Equipment For Sale

10047 Results Found

CAM-WOOD - XL 300, ...Dip Chain Gang Rip Saw: Short Stock version12" Width cap.; 3/8" min. to 3-3/4"; max. cutting depth; 7" min. stock length.Specifications: -- 70 mm Dia. saw sleeve (one is included) with (2) keyways and the following spacers: (4) 15 mm, (4) 10 mm, (18) 1 mm, (10) 0.5 mm, and (8) 0.25 mm (see drawing after the "literature link); with 12"; usable cutting width. -- Accepts saw blades from 10"; - 12"; dia.; arbor is powered by a 40 HP motor driving the spindle at 3,200 RPM. -- Feed chain is powered by a 2 HP motor with variable chain speeds from 30 - 100 FPM; feed chain is 12"; wide. -- Table: 28"; Wide x 67"; with 12"; between the column and the 1st saw blade. - Integrated 6"; dia. dust extraction connection.General Description: -- Designed for high-quality Production Line use. CAM-WOOD’s Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- Precision fence ensures absolute accuracy between blade & fence; equipped with: Measuring ruler gauge. -- Triple anti-kickback fingers mounted at the infeed side provide max. safety protection; (2) rows from the top and (1) row from the bottom. -- Heavy-Duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage.Feed System: -- Variable feed speed enables the machines to meet different requirement of work. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain running smoothly. -- Auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil to increase the durability of the machines. Features & Equipped with: -- Precision-built saw head ensures accuracy for straight-line rip saw operations. -- (4) Bearing spindle assembly ensures rigidity & long life. -- Power raise & lower to the arbor. -- (4) Pressure rollers & (2) holddown plates for precise cutting of large and small workpieces. -- 10-Piece V-Belt for max. motor power output and guarantees Heavy-Duty multiple rip cutting. -- The saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue, heat treated, precision ground and balanced providing precise cutting performance. -- Adjustable guide rollers make cutting straight or slight radial rip cuts. They also firmly secure lumber to the feed chain for glue joint work on short parts or longer length boards.

$ 22,990

CAM-WOOD WS-DA2560 Wide Belt Sander, (2) HeadsWith the two-head 25" width capacity wide belt sander, you can accurately, and heavily sand your stock with the first drum head and with the second combination head you can give an unlimited fine finish. -- Rugged heavy-duty sheet metal construction designed for durability usage -- Powerful industrial motors drive sanding and auto infeed smoothly. -- Infeed and outfeed are spring-loaded hold-down rollers to ensure positive feeding without sanding marks. -- Combination platen & drum sanding head for best sanding choice such as: -- With the platen up, the sander functions as a drum-only machine, for sanding with a 40 ~ 100 grit belt. -- With the platen and drum same level, intermediate and final finishing is possible, using a grit of 120 ~ 180. -- With the platen down (below the drum), used for the fine finishing or lacquer sealer sanding, with 180 ~ 600 grit.Head Configuration1st Head : 15 HP Drum2nd Head : 10 HP Combination HeadSpecifications: -- Max. Working Width 25" Max. -- Working Thickness 5" -- Min Working Length 12½" -- Sanding Belt Dimensions (W x L) 25" x 60" -- Dust Collection Hood (Dia x Holes) 5" x 2 -- Main Motor 15, 10 HP; -- Feed Motor 2 HP -- Table Raising / Lowering Motor ½ HP -- Var. Feed Speed (FPM) 20 ~ 80 20 -- Working Air Pressure 6 CFM -- Exhaust Volume Require 1800 CFM -- N.W. 4400 Lbs - G.W. 5000 LbsEquipped with and Features -- Sanding platen with a quick release and lock down design for easy removal or loading of graphite platen. -- Computerized thickness adjustment control with accurate digital readout; key in the size desired and automatic table movement for sanding thickness within 0.005"; accuracy. -- Large-size diameter contact drum is dynamically balanced, rubber-covered spiral grooves designed to provide considerable advantages for the effective removal of material. -- Special rubber feed belt for safe non-slipping, transporting the workpieces. -- The abrasive belts are tracked by oscillating cylinders linked to the upper roller. The edge of the belt is detected by an electric eye sensor, which in turn controls the air supply to the position via solenoid value. Also, one limit switch is located on each end of the top roller of the sandpaper for quick stop in case of belt breakage. -- The main table is designed with a convenient leveling adjustment which ensures greater stability with excellent tolerance providing a variable range from 0"; ~ 5"; sanding thickness. -- (4) Heavy-duty jack screws power conveyor table elevation.

$ 24,990

CAM-WOOD WS-DA3760 Wide Belt Sander, (2) HeadsWith the two-head wide belt sander, you can accurately, and heavily sand your stock with the first drum head, and with the second combination head, you can give an unlimited fine finish.Application: -- Rugged heavy-duty sheet metal construction designed for durability usage. -- Powerful industrial motors drive sanding and auto infeed smoothly. -- Infeed and outfeed have spring-loaded hold-down rollers to ensure positive feeding without sanding marks. -- Combination platen & drum sanding head for best sanding choice such as: --With the platen up, the sander functions as a drum-only machine, for sanding with a 40 ~ 100 grit belt. -- With the platen and drum same level, intermediate and final finishing is possible, using a grit of 120 ~ 180. -- With the platen down (below the drum), used for the fine finishing or lacquer sealer sanding, with 180 ~ 600 grit.Head Configuration:1st Head : 20 HP Drum2nd Head : 15 HP Combination HeadSpecifications: -- Max. Working Width 37" Max. -- Working Thickness 5". -- Min Working Length 12½". -- Sanding Belt Dimensions (W x L) 37" x 60". -- Dust Collection Hood (Dia x Holes) 6" x 2. -- Main Motors 20 and 15 HP. -- Conveyor bed Feed Motor 2 HP. --Table Raising / Lowering Motor 1/2 HP -- Variable Feed Speed 20 - 80 FPM. -- Working Air Pressure 6 CFM. -- Exhaust Volume Require 2,400 CFM. -- N.W. weight 5,100 Lbs.Equipped with and Features: -- Sanding platen with a quick release and lock down design for easy removal or loading of graphite platen. -- Computerized thickness adjustment control with accurate digital readout; key in the size desired and automatic table movement for sanding thickness within 0.005"; accuracy -- Large size diameter contact drum is dynamically balanced, rubber-covered spiral grooves designed to provide considerable advantages for the effective removal of material. -- Special rubber feed belt for safe non-slipping, transporting the workpieces. -- The abrasive belts are tracked by oscillating cylinders linked to the upper roller. The edge of the belt is detected by an electric eye sensor, which in turn controls the air supply to the position via solenoid value. Also, one limit switch is located on each end of the top roller of the sandpaper for quick stop in case of belt breakage. -- The main table is designed with the convenient leveling adjustment which ensures greater stability with excellent tolerance providing a variable from 0"; ~ 5"; range sanding thickness. -- (4) Heavy-duty jackscrews power conveyor table elevation.

$ 10,990

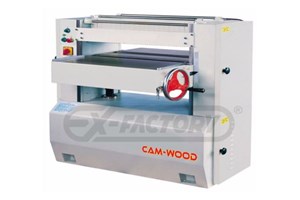

CAM-WOOD WP-2400S SINGLE SIDED PLANER WITH SPIRAL HEADFeatures & Specifications: -- Self-braking motor 5 HP, Magnetic starter & thermal overload switch. -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws, up to 7" opening. -- Scale & pointer readout for accurate thickness adjustments. Spiral Head & Feed: -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers.Complete with: -- Hinged top for easy access to cutterhead & gear assembly. -- Emergency stop. -- Operations manual, parts list & tool kit.1250 lbs

$ 7,990

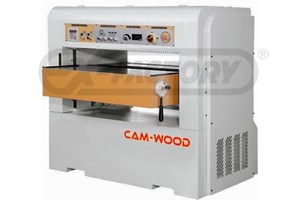

CAM-WOOD WP-2400 Single Sided PlanerFeatures & Specifications: -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- solid steel 3 knife cutter head -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor 5 HP. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit..

$ 39,990

CAM-WOOD WS-DA4375X DUAL HEAD WIDE BELT SANDERWith the two-head wide belt sander, you can accurately, heavily sand your stock with the first drum head, and with the second combination head, you can give an unlimited fine finish.Application: -- Rugged heavy-duty sheet metal construction designed for durability usage. -- Powerful industrial motors drive sanding and auto infeed smoothly. -- Infeed and outfeed have spring-loaded hold-down rollers to ensure positive feeding without sanding marks. -- Combination platen & drum sanding head for best sanding choice such as: --With the platen up, the sander functions as a drum only machine, for sanding with a 40 ~ 100 grit belt. -- With the platen and drum same level, intermediate and final finishing is possible, using a grit of 120 ~ 180. -- With the platen down (below drum), used for the fine finishing or lacquer sealer sanding, with 180 ~ 600 grit.Head Configuration:1st Head : 30 HP Drum2nd Head : 20 HP Combination HeadSpecifications: -- Max. Working Width 43" Max. -- Max. Working Thickness 5". -- Min Working Length 12½". -- Sanding Belt Dimensions (W x L) 43" x 75". -- Dust Collection Hood (Dia x Holes) 6" x 2. -- Main Motors 30 and 20 HP. -- Conveyor bed Feed Motor 3 HP. --Table Raising / Lowering Motor 1/2 HP -- Variable Feed Speed 20 - 80 FPM. -- Working Air Pressure 6 CFM. -- Exhaust Volume Require 3,800 CFM. -- N.W. weight 6,160 Lbs.Equipped with and Features: -- Sanding platen with a quick release and lock down design for easy removal or loading of graphite platen. -- Computerized thickness adjustment control with accurate digital readout; key in the size desired and automatic table movement for sanding thickness within 0.005"; accuracy -- Large size diameter contact drum is dynamically balanced, rubber covered spiral grooves designed to provide considerable advantages for the effective removal of material. -- Special rubber feed belt for safe non-slipping, transporting the workpieces. -- The abrasive belts are tracked by oscillating cylinders linked to the upper roller. The edge of the belt is detected by an electric eye sensor, which in turn controls the air supply to the position via solenoid value. Also, one limit switch is located on each end of the top roller of the sandpaper for quick stop in case of belt breakage. -- Main table designed with the convenient leveling adjustment which ensures greater stability with excellent tolerance providing a variable from 0"; ~ 5"; range sanding thickness. -- (4) Heavy-duty jackscrews power conveyor table elevation.

$ 35,990

CAM-WOOD WS-M1000 NAX Planer Sander -- 2 Heads with 39.4" width capacity planer head and combination sanding headFeatures: -- This machine is especially designed for tale off heavy materials such as glue panel, bend board, rough lumber. -- The first head is a knife planer head, with 25 HP motor. The spiral planer cutterhead is fitted with 14 x 14 mm, four edge throw away Tungsten Carbide knife inserts, providing superior chip removal rate, minimum noise, and extremely smooth cutting effect. Changing knife inserts are conveniently done without removing the cutterhead. -- The second head is a combination of drum and platen driven by a 20 HP motor, belt size 40.5" x 78 3/4". (1030mm X 2000 mm) -- Anti-kickback fingers, mounted at the infeed of the machine, this anti-kickback finger gives a safety guard for the operator. -- Insufficient pressure protection, in case insufficient working air pressure occurs, the machine brakes automatically for safety guard.Irreversible running of pressure roller, runs a single direction only, giving an additional safety guard for panel kickback. -- Motorized elevation of conveyor table (micro-computer controlled with digital readout), it accurately displays the position of the conveyor table and automatically moves to the setting thickness for planning, sanding. -- Panel cleaning brush roller; built at outfeed end of the machine, this cleaning brush roller cleans the powder on the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Technical Specification: -- Working width 39.4" (1000 mm). -- Working thickness up to 6 1/4". -- Minimum working length 21". -- Feed speed 10 to 90 FPM inverted driven by 3 HP motor. -- Table raised and lowered by 1/2 HP motor. -- Cleaning brush driven by 1/2 HP

$ 35,990

CAM-WOOD WS-MN700NAX Planer/Sander Equipped with: -- (2) Heads with 27" width capacity planer head and combination sanding head -- This machine is specially designed for take-off heavy materials such as glued-up panels, bend boards, and rough lumber. -- The first head is a knife planer head, with 20 HP motor. The spiral planer cutterhead is fitted with 14 x 14 MM, four edge throw away Tungsten Carbide knife inserts, providing superior chip removal rate, minimum noise, and extremely smooth cutting effect. Changing knife inserts are conveniently done without removing the cutterhead. -- The second head is a combination of drum and platen driven by a 20 HP motor, belt size 28 3/4" X 75" -- Anti-kickback fingers, mounted at the infeed of the machine, these anti-kickback fingers provide a safety guard for the operator.Features: -- Insufficient pressure protection, in case insufficient working air pressure occurs, the machine brakes automatically for safety guard.Irreversible running of pressure roller, runs a single direction only, giving an additional safety guard for panel kickback. -- Motorized elevation of conveyor table (micro-computer controlled with digital readout), it accurately displays the position of the conveyor table and automatically moves to the setting thickness for planning, sanding. -- Panel cleaning brush roller; built-in at the outfeed end of the machine, the cleaning brush roller cleans the fine sanding dust off the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Technical Specification: -- Working width 27" -- Working thickness up to 6 1/4" -- Minimum working length 20" -- Feed speed 20 to 90 FPM inverted driven by 3 HP motor -- Table raised and lowered by 1/2 HP motor -- Cleaning brush driven by 1/2 HP

$ 198,900

CAM-WOOD WP-16L- V5HX 4 Sided 5 Heads High Speed Planer Designed for furniture, cabinet, flooring, intermittent planning mill work, and other industrial uses. Perfect Planer for S2S and S4S planning, tongue & groove flooring, wall paneling, etc. up to approximately 180 FPM depending on depth of cuts and dimensions of partsSpecifications: -- Width: ¾"; to 16"; -- Height: 3/8"; to 4"; -- Length: Maximum Unlimited, Minimum 70";. -- Maximum Cutting Depth; 8 mm -- Feed Rate 40 to 180 fpmFeatures:Horizontal Top & Bottom with Slip-On Spiral Head or Optional Profile cutter head, Tooling Information. -- Standard supply with Slip-On HAR Series Profile / Spiral Cutter head, Profile Knives combined with Carbide Insert 15 x 15 x 2,5 mm. Max depth of cut 8 mm each side (Standard 7"; O.D. Shaft 46 mm): Vertical with Helical or Optional Profile cutter heads -- Left & Right Side/ Standard HAR Series Vertical profile heads. -- Max depth of cut 8mm, 7"; OD, Spindle arbor diameter: 40 mm, -- Left & Right-side Heads can be profile work with owner provided tooling. Fifth head for moulding or sawing -- 15 HP Top Saw Head, raise/lower power digital by HMIQuality Features: -- Simple touch screen with Digital Positioning Controllers for width, thickness adjustment and variable feed speed. -- Hard Chrome plated table for long life -- Automatic top spindle – cutter head height adjustments entered via HMI touch screen control with PLC. -- Floating bottom infeed rolls for smooth, positive feeding -- Variable feed speeds by VFD. Controlled from touch screen. -- Heavy-duty spindle assemblies for durability & smooth finishes. -- Overhead assembly travels up/down and positions via touch screen control, Assembly is support by (4) hard chromed, polished posts and precision screws. -- Tables, fences, etc. are precision ground, polished and hard chromed to provide long life and smooth feeding. -- Massive, heavy-duty sheet metal frame for vibration absorbing finishes and extra-long bearing life. Compact construction with exclusive see-through top guard. -- Motor Control Center with under voltage and overload protection. UL and CSA labeled electric components.Motor Sizes and Feed Works: -- Top and Bottom Cutter Heads Motors each: 30 HP, 5,000 RPM -- Right & Left Side Cutter Motors each: 25 HP, 5,000 RPM -- Second top head for Top saw head, raised and lowered motorized digitally by HMI, drive motor 15 HP -- Variable Feed speeds from 40 to 180 FPM by VFD (invertor) -- Feed is powered by (2) each 5 HP VFD feed motors, (1) motor drives the top infeed and (1) Motor drives the top outfeed feed rolls. Top powered feed rolls are air cylinder loaded / Floating. (4) idle bottom infeed feed rolls and (4) idle bottom outfeed rolls.Overall dimensions: 167" X 71" X 73".

$ 8,389

CAM-WOOD WP-2000S Single Sided Planer20" Planer with solid cast iron construction and Spiral Cutter Head.Features & Specifications: -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- Fixed feed (30 FPM) speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- 3 HP Self-braking motor. -- Magnetic starter & thermal overload switch and Emergency stop. -- Operations manual, parts list & tool kit. Optional: CT-SCH-14T - 14 mm x 14 mm SPIRAL CUTTERHEAD BLADES ...$3.30 each

$ 59,900

CAM-WOOD WP-20L8-V4X, 20"; WIDE X 5" HIGH 4-SIDED PLANER/MOULDER, (8" Optional)Planer or Combination Planer/Ripsaw is designed for furniture, cabinet, flooring, intermittent planing millwork, and other industrial applications. The perfect Planer for S2S and S4S planing, planing and ripping, tongue & groove flooring, wall paneling, etc. up to approximately 75 FPM depending on the depth of cuts and dimensions of parts.Working Capacities: -- Width: 3/4"; to 20";. -- Height: 3/8"; to 5", (8"; optional additional $4,900). -- Length: 20"; Minimum, Maximum Unlimited. -- Maximum Cutting Depth: Top & Bottom Heads 1/2";, Side Heads 1";. Included Tooling Is Slip-On Spiral or Profile Cutterheads: -- Standard with Slip-On HAR Series Profile / Spiral Cutter head. Profile Knives combined with 15 x 15 mm x 3° Carbide Insert knives. 1/2"; Max depth of cut. The top and Bottom spindles are 60 mm (2.36";) in diameter. Optional Profile Cutterheads Available. -- Left & Right-Side Spindles with Standard HAR Series Profile Heads. -- Max depth of cut 1";. With 40 mm (1.57";) Spindle Diameter. Cutting Circle from 6" to 7";. -- Left & Right-Side Heads will run profiles with owner-provided tooling. Quality Features = Long and Outstanding Performance -- Simple touch screen with Digital Positioning Controllers for width adjustment, thickness adjustment and variable feed speed. -- Hard Chrome Plated Table for long life and smooth feeding. -- Automatic Top Head Adjustment – cutter head height adjustment entered via HMI touch screen control with PLC. -- Floating Bottom Infeed Rolls for smooth, positive feeding. -- Variable Feed Speeds by VFD Controlled from Touch Screen. -- Heavy-duty Spindle Assemblies for durability & smooth finishes. -- Overhead assembly travels up/down and positions via touch screen control. Assembly is support by (4) hard chromed, polished posts and precision screws. -- Tables, fences, etc. are precision ground, polished and hard chromed to provide long life and smooth feeding. -- Massive, heavy-duty sheet metal frame aids in vibration absorbing finishes and extra-long bearing life. Compact construction with exclusive see-through top guard. -- Motor Control Center with under voltage and overload protection. UL and CSA labeled electric components. Motors and Feed Works: -- Top and Bottom Cutter Heads Motors, each: 15 HP, 5,000 RPM. -- Right & Left Side Cutter Motors, each: 10 HP, 5,000 RPM. -- Variable Feed Speeds from 20 to 65 FPM by VFD (invertor). -- Feed is powered by (2) each 2 HP VFD feed motors. -- (1) motor drives the top infeed and (1) Motor drives the top outfeed feed rolls. Top-powered feed rolls are air cylinder loaded / floating. -- (8) non-powered bottom rolls, (4) infeed and (4) outfeed.Machine Sizes / Dimensions and Weight: -- 76"; Length x 52"; Width x 71"; Height. -- Weight 4,920 LbsOptional Equipment: -- Type MP Carbide Side Head Tooling for profile work. Price on request. -- With a 20" spindle length -- 40 mm arbor diameter

$ 194,900

CAM-WOOD WP-4 S2C-500-16 4-SIDED PLANEROutstanding Performance - Quality Components -- Floating bottom infeed rolls for smooth, positive feeding -- PLC controls with touch-screen interface for ease of operation -- Variable feed speeds by VFD. Controlled from touch screen -- Drive shaft and universal joint feed roll transmission for each feed roll -- Power elevation of overhead mechanism via touch screen control -- Thickness settings from touch screen control -- With cutterheads and carbide knives for straight knife work -- With spindles for easing top edges -- Tables, fences, etc. are precision ground and hard chromed to provide long life and smooth feeding -- Overhead mechanism travels up/down and is support by (6) hard chromed posts -- Motor Control Center with under voltage and overload protection; includes UL and CSA approved electrical componentsWorking Capacities: -- 19 3/4" wide x 16"; high -- Min. thickness: 3/4"; -- Min. width 4-3/4"; -- Max. depth of cut: 1/4"; all heads -- Max. length: Unlimited -- Min. length: 70"; for feed-thru; butt-feed down to 40". (40"; to 70"; may have minor inaccuracies at edge due the hold-down restrictions) -- Feed speeds from 20 to 65 FPMCutterhead Motors: -- 25 HP Top and Bottom (see optional equipment for larger motors) -- 20 HP Right & Left Side Heads (see optional equipment for larger motors) -- Includes Right & Left Spindles for eased edge at top of board; consists of (2) 1 HP floating spindles to accurately ease top edges. Profile knives in primary side heads ease bottom edges.Feed Works: -- (2) 5 HP VFD’s -- (1) motor drives top set and (1) motor drives the bottom set of feed rolls -- Boards synchronize top and bottom feed roll speed and torque Cutterheads and Spindles: -- Top and bottom spindles with 60mm (2.362";) spindle dia. Other diameters on request. -- Includes a set of (2) 4-knife x 25-1/2"; long x 5-1/2"; dia. spiral carbide cutterheads. -- Side heads with 1-1/4" spindle dia. Other diameters on request -- Includes a set of (2) 4-knife x 20"; long spiral carbide heads -- Includes (1) set per head: 15 x 15 x 3mm carbide knives with (4) cutting edges -- All spindles with hydro-lock outboard bearings -- Left & Right Side Heads can be used for profile work with owner provided tooling -- Eased Edge Spindles: 1-1/4"; dia. -- Eased Edge Cutting Circle: 4.9";Dust hoods: -- 8"; dia top and bottom head hoods; 6"; dia. side head hoodsOptional Equipment: -- Optional HP on Top & Bottom Heads, up to 40 HP, -- Optional HP on Right & Left, up to 30 HP, -- Electric Brakes for side spindles, -- Power raise/lower and auto-setting for side spindles, Machine Dimensions and Weight: -- 10’ long x 7-1/2’ wide x 6-1/2’ high x 20,000 Lbs.

$ 199,900

CAM-WOOD WP-4S-500-2C 4-SIDED, 19-5/8" WIDE X UP TO 20" HIGH PLANER SPECIFICATIONS FOR 6"; X 19-5/8"; HEAVY-DUTY PLANER: -- Width Capacity from 2-3/4" to 19-5/8" -- Thickness Capacity from 3/4" to 6"; (see options for taller side spindles) -- Variable Feed Speeds from 18 to 75 FPM (higher on request) -- 25 HP Top and Bottom Spindle Motors -- 20 HP Left and Right Vertical Spindle Motors -- (2) 1/2 HP Left & Right Chamfer Motor -- (2) 7-1/2 HP Feed Motors -- Belt-driven, high speed, 7,000 RPM spindle speeds. -- TEFC motors with sealed-for-life ball bearings provide accurate, vibration-free spindle vibration. -- Top & Bottom Cutterhead Dia. 5" -- Right & Left Cutterhead Dia. 5" or 6" -- Top & Bottom Spindle Dia. 60 mm -- Right & Left Spindle Dia. 40 mm (1-13/16" available) -- Chamfer Spindle Dia. 30 mm -- Insert Cutter Size 15 x 15 x 2.5 mm -- (4) 6" Diameter Dust Hood -- Machine Size 110" x 86" x 94" x net 15,200 Lbs. Additional Equipment and Options: -- Right side fixed fence (no charge) -- Change side head spindle rotation to rotate with the direction of feed (no charge) -- 1-13/16" side spindle dia. (no charge) -- Top & bottom spindle rotation against the direction of feed (standard) -- Wired for 480-Volt operation (no charge). -- Pair Auto-Set and Power Raise/Lower of right and left side spindles (included). -- Pair Spindle Brake on right and left side spindles (included). -- 12"; High side spindle with outboard bearing, add $19,000 -- 16"; high side spindle with outboard bearing, add $25,500 -- 20"; high side spindle with outboard bearing, add 30,700. FEATURES: -- Compact construction, huge moulding or planing capacity, extremely flexible and high-performance design. -- Digital controller automatically sets thickness & width adjustment -- Rigidly mounted alloy steel spindles with outboard bearing support provide accurate vibration-free power transfer. -- Spindle height adjustment by precision rack & gear sets -- Beds and fences are precision ground then chrome-plated and polished to a smooth mirror finish. The wear resistant surfaces are easy to clean and maintain -- Variable speed invertor controls for smooth adjustment of feed rate depending on the material hardness, depth of cut & width will provide the best finish surface and fast cutting performance -- The floating powered feed rollers are driven by geared transmission boxes linked to the feed rolls by heavy-duty universal joint axels while firmly holding stock securely to the bed; feeds positively to provide a smooth, even feed rate during rough or finish planning -- The heavy-duty welded and heat treated steel frame supports the beds and helps dampen vibration while safeguarding future years of dependable service -- Industrial rated motors for maximum stock removal and feed rates -- Precision sealed, long-life bearings throughout -- Removable cutter heads are designed for convenient knife changing even on the on the bottom cutterhead -- Changing

$ 62,900

CAM-WOOD WS-NDA 1300 3-Head Planer Sander[Equipped with Planer, Drum and combi head]Features: -- This machine is especially designed for removing heavy material such as glued-up panels, bent boards, and rough lumber. -- The first station is a knife planer head, followed by a combi head with drum and platen at the second station and a finishing platen head at the third station. -- Head configuration can be made to meet customer’s requirements. -- The spiral planer cutter head is fitted with 14 x 14 MM, four-edge throwaway Tungsten Carbide knife inserts, providing a superior chip removal rate, minimum noise, and an extremely smooth cutting effect. -- Changing knife inserts is convenient without removing the cutter head. The spiral cutter head is precision machined from special aluminum alloy steel, tempered, and precision ground by a CNC machine center. -- Anti-kickback fingers, mounted at the infeed of the machine, this anti-kickback finger gives a safety guard for the operator. -- Insufficient pressure protection: If inadequate working air pressure occurs, the machine brakes automatically for safety guard. -- The irreversible running of the pressure roller runs in a single direction only, giving an additional safety guard for panel kickback. -- Automatic elevation of conveyor table (micro-computer controlled with digital readout): it accurately displays the position of the conveyor table. It automatically moves to the setting thickness for planning and sanding. -- Panel cleaning brush roller: built at the outfeed end of the machine, this cleaning brush roller cleans the powder on the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Specifications: -- First head Planer with 40 HP motor -- Second head combi drum & platen with 30 HP motor -- Third head finishing platen with 30 HP motor -- Panel cleaning brush at outfeed with 1/2 HP motor -- Working width: 52" -- Working thickness up to 6 1/4" -- Minimum working length: 21" -- Feed speed 10 FPM to 90FPM inverted driven by 5.5 HP motor -- Table hoist motor 1 HP -- Sanding belt size 52" X 75" -- Floor space requirement: 107" X 103" X 80", weight 12,300 Lbs

$ 39,990

CAM-WOOD WP-1010H 40"; Heavy Duty Planer with S.C.H.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- Maximum thickness capacity 8" -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planing with low noise levels. -- With (4) each 4" diameter dust outlets -- 20 HP Main drive motor. -- 3 HP Variable feed speed 10 to 50 FPM. -- Maximum depth of cut 1/4". -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 40" -- Max. Cut Thickness 8" -- Max. Cut Depth ¼" -- Min. Cut Length 9" -- Cutting Speed 3600 RPM -- Table Size (W x L) 43" x 55" -- Main Motor 20 HP, 3 Ph -- Feed Motor 3 HP -- Table Raising Motor 1 HP -- Feed Rate (Variable) FPM 10 ~ 50 -- Net Weight 4,750 Lbs -- Shipping weight 5,500 LbsFOR UPGRADE TO 25 HP ADD ...$900.00

$ 45,139

CAM-WOOD WP-1400H 52"; Heavy Duty Planer with S.C.H.55" Cap. solid cast iron construction planer with powerful 25 HP motor.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering, manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planning with low noise levels. -- With (4) each 4" diameter dust outlets. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 52". -- Max. Cut Thickness 8". -- Max. Cut Depth ¼". -- Min. Cut Length 9". -- Cutting Speed 3,600 RPM. -- Table Size (W x L) 55" x 55". -- Main Motor 25 HP, 3 Ph. -- Feed Motor 5 HP. -- Table Raising Motor 1 HP. -- Feed Rate (Variable) 0 ~ 50 FPM. -- Shipping weight 7,400 Lbs.

CAM-WOOD - XL 300, ...Dip Chain Gang Rip Saw: (...Typically in stock for immediate delivery!)12" Width cap.; 3/8" min. to 4-3/4"; max. cutting depth; 14"; min. stock length.Specifications: -- 70 mm Dia. saw sleeve (one is included) with (2) keyways and the following spacers: (4) 15 mm, (4) 10 mm, (18) 1 mm, (10) 0.5 mm, and (8) 0.25 mm (see drawing after the "literature link); with 12"; usable cutting width. -- Accepts saw blades from 12"; - 14"; dia.; arbor is powered by a 50 HP motor driving the spindle at 3,200 RPM. -- Feed chain is powered by a 2 HP motor with variable chain speeds from 30 - 100 FPM; feed chain is 12"; wide. -- Table: 30"; Wide x 62"; with 12"; between the column and the 1st saw blade. - Integrated 6"; dia. dust extraction connection.General Description: -- Designed for high quality Production Line use. CAM-WOOD’s Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- Precision fence ensures absolute accuracy between blade & fence; equipped with: Measuring ruler gauge. -- Triple anti-kickback fingers mounted at the infeed side provide max. safety protection; (2) rows from the top and (1) row from the bottom. -- Heavy-Duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage.Feed System: -- Variable feed speed enables the machines to meet different requirement of work. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain running smoothly. -- Auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil to increase the durability of the machines. Features & Equipped with: -- Precision-built saw head ensures accuracy for straight line rip saw operations. -- (4) Bearing spindle assembly ensures rigidity & long life. -- Power raise & lower to the arbor. -- (4) Pressure rollers & (2) hold-down plates for precise cutting of large and small workpieces. -- 10-Piece V-Belt for max. motor power output and guarantees Heavy-Duty multiple rip cutting. -- The saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue, heat treated, precision ground, and balanced, providing precise cutting performance. -- Adjustable guide rollers make cutting straight or slight radial rip cuts. They also firmly secure lumber to the feed chain for glue joint work on short parts or longer length boards. Options when ordering with machine: -- (1) Set spare feed chain link, please add ...$ 96. -- (1) Set of arbor drive belts consisting of (6) matched belts, add ...$680. -- Additional saw sleeve with spacer set consisting of: (2) 50 mm, (3) 25 mm, (4) 10 mm, (18) 1 MM, (10) 0.5 mm, (8) 0.25 mm, Please add... $745

CAM-WOOD XL300/5116 DIP CHAIN GANG RIPSAW12" Width cap.; 5-5/8"; max. cutting depth; 14"; min. stock length; Designed to meet the exacting standards required for high quality production line use. CAM-WOOD’s Rip Saws are manufactured to precise tolerances, and feature the newest designs for operator safety and volume productionSpecifications: -- Accepts saw blades from 12"; to 16"; diameter. -- Arbor is 70mm dia. with (2) keyways -- Saw arbor is powered by a 60 HP motor driving the spindle at 3,200 RPM; Soft start starters and low voltage controls are standard equipment. -- Feed chain is powered by a 2 HP motor with variable chain speeds from 8 to 80 FPM; feed chain is 12"; wide -- Table is 28"; wide x 67"; and 12"; between the column and the 1st saw blade. -- (2) Integrated 6"; dia. dust extraction connections.Complete With: -- (1) 70 mm ID saw sleeve with (2) keyways and the following spacers: (4) 15 mm, (4) 10 mm, (18) 1 mm, (10) 0.5 mm, and (8) 0,25 mm (see drawing after the "literature link). -- Two (2) rows of anti-kickback fingers mounted on the top and one (1) row from the bottom (total 3 rows) provides maximum safety protection. Equipped with: -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Power raise and lower to the arbor. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frame for durability usage. -- Variable feed speeds enables the machine to meet different work requirements. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain longevity smoothness -- Automatic chain lubrication device equipped with an alarm that sends signals upon a lack of lubrication oil. Features: -- Precision built saw head ensures accuracy for straight line rip saw operations. -- Four (4) bearing spindle ensures rigidity & long life. -- Saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue; spindle is heat treated, precision ground and balanced to provide the utmost in precision cutting performance -- Four (4) pressure rollers & two (2) hold-down plates for precise cutting of large and small workpieces. -- Ten (10) groove pulley and V-Belt arrangement ensures maximum motor output, excellent HP delivery to the saw spindle, and guarantees proper power transmission for heavy-duty multiple rip cutting. -- Adjustable guide rollers make cutting straight for slight radials material; they also secure glue joint at short pieces or long stacks.Options when ordered with machine: -- Additional saw sleeves (sleeve only), each, $415 -- Additional saw with spacer set consisting of: -- (2) 50 mm -- (3) 25 mm -- (4) 10 MM, -- (18) 1 MM -- (10) 0.5 MM -- (8) 0.25 MM -- Add per Sleeve with Spacer Set, $795 -- Laser Light with Mounting Bracket, each $1,190 -- Power raise & lower of the hold-down system when ordered with

$ 160,545

CAM-WOOD MODEL PL-52 SHX TOP AND BOTTOM SURFACERSpecifications: -- 52"; Maximum Working Width -- 12-1/4"; Maximum Working Thickness -- 1/2"; Minimum Working Thickness (3/8" on request) -- 1/2"; Max. Depth of cut (Per Side) -- 4,000 RPM Cutter Head Speed -- 6-1/4"; Cutter Head Diameter -- 15 x 15 x 2.5 mm Spiral Cutter Head Carbide Insert Knives -- 40 HP Top Cutter Head Motor -- 30 HP Bottom Cutter Head Motor -- 2 HP Elevation Motor -- Feed Speed (Variable by Invertor drive) from 12 to 55 FPM -- 5-3/4 Feed Roll Diameter -- (2) 5 HP Feed Motors -- Machine Weight, 15,700 Lbs -- Machine Size (L x W x H) 81" x 112" x 63" Features: -- Roll feed eliminates slipping when running green and heavy wood. -- Universal Jointed Shaft Feed Rolls to ensure adequate feeding power for wet, rough lumber as well as warped, cupped and bowed material for heavy cutting depths -- Top and bottom feed rolls are directly driven by universal joints and drive shafts for full-power transmission. -- Movable control box provides additional convenience in operation and setup. -- Standard equipment includes automatic thickness control to aid in easy and quick setting for the thickness to be planned. -- Worktable surface is precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear-resistant surface is easy to clean and maintain and promotes good feeding of all types of wood. -- Stepless variable speed control for smooth adjustment of feed rate depending on the material hardness, depth of cut & width. Used to provide the best finish surface and fast feed performance. -- A twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload. -- Heavy, rigid cast iron frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial-duty motors for maximum power transmission. -- All precision sealed, long-life bearings for durability. -- A swivel stand is designed for convenient knife changing on the bottom cutterhead. -- Setup time is minimized to set cutterhead height using the auto material thickness device. -- The top and bottom cutterheads are precision balanced to provide consistently smooth, chatter-free planing regardless of the feed rate or hardness of material being planed.

$ 64,500

CAM-WOOD INFEED AND OUTFEED PLANER TRANSFER LINE: 20"; Wide X 20’ Long Roller Conveyors with 6,000 lbs capacity and Consisting of the following: NON POWERED IDLE INFEED RIGHT ANGLE ROLLER TRANSFER CONVEYORS -- (4) Conveyor Sections, each 14"; Wide X 8’ Long (SEE DRAWING). -- 2-11/64"; Roller Diameter -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 6,000 lbsPOWERED INFEED CANTED ROLLER CONVEYOR -- With VFD Drive with speed feed 18' to 70 FPM -- 22"; Wide X 20’ Long -- Heavy Duty 3-11/32"; Roll Diameter -- (9) Rolls on 36"; Centers -- (5) Pneumatic jumped transfer roll -- Back Side Adjustable FencePOWERED OUTFEED STRAIGHT ROLLER CONVEYOR -- With VFD Drive with speed feed 18' to 70 FPM -- 22"; Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32"; Roll Diameter -- Rolls on 36"; Centers -- Includes (4) Sections of Pneumatically Jumped Skate Rolls -- Heavy Duty Type, Sections are 6"; Wide X 20"; Long NON POWERED IDLE OUTFEED RIGHT ANGLE TRANSFER ROLLER CONVEYORS (SEE DRAWING) -- (4) Conveyor Sections, each 14"; Wide X 8’ Long. -- 2-11/64"; Roller Diameter. -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 6,000 Lbs.

.gif)