Equipment For Sale

9689 Results Found

Call for Price

EXPRESS SCALE MCRS-180ELECHYD LOOSE BAGGING LINEComplete Loose Bagging Line including the Following; -- Hopper Stand and Support 37 cu' BF/GV/AUG -- GB Bag Fill Machine -- BF-14 Belt Feeder -- Bag Closing Conveyor 510-LP -- Fishbein Sewing Machine -- Hopper 87 cu' with Support -- Belt transfer Conveyor 27' -- Loaded on your Truck

Call for Price

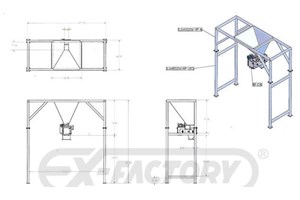

SPECIAL FEEDER FOR HAMER 2080FFS BAGGER -- Hopper 37 Cubic Feet and Support -- With Scale Support System -- Belt Feeder with Discharge to Existing Hamer Form-Fill and Seal -- Brand New -- Loaded on your Truck

Call for Price

LOOSE BAGGING SYSTEM "MCSRE"System includes and is supplied with: -- Hopper BF 87 Cu/Ft. and Support, Charging Hopper to Integrate with product Delivery Conveyor -- CON PD 24X24: 24 Feet Product Delivery Conveyor -- Hopper Stand BF: Hopper and Support 37 Cu/Ft. Surge Hopper for 5 GV Duplex Net Weight Bagging System -- GV-52 - DUPLEX GRAVITY/VIBRATORY TRAY: Duplex unit for (20) Bags/Minute -- Spout to Meet Customer's Bag -- CON 512: Bag Closing Conveyor. 12 Feet Long -- PACKRITE XROL: Heat Sealer with Extra Set of CO.Loaded on your Truck

Call for Price

MCRS is a Bagging System for mulch, compost, rock, or sand. This system is complete with a 2-yard product surge hopper, a 20' X 24" wide troughed incline product delivery conveyor with a cleated belt, an 8' bag closing conveyor, and a custom 7.5 HP Elec/hydraulic power unit. The system can fill bags by time and depth of stream or digitally with load cells.Standard construction carbon steel Powder Coated Industrial Gray(RAL 7046).The MCRS operation has been designed for one man to bag fill, bag close, and stack three bags per minute continually. -- The operator hangs bag #1 on the scale, hits the palm switch to close the CG spout, and automatically fills it. -- Bag #1 will drop once the timer times out onto the moving conveyor and hangs bag #2 into position, hits the palm switch, and starts the filling. -- The operator steps to his left. Bag #1 contact a wand switch and is in position underneath the impulse sealer. --The operator starts the bag into the impulse sealer. Once completed, bag #1 is then manually stacked. -- Bag #2 filled and waiting for the operator's return. -- Bag #2 is then released, and bag #3 hung. -- The process is then repeated.The Front End loader feeds the system. Consists of the following --infeed hopper --incline conveyor --dosing system --bag closing system:Bag Closing System Consists of a (CON 508) 8' long x 1' wide smooth top belt to take bags into aposition where a wand switch manually stops them. The bags are then prepared and enteredinto theImpulse Sealer (31103737610) Programmable Impulse Sealer for the repeated sealing of thermoplastic films such as polyethylene and polypropylene. This automatic single-impulse heat sealer is controlled by a plug-in transistorized circuit board and electronic timers. The timed closure ensures an even and consistent seal. --THE PRICE REFLECTS AN UPGRADE FROM THE IMPULSE SEALER TO A SEWING SYSTEM.The operator has hands free to handle the product quickly. This type of machine generally increases workers' productivity.The electric foot pedal is included for manual operation. -- Seal Length: 24" -- Seal Thickness: 8 mil -- Seal Width: 10 MM

EXPRESS SCALE CM-780D-II Bagging System with ConveyorsSpecifications: -- Air-operated double door weigh hopper: 3.5 CuFt -- Load cells: 100 KG (220 Lbs) -- Weigh Range: 10-110 Lbs or 5-100 kG -- Cycle Speed (simplex): 13 bpm (50 lbs or 25 kG) -- Cycle Speed (duplex): 22 bpm (50 lbs or 25 kG) -- Typical Accuracy: ±2-3 oz. or ±56-85 gramFeatures: -- 1280 Express Digital Programmable Controller with digital readout -- RS232 output -- Operator station. -- Protect individual or all parameters via pass-code protection -- Ethernet connectionSystem Equipped with: -- Gravity Feeder: High-Output Gravity Gate (13" x 8") 2-position for bulk and dribble feed. Handlingfree-flowing products such as grain, seed, and prilled fertilizers. Rated at 14-16 bags per minuteSimplex or 22-24 BPM - duplex. Typical accuracies will be +/- 2-3 ounces (56-85 grams). -- Spout Assembly: Dust Tight 21", 25", or 31" Circumference -- Hopper Surge: For simplex scale only, mild steel construction gray powder coated 40 CU' capacity(operator platform and handrail not included) 4"x 4" x 1/4" wall tube, 3/16" Metal Plate for wallsof Hopper. -- Conveyor: 22' x 18" product delivery: 2 HP Motor, 3" Scoop Cleat Belting w/ Hopper for Unloading Bulk Bags -- Bag Closing Conveyor with Air-Flo Hot Air Heat Sealer: 10' overall length, 1/2 HP motor, 12"-wide 3-ply neoprene smooth top belt, 110V variable speed motor mounted internally, adjustable conveyor height 13.5" to 18.5" and adjustable back plate, electrical controls include on/off switch.Backed by a 1 year warranty and lifetime customer support.

Call for Price

COMPLETE LOOSE BAGGING SYSTEM System includes: -- Feed Hopper 3 Yards Capacity. ( 87 Cu.Feet) -- 24 feet Incline Conveyor. -- GB Mechanical Bagging Scale -- Feeding Hopper 37 Cu.Feet with Stand. -- Packrite Xtrol Impulse Sealer. -- Motorized Bag Conveyor. -- Loaded on your Truck.

$ 92,500

2005 Extec S5 Incline Screen -Double Deck Track Plant -2 deck vibratory feeder grid -New motor installed in 04/2023 -Rebuilt pumps installed 06/2022 -Service receipt for engine and pump overhaul available upon request -One new side belt included -Spare screens included -Additional stacker can be added for addtional cost Ready to work

$ 70,000

$ 140,000

2012 Extec S-5 -5500 hours -New Deutz engine maybe 60 hours on it -Vibratory deck -Serviced regularly -Belts are good Turnkey Unit have videos upon request!!!

Call for Price

$ 22,999

EXTREMA XS-1E43 Single Head Wide Belt Sander42" Working width, up to 5" max. opening with electronic digital microprocessor thickness control.Equipped with: -- Rubber-covered contact drum and 2-1/2" wide finishing platen, 25 HP main motor; -- 43" x 60" Abrasive belt, TRU-TRAK solid-state electronic belt sensing with pneumatic tracking. -- GOODYEAR Endless conveyor belt with pneumatic tracking, 2 HP variable speed feed motor from 15 - 48 FPM. -- 0.5 HP Motor to raise & lower table via (4) jack screws, an over-thickness bar at the infeed of machine, and AUTO-SET thickness device. Complete with & Features: -- Double infeed & outfeed rubber covered holddown rolls. -- Air operated disc brakes on main motor, front & rear emergency stop buttons, and motor load meter. -- SQUARE D Electrical controls; magnetic Starter with overload protection, and electrical interlock at sanding belt access doors.NOTE: Also available wired for ...460V operation.

$ 20,999

EXTREMA 126TV Single Sided Planer;26" Max. width capacity, 11.75" thickness, Solid cast iron construction. -- Precision ground cast iron table with motorized programmable height adjustment; 1/2 HP elevation motor. -- 20 HP Main drive motor -- Scale & pointer readout for accurate thickness adjustments. -- "VECTOR" cutterhead with (6) rows of 4-sided inserts. -- 1 HP Feed drive, variable feed speed setting from 20 to 75 FPM. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers; (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor with magnetic starter & thermal overload switch and Emergency stop. -- Includes Operations manual, parts list & tool kit.

Call for Price

EXTREMA XP-615AZ Single Sided Head PlanerSpecifications: -- Width: 24" -- Main HP: 15 HP -- Feed HP: 1 HP -- Elevation HP: 0.5 HP -- Max. Thickness: 8.75" -- Min. Thickness: 0.375" -- Max. Cut: 0.25" -- Min. Length: 10.5" -- Cutterhead Speed: 6000 RPM -- Feed Speed: 20-42 ft/min -- Air Requirements: 1000 CFM -- Thickness Adjustment: PLC ControllerBed Roller Adjustment: External -- Powered Bed Rollers: Top and Bottom -- lnfeed Roller: Standard -- Amps (230V / 460V): 41A/20A -- Weight: 2345 LbsFeatures: -- Solid cast-iron construction -- Sectional infeed rollers -- Huge 8-3/4"thickness capacity -- 6000 RPM cutterheads -- Anti-kickback fingers -- Segmented chip breakers -- Sectional feed rollers -- XP-615 Digital Controller -- Motorized table elevation -- Available with straight, STEALTH, or ilECTDFi cutterheads -- Heavy duty screwjack elevation system -- Easy access internal workings -- External bed roller adjustmentsOptional: -- In-feed Roller

Call for Price

Manufacturers Specification - ? [Specifications](https://extremausa.com/product/magnum-xp-series-25-double-sided-planer/#tab-test_tab) Horsepower: 40 / 30 HPVoltage: 230V / 460VPhase(s): 3 PHWidth: 25"Top Motor: 40 HPBottom Motor: 30 HPElevation Motor: 2 HPFeed Motor: 5 HPMax Thickness: 8"Min Thickness: 3/8"Min Stock Length: 16"Cutterhead RPM: 6000Top Cutter Access: Super SlideBottom Cutter Access: Super SlideDisc Brakes: YesFeed System: CarpetDrive System: ShaftFeed Speed: 20-110 ft/minCFM Requirements: 3000AMPS (220V/440V): 188 / 94Weight: 9300 lbs

Call for Price

EXTREMA XP-124TV Single Head PlanerSpecifications: -- Solid cast iron construction. -- 15 HP Main drive motor, 1 HP feed motor 20 to 70 FPM, 1/2 HP elevation motor. -- Precision ground cast iron table w/motorized programmable adjustment. -- Scale & pointer readout for accurate thickness adjustments. -- "VECTOR" insert cutterhead with (4) sided inserts. -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers.Features: -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. -- Options: Single-phase power, please add ...$ 100, 460 volt add...$ 150.

$ 14,999

EXTREMA XP-610 SINGLE SIDED PLANER24" Width capacity, 8-3/4" thickness, solid cast iron construction. -- 10 HP main drive motor -- Precision ground cast iron table w/motorized height adjustment, with digital thickness display; 1/2 HP elevation motor. -- Scale & pointer readout for accurate thickness adjustments. -- "VECTOR" cutterhead with (6) rows of 4-sided inserts. -- Variable feed speed from 20 to 42 FPM; 1 HP feed drive. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor with magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit.

EXTREMA - DCY-1220 L3 TYPHOON: Cyclone Filtration Dust Collection System. -- Powerful 2-stage dust collection drops out heavier dust particles through a Rotary Air Lock, allowing you to choose the disposal system before passing finer particles through the fan and filter. -- Air volume rated @ 8,800 CFM. -- Unit includes: 20 HP Motor with a Soft Start already wired in. -- Rotary air lock with: 1 HP Motor @ 38 CFM. -- Low noise operation. -- Standard support frame: LEG 3; 164" clear height x 149" clear width x 91" clear depth. Includes after filter Baghouse DC-327E. Features: 16" Inlet; (3) sections with (9) socks per section. -- Filter Socks: 6" Dia. x 70-7/8" for greater air-to-filter ratio; (1) micron filter. -- Unit is enclosed.

$ 17,999

EXTREMA EXCESS XS-1E37 SINGLE HEAD WIDE BELT SANDER37" Width capacity, 0" to 6" conveyor bed opening. Mono-block construction for solid, vibration free operation and increased durability. -- Equipped with: Combination sanding head with rubber covered contact roll & graphite covered platen. -- Over thickness material feeding safety device. -- Digital material thickness controller setting with LED readout accurate to a thousandths of an inch. -- "Automatic Thickness Setting" device for easy setup. -- OMRON Electronic abrasive belt tracking. -- GOODYEAR Endless conveyor belt with automatic belt tracking. -- 20 HP Main motor. -- REGAL Variable feed speed drive unit; 2 HP motor. -- 1/2 HP Power elevation motor. -- Large cabinet style doors for easy service access. -- Pneumatic abrasive belt tensioning. -- Double infeed & outfeed covered holddown rollers. -- Infeed conveyor extension with safety stop bar, emergency stop button and motor load meter. -- Operations manual & free box of 3M Sanding Belts. -- Optional 460 Volt / 3 Phase.

EXTREMA DCY-1000 TYPHOON Cyclone Dust Collector. Cyclone & fabric filtration Dust Collection System. -- Powerful 2-stage dust collection drops out heavier dust particles through a 1/2 HP Rotary Air Lock with 10 CFM capacity, allowing you to choose the disposal system, before passing finer particles through the fan and filter. -- (2) Fabric filter bags placed above plastic collection bags; air volume output rated @ 6,400 CFM. -- Equipped with: 10 HP Induction motor, 16" steel blower fan impeller and is dynamically balanced and 12" inlet. -- Includes: Collection bag snap-in ring for easy addition or removal of plastic bag; filter bags filter dust particles down to (1) Micron in size; low noise operation. -- Supplied with: Heavy Duty support frame to allow usage with a waste hopper under the Cyclone.

EXTREMA DC-203.1 TYPHOON Cyclone & Fabric Filtration Dust Collection System. -- Powerful two-stage dust collection drops out heavier dust particles into a drum before passing finer particles through the fan and filter. -- (1) Fabric filter bag placed above plastic collection bag. -- 1,785 CFM Output. -- 3 HP Induction motor. -- 13" Steel blower fan impellers are dynamically balanced. -- Collection bag snap-in ring for easy addition or removal of plastic bag. -- Filter bag filters dust particles down to (1) Micron in size. -- Low noise operation. -- Includes: Sturdy steel tripod cyclone mounting stand and drum dollies (drum not included.)

.gif)