table lubrication ports. -- Side pressure roller at infeed. -- Hard chrome-plated table for maximum wear resistance. -- Full sound and safety enclosure and manuals.

$ 26,500

CAM-WOOD SM-124TAX Feed Through Moulder4-Head Moulder with a 11-3/4" width x 9" maximum thickness when used as a 2-sided planer, and 10-1/4" width x 4" maximum thickness when used in 4-sided operation ( please see literature ).Equipped with: -- Cast Iron mainframe to maximize stability & minimize vibration during operation for years of use. -- Fully enclosed sound hood with lift-up door for easy set-up access. -- Adjustable infeed table w/fence for straightening rough sawn material. -- 11 - 52 FPM Variable feed speed system with top-driven rollers. -- All spindle adjustments with mechanical digital readouts. -- Left and top spindles with mechanical digi-set readouts. Chipbreaker and pressure element with mechanical digital readouts for accurate adjustment and precise settings.Complete with: 40" Infeed table length, Chromed table plates, fences, and pressure shoes. Manual waxilit pump, Central lubrication of the machine from the front side.SPECIFICATIONS SM-124TA Max. (Min.) Working Width 10-1/4"Max. (Min.) Working Thickness 4"1st Spindle Horsepower 4.1 HP - 7,000 RPM2nd, 3rd Spindle Horsepower 4.1 HP - 7,000 RPM4th, Spindle Horsepower 4.1 HP - 7,000 RPMFeed Motor 1/2 HPSpindle Diameter 40 MMCutter Speeds 6,500 (RPM)Variable Feed Speeds (FPM) 17 ~ 66Cutter head Diameter 1-1/4" or 30 mmPneumatic Air 90 PSI (CFM) 5Dust Outlet Diameter 5" x 4"N.W. 1,157 LbsG.W. 1,366 LbsIncludes: -- Operator/spare parts manuals and set-up tools.

$ 129,900

CAM-WOOD SM-632LX 6-Head Feed Through Moulder[6-Head (B-R-L-T-T-B), working cap. 12-1/2" x 6"]Specifications: -- Max/Min working width 12-1/2" - 3/4" -- Max/Min thickness 6" - 5/16" -- Minimum length 9-1/2" -- Head sequence: Bottom 15 HP, right 15 HP, left 15 HP, top 25 HP, top 20 HP and bottom 20 HP motor. -- All Horizontal spindles have outboard bearings -- Spindle dia. 50 mm with a cutterhead speed of 7,600 RPM. -- All spindles are equipped with mechanical digital readouts, "Dual mechanical" readouts on left and top spindles. Mechanical readouts for pressure elements and chip breakers; all chip breakers and pressure elements with pneumatics. -- Feed works: Inverter driven 10 HP feed system with feed speeds of 38 - 98 FPM. (up to 120 FPM available)Infeed table 2M (6'6"), chromed tables and fences. Side pressure roller mounted at infeed. Features and complete with: -- Feed speeds ranging from 20' ~ 98' per minute are a standard feature. -- The full safety enclosure covers as a chip guard and helps to reduce noise. -- Table surface is hard chrome-plated for maximum wear resistance. -- All manually adjusted turning parts are housed in dry bearings for oil-free lubrication. -- One piece cast iron machine frame and table is especially normalization heat treated for maximum stability and rigidity. -- Fence adjustment is quickly accomplished by a quick-setting lever. -- The three independent section pneumatic pressure for the infeed rollers, in-process rollers and outfeed rollers can be set with individual pressure allowing for consistent feeding results and outstanding effect. -- All control levers for the spindles are located at the front of the machine for convenient adjustment. -- Each spindle is provided with a mechanical digital readout, giving accurate adjustment. -- Vertical spindle adjustment up to 80 mm, allows to fit several tools on the vertical spindle, eliminating troublesome cutter change. -- Separate adjustment of the vertical spindle and insert table permits the table to be positioned extremely close to the cutterhead for added cutting stability. -- An individual motor drives each spindle and is separately mounted to eliminate spindle chattering during high-speed running. -- Centralized lubrication system Available options: -- SM Automatic feed magazine -- DC Automatic digital control -- SM Knife setting stand

.gif)