Equipment For Sale

9629 Results Found

$ 26,990

CAM-WOOD SET-52SAT 6-Head Double End Tenoner (Not Feed Through)Capacity: -- Length of cut: 12" to 60" (opening). -- Max. width of cut: 24" (cross cut). -- Max. clamping thickness: 4-1/2". -- Saw blade dia. 8" to 12"; saw arbor dia. 1"; saw blade speed 3,400 RPM; saw head swivels 180 degrees. -- Moulder (Shaper) spindle: 1" Dia. x 5" long; spindle speed 6,000 RPM; spindle swivels 180 degrees. -- Vertical travel: 17" vertical. -- Carriage (table) travel (front/back): 24".Equipped with: -- Saw motors: (4), each 2 HP motors (1 top & bottom each side). -- Shaper spindles: (2), each 2 HP motors (1 each side). -- Out Feed Conveyor drive: 1 HP motor (not this model!). -- Powered length setting: 1/2 HP motor (machine opening).Features: -- With the double end miter saw set-up, you can cut-off stock faster or consider a double end miter saw combined with moulding (shaper) head. It lets you cut and machine stock and moulding pattern in a single feed, saves time, space and cost. -- Air-operated vertical clamps hold sticks firmly in place. After the work piece is clamped, table start to feed, performs trimming and shaping operations. -- Trim saw allows to cut stock accurately with a clean cut. -- Moulding (Shaper) spindle mounted at the rear of saw head enables the machine to perform edge moulding after stock is cut off. -- The entire cutting cycle, cut-off, shaping/tenon or mortise is automatically operated in a single pass of stock feeding. -- The material Clamping table travels on a precision linear motion guide for stability. -- The table traverse is motorized, ensuring very stable, smooth workpiece feeding. -- Material transport thru machine powered by variable speed inverter drive for 10 to 20 Sec per cycle -- Variable feed speed permits proper feed selection for hard or soft wood materials. -- Large hand-wheel to adjust depth of cut. -- All controls are grouped in a control panel. -- Industrial motors for optimal cutting results.Machine Stations: -- 1: Top & Bottom Trim Saws powered by (4) 2 HP saw arbor motors for trimming to length. -- 2: Shaper spindles powered by (2) 2 HP spindle motors for applying tenons and grooves. -- Floor space requirement: 94" X 40" X 54" high. -- Cycle time: 10 to 20 Sec per cycle.Available option at additional cost: -- Auto Outfeed device -- Return conveyor

$ 21,990

CAM-WOOD A-3775 Single Head Wide Belt SanderSpecifications: -- 36" Width cap. - Combination Sanding head with rubber-covered contact roll and adjustable finishing platen. 20 HP main drive motor. -- 37" X 75" Abrasive belts, pneumatic abrasive belt tensioning. -- 0" - 5" Feed through bed adjustment, Digital thickness set-up via 0.5 HP motor power elevation for thickness opening. -- Variable conveyor feed speed from 20 to 60 FPM, 2 HP feed motor. -- 5" Max. working thickness, 7" min. working length, -- Double Infeed & outfeed spring loaded holddown rolls.Complete with: -- Magnetic controls, 6" dia. dust collection hood, and safety shutoff. - 1,500 CFM Dust collection required.

$ 165,500

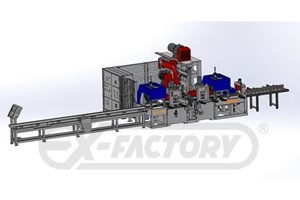

CAM-WOOD SET-812 SCCWW, Double End Tenoner with Sanding12-Head Double End Tenoner, suitable for mass production in a woodworking factory, processing double end cutting, tenoning, grooving, moulding, and sanding.Features: -- Automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 75 FPM. -- In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of length sizes for tolerance within 0.004". -- The numeric control system provides highly accurate settings, and a special memory retains all settings, even if there is a power failure. -- Variable speed, through feed, wide rubber pads with spring-loaded dogs located at 16" center distance with conveyor speed for the best finish selections. -- Heavy-duty powered pressure rolls at top of the wide width conveyor holds the material tight to prevent sliding during the cutting and sanding process. -- Shaper head can be moved up & down, forward & backward. -- Workstations are powered by industrial motors for full power cutting and utilizing the entire sanding capacity range. -- Two sanding heads can use brush, flap wheel or profile disc for fine finish with one pass. -- Trim saws and sanding heads can be tilted for different angular setup. -- Heavy cast iron base for durability and heavy duty usage.Specifications: -- Thickness: ½" to 4" -- Length: 10" to 96" -- Miter Saw Blade: 10" x 30 mm Dia. -- Grooving Saw Blade: 8" x 1" Dia. -- Shaper Cutter: 6" - 10" x 30 mm Dia. -- Feed Speed: Variable, 20 ~ 75 FPM -- Trim Saw 3 HP x 2, 3,450 RPM -- Hogging Saw 10 HP x 2, 3,450 RPM -- Jump Shaper 10 HP x 2, 4,500 to 7,000 RPM -- Shaper 10 HP x 2 4,500 to 7,000 RPM -- Belt Sanding 3 HP x 2, 0-1500 RPM -- Brush Sanding 3 HP x 2 with 30 mm arbor 0-1500 RPM -- Feeding 3 HP x 1 -- Width (Opening) Setting 1 HP x 1 Option: -- Sound enclosure ...$ 7800

CAM-WOOD TRS-3016 Single Blade Bottom Cut Straight Line Rip Saw 15 HP - 3,600 RPM Direct drive BOTTOM mounted arbor,Specifications: -- 1" Dia. arbor, 10" to 16" max. blade cap., 3-1/4" max. depth of cut, 12" min. length; 19" throat cap., 69" long x 43" wide table. -- Precision-built saw head designed for straight-line rip saw operations.Feed System: -- 2 HP Variable feed motor, 30 - 85 FPM, 8-3/4" Twin chain drive, Automatic chain and lubrication to V-Way track; Top pressure system with roller holddowns. -- Double anti-kickback fingers mounted at the infeed; feed chain with V-way track and chain block surface, heat-treated for long wear resistanceFeatures: -- Hard chrome plated table for maximum wear resistance; precision fence with measuring ruler gauge. -- Saw arbor manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue, heat treated, precision ground and balanced for precise cutting performance; -- (4) Bearing spindle mount ensuring rigidity & long life; Anti-kick finger, two long rollers, in front of saw blade, 4 x 2 = 8 short rollers at the side of the saw blade, two long rollers at outfeed heavy-duty cast iron table. Complete with: -- Rip fence, push buttons, magnetic starter, and 4" dia. dust outlet. -- Optional Laser Beam Light, please add ...$980.

CAM-WOOD TRS-3018 Single Blade Bottom Cut Straight Line Rip SawEquipped with & Features: -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage. -- The variable feed speed enables the machine to meet different requirements of work. -- V-way track and chain block surface are heat-treated for long wear resistance. Automatic lubrication to the V-Way track facilitates the chain running smoothly. -- Precision-built saw head ensures accuracy for straight line rip saw operations. -- Four bearing spindle mount ensures rigidity & long life. -- Anti-kickback finger, two long rollers, in front of the saw blade, 4 x 2 = 8 short rollers at the side of the saw blade, two long rollers at outfeed. -- The auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil to increase the durability of the machines.Specifications: -- Maximum Cutting Depth: 4-3/4", Arbor Diameter 2". -- Saw Blade Size: 14" - 18" in diameter. -- Table Dimensions: 58" x 78". -- Spindle Speed: 3,600 RPM. -- Feeding Speed: 30 - 85 FPM. -- Throat to Blade 26". -- Main Motor: 20 HP, Feed 3 HP motor. -- Feed Chain Width: 8-3/4". -- Minimum Workpiece Length: 8" . -- Exhaust Hood Diameter 4". -- NW: 3,800 Lbs. Note: LA-6000 Laser Beam Light Available @ $980.00

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-210"Up to 210 mm (8") Wide x 75 mm (2.95") Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39"; to 118" (1,000 mm - 3,0000 mm). -- Board widths from 1.96"; to 8.26"; (50 mm - 210 mm). -- Board thickness from 1" to 2.95"; (25 mm - 75 MM). -- Board out-feed length unlimited (Conveyor to be quoted separately) -- Glue type to be used: PVAC. with Standard pneumatic pump and spreader included ( For different glue then PVAC Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-210 Mechanical Specifications: -- Top infeed feed rolls powered with (1) 2 HP motors. -- Bottom infeed feed rolls powered with (1) 2 HP motors. -- In-feed Inverter with (1) 5 HP motors. -- Top Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 8.2“(210 mm). -- Maximum Cutterhead diameter, 7"“(180 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 195 FPM (10 ~60 m/Min). -- Outfeed cut-off saw motor, 5 HP. -- Cut-off sawblade, 14“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Top outfeed feed rolls powered with (1) 2 HP motors. -- Lower outfeed feed rolls powered with (1) 2HP motors. -- Out-feed Inverter with (1) 5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. Infeed/Outfeed options: -- Infeed power roller conveyor 6000mm (236") long Additional: $ 8390 -- Outfeed powered roller conveyor 15,000 mm (48') long Additional $ 43,890Optional Automatic 20 ft Cross InfeedPower Conveyor System Working size L = 1000 MM ~ 6000 MM, W= 50 ~ 305 MM, T=25 ~ 110 MM ( Lenght 39" - 236" X Width 2" -12", Thickness: 1" to 43.3")Infeed roller Conveyor 3 HP1Cross feeding system 3 HP1Feeding speed of 15 M/min (48'/min.)Storage area width 2500 mmAdditional cost: $61,990 -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for finger jointer (we can provide quote) -- Gluing system with pump and nozzle if different then PVAC glueGlue pump Option: -- Graco 1K PUR Glue System Additional cost: $ 48,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 KG/cm² – 8 BAR --Electrical c

$ 64,900

CAM-WOOD - IN-408-R, ...4' x 8' CNC Router with Automatic Rotary Tool Changer:4' x 8' Flat Table CNC Router, Perfect for your 3-axis routing applications including "Nested Base Manufacturing".Machine Bed/Base: -- The Welded & Structurally Engineered machine base provides a solid foundation for superior cut quality; the entire frame is stress relieved and heat treated. -- The Moving Gantry Bridge travels in the X- & Y-axis via inclined toothed Helical rack & pinion on "HIWIN" 1" (25 mm) thick hardened & precision ground rectangle linear guide ways providing extra smooth movement, high-speed traverse and accurate cutting. -- The Tool Gantry Movement for the vertical Z-axis travels on a 1" (25.4 mm) dia. precision ball screw for smooth & consistent movement.CNC Control & Operator Interface: -- Industrial Grade "SYNTEC" controller with network-compatible WINDOWS PC-based front-end, color monitor, keyboard, mouse. Absolute & incremental programming, cutter & tool length compensation, feed rate & spindle speed override, inch/metric operation, and linear/circular & helical interpolation.. -- Compatible with virtually all CAD/CAM programming software on the market. - You choose the software that best suits your needs.Working Table/Envelope: -- 51" (1,295 mm), 98" (2,489 mm), 7.75" (197 mm). -- (6) Independent vacuum zones.Axes Travel Range & Feed Speed: -- Max Traverse Speeds: 2,350 IPM -- Max Working Speed: 1,100 IPM. -- Yaskawa "AC" Servo drives & SHIMPO Gear Boxes power all axes movements.Routing & Machining: -- (1) 12 HP HSD Air cooled Router Spindle with: ISO 30 Adaptor ER-32, variable programming speeds from 6,000 to 24,000 RPM, -- (1) 12-Position ATC (automatic rotary tool changer)Complete With: -- 10 HP Vacuum Pump. -- (3) ISO 30 tool holders -- two pop up pins at X, axis & three pop up pins at Y,. -- Automatic tool offset device. -- Automatic lubrication device with filter. -- Standard MPG hand wheel -- safety light curtain and Estop -- 1-Year manufacture warrantyUtilities and Dims: -- Machine power supply is wired for 220 Volts, 60 Cy, 3-Phase, 53 Amps. -- Machine weighs approx. 3 960 Lbs. -- Machine air consumption at 90 PSI is approx. 15 CFM;Extra options not included in machine price: HSD 9-spindle vertical Drill-bank ...$7,675

$ 69,800

CAM-WOOD - IN-510-R, ...5' x 10' CNC Router with Automatic Rotary Tool Changer:5' x 10' Flat Table CNC Router, Perfect for your 3-axis routing applications including "Nested Base Manufacturing".Machine Bed/Base: -- The Welded & Structurally Engineered machine base provides a solid foundation for superior cut quality; the entire frame is stress relieved and heat treated. -- The Moving Gantry Bridge travels in the X- & Y-axis via inclined toothed Helical rack & pinion on "HIWIN" 1" (25 mm) thick hardened & precision ground rectangle linear guide ways providing extra smooth movement, high-speed traverse and accurate cutting. -- The Tool Gantry Movement for the vertical Z-axis travels on a 1" (25.4 mm) dia. precision ball screw for smooth & consistent movement.CNC Control & Operator Interface: -- Industrial Grade "SYNTEC" controller with network-compatible WINDOWS PC-based front-end, color monitor, keyboard, mouse. Absolute & incremental programming, cutter & tool length compensation, feed rate & spindle speed override, inch/metric operation, and linear/circular & helical interpolation. -- Compatible with virtually all CAD/CAM programming software on the market. - You choose the software that best suits your needs.Working Table/Envelope: -- X 63" (1,600 mm), Y 126" (3,200 mm), X 7.75" (197 mm). -- (6) Independent vacuum zones.Axes Travel Range & Feed Speed: -- Max Traverse Speeds: 2,350 IPM -- Max Working Speed: 1,100 IPM. -- Yaskawa "AC" Servo drives & SHIMPO Gear Boxes power all axes movements.Routing & Machining: -- (1) 12 HP HSD Air cooled Router Spindle with: ISO 30 Adaptor ER-32, variable programming speeds from 6,000 to 24,000 RPM, -- (1) 12-Position ATC (automatic rotary tool changer)Complete With: -- 10 HP Vacuum Pump. -- (3) ISO 30 tool holders -- two pop up pins at X, axis & three pop up pins at Y. -- Automatic tool offset device. -- Automatic lubrication device with filter. -- Standard MPG hand wheel -- safety light curtain and Estop -- 1-Year manufacture warrantyUtilities and Dims: -- Machine power supply is wired for 220 Volts, 60 Cy, 3-Phase, 53 Amps. -- Machine weighs approx. 4,480 Lbs. -- Machine air consumption at 90 PSI is approx. 15 CFM;Extra options not included in machine price: HSD 9-spindle vertical Drill-bank ...$7,675 Add second 10 HP Vacuum Pump with stand ...$6,000

$ 51,200

CAM-WOOD SET DADOX Double End Trim & Dado (Angle gain)Trim Saw and Dado Cutter for Door Jamb and CasingSpecifications: -- Working Length 450 ~ 2650 mm (17.7" - 104") -- Working Width 30 ~ 185 mm (1.18" - 7.28") -- Working Thickness 9 ~ 35 mm (.350 - 1.37") -- (4) set of Holddown CylinderEquipped with: -- (2) Sets Trim Saw Heads, 5 HP motor each; Spindle 1" Dia., Spindle Speed 3000 RPM; -- (2) Shaper Heads, 5 HP motor each; Spindle 1 1/4" Dia., Spindle Speed 6600 RPM, Cutting Angle adjustment 0 to 10°. Cutter head movement on linear rails -- Feed Magazine 24"; Height Magazine -- Pneumatic feed Feed system with Stops -- (4) Dust Hood units, each 4"; opening -- Central support -- Air tank -- Cycle time 8 to 10 Pcs/Minute

$ 62,900

CAM-WOOD WS-NDA 1300 3-Head Planer Sander[Equipped with Planer, Drum and combi head]Features: -- This machine is especially designed for removing heavy material such as glued-up panels, bent boards, and rough lumber. -- The first station is a knife planer head, followed by a combi head with drum and platen at the second station and a finishing platen head at the third station. -- Head configuration can be made to meet customer’s requirements. -- The spiral planer cutter head is fitted with 14 x 14 MM, four-edge throwaway Tungsten Carbide knife inserts, providing a superior chip removal rate, minimum noise, and an extremely smooth cutting effect. -- Changing knife inserts is convenient without removing the cutter head. The spiral cutter head is precision machined from special aluminum alloy steel, tempered, and precision ground by a CNC machine center. -- Anti-kickback fingers, mounted at the infeed of the machine, this anti-kickback finger gives a safety guard for the operator. -- Insufficient pressure protection: If inadequate working air pressure occurs, the machine brakes automatically for safety guard. -- The irreversible running of the pressure roller runs in a single direction only, giving an additional safety guard for panel kickback. -- Automatic elevation of conveyor table (micro-computer controlled with digital readout): it accurately displays the position of the conveyor table. It automatically moves to the setting thickness for planning and sanding. -- Panel cleaning brush roller: built at the outfeed end of the machine, this cleaning brush roller cleans the powder on the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Specifications: -- First head Planer with 40 HP motor -- Second head combi drum & platen with 30 HP motor -- Third head finishing platen with 30 HP motor -- Panel cleaning brush at outfeed with 1/2 HP motor -- Working width: 52" -- Working thickness up to 6 1/4" -- Minimum working length: 21" -- Feed speed 10 FPM to 90FPM inverted driven by 5.5 HP motor -- Table hoist motor 1 HP -- Sanding belt size 52" X 75" -- Floor space requirement: 107" X 103" X 80", weight 12,300 Lbs

$ 30,990

CAM-WOOD BX-1616HR Single-Head Band Resaw w/Return ConveyorCan be used to cut boards, cants, or reclaim slabs; max. working height up to 16" under pressure roller x 16-1/2" Widths; 1/4" - 12" between blade and conveyor; VFD controlled variable speed from 0 - 60 ft./min.Equipped with: -- 30 HP Saw Motor, 32" x 2" dynamically balanced cast iron band wheels, 230-1/4" x 2" - 4" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- 3 HP Frequency Drive motor; variable feed speed 0 - 60 FPM; return gravity roller conveyor; a side support is applied for safe and stable cutting operations.Complete with: -- Digital controller for convenient and accurate thickness setting; 1/4 HP blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

CAM-WOOD TRS-2216 -- 16" Single Blade Bottom Cut Straight Line Rip Saw;Precision fence ensures absolute accuracy between blade & fence, with a precision gauge.Equipped with and Features: -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage. -- The variable feed speed enables the machine to suit different wood species and work applications. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain running smoothly. -- Precision built saw head ensures accuracy for straight line rip saw operations. -- Four bearing spindle mount ensures rigidity & long life. -- Anti-kick finger, two long rollers, in front of saw blade, 4 x 2 = 8 short rollers at side of saw blade, two long roller at out feed. -- The auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil. Specifications: -- Max. cutting depth: 3-1/8". -- Arbor dia.: 2". -- Saw blade size: 16". -- Spindle speed: 3,300 RPM. -- Feed speed 21 - 85 FPM. -- Throat to blade depth 16". -- Main motor: 10 HP. -- Feed motor 2 HP. -- Min. work piece length: 8". -- Dust Collection Hood dia. 4".Options- LA-6000 LASER BEAM LIGHT ...$980.00

Cam-Wood TRS-MR-1300 X 100mm Roll Feed Gang Rip SawSpecifications -- Working thickness: 10 - 100mm • -- Working width: 530 - 1300 mm • -- Working thickness : 10 – 75 mm / 100 mm • -- Saw Blade 14", • Washer Diameter 110mm • -- Minimum length of work piece when feeding consecutively: 600mm • -- Number of spindle : 1 • Equipped with & Features -- Up & down motor : 1 HP x 1 • -- Feed speed : 6 - 15 M/ min. • -- Feed motor: 7.5 HP x 1 with Inverter • -- Multiple rip saw spindle motor:150 HP / 200 HP • -- Spindle diameter : 80 mm with two key-ways 10 mm5 mm • -- Spindle R.P.M.: 4,000 R.P.M. • -- Movable 1300 mm Saw Shaft Support for easy saw blade replacement.

CAM-WOOD TRS 0012, Straight Line Rip-SawSpecifications: -- Max. cutting depth 3-3/4". -- Arbor Diameter 1". -- Saw Blade Size 8½" - 12". -- Throat to Blade Depth 15". -- Table Dimensions 33" x 59". -- 10 HP Main Motor. -- Spindle Speed 4,500 RPM. -- Feed Motor 1 HP. -- Feed Chain Width 6". -- Feeding Speed 30 - 85 RPM. -- Automatic Lubrication. -- Chip & Dust Collection Hood Diameter 4".Features: -- Cast iron and hard chrome plated table for durability & extended wear. -- Precision machined saw trunnion & fence assure optimal accuracy. -- Measuring ruler gauge for easy & accurate fence adjustments. -- Double anti-kickback fingers mounted at the infeed provide safety protection for the operator. -- Heavy-duty industrial motor for powerful cutting capacity. -- Rugged fabricated durable steel construction for years of use.Feed System: -- Variable speed settings enable the machine to meet different application needs. -- V-way track and chain block surfaces are heat-treated for longer, lasting usage. -- Automatic lubrication to V-Way track allows the chain to operate smoothly. -- (4) Pressure Rollers for accurate cutting of both large and small workpieces.Special Features: -- Saw arbor is manufactured from NI-Cr-MO alloy steel to provide the best durable and anti-fatigue, heat treated, and balanced for a more accurate cut. -- (4) Bearing spindle mount for prolonged life usage.

$ 14,990

CAM-WOOD BX-1212BEEX Single Bottom Head Band Resaw.Can be used to cut boards, cants, or reclaim slabs; Specifications: -- Can process up to 12" H x 12" W; 5/16" - 5-1/4" from blade to conveyor. -- 2 HP Electric motor controlled variable speed from 12 - 80 FPM. -- This Model BX-1212BEE is equipped with: -- 20 HP Saw Motor, 28" x 1" band wheels, 168" x 1" band saw blade (not included). Features: -- Hand-wheel blade tensioning; manual elevation adjustment; 2 HP hydraulic system pump motor. Complete with: -- Spring-loaded steel and rubber upper-pressure rolls; 11" X 215" conveyor belt.

$ 39,890

CAM-WOOD BX-2410HR Single-Head Band Resaw w/30° Bevel CuttingCan be used to cut boards, cants, or reclaim slabs; max. working height up to 10" H under pressure roller x 24" W; 5/32" - 10" between blade and conveyor; VFD controlled variable speed from 0 - 82 FPM.Equipped with: -- 30 HP Saw Motor, 28" x 2" dynamically balanced cast iron band wheels, 195-1/2" x 2-1/8" x 3/64" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Tilting 23" x 215" infeed conveyor from 0° - 30° with side support for bevel cutting; hydraulic infeed and outfeed conveyor drive motor; variable feed speed 0 - 82 FPM; return gravity roller conveyor. -- Complete with: -- Digital controller for convenient and accurate thickness setting; 1/4 HP blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. -- Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

CAM-WOOD MRS-340-1M Dip Chain Gang Ripsaw with one Shifting Blade:Specifications: -- Cutting width up to 13";; machine will pass thru 25-1/2"; -- 3"; Maximum depth of cut with 12"; diameter blades. - Will cut 4"; thick with 14"; blades (optional). -- With 70 mm saw spindle; accepts 90 mm bore sawblades -- With air-loaded pressure rolls, standard fence, and feed chain. -- Urethane Chain Pads and Pad Holders optional -- With (1) powered moveable blade and fixed blades. -- Moveable blade controlled with a joystick. -- With (10) push buttons for pre-programmed selective ripping -- The shifting blade moves at 20 to 80 mm/second (up to 3"; per second). -- Moveable saw blade traverses from 0.59" thru 13.38" -- 50 HP Saw arbor motor; -- 3 HP Feed motor with feed speeds from 15 to 130 FPM -- (2) 1/2 HP Lift motors for pressure rolls and saw arborOptional Equipment when ordered with the machine: -- TRS-FT AUTOMATIC INFEED CONVEYOR SYSTEM, with Movable Fence with Digital Display and Shifting Laser Light for Rip Width Setting: .. -- Hydraulic Quick Lock Spindle Assembly. The hydraulic locking spindle assembly is designed to provide for quick changeover between various ripping requirements. Simply turn the locking knob to pressurize the arbor and lock the blades in position. Turn it in the opposite direction to unlock the blades. The sawblades are mounted to solid steel blade collars: ... -- Additional Quick Set Mechanically-Locked Saw Collars for fast, accurate, sure holding of saw blades in any stationary position ... -- 60 HP Saw Arbor Motor: -- Additional 30 MW Laser Unit with Bracket & Wiring: ... -- Pneumatic Pressure to Hold Down Feed Rollers (In lieu of spring pressure). Provides better control of the product being fed. Each pressure roll is controlled by an individual pressure regulator: .. -- Short stock feeding device for 14"; blades (see specifications for cutting capacity information): -- Feed Chain with (69) Easily Replaceable Bolt in Cast Iron Pads. Allows for changing chain pads as they wear or get cut into rather than replacing the complete chain assembly. NOTE: Specially ground down to 0.06"; square tip for optimum hold with virtually no marking: ... -- Feed Chain with (69) Easily Replaceable Urethane Non-Marking Strip Inserts. Urethane is vulcanized to metal backing bars and bolted in place: ... -- 12" Dia. carbide tipped ripsaw blades, cuts up to 3" material: ... -- 14" Dia. carbide tipped ripsaw blades, cut's up to 4" material: ...NOTE: Foot Pedal seen in the photo is only used with a powered Infeed Table and is designed to release boards from the Feed Table.

CAM-WOOD TRS-405-SS Short Stock Rip Saw ...with the following specifications and features:Specifications: -- Max cutting width: 12.6"; -- Min length part: 3.15"; -- Short stock ratio of thickness to length: 2:5 -- Distance from center of chain to throat, 30"; -- Saw arbor powered by 50 HP Std. - 30 HP, 60 HP and 75 HP optional -- Spindle speed, 3,200 RPM -- Sawblade diameter to thickness: 10"; dia = 2"; thick, 12"; dia = 3"; thick, 14"; dia = 4"; thick, 16"; dia = 5"; thick -- Sleeve diameter (sawblade bore), 70 mm -- Sawblade keyway, 2 each 20 mm wide -- Spacer size, 70 mm ID x 95 mm OD -- 2 HP feed motor, 3 HP optional -- Variable feed speeds from 20 to 80 FPM -- Head elevation powered by ¼ HP motor -- With (2) 6"; dia. dust outlets -- NET weight, 5,500 Lbs. Features and Benefits: -- Exclusive feed track - Design for short stock feed – see literature! -- Exclusive length capacity on a standard Gang Ripsaw, as short as 3";! -- Turn waste blocks into useable parts -- Pressure rolls supported from both sides hold stock securely for even, smooth ripping -- Pressure plate (hold-down shoe) supported from both sides; helps prevent split parts from damaging sawblades -- Power raise and lower for overhead pressure roll and hold-down assembly -- Variable feed speeds allow ripping a variety of material, hard or soft, thick or thin -- 2-Top and 1-bottom rows of kickback fingers plus side splitter guards provide operator safetyNOTE: ...Where have you seen a Gang Ripsaw capable of ripping as short as 3"!!! ...Also perfect for slats!

$ 48,689

CAM-WOOD TRS-350X Heavy-Duty Dip Chain Gang Ripsaw75 HP! ... plenty of power for those with a lot of ripping work!Specifications: -- Maximum cutting width, 13-3/4"; -- Maximum depth of cut, 5-1/4"; -- Distance from column to first blade, 15"; -- Minimum working length, 25"; -- Maximum blade diameter, 16"; -- Minimum blade diameter, 10"; -- Sawblade bore, 2.756"; -- Saw arbor diameter, 2.165"; -- Saw arbor speed, 3,000 RPM -- Saw arbor motor, 75 HPFeatures: -- Variable feed speeds, 25 to 100 FPM -- Feed motor, 2 HP -- Roller holddown elevation motor, 1/2 HP -- Table working area 72"; x 31";Shipping dimensions, 84"; x 71"; x 68"; x 6,000 Lbs

$ 9,439

CAM-WOOD EGS-948 Oscillating Edge Sander with End Table.Features: -- Sandpaper automatically oscillates up & down so it will not overheat to get longer life usage and better finish result. -- 13" x 18" End table mounted at left side of the machine to use as contour sanding. -- Heavy gauge sheet metal cabinets stand and table for heavy work. -- The height of front & back table is adjustable by 5". -- Easily adjustable belt tension device. -- Twin main working tables can be tilted up to 45° reducing material burning and promotes longer belt life. -- The graphite pad lubricates the sanding belt and allows the belt to run cooler and smoother. -- All sealed long-life ball bearings and rubber contact motor pulley. -- Several typical profile blocks can be used for the edge profile sander. -- Powerful industrial motor for durability usage. -- Overload protect magnetic switch.Specifications: -- Sanding Belt Size: 9" x 142". -- Main Working Table (2 Units) 10-1/2"; x 48";. -- Side Working Table: 13"; x 17";. -- Belt Linear Speed: 3,230 FPM. -- Belt Drive Motor: 7-1/2 HP, 3 Ph. -- Oscillating Motor: Belt drive motor. -- Net Weight. 1,260 Lbs

.gif)