Equipment For Sale

9573 Results Found

$ 14,950

CAM-WOOD TG-923 1:1 Profile Knife GrinderEconomical model built for shops with 1 or 3 Moulders or a series of Spindle Shapers.Features: -- Work table and cutterhead moves front to back and left and right. -- Table travels on linear bearing with cross roller rail sets. -- Table travel is designed for extreme accuracy. -- Template holder setup is fast and simple for copy tracer. -- Grinding angle is adjusted on dovetail ways. -- Grinding center DOES NOT change with knife angle adjustments. -- Includes stainless steel water splash guard, coolant tank; with pump and filter, easy and efficient to operate. -- Heavy steel cabinet and stand. -- Cast iron Grinder body. -- Built for high precision and durability.Specifications: -- Grinding Capacity: 12"; dia. x 10"; long. -- Grinding Wheel Size: 7.5" dia. with 60 mm bore. -- Grinding Head Travel: 13". -- Grinding Wheel Speed: infinitely variable from 1,500 to 4,500 RPM. -- Grinding Wheel Motor: 2 HP. -- Coolant Pump Motor: 1/8 HP. -- Net Weight: 1,100 Lbs.

CAM-WOOD MRS-340-1M Dip Chain Gang Ripsaw with one Shifting Blade:Specifications: -- Cutting width up to 13";; machine will pass thru 25-1/2"; -- 3"; Maximum depth of cut with 12"; diameter blades. - Will cut 4"; thick with 14"; blades (optional). -- With 70 mm saw spindle; accepts 90 mm bore sawblades -- With air-loaded pressure rolls, standard fence, and feed chain. -- Urethane Chain Pads and Pad Holders optional -- With (1) powered moveable blade and fixed blades. -- Moveable blade controlled with a joystick. -- With (10) push buttons for pre-programmed selective ripping -- The shifting blade moves at 20 to 80 mm/second (up to 3"; per second). -- Moveable saw blade traverses from 0.59" thru 13.38" -- 50 HP Saw arbor motor; -- 3 HP Feed motor with feed speeds from 15 to 130 FPM -- (2) 1/2 HP Lift motors for pressure rolls and saw arborOptional Equipment when ordered with the machine: -- TRS-FT AUTOMATIC INFEED CONVEYOR SYSTEM, with Movable Fence with Digital Display and Shifting Laser Light for Rip Width Setting: .. -- Hydraulic Quick Lock Spindle Assembly. The hydraulic locking spindle assembly is designed to provide for quick changeover between various ripping requirements. Simply turn the locking knob to pressurize the arbor and lock the blades in position. Turn it in the opposite direction to unlock the blades. The sawblades are mounted to solid steel blade collars: ... -- Additional Quick Set Mechanically-Locked Saw Collars for fast, accurate, sure holding of saw blades in any stationary position ... -- 60 HP Saw Arbor Motor: -- Additional 30 MW Laser Unit with Bracket & Wiring: ... -- Pneumatic Pressure to Hold Down Feed Rollers (In lieu of spring pressure). Provides better control of the product being fed. Each pressure roll is controlled by an individual pressure regulator: .. -- Short stock feeding device for 14"; blades (see specifications for cutting capacity information): -- Feed Chain with (69) Easily Replaceable Bolt in Cast Iron Pads. Allows for changing chain pads as they wear or get cut into rather than replacing the complete chain assembly. NOTE: Specially ground down to 0.06"; square tip for optimum hold with virtually no marking: ... -- Feed Chain with (69) Easily Replaceable Urethane Non-Marking Strip Inserts. Urethane is vulcanized to metal backing bars and bolted in place: ... -- 12" Dia. carbide tipped ripsaw blades, cuts up to 3" material: ... -- 14" Dia. carbide tipped ripsaw blades, cut's up to 4" material: ...NOTE: Foot Pedal seen in the photo is only used with a powered Infeed Table and is designed to release boards from the Feed Table.

CAM-WOOD XL300/5116 DIP CHAIN GANG RIPSAW12" Width cap.; 5-5/8"; max. cutting depth; 14"; min. stock length; Designed to meet the exacting standards required for high quality production line use. CAM-WOOD’s Rip Saws are manufactured to precise tolerances, and feature the newest designs for operator safety and volume productionSpecifications: -- Accepts saw blades from 12"; to 16"; diameter. -- Arbor is 70mm dia. with (2) keyways -- Saw arbor is powered by a 60 HP motor driving the spindle at 3,200 RPM; Soft start starters and low voltage controls are standard equipment. -- Feed chain is powered by a 2 HP motor with variable chain speeds from 8 to 80 FPM; feed chain is 12"; wide -- Table is 28"; wide x 67"; and 12"; between the column and the 1st saw blade. -- (2) Integrated 6"; dia. dust extraction connections.Complete With: -- (1) 70 mm ID saw sleeve with (2) keyways and the following spacers: (4) 15 mm, (4) 10 mm, (18) 1 mm, (10) 0.5 mm, and (8) 0,25 mm (see drawing after the "literature link). -- Two (2) rows of anti-kickback fingers mounted on the top and one (1) row from the bottom (total 3 rows) provides maximum safety protection. Equipped with: -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Power raise and lower to the arbor. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frame for durability usage. -- Variable feed speeds enables the machine to meet different work requirements. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain longevity smoothness -- Automatic chain lubrication device equipped with an alarm that sends signals upon a lack of lubrication oil. Features: -- Precision built saw head ensures accuracy for straight line rip saw operations. -- Four (4) bearing spindle ensures rigidity & long life. -- Saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue; spindle is heat treated, precision ground and balanced to provide the utmost in precision cutting performance -- Four (4) pressure rollers & two (2) hold-down plates for precise cutting of large and small workpieces. -- Ten (10) groove pulley and V-Belt arrangement ensures maximum motor output, excellent HP delivery to the saw spindle, and guarantees proper power transmission for heavy-duty multiple rip cutting. -- Adjustable guide rollers make cutting straight for slight radials material; they also secure glue joint at short pieces or long stacks.Options when ordered with machine: -- Additional saw sleeves (sleeve only), each, $415 -- Additional saw with spacer set consisting of: -- (2) 50 mm -- (3) 25 mm -- (4) 10 MM, -- (18) 1 MM -- (10) 0.5 MM -- (8) 0.25 MM -- Add per Sleeve with Spacer Set, $795 -- Laser Light with Mounting Bracket, each $1,190 -- Power raise & lower of the hold-down system when ordered with

$ 74,990

CAM-WOOD SM-623L Moulder, Feed Through 6-Head (B-R-L-T-T-B), working cap. 9-3/4" x 5-1/4". Head sequence: -- Bottom 10 HP, right 10 HP, left 10 HP, top 20 HP, top 15 HP, and bottom 20 HP motor. -- Spindle dia. 40 mm with a cutter-head speed of 7,200 RPM. All spindles with mechanical digital readouts. -- Feed: Variable speed of 26 - 119 FPM, with 7-1/2 HP feed drive motor. Powered feed rollers top and bottom. -- Infeed Straightening table 2M (6'6"), with side pressure roller and table lubrication pump. -- Dust outlet Diameters are 5" X 6" outlets. Includes: -- Hard chrome-plated fences and table, -- Operator/spare parts manuals, -- Centralized control panel, -- Sound and safety enclosure, -- Short stock feeding mechanism (9 1/2" min length), -- Power elevation (1-1/2 HP beam.)Options:Training and installation, tooling & rigging are optional. -- SM-KFST Knife Setting Stand ...$1,970.00The machine base is one piece coated from high-quality cast iron (FC-25) for maximum stability of the structure. Base is machined by CNC machine equipment to ensure the utmost working accuracy. Net weight 11,220 Lbs Shipping weight 12,300 Lbs.

CAM-WOOD HIAT-620-205 WITH 3"; HIGH X 8"; WIDE X 20’ LONG WORKING CAPACITIESTECHNICAL SPECIFICATIONS:Incoming Block Requirements: --Incoming block lengths from 6'' to 39"; (optionnal 122") --Blocks must be at least 50% longer than their width. --Block thickness from 1/2"; to 3 1/2" --Block width from 1"; to 8" - --Assembled lengths from 10’ to 20’ - 24’ Optional --For use with PVAC adhesives --Works equally well with soft & hardwoods. --Moisture content preferred from 8% to 12% --Blocks should be surfaced (4) sides to ± 0.2 mm with 90° right-angle corners. To be supplied by the customer: --Electric power supply to electrical cabinet --Constant voltage with deviations of 5% or less --Temperature range for computer control should not exceed 95°F. --Maximum humidity for computer control system under 65% --Hydraulic oil --Skilled operating and maintenance personnel --Motor Control Center with under-voltage and overload protection; includes UL and CSA approved electrical components. Electric parts only, not the complete machine. --Total electricity demand: 63.75 KW, 85 HP --30 HP Compressor with a 50-to-60-gallon Air Receiver PRODUCTION CAPACITIES:Shaper Capacity: --Shift = 480 minutes --Finger length to buyer’s requirement --As an example: 1-1/2"; X 5/1/2"; X 24"; average finished block size at the Shapers --Shaper max. speed of (3) table strokes per minute --Table cycles will change as block widths become “wider"; or “taller"; at the Shapers --Table accepts up to (16) blocks when vertical finger jointing 1-1/2"; X 5/1/2"; example blocks. --Table accepts up to (4) blocks when horizontal finger jointing 5-1/2"; x 1-1/2"; example blocks.Press Capacity: --Assembly Press w/2 operators: -- (4) Table loads per min. x 20’ lengths x 480 min. per shift x 0.8 rate of utilization = 30,720 lineal feet per shift OR 36,864 lineal feet per shift with 24’ Press)Production Calculations: --VERTICAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 1-1/2"; x 5-1/2"; x 2’ long blocks: (3) tables stroke per minute X 16-blocks per table load X 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 36,864 lineal feet per shift (63.34 M³) --HORIZONTAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 5-1/2"; x 1-1/2"; x 2’ long blocks: (3) table strokes per minute X 4 blocks per table load x 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 9,216 lineal feet per shift (19.46 M³) NOTE: Capacity is maximum as shown at Assembly Section and is dependent on blocks thru the Shapers System consists of

$ 10,900

CAM-WOOD TX-P3200SAX Sliding Table Panel Saw w/Motorized Raise & Lower.Heavy-duty construction, vibration-free operation. Easy to set up and quickly adjusts. High accuracy, free movement sliding table without wear resistance.Specially designed double rollers carriage made by aluminum profile. Stable, torsion-free cross slides with easy running swinging arm.Features: -- 126" Cutting length w/scoring; 126" x 17" Anodized sliding table that locks in any position for easy loading. -- Motorized Saw blade up or down movement by 1/4 HP electric servo motor; tilting by manual handle wheel. -- Scoring unit for clean, accurate chip-free cutting, ready for edge banding. Specifications: -- 7.5 HP Main saw motor; 45° tilting (30 mm) main saw arbor; 14" Main blade dia.; 3,000/4,000 & 5,600 RPM arbor speed. -- 5.3" Max. material thickness at 90°; 3.1" at 45°. -- 1 HP Scoring saw motor, 5" dia. scoring blade; 8,000 RPM. -- Equipped with: 49" Max. ripping cap.; micro-adjustable rip fence and extendable crosscut fence to 10' with (2) flip stops. -- Articulating overarm protection guard; outboard and rear extension tables. -- Includes: Saw Blade(s), Maintenance Tools, Operators' & Parts Manual and covered by (1) Year Warranty.

$ 16,900

CAM-WOOD TX-P3200PL Sliding Table Saw w/Motorized Raise/Lower/Tilt & Programmable Rip FenceHeavy-duty construction, vibration-free operation. Easy to set up and quickly adjusts. High accuracy, free movement sliding table without wear resistance.Specially designed double rollers carriage made by aluminum profile. Stable, torsion-free cross slides with easy running swinging arm.Specifications & Features: -- 126" Cutting length w/scoring; 126" x 16" Anodized sliding table that locks in any position for easy loading. -- Saw blade moves up or down, tilting and fence movement driven by 1/4 HP electric servo motor. -- Scoring unit for clean, accurate chip-free cutting, ready for edge banding. Equipped with: -- 9 HP Main saw motor; 45° tilting (34 mm) main saw arbor; 15-3/4" Main blade dia.; 4,000/5,600 RPM; -- 5.3" Max. material thickness at 90°; 3.1" at 45°. -- 1 HP Scoring saw motor, 5" scoring blade; 8,000 RPM. -- 49" Max. ripping cap.; (200) memory program control for the rip fence, saw blade height and tilting angle via touch control screen for convenient operations; -- Extendable crosscut fence to 10' with (2) flip stops. -- Articulating overarm protection guard; outboard and rear extension tables.

$ 38,990

CAM-WOOD 86PAAU Raised Panel Door Machine machines entry door stile and rail door parts as well as cabinet door parts, chair legs and furniture parts, up to 86" length and 7" width.. One operator to machine profiles to the rail copes, stile and rail sticking and raised panels with rapid change over all on one machine for high productivity. Features Include: -- Hydraulic table movements from right to left to achieve powerful cutting and adjust cutting speed variability. Table movements in and out are pneumatic powered to follow a template sensitively. --One operator to machine all profiles for stiles and rails on one machine, along with raising all panels both edges top and bottom. -- Capacity for machining a 6" arch/oval on panels and rails, and raises both face on a raised panel at the same time (arc size varies depending on cutter diameter). -- Raise a curved panel up to 6" radius both on rails and panels. -- Hydraulic pump unit for accurate table speed control. -- Simple guide system follows templates for curved or arched profiles and is quickly repositioned for straight machining profiles. -- Cutterhead knives can be stacked on the same spindle to eliminate changing machines to machine door parts. -- Easy stop system for door stiles or rail lengths. Two separate stops work for rail/stile/panel arch cut positions. -- Heavy duty 10 HP motor, allows for high speed cutterhead to eliminate unnecessary sanding. -- Proximity switches control the cutting stroke. Linear guide rails and bearing for a lightweight & smooth slide. -- More than one part may be milled at one time. Pneumatic holddown cylinders hold parts tightly without slide during cutting. -- Easy positioning of parts on a precision ground, cast iron table ensures accurate stile rail and panel machining and alignments. -- Machines door stiles up to 86" in length.More Specifications: -- Spindle Motor 10 HP @ 7,000 RPM; Hydraulic Motor 1 HP; Feed Speed 0-60 FPM. -- Spindle Diameter 1-1/4"; Spindle Height 7"; Depth of Radius Cut 6";; Min. Radius Cut 6" (based on cutter diameter) machine door stiles up to 86" in length. Dust Hood is 4" dia. -- Dimension: Length 120";; Operating Length 228";; Width 48";; Height 48";. Weight 300 lbs. Air Supply Required 100 PSI -- Note: Delivery time about 10-12 weeks.

$ 45,900

CAM-WOOD 102PAAU Raised Panel Door MachineMachines entry door stile and rail door parts as well as cabinet door parts, chair legs and furniture parts, up to 102" in length and 7" in width. One operator to machine profiles for the rail copes, stile and rail sticking and raised panels with rapid changeover, all on one machine with high productivity. Features Include: -- Hydraulic table movement from right to left to achieve powerful cutting and adjust cutting speed variability. Table movements in and out are pneumatically powered following a template with very high accuracy. -- One operator to machine all profiles for stiles and rails on one machine, along with raising all panels both edges top and bottom. -- Capacity for machining a 6" arch/oval on panels and rails, and raising both faces on a raised panel at the same time (arc size varies depending on cutter diameter). -- Raise a curved panel up to 6" radius both on rails and panels. -- Machines door stiles up to 102" in length.Technical Features: -- Hydraulic pump unit for accurate table speed control. -- Simple guide system follows templates for curved or arched profiles and is quickly repositioned for straight machining profiles. -- Cutterhead knives can be stacked on the same spindle to eliminate changing machines to machine door parts. -- Easy stop system for door stiles or rail lengths. Two separate stops work for rail/stile/panel arch cut positions. -- Heavy duty 15 HP motor, allows for high speed cutterhead to eliminate unnecessary sanding. -- Proximity switches control the cutting stroke. Linear guide rails and bearing for a lightweight & smooth slide. -- More than one part may be milled at one time. Pneumatic holddown cylinders hold parts tightly without slide during cutting. -- Easy positioning of parts on a precision ground, cast iron table ensures accurate stile rail and panel machining and alignments.More Specifications: -- Spindle Motor 15 HP @ 7,000 RPM; Hydraulic Motor 1 HP; Feed Speed 0-60 FPM. -- Spindle Diameter 1-1/4"; Spindle Height 7"; -- Depth of Radius Cut 6";; Min. Radius Cut 6" (based on cutter diameter). Dust Hood is 4" dia. Dimension: -- Machine Length 120";; Operating Length 228";; Width 48";; Height 48";, Weight 300 Lbs; Air Supply Required 100 PSINote: Delivery time about 10-12 weeks.

$ 19,500

CAM-WOOD PT-48VAX Door Clamp (Single Sided). -- Work Space: 48" Max. width x 97" max. length, hydraulically operated.Specifications: -- Applies max. 11,000 PSI pressure from (2) sides; 90 PSI from holddown. -- Includes 5 HP hydraulic pressure system. -- Hydraulically operated assembly table; twin hydraulic cylinders for moveable rams at two sides pressing for max. assembly capacity. -- Easy adjustments of rams, makes changing sizes simple; separate controls for adjusting the each side of press rams. -- Fixed reference points for lower & left edges ensure 90° assembly of face frames; heavy gauge steel metal table & frame.NOTE: Also available as a 2-sided Clamp for ...$26,500.

$ 19,500

CAM-WOOD PTX-2513 Entry Door/Window Hydraulic Assembly Press, 4' x 8'. Hydraulically operated. Solidly constructed and welded with great precision.Specifications: -- Working area:1300 mm (51") Max. width; 2500 mm (98") max. length. -- (2) Vertical cylinders, each of stroke 80 x 600st; (2) side cylinders, each of stroke 50 x 800st. -- Comes with: 2 HP hydraulic pump motor. -- Outer structure is made of two vertical beams which are individually located at the upper and the bottom side of the machine. The horizontal beams have vertical hydraulic cylinders thereby moving beams up and down to distribute the pressure evenly on the workpiece. The overhead push button operates the hydraulic motor. -- Stops (square blocks) are moved manually to set to the desired position. The mobile pressing platen of the square block and the horizontal upper beam can be moved by the vertical hydraulic cylinder. -- Equipped with: A pressure gauge and pressure control valve to regulate the vertical and horizontal hydraulic cylinders for precise, desired working pressure. -- Overall Dimensions/eight: 3000 x 1200 x 2200 mm (120 x 48 x 87"). Weight: 1200 Kg (2650 Lbs).NOTE: Also available in 5' x 10' Press for ...$26,500.

$ 20,990

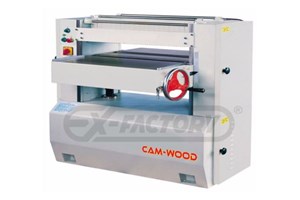

CAM-WOOD WP-760 15 HP Single Sided 30" Planer Features: -- Spiral cutterhead provides precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate setting. -- Motorized worktable raises & lowers by separate motor for more efficient operation. -- Specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the exact feed rate and allows precision smooth finish planing on both hard or softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provides greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base for maintenance-free serviceSpecifications: -- Table Area 38" x 31" -- Max. Planing Width 30" -- Max. Planing Thickness 8" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5,500 RPM -- Cutterhead Diameter 4-3/4" Spiral -- Knife Dimensions 14 mm x 14 mm -- Feeding Speed (Var.) 15 ~ 75 FPM -- Max. Cutting Depth 5/16" -- Feed Motor 2 HP -- Cutterhead Motor 15 HP, 3 Ph, 230 V -- Table Elevation Motor 1 HP -- Digital Thickness Control Yes -- Dust Hood Outlet 5"G.W. 2450 Lbs

$ 8,389

CAM-WOOD WP-2000S Single Sided Planer20" Planer with solid cast iron construction and Spiral Cutter Head.Features & Specifications: -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- Fixed feed (30 FPM) speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- 3 HP Self-braking motor. -- Magnetic starter & thermal overload switch and Emergency stop. -- Operations manual, parts list & tool kit. Optional: CT-SCH-14T - 14 mm x 14 mm SPIRAL CUTTERHEAD BLADES ...$3.30 each

$ 46,750

CAM-WOOD WP-1400H 52"; Heavy Duty Planer with S.C.H.55" Cap. solid cast iron construction planer with powerful 25 HP motor.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering, manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planning with low noise levels. -- With (4) each 4" diameter dust outlets. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 52". -- Max. Cut Thickness 8". -- Max. Cut Depth ¼". -- Min. Cut Length 9". -- Cutting Speed 3,600 RPM. -- Table Size (W x L) 55" x 55". -- Main Motor 25 HP, 3 Ph. -- Feed Motor 5 HP. -- Table Raising Motor 1 HP. -- Feed Rate (Variable) 0 ~ 50 FPM. -- Shipping weight 7,400 Lbs.

CAM-WOOD XCL-1000S 4-Spindle Auto Copy Lathe/Shaper w/Sanding of Asymmetrical parts .via a template. Shaping with (4) cupped cutters and sanding with individual belts.Specifications: -- Capacity: (4) Spindle duplicating/carving/copy heads with (4) copy belt sanders for asymmetrical parts. Working length 6-3/8"- 39.5" -- Working dia. 1-1/8" - 8-1/4". Cutter diameter approx. 1.4" -- Speeds: Spindle Speed : Variable 2000 - 6000 RPM. Cutting Circle 2 - 12 times/min. -- Features: (4) Spindles with pre-loading centering station and pneumatic clamping. -- Drives: Hydraulic carriage motor 3 HP; Cutter drive motor 7.5 KW (10 HP). Sanding heads motor 2 x 1 HP. -- Electrical controls: 220 V Relay style. -- Overall Dimensions: 120" long x 47" deep x 110" high -- Approx. net weight: 6,240 Lbs. -- NOTE 1: Larger diameters are possible by using every second carriage position, ie. (2) heads instead of four heads. -- NOTE 2: Version without Sanding, XCL-1006 is priced at

$ 10,990

CAM-WOOD WP-2400S SINGLE SIDED PLANER WITH SPIRAL HEADFeatures & Specifications: -- Self-braking motor 5 HP, Magnetic starter & thermal overload switch. -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws, up to 7" opening. -- Scale & pointer readout for accurate thickness adjustments. Spiral Head & Feed: -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers.Complete with: -- Hinged top for easy access to cutterhead & gear assembly. -- Emergency stop. -- Operations manual, parts list & tool kit.1250 lbs

$ 38,500

CAM-WOOD - VPS Twin, ...Automatic Vertical Panel Saw, for Cutting & Grooving Aluminum Composites (78-3/4" x 157-1/2").The VPS TWIN is engineered with specific features for cutting or grooving Aluminum Composite or similar materials. Top to Bottom cutting height is 2,000 mm (78-3/4"). Saw head w/motor rotates 90° for rip or crosscutting grooving.Automatic Cutting Cycle: Cutting or grooving length "rip cut: Left/right" is 4,000 mm (157-1/2"); cuts or grooves panels up to 20 mm (3/4") in thickness; Digital LED readout scales for both X- & Y-axis measurement. Unique saw head design: (1) Standard Saw blade and (1) V-grooving blade all in (1) housing. An operator can select a standard or V-grooving cut automatically by a flip of a switch. Automatic “Flip of the Switch"; changeover from a cut-to-size blade cutting operation to channel grooving cutting; includes precision depth control required for ACM (Aluminum Composite Material) panel grooving and bending.4.0 HP Motor (5.5 HP Option): Spring-loaded floating shoe guide enhances dust collection and safety by enclosing the blades & cutterhead, automatically shifting material back support grid; shifts away from the saw blade cut line, preventing cuts into the grid support strips, while rip cutting horizontally; grid senses the blade/cutter position and automatically shifts away, built-in Dust Collection with collection bag mounted on the rear of the Saw frame. Alternatively, remove & bypass the bag for easy connection to your existing Dust Collection System.Equipped with: Precision ground bottom edge support rollers to facilitate easy loading & positioning of the larger or heavy panels.Vertical cutting stations are spaced at 40" increments to lock in the Saw beam for vertical crosscuts. Cross- or rip cutting: Material always rests firmly against the "slightly angled" back grid support; repeat rip gauge for duplicating multiple horizontal cuts; a foldout shelf that runs the entire length of the frame for small parts cutting and (2) standard flip-stops for dimension setting.Includes WARRANTY: 12-Month Factory Warranty covering defective parts and workmanship (not including wear parts); 6-Month Factory Warranty on electrical; manuals; (1) 62T x 230 mm dia. Main Saw Blade; (1) 10T x 200 dia. V-grooving blade (90°); 5,800 RPM.

$ 26,900

CAM-WOOD - VPS IS Compact, ...Vertical Panel Saw (76" x 122" w/Scoring)Short 10' Frame Compact Model with Scoring offers many features in a compact space-saving design. -- Top to Bottom cutting height is 2,030 mm (78-3/4") without scoring and 1,930 mm (76") with scoring; saw head w/motor rotates 90° for rip or crosscutting. -- Cutting length "rip cut from left/right" is 3,100 mm (122"); cuts single or stacked panels up to 42 mm (1-5/8") in thickness.Features: -- Separate 5" dia. scoring blade belt driven at 7,800 RPM to insure clean cuts on everything from Plywood to Melamine & Hardwood, especially preventing surface chipping when cutting laminated materials. -- Includes: -- 4 HP Motor and true scoring with a 125 mm (5") dia. 24-teeth blade, 250 mm (10") dia. 80-tooth main blade; spring loaded floating saw blade enclosure - shoe glides over panel surface applying a holddown force while it enhances dust collection & safety by enclosing the saw blades. -- Auto-shifting material back support grid shifting away from the saw blade cutline prevents cutting into the grid support strips while rip cutting horizontally; it senses the blade/cutter position and automatically shifts away.Equipped with: -- Precision ground bottom edge support rollers to facilitate easy loading & positioning of the larger or heavy panels; both standard inch & metric preset "beam lock" stations. -- Vertical cutting stations are spaced at 40" or 1,000 mm (in inch or metric) increments to lock in the saw beam for vertical crosscuts. -- (2) Adjustable flip-stops on inch (metric available) measuring scales, one located on the lower rail and the other on the foldout shelf at the middle of the frame. -- Retractable Material Support Shelves throughout the entire length of the machine frame allows for ergonomic cutting of smaller parts, at any cutting station without the need for the operator to bend down. -- Includes: -- Pneumatic lock System; Repeat Cutting Device; (1) 250 mm (10") dia. 80-tooth, 30 mm bore main blade; (1) 80 mm (3.14") dia. 24-tooth, 20 mm bore scoring blade.Optional: -- Add ACCURATE TECHNOLOGY Proscale Digital Readouts on X & Y axis ($ 2,000 upgrade).

$ 28,750

CAM-WOOD - VPS I, ...Vertical Panel Saw (82.677" x 161.417" w/Scoring)Top to Bottom cutting height is 2,100 mm with or without scoring; saw head w/motor rotates 90° for rip or crosscutting; cutting length 4,100 mm; cuts single or stacked panels up to 60 mm (2.36") in thickness. Standard features: -- 4 HP Motor with a 250 mm (10") dia. 80-tooth main saw blade. -- Separate 3.15" Dia. scoring blade, belt driven at 7,800 RPM; single-screw adjustment for side-to-side and depth. -- Auto-shifting material back support grid; shifting away from the saw blade cut line prevents cutting into the grid support strips while rip cutting horizontally; it senses the blade/cutter position and automatically shifts away. Equipped with: -- Precision ground bottom edge steel support rollers to facilitate easy loading and positioning of the larger or heavy panels; both standard inch and metric preset "beam lock" stations. -- Vertical cutting stations are spaced at 40" or 1,000 mm increments to lock-in the saw beam for vertical crosscuts. -- (2) Adjustable flip stops on inch (metric available) measuring scales, one located on the lower rail and the other on the foldout shelf at the middle of the frame. -- Retractable Material Support Shelves throughout the entire length of the machine frame allows for ergonomic cutting of smaller parts, at any cutting station without the need for the operator to bend down.Includes: -- (1) 250 mm (10") dia. 80-tooth, 30 mm bore main blade; (1) 80 mm (3.14") dia. 24-tooth, 20 mm bore scoring blade; Repeat Cutting Device.Optional Equipment available: Built-in Dust Collector, please add ...$ 1.250.

$ 29,900

CAM-WOOD - VPS I +, ...Vertical Panel Saw (82.67" x 161.41" w/Scoring), Vertical-Horizontal Digital Readouts & Auto Lock System. Top to Bottom cutting height is 2,100 mm with or without scoring; saw head w/motor rotates 90° for rip or crosscutting; cutting length 4,100 mm; cuts single or stacked panels up to 60 mm (2.36") in thickness.Standard features: -- 4.0 HP Motor (5.5 HP Option) with a 250 mm (10") dia. 80-tooth main saw blade. -- Separate 80 mm (3.15") Dia. scoring blade, belt driven at 7,800 RPM; single-screw adjustment for side-to-side and depth. -- Auto-shifting material back support grid; shifting away from the saw blade cut line, prevents cutting into the grid support strips while rip cutting horizontally; it senses the blade/cutter position and automatically shifts away. Equipped with: -- Precision ground bottom edge steel support rollers to facilitate easy loading and positioning of the larger or heavy panels; both standard inch and metric preset "beam lock" stations. -- Vertical cutting stations are spaced at 40" or 1,000 mm increments to lock in the saw beam for vertical crosscuts. -- (2) Adjustable flip-stops on inch (metric available) measuring scales, one located on the lower rail and the other on the foldout shelf at the middle of the frame. -- Repeat Rip Gauge for duplicating multiple horizontal cuts. -- Retractable Material Support Shelves throughout the entire length of the machine frame allows for ergonomic cutting of smaller parts, at any cutting station without the need for the operator to bend down.Includes: Vertical-Horizontal Digital Readouts; Pneumatic lock System; Repeat Cutting Device; (1) 250 mm (10") dia. 80-teeth, 30 mm bore main blade; (1) 80 mm (3.14") dia. 24-tooth, 20 mm bore scoring blade.Optional Equipment available: Built-in Dust Collector, please add ... $ 1,250.

.gif)