Equipment For Sale

10023 Results Found

$ 8,750

ROBINSON - EF/T, ...36" Band Resaw Solid Heavy-Duty Vertical Resaw. Equipped with: -- 3-Phase Electric Motor. -- 36" Dia. balanced steel wheels. -- 4" Max. band width capability provides feed speeds up to 100 FPM. Complete with: -- Large work surface for the most demanding jobs

$ 4,900

Robinson Hurricane Chop Saw 18" 5 HP 3 phase 208-230/460 volt Right to left hand Pneumatic pedal control

137.5" WIDE 4 YARD CAPACITY FOR CATERPILLAR 980M FOR CATERPILLAR 980M PIN ON LUGGING ROCKLAND ROCK BUCKET SOLD AS IS

2 TINE DESIGN 74" TOTAL TIP RADIUS FOR USE WITH Pin Lock/Wain Roy 36"dig bucket 550-9703 INCLUDES CONNECTING LINES INCLUDES HYRAULIC CYLINDER INCLUDES MOUNTING BRACKET ROCKLAND HYDRAULIC UTILITY THUMB ROCKLAND PART NUMBER BTH-B-61-F SOLD AS IS Thumb for use with Pin Lock/Wain Roy Style tilting coupler 514-9167/6199323/6199321

CONNECTING LINES NOT INCLUDED FOR USE WITH CATERPILLAR M318F INCLUDES HYRAULIC CYLINDER INCLUDES MOUNTING BRACKET ROCKLAND HYDRAULIC UTILITY THUMB SOLD AS IS

$ 6,500

Rockland 7 CU YD loader bucket, very good condition, fits to loaders using a JRB 418 coupler. Price Reduced! $6,500 330-440-3312 OH

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i5w 2 HP Motor, belt driven to saw arbor, 10" blade cap., 5/8" dia. tilting arbor, tilts 0° - 45°; 36" x 27" table. 18" left of the blade. Complete with: 2-3/4" x 33" Rip Fence with approx. 25" travel. NOTE: The above specs are taken from literature and considered accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

$ 1,750

ROCKWELL/DELTA 16-RAS, 16" Radial Arm SawSpecifications: -- Blade dia. 16";; base size 37" x 37 x 31"; H; approx. 18" crosscut cap.; approx. 42"; out & 26"; rip cap.Equipped with: -- 5 HP - 3,450 RPM Motor; 34-1/2" table height sitting on mobile base; 32-1/2" without.

Call for Price

For dumping (1) load of fingerjoint blocks at a time. Hoist is fabricated from steel tubing with a box cradle that pivots at the top. -- 3-Sided cradle will hold the box, pallet, OR unit when it is pivoted up to 135° to the final dumping position; cradle opening is 88" long X 48" wide X 50" high . -- A pair of replaceable forks hold pallets in place in the cradle. The cradle is pivoted by a hydraulic cylinder driven by a 3 HP hydraulic pump. The hydraulic cylinder is manually energized by the fingerjointer operator with foot switches. -- Scope of supply includes all mechanical equipment, electric powered hydraulic pump, and two foot switches. All wiring by others.

ROSE BPUDH BOX, PALLET & UNIT DUMPING HOISTDescription: --Box, Pallet & Unit Dumping Hoist, for dumping one load at a time. --The hoist will be fabricated from steel tubing with a box cradle that pivots at the top. The three sided cradle will hold the box, pallet, or unit when it is pivoted up 135 degrees to the final dumping position. --A pair of replaceable forks hold pallets in place in the cradle. --The cradle will be pivoted by a hydraulic cylinder driven by a 3 HP hydraulic pump. The hydraulic cylinder is manually energized by the operator with foot switches. --Manufacture will supply all mechanical equipment, electric powered hydraulic pump, and two foot switches. --Cradle opening is: 168";L x 60";W x 60";H.Payment Terms: --50% with order, 40% prior to shipment, and the balance 10% net 30 days after receipt of equipment. Delivery is subject to the order file at the time the order is placed.Lead Time: --Delivery can be made in 12 weeks ARO at this time.Conditions: --The fabricated frames and appropriate parts of the items in this quotation will be painted with one coat of industrial grade Shady Lane Green enamel. Guards and appropriate moving parts will be painted Safety Orange. All gear-motors, mechanical equipment, limit switches, sensors or photoelectric devices as required for each item of this quotation, will be supplied and mounted. All pneumatic cylinders or other pneumatic power devices and their valves will be supplied and mounted. They will have connecting hoses and fittings installed. Filter/Regulator units will be supplied, mounted and connected by hose to the valves. Compressed air service to equipment is by others.Exclusions: --This proposal describes the machinery to be provided by Rose Machinery Inc. to the Buyer. The equipment supplied by Rose Machinery Inc. is specifically limited to the items actually described in the itemized detail pages of this quotation. Unless specifically mentioned herein, all other items and services are the responsibility of the Buyer. We do not include any state or local sales taxes, or any permit or other fees that may be required. All field wiring, plumbing, and installation is not included. Warranty: --Rose Machinery Inc. d.b.a. Complete Millwright Services, warrants all products of its manufacture to be free of defects in material, and workmanship, for a period of one year from date of shipment. Equipment provided by other manufacturers and incorporated within equipment manufactured by Rose Machinery will be warranted to the extent of the warranty provided by the respective manufacturer. Rose Machinery agrees to repair, or replace, at its option, any component found to be defective provided the purchaser promptly notifies Rose Machinery of the defect. Rose Machinery shall not be liable for incidental or consequential damages arising from said defective material. No other warranty written or implied is offered beyond that stated above unless specifically written and signed by an authorized a

For dumping (1) load at a time. Hoist is fabricated from steel tubing with a box cradle that pivots at the top. The cradle holds the box as it is pivoted up to 135° to the final dumping position. The cradle is pivoted with a hydraulic cylinder driven by a 3 HP hydraulic pump. The cylinder is manually energized via operator foot-switches. -- System includes all mechanical equipment, electric powered hydraulic pump, and (2) foot switches. All wiring and controls by others. ~ Accepts a standard 96" long X 60" wide X 60" high box.

Call for Price

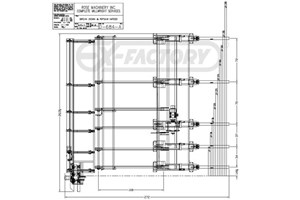

ROSE MACHINERY BDH/LC/LCFT Automated Infeed SystemAutomated, high speed Infeed System for Gang Rip Saws of all makes and models and other similar machines. -- 5-Arm Breakdown Hoist - Electric hoist accepts loads 4' wide x 4' high x 4' - 24' long; 10 HP gear motor (with brake) powers the hoist and holds the load. -- Hoist actuated through foot switches for up & down; limit switches provide max. up & down positions; (5) lifting arms tilt load at 50° allowing layers to spill onto the takeaway conveyor; 16,000 Lbs. max. lift cap. -- Landing Chain - Features: (6) Strands of roller chain; powered by a 5 HP gear motor at 60 FPM nominal rate. -- Tail end constructed with integral slide, stock transits from Breakdown Hoist; head shaft & gear motor supported by tubular steel frame with bolts to allow for leveling at installation. -- Material stops at the head end so the operator can flip & grade each piece. -- Chain races fabricated from steel, UHMW PE wear strips on the top race and on the return race; conveyor is 42' long. -- Magnetic motor starter with foot switch for operator to start & stop of the chain. -- Lateral Chain Feed Table "LCF2013-20": Feeds material 3" - 10" wide x 4' to 24' long x 1" to 3" thick; variable 50 - 200 FPM Feed rate; adjustable fence throughout 3/4" range for alignment with the Rip Saw (or other machines). -- (6) 30" long, low friction steel flattop infeed chains for long life non-marking transport; 1 HP gear motor. -- (3) Powered smooth steel & non-marking feed rolls, 2 HP gear motor; rolls & chains controlled by variable speed drives. -- (3) Overhead pinch rollers, 5" dia., urethane covered; 1st (2) pinch rollers powered by individual 2-1/2" bore air cylinders to singulate pieces onto a 2' bridge; 3rd roller keeps the board moving on the bridge; pinch rolls triggered by photoelectric cells. -- Note: Fabricated frames and appropriate parts of the items in this quotation will be painted with (1) coat of industrial grade Shady Lane Green enamel; guards and appropriate moving parts painted with Safety Orange. -- All gear motors, mechanical equipment, limit switches, sensors or photoelectric devices, as required for each item of this quotation, are supplied and mounted; all pneumatic cylinders or other pneumatic power devices and their valves supplied and mounted; connecting hoses & fittings installed. -- Filter/Regulator units supplied, mounted, and connected by hose to the valves; Note: Compressed air service to equipment is by others.

ROSE GBUB-80 Glue-Bound Unit Breaker. Machine breaks the glue bond in a staggered stack of finger jointed material - see picture of material with the checkerboard end pattern. --Features -- Equalized Hydraulic squeeze, provides uniform load compression. --Hydraulic length change. Air operated Locking Pins on the Backstop Platen. --Backstop platen position indicator. --Simple manual controls for load length adjustment and crushing stroke on the control panel. --Heavy Duty Structural Steel Construction, Ease of Maintenance and Simple Operation (no cables).Does not use cables!Specifications: --Maximum opening is 16’-10"; for a single 4' x 4' x 16' unit. --Backstop Platen locks at 12" increments (2' minimum load length) --Pressure Platen, hydraulic actuated with 18" stroke. --Platen size 5' x 5' --5 HP Hydraulic Unit with a Pressure Compensated Pump (approx. 1 minute squeeze time) --Overall size approximately 5' x 25' x 7' high --480 VAC, 60 hertz, 3 phase, 30 ampsOptions: --10 HP hydraulic unit with approx. 30 second squeeze time, add $4,200 --Double unit capacity; crushes (2) 4' x 4' loads with 5' x 10' platen, add $19,700 --Automated Control Package with 2 Remote Controls for initiation of Pressing Stroke; Automatic open and hydraulic shut down; PLC Controls, automated load length adjustment with lighted indicators, add $ 7,400

Call for Price

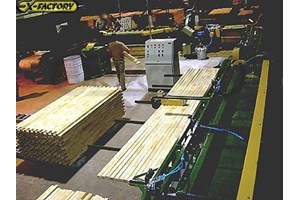

Ripsaw Feeder with 32" wide feed rolls on 18" thru 28" roll centers; will feed 3' thru 16' lumber. With 24" of in-out fence travel; feed speeds from 50 to 150 FPM; 3/4 HP feed roll drive and 3/4 HP fence drive via gear motor with brake. -- Fabricated frame of structural steel with boots that allow +/- 1" elevation adjustment. 3-1/2" dia. steel feed rolls driven by a variable frequency drive for speed adjustment; rolls are canted to aid in holding stock against the fence. -- Powered fence with 24" fence travel is easily shifted via joystick control for stock alignment with the sawblades. -- With pneumatic powered gate to keep material from feeding until the operator initiates the feed sequence. -- Urethane covered idler pinch roll is attached to the fence and is powered down at the start of the feed sequence. When a photocell detects the board is clear of the gate, the pinch roll and gate will return to their normal position. Electrical control panel ready for connection to the power supply.

Call for Price

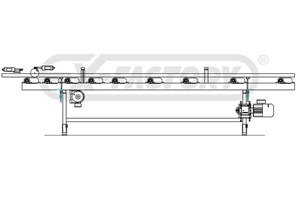

ROSE MACHINERY HBR Horizontal Band RE-RIP SawThe Horizontal Band Re-Rip Saw is an effective and efficient means of ripping short blocks into as many as six (6) set rip widths. Rip widths are easily adjustable, as well as the setting for stock thickness.Advantages of the system: -- Compact, efficient use of floor space. -- Accurate cutting of rips with minimum tear-out. -- Short blocks, 4" minimum length, without taper problems. -- Straight through feed design, good for sorting. -- Minimum dust collection required. -- Single point scrap collection. -- One saw drive motor, requires less power. -- Safety, no kickback problems.Specifications: -- Five (5) rip widths - (6) optional -- 20 HP bandsaw drive -- 30" diameter band wheels, 2" wide face -- (2) 3/4 HP feed works drives -- 1-1/2 HP feed belt drive -- 1" to 6" rip width (independently adjustable in each lane) -- 10" maximum board width at maximum rip -- 4" maximum waste piece width -- 3/4" to 2" stock thickness (all lanes adjust together) -- 4" minimum stock length -- 36" maximum stock length -- 80 FPM feed speed -- 52" to 58" pass line height -- Motor starters and push buttons included, wired for 440 volt, 3 phase, 60 Hz (uses standard mag starters) -- An automatic band lubrication system is includedOptional Equipment: -- For SIX (6) LANES, add ...$5,600 (SORTER increases $3,700) -- Automatic machine grease lubrication system, add ...$ 9,200 -- Ergonomic overhead stock slide, add ...$ 5,600 -- Output conveyor and sorter for 5-LANEsingle side discharge, add ...$47,300 -- Output conveyor and sorter for 6-LANE single side discharge, add ...$51,100 -- Operator's platform, add ...$ 7,900 -- Optional voltage configuration: 220/380/440V, 50HZ, add ...$2,900 -- Start-up and training, add $1,000 per day plus expenses at costHorsepower Requirements: -- (1) @ 20 HP -- (1) @ 1-1/2 HP -- (2) @ 3/4 HPDust Collection: -- (2) outlets, 6" diameter, 5,200 FPM velocity @ 2,300 CFMCompressed Air Required: -- 90 PSI @ 1.4 CFM

.gif)