704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2024 Results Found

704-841-2001

QUICK R-RCGS-2-54 TOP & BOTTOM GLUE SPREADER54" Wide Top and Bottom Glues spreader with 0.04" - 1.75" thickness Capacity. -- Features: (2) Grooved rubber covered 8.3" glue rollers are acid and heat resistant, (2) 6.9" hardened rubber doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 80 FPM feed rate (Optional: Variable Speed Drive). -- Durable chain drive gives years of trouble-free operation. -- Simple to access hand wheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars roll guard hood, all aluminum drip pan catches clean-up water. -- Available Widths: -- 17" Wide -- 24" Wide -- 36" Wide. -- 48" Wide. -- 63" Wide.

QUICK R-RCGS-2-54-10 Top & Bottom Glue Spreader54" Wide Top and Bottom Glue Spreader with 0.04" - 10" thickness Capacity. Specifications: -- (2) Smooth rubber covered 8.3" glue rollers are acid and heat resistant, (2) 7" Chromed doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 80 FPM feed rate (Optional 40 - 118 FPM Variable Speed Drive for additional $900.).Features: -- Durable chain drive gives years of trouble-free operation. -- Simple to access hand wheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars roll guard hood, all aluminum drip pan catches clean-up water. -- Stock photograph, does not represent actual machine.

QUCK R-RCGS-2-17 Top & Bottom Glue SpreaderQUICK 17" wide Top and Bottom Glue Spreader with 0.04" - 1.75" thickness capacity.Features: -- (2) Grooved SBR Rubber (60 Durometer) covered 8" glue rollers, (2) 5.8" chrome covered doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 64 FPM feed rate (Optional 40-118 FPM Variable Speed Drive). -- Durable chain drive gives years of trouble-free operation. -- Simple-to-access hand wheels allow the operator to make quick adjustments when panel thicknesses change.Complete with: -- Roll guard hoods -- Emergency stop bars at front and back of machine for Operator Safety. -- Stainless Steel drip pan catches clean-up water.

Call for Price

QUICK MACHINERY N-P80 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 62" x 146" with end loading on 62" side. -- 80 PSI Platen pressure over the entire surface area with 105 PSI supply air pressure. Pressure is applied by (60) 12.8" dia. air pods with 5.9" stroke; -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 62" X 146". (2) Air pressure zones for upper platen: (4' x 8' and 5' x 12') -- Optional powered roller tracks for an additional fee. -- The press model shown in pictures is a dual platen powered feed through end load press. -- Actual model is N-P80-05-12-EL-1PL-M-40-2Z

Call for Price

QUICK MACHINERY N-P50 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 62" x 146" with side loading on 146" side (also available as end loading). -- 50 PSI Platen pressure over the entire surface area with 90 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (36) air pods total for this size press. -- (2) Pressure air pressure zones: 5' x 12' and 4' x 8'. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of idle conveyor roller tracks by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired.

Call for Price

QUICK MACHINERY N-P50 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 62" x 146" with side loading on 146" side. -- 50 PSI Platen pressure over the entire surface area with 93 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (36) air pods total for this size press. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired.Actual Model is a N-P50-05-12-SL-1PL-M-40-R-1Z.• Maximum platen pressure: 50 PSI at 93 PSI supply pressure• Lower platen dimensions: 5' x 12'• Side-loading design• Number of upper platens: 1• Upper platen dimensions: 5' x 12'• Vertical opening: Motorized adjustable from 2" to 40"• Lower platen roller tracks: Yes, non-powered roller tracks• Number of 12.8" diameter, 5.9" stroke air pods: 36• Number of air pressure zones: 1 (5' x 12' pressing)Optional powered roller tracks are available. -- The press model shown in pictures is a dual platen powered feed through end-load press.

QUICK L-HLPP-2-20-43-8-12 ...2-Sided Hydraulic Laminating Press: -- Number of working sections: (2) -- Working width, section #1: 6" and 8" -- Working width, section #2: 8", 10"; and 12" -- Maximum working length: 6,200mm (20.3') -- Maximum working height: 1,100mm (43.3") -- Pressure at the glue line: Up to 175 PSIMain Laminating Cylinders: -- Number of cylinders, section #1: (14) -- Number of cylinders, section #2: (21) -- Size of cylinders: 100 mm dia. x 80 mm strokeHolddown Cylinders: -- Number of cylinders, section #1: (14) -- Number of cylinders, section #2: (21) -- Size of cylinders: 40 mm dia. x 150 mm strokeLift Cylinders: -- Number of cylinders: (2) on each side = (4) -- Size of cylinders: 63 mm dia.Hydraulic Pump: -- Drive motor: 10 HP -- Maximum pressure: 140 kG/cm² -- Maximum Holddown Cylinder Pressure: 50 kG/cm² -- Maximum Side Lift Cylinder Pressure: 50 kG/cm² -- Shipped without hydraulic oil in the oil tank

Call for Price

QUICK MACHINERY N-P80 Air Pod style Cold Press -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface. -- Specifications: -- Platen pressing area size: 38" x 98"; with end loading on 37" side. -- 80 PSI Platen pressure over the entire surface area with 105 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 1" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 38" X 98". -- Optional: powered roller tracksSpecifications:QUICK Laminating Pod PressN-P80-03-08-EL-1PL-M-40-R-1Z• Maximum platen pressure: 81 psi at 90 psi supply pressure• Lower platen dimensions: 3' x 8' (38" x 98")• End-loading or Side-loading: End-loading• Number of upper platens: 1• Upper platen(s) dimensions: 3' x 8' (38" x 98")• Vertical opening: Motorized adjustable from 2" to 40"• Lower platen roller tracks: Yes, Non-powered roller tracks• Number of 12.8" diameter, 5.9" stroke air pods: 24• Number of air pressure zones: 1 -- The press model shown in pictures is a dual platen powered feed through end-load press.

Call for Price

QUICK N-P50 Fixed Daylight Opening Air Pod PressThis Pod Press can produce a maximum 50 PSI platen pressure over the entire surface at 100 PSI supply air pressure. Press has a fixed vertical daylight opening of 44". The (18) 12.8" max. diameter air pods have 5.9" stroke.Material conveyance is via automatically extending and retracting (via pneumatic cylinders) non-powered roller tracks. A cycle timer provides visual and audible signals at the end of each cycle if desired, and also automatically releases platen air pressure at the end of each cycle, if desired.Specifications: -- Maximum platen pressure: 50 PSI at 100 PSI supply pressure. -- Lower platen dimensions: 4' x 8' -- End-loading or Side-loading: End-loading -- Number of upper platens: 1 -- Upper platen(s) dimensions: 4' x 8' -- Vertical opening: Fixed at 44" -- Lower platen Non-powered roller tracks. -- (18) 12.8" diameter, 5.9" stroke air pods. -- Number of air pressure zones: 1Lead Time: Approximately (12) weeks from time of order.Actual Model: N-P50-04-08-EL-1PL-F-44-R-1ZNOTE: Please let us know of any "Special or Specific" safety equipment requirements that you may have prior to order

QUICK MODEL L-HLPP-1-36-43-6 SINGLE SIDED HYDRAULIC LAMINATING PRESS FOR POSTS AND BEAMS: -- Number of working sections: 1 -- Maximum working length: 36'. The 36' length achieved by manufacturing the machines in two 18' long pieces; the two 18' pieces are then joined together, resulting in 36' total working length. -- Maximum working width: 43" -- Maximum working thickness: 6"Main Laminating Cylinders: -- Number of cylinders: (30) -- Size of cylinders: 80mm dia. x 80mm strokeHolddown Cylinders: -- Number of cylinders: (30) -- Size of cylinders: 40mm dia. x 150mm strokeSide Lift Cylinders: -- Number of cylinders: (2) per section = (4) -- Size of cylinders: 63mm dia.Hydraulics: -- Hydraulic pump drive motor: 7-1/2 HP -- Maximum pressure: 140kg/cm2 -- Maximum Holddown Cylinder Pressure: 50kg/cm2 -- Maximum Side Lift Cylinder Pressure: 50kg/cm2 -- NOTE: Shipped without hydraulic oil

Call for Price

QUICK MACHINERY N-P80 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 49" x 97" with end loading on 49" side. -- 80 PSI Platen pressure over the entire surface area with 102 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (28) air pods total for this size press. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 49" X 97" . -- The press model shown in pictures is a dual platen powered feed through end load press. -- Actual model is N-P80-04-08-EL-1PL-M-40-R-1Z

QUICK Clamp Rack 8' -- Description: The QUICK Clamp Rack features a cleanly-designed, exceptionally strong frame, with massive 4" x 4" structural tubing cross beams and feet, and 4" x 6" structural tubing legs.The innovative “two-sided"; frame design allows for either one-sided or two-sided operation, at the shop owner’s discretion. The one-sided configuration allows for placement of the frame tightly against a wall, for maximum compactness. The two-sided configuration doubles the amount of easily-accessible clamping area, for industry-leading “room to work."; The Rack is configured by choosing either of the two available foot mounting positions. -- Specifications:96" Wide (36) Clamps 3.5" X 40" opening

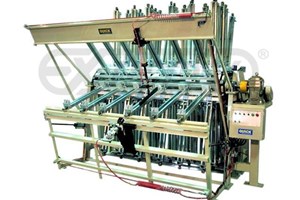

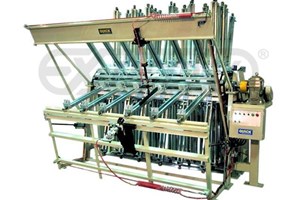

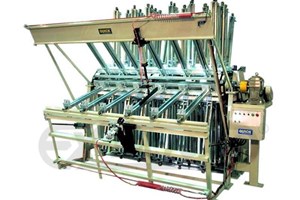

QUICK 20 Section 16.5' Heavy Duty Clamp Carrier Specifications: -- 20-Section Thick Stock Pneumatic Clamp Carrier; 16-1/2' width cap.; -- (12) Clamps, each with 3 1/2" high jaws and 44" clamp opening for a total of (240) clamps. -- All clamps are heavy duty type; zinc plated and with 1° inward draftEquipped with: -- Dual operator package with (2) pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners. -- Semi-automatic rotation via electric motor drive and separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward and Front Rest In.Standard features: -- Heavy-duty thick stock frame with 3" dia. shafts and 6" I-beam legs; -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with maintenance tools.

QUICK F-CGAP-20-11-17 20" Wide Conveyorized Glue Applicator -- 20" Conveyorized Glue Applicator, 20" wide grooved rubber glue applicator roll and holddown roller with stainless steel doctor blade and glue reservoir.Features: -- Easy adjustment or removal of doctor blade, 30' overall length. -- 11' Infeed before the glue roller . -- 17' Outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers. -- Heavy Duty crossbars. -- Chain guard, high quality anti-stick Urethane finish. -- Owner & operator's manuals.OPTION:Hold Down roll for face gluing 20" wide: $ 700 additional

QUICK 20 Section Heavy Duty Pneumatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 44" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation: Push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! -- Complete with & Includes: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 6-Section Pneumatic Clamp Carrier with 20-1/2' width cap. & Dual Operator's Stations, -- (16) Heavy Duty zinc plated clamps per section (96) clamps total), 50" opening on clamps. Jaw sizes of clamps is 3-1/2" high x 4-3/4" wide, with 1° inward draft. Equipped with DUAL OPERATOR'S STATIONS including: -- (2) Pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners -- Semi-automatic rotation via electric motor drive; with separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In.Standard Supply includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

Quick Hydraulic Clamp Carrier with 20-sections and 12-1/2' width capacity.This special "thick stock" frame accepts (12) Heavy Duty zinc plated clamps per section. Includes: -- 240 clamps with 36" openings and 6" high x 4-3/4" wide jaws with 1° inward draft. -- Integral hydraulic overhead panel flattener. -- (2) Hydraulic clamp tightener with adjustable torque limiter. -- (2) Pneumatic panel flattener -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.Note: Could be order with single tightener and panel flattener

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.OAL Dimensions are 163" W x 182" D x 125" H

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

²QUICK 14-Section Pneumatic Clamp Carrier with 10-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. -- Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- A 14-Section Clamp will produce approx. 300 panels