LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleThe Southern Forest Products Association (SFPA) has announced that, for the fourth consecutive year, shipments of Southern Pine lumber recorded an increase from the previous year.

Shipments in 2013 totaled 15.026 billion board feet (Bbf), an increase of 5% over the volume shipped in 2012 (14.279 Bbf) and 27% above 2009 shipments (11.79 Bbf).

Tabulation of Southern Pine shipment totals is a cooperative effort with the Southern Pine Inspection Bureau (SPIB) and Timber Products Inspection (TP).

SFPA is a nonprofit trade association that has represented manufacturers of Southern Pine lumber since 1915.

Today, SFPA is the leading source of information about Southern Pine products for design-build professionals and consumers.

2900 Indiana Ave. Kenner, LA 70065 • 504/443-4464 FAX: 504/443-6612

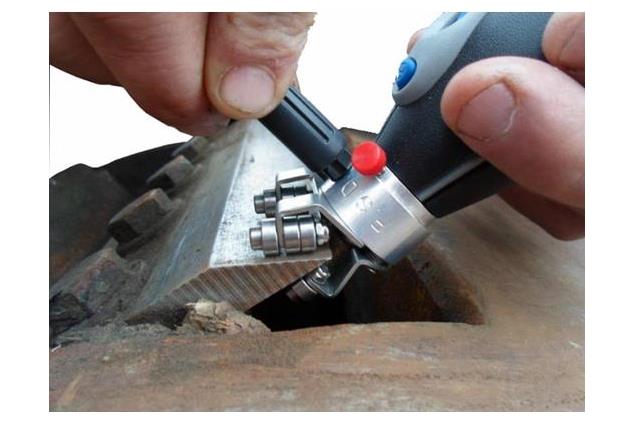

Winn, Mich. (March 6, 2014) – Morbark, Inc., a leading manufacturer of durable, high-performance wood waste reduction equipment for more than 50 years, is proud to announce that it has signed a contract with Precision Sharpening Devices Inc. to sell the Bevel Buddy™ Chipper Knife Sharpener through its authorized dealer network.

Since 1988 Precision Sharpening Devices, Inc., has been manufacturing counter grinding/back beveling equipment for knives used by a variety of industries, mostly for the pulp and paper, sawmill, plywood, and whole tree chipping markets.

The Bevel Buddy handheld sharpener allows the knives to be re-sharpened without needing to be removed from the machine. The knives can be re-sharpened this way two to three times, reducing customer downtime.

“The partnership between Morbark, Inc., and Precision Sharpening Devices, Inc., with their line of Bevel Buddy™ Chipper Knife Sharpeners will offer our customers a product that helps them operate their equipment at the highest levels of efficiency,” said Mark Mills, Precision Sharpening Devices, Inc. “The results are fuel savings, meeting production quotas, less down time, and greatly reducing their overall costs while maintaining a quality product and a safer work environment. Both parties view this as a ‘What’s best for the customer’ focus.”

“We’re always looking for ways to make our customers more productive, more efficient and more successful,” said John Foote, Morbark VP of Sales and Marketing. “Partnering with Precision Sharpening Devices, Inc., to offer the Bevel Buddy through our worldwide network of authorized Morbark dealers gives our customers easy access to another tool to help them be more productive, and ultimately, more successful.”

About Morbark:

Morbark, Inc., based in Winn, Mich., builds equipment that creates opportunities in the forestry, recycling, sawmill, bio-energy and tree care markets. Innovating and manufacturing durable, high-performance equipment for more than 50 years, Morbark offers a full line of whole tree and waste wood chippers, flails, brush chippers, horizontal and tub grinders, sawmill equipment, material handling systems and more. Morbark equipment helps customers harvest, process and convert wood and organic waste materials into valuable, useful and environmentally sound products.

Visit www.morbark.com, “Like” us on Facebook or subscribe to our YouTube channel.

Universal Machinery Sales has just introduced a new line of premium Steel Self- Dumping Hoppers for wood scrap applications. These Hoppers may be customized according to customer specifications. The '2-Yard' Model is a basic design, constructed with 1/8" steel plate. Dimensions for the '2-Yard' Hopper: width 54"; length 65"; height 48"; and depth 39-1/2". Standard Hopper sizes are '1-Yard', '2- Yard', and '3-Yard' load capacities. The Hoppers are equipped with forklift channels for improved mobility, and a 54" total reach provides increased load stabilization. The load may be locked in place, but the Hopper has a trip-lever for easy dumping.

For more information, Contact Mona Tracy at Universal Machinery: 855-298-8890

"If It's New, It's Here," proclaims the Association of Equipment Manufacturers of the CONEXPO/CON-AGG trade show, and Morbark® does not disappoint on that score. Morbark, Inc., a leading manufacturer of durable, high-performance wood waste reduction equipment for more than 50 years, will debut an exciting new product at this year's CONEXPO show.

Morbark partnered with its European dealer, OBMtec, to produce the Barracuda, a single-rotor, slow-speed shredder for markets outside of Europe. The Barracuda, developed by OBMtec and manufactured at Morbark's Winn, Mich., factory, offers a universal solution for industrial, C&D, wood and other waste streams, providing a high-quality end product with low operating, maintenance and fuel costs.

"Adding the Barracuda shredder to our industrial product line allows our customers to easily expand their capabilities in C&D and industrial waste reduction," said John Foote, Morbark VP of Sales and Marketing. "Our ultimate goal is to make our customers successful, so the machine was designed for versatility and ease of maintenance. With high fuel efficiency and low operating and maintenance costs, combined with the versatility to process a wide variety of materials, the Barracuda provides exceptional value to our recycling customers."

Key benefits of the Barracuda include:

• Ease of maintenance: The Barracuda is designed with serviceability in mind. All daily maintenance, such as cleaning the air filter, and checking and changing fluids, can be done while standing at ground level.

• Versatility: The Barracuda's ground-level adjustment door allows you to adjust grates in as little as 2 minutes, reducing downtime and increasing productivity. The counter knives can be repositioned to 5 different heights-higher for waste wood or lower for industrial waste-to give you the best end product for whatever you run through it. Available setup options from 20 to 40 hammers and counter knives give you multiple alternatives to find the right mix of speed, fuel economy, and output quality to best fit your needs.

• Low operating costs: The Barracuda's single rotor and bolt-on hammer inserts for reduced maintenance times, the internal rotor gearbox with high torque for greater fuel efficiency and large hydraulic reservoir for lower operating temperatures all play a part with the many other key features to reduce operating costs in this new design - all to increase your bottom line!

To get the first look at the Barracuda, visit Morbark in the Silver Lot at CONEXPO in booth #3491.

About Morbark:

Morbark, Inc., based in Winn, Mich., builds equipment that creates opportunities in the forestry, recycling, sawmill, bio-energy and tree care markets. Innovating and manufacturing durable, high-performance equipment for more than 50 years, Morbark offers a full line of whole tree and waste wood chippers, flails, brush chippers, horizontal and tub grinders, sawmill equipment, material handling systems and more. Morbark equipment helps customers harvest, process and convert wood and organic waste materials into valuable, useful and environmentally sound products.

Introduced by Terramac® LLC, a manufacturer of innovative rubber track crawler carriers, the Terramac RT9 multi-purpose crawler carrier is designed for customization and versatility to tackle a wide variety of asphalt, aggregates, concrete, construction, earthmoving, lifting, mining and utility applications. The largest mid-sized rubber track carrier that does not require special oversize permitting to transport the machine, the Terramac RT9 will be on display at the company’s exhibit (Booth 70028, Gold Lot) at CONEXPO-CON/AGG 2014, March 4-8 in Las Vegas.

Manufactured in North America, the CE-certified Terramac RT9 carrier can be customized with an array of equipment, such as bark blowers, cranes, drills, flatbeds, generators and tanks. With an operating weight of 26,000 pounds (11,794 kg) and a maximum carrying capacity of 18,000 pounds (8,165 kg), the RT9 crawler carrier eliminates the need for additional equipment and minimizes environmental impact and restoration costs associated with jobsite ground damage.

“No matter what business you’re in – from aggregates, construction or earthmoving, to mining, oil and gas or utility – the Terramac RT9 crawler carrier can help you tackle any jobsite challenge that comes along,” said Mike Crimaldi, CEO of Terramac LLC. “We can customize electrical power sources, frame adjustments and hydraulics on the RT9 to suit any configuration.”

Terramac RT9 Crawler Carrier Tackles Variety of Construction Industry Applications

When fully loaded, the ground pressure on the RT9 is only 5.1 psi (0.36 kg/c2). Featuring a 10-ft (3-m) turning radius, the rubber track crawler carrier has an overall length of 20 ft (6 m), a width of 8 ft 5 in (2.6 m), a height of 9 ft 3 in (2.8 m) and a minimum ground clearance of 20 in (0.51 m). The unit can travel at speeds up to 6 mph (10 kph).

Mining applications

The standard RT9 features a dump bed, but for mining applications, it can be configured with a flat bed, water tank and hydraulic crane to handle drill sections. Power for the crane comes from the gear pump powering the dump bed.

The Terramac RT9 can be mounted with a spray boom for dust control on mine roads. The machine’s low ground pressure makes it ideal for loose and wet ground conditions where heavy, wheeled trucks are likely to get stuck. An RT9 equipped with a spray boom can also be used in agriculture applications requiring wet ground conditions.

Pipeline applications

“On the pipeline right of way, there’s just dirt, no road,” Crimaldi said. “When it rains, access for wheeled vehicles is terrible, but not for the RT9 track carrier.”

In addition to carrying mats onto pipeline sites to create more stable working environments for larger construction equipment, the RT9 crawler carrier is also used for drilling, material handling and site investigation applications on oil and gas construction projects. The crawler carrier can be easily outfitted with a variety of tools and equipment, such as bark blowers, cranes, sandblasters and vacuum excavators to assist with pipeline construction.

“A welding machine attached to the bed of an RT9 crawler carrier can be removed in less than an hour,” Crimaldi said. “Within a couple hours, one RT9 can be used for a variety of applications, which also makes our crawler carrier ideal for rental companies with customers looking to use the machines for multiple jobs. They can switch out the bed to match the customer’s specific needs.”

Utility applications

A digger derrick can be installed on the RT9 for digging holes and setting poles in remote, hard-to-reach locations. The RT9 can also be outfitted with a boom lift for lifting materials.

Terramac RT9 Crawler Carrier Tackles Variety of Construction Industry Applications

Geotechnical and environmental drilling applications

For drilling jobs where access is challenging due to ground conditions, grade or working angles, the RT9 can be mounted with drilling rigs for a variety of environmental and geotechnical drilling applications, including soil boring, sampling and testing, monitoring and soil and groundwater remediation.

Because of the flotation from the RT9’s rubber tracks, contractors can keep working in all types of adverse ground and weather conditions, and can complete projects faster. The rubber tracks also allow for faster climbing on hills and reduced slippage in wet conditions.

“Unlike steel-track crawler carriers, the RT9 rubber-track crawler carrier won’t tear up the ground or road surface – a significant advantage for preventing costly jobsite ground damage,” Crimaldi said.

The RT9 is equipped with a 230-hp (172-kW) Cummins diesel engine. Rollover protective structure (ROPS) and falling object protective structure (FOPS) are standard. Open- and closed-cab options are available.

Ideal for carrying supplies and materials, the bed on the RT9 elevates to a 48-degree angle for dumping gravel, sand, dirt and other materials. The bed can fold down, allowing the operator to side-load materials or equipment for carriage across rough terrain, delicate soil conditions and remote areas.

Designed with ease of maintenance in mind, the RT9 features a tilt hood providing easy access to key service areas. Terramac provides parts and service support – as well as custom fabrication and mounting services to install a wide range of equipment and configurations on the RT9.

Available for sale or rent, the Terramac RT9 crawler carrier can be ordered from the factory with the correct body configuration to accept custom accessories. For more information on the Terramac RT9, or to schedule a demonstration, please visit www.terramac.com.

The NHLA strategic planning task force, under the chairmanship of past president Jim Howard, recently brought several motions to the full NHLA board of managers for a vote. In a special meeting called on February 17 the NHLA board voted and approved all of the changes that the strategic planning task force put forth including a new Vision, Mission and Goals for the Association.The approved changes further support the path that NHLA began several years ago with the adoption of the tagline: "Strong Roots. Global Reach."

The new vision statement, "To be the global standard for hardwood trade and commerce," is confirmation of the extensive global presence that NHLA has maintained since 2008.

The new mission statement follows the same theme, "To serve NHLA members engaged in the commerce of North American hardwood lumber by: maintaining order, structure and ethics in the changing global hardwood marketplace; providing unique member services; promoting North American hardwood lumber and advocating the interest of the hardwood community in public private policy issues; and providing a platform for networking opportunities."

The board also approved 6 strategic goals in order to fulfill the new Vision and Mission. They are as follows:

1. Maintain a uniform system of grading Rules for the inspection and measurement of hardwood lumber.

2. Foster integrity within the hardwood community by assisting with dispute resolution and providing a meaningful Sales Code.

3. Continually train lumber inspectors for the industry.

4. Provide forums for individuals to meet and learn.

5. Explore organizations with whom NHLA can partner or collaborate.

6. Maintain inspection services to support dispute resolution.

The most significant of the goals listed above is number six. The adoption of goal number six is to assure the hardwood industry that NHLA is committed to maintaining its Inspection Field Services both in North America and around the globe.

Questions regarding the new vision, mission and goals of the Association? Contact Mark Barford, CAE, Executive Director at 901-377-1082 or by email at [email protected].

Amark Lumber Markers, is proud to announce a completely redesigned e-commerce website, created by LumbermenOnline.com, the sister company of LUMBERMEN’S Equipment Digest. The new website features quick and easy order placement as well as full information to assist customers in determining which size, color or hardness will work best for their application. In addition to fast and easy ordering with several payment options the new site includes details about Amark’s exclusive Stub Recycling Program, related products such as crayon holders and the new no obligation contact form to assist in your research. If your operation needs bright, high quality, versatile markers visit www.amarkers.com and see just how quick and easy ordering your next shipment can be.

Lyme, NH- Lock and Lube LLC recently introduced the Lock N Lube grease coupler to the North American market. Invented and manufactured in South Africa by Gurtech PTY Ltd. The inventor Dick Gurney, a sugar cane farmer, had grown tired of the short comings associated with the standard grease coupler. Fortunately, Dick has a skilled and creative mind and produced a better grease coupler.

With its patented external jaws and sliding locking sleeve, he achieved a coupler that not only locked on and stayed on but also came off when you wanted it off. The internal long wearing Nitrile sliding seal achieved not only excellent sealing for S.A.E. and metric fittings but also a greater tolerance for worn and out of spec. fittings. The result is a robust tool that takes the common hassles out of greasing, saves grease, and gets the machines the grease they so desperately need. To purchase the Lock N Lube coupler call Russell Barnes at 603-795-2298 or Search eBay or Amazon for" Lock N Lube"

The Southern Forest Products Association (SFPA) Board of Directors has appointed Tami Kessler to serve as Executive Director. Tami has most recently served the association as Corporate Secretary and Director of Administration. Since she joined the staff in 1976, Tami has served in multiple capacities including accounting, 28 years as Director of Administration, plus two terms as director of SFPA’s Forest Products Machinery & Equipment Exposition.

“Tami brings a comprehensive set of skills set to the management of SFPA operations at our headquarters, and the Board congratulates her on this well-deserved promotion,” stated SFPA Chairman Joe Kusar after making the announcement at a recent Board of Directors meeting in Atlanta. “Knowing what she does about our daily operations, she is well prepared to manage the future progress of our association,” he added.

“Working with SFPA’s staff of dedicated professionals, I am looking forward to continuing to serve all SFPA members and further enhance the value of their membership,” Tami said. She can be reached by phone at 504/443-4464 ext. 222, or by e-mail to [email protected].

Hutto Wood Products is proud to announce a completely redesigned interactive website, created by LumbermenOnline.com, the sister company of LUMBERMEN'S Equipment Digest. The new website features a complete layout of Shaving Mills, and Material Handling equipment offered by HWP, along with Trade-Ins, complete company information, and an updated map to show the reach of HWP's mills and elated customers. Showing the customization options, total value, complete in and outs, and knowledge behind each piece of equipment was the main focus of Patrick Hutto, owner of Hutto Wood Products.

If you're looking to add shavings production to your mill or simply are tired of paying for bagged shavings for your barn, HWP offers a full line of Shaving Mills, check them out at www.HWPShavers.com, or call 803-564-7173.

Abneyco Equipment LLC of Chelsea, Alabama is pleased to unveil their new website, designed and hosted by LumbermenOnline.com, the sister company of LUMBERMEN'S Equipment Digest. The new website allows customers to easily and quickly find equipment through drill-down search fields or to simply browse Abneyco's updated inventory. However, as shown on their custom services page, Abneyco is much more than used equipment. They offer a long line of services focused on getting your mill started and/or continuing smooth operation. Find out more by using the simple, no obligation "Contact Form" to see what Abneyco can do for you.

Abneyco has been helping customers find used sawmill, pallet, and woodworking machinery as well as providing other services; Engineering/Design, Machine Installation, Repo/Storage and Salvage/Recycling since 1989. Whether you're looking for equipment, want a complete mill set up, need equipment removed, or any other offered service, call 706-590-3624 or visit www.Abneyco.com today!

NHLA is happy to report that NHLA member company, Emporium Hardwoods has successfully shipped to the European Union solely with the NHLA Kiln Drying Certificate. Emporium Hardwoods, a division of Rossi Group, shipped containers of hardwood lumber to the United Kingdom on January 8 with no incident.

On December 18, 2013 the EU implemented the Memorandum of Understanding (MOU) between NHLA and the USDA APHIS as the NHLA KD Certificate replaces the need for a Phytosanitary Certificate.

The current list of countries that accept the NHLA KD Certificate as an equivalent to the PHYTO are as follows: Australia, Brazil, European Union (Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania,

Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Vlovenia, Spain, Sweden and United Kingdom), Venezuela and Vietnam.

China and Mexico are currently reviewing acceptance of the NHLA KD Certificate. Information will be released on additional country acceptance as NHLA is notified.

The KD Certificate Program achieves the same goals as the APHIS PHYTO Certificate but at less cost to both APHIS and the U.S. hardwood industry. The Program involves regular inspections of subscribing hardwood facilities in the U.S. by both NHLA contracted inspectors and APHIS inspectors to ensure continuing performance to the Kiln Drying Sawn Hardwood Standard.

If your company is interested in learning more about the NHLA KD Program or would like to join, contact NHLA Chief Inspector, Dana Spessert at [email protected] or by phone at 901-399-7551.

Contributed by:

National Hardwood Lumber Association

.gif)