Equipment For Sale

9709 Results Found

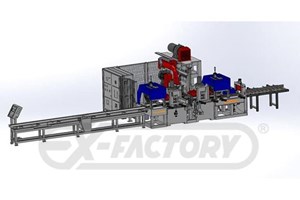

CAM-WOOD TYPE F1, MODEL FAH 8" X 20’ AUTOMATIC HORIZONTAL FINGER JOINT SYSTEM - SINGLE CHAIN TYPE (including Feeding System from Optimizing saw)Technical Specifications: -- Working thickness: 17 mm to 60 mm (0.66" to 2-3/8") -- Working width: 25 mm to 205 mm ( 1" to 8") -- Maximum finish length: 6.2 Meters ( 20') -- Glue type: PVAC -- Timber moisture: 8% to 12% -- Infeed quality must be S4S with tolerance +/- 02 mm, wood need 90° right angle and straight MECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 180 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Working size: Length 150 mm to 900 mm ( 6" to 35-7/16"); Width 25 to 205 mm (1" to 8") -- Speed: 70 m/Min ( 230 FPM) -- Infeed inverter : (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: -- Working size: Thickness 17 mm to 60 mm (5/8" to 2,3/8"); Width 25 mm to 205 mm (1" to 8") --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 10 to 90 m/Min (32 to 292 FPM) (H) MECHANICAL SPECIFICATIONS: 20’ (6.2 M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 8"; wide x 0.60"; to 2-3/8"; high x up to 20’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 10 m to 70 m/Min (32 to 227 FPM) --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high-speed oil tank) --Cycle Speed: 1 to 6 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 500 mm (20";) --Average block cros

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-305"Up to 12"; Wide x 4-1/4" Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39"; to 236" (1,000 mm - 6,0000 mm). -- Board widths from 2"; to 12"; (50 mm - 305 mm). -- Board thickness from 1" to 4.3"; (25 mm - 110 mm). -- Board out-feed length 40’. (could be increased with an outfeed conveyor) -- Glue type to be used: PVAC. (Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-305 Mechanical Specifications: -- Top infeed feed rolls powered with (2) 2HP motors. -- Bottom infeed feed rolls powered with (2) 2 HP motors. -- In-feed Inverter with (2) 7.5 HP motors. -- Auxiliary conveyor wheel with 2.6 HP servo motor. -- Top Shaper Spindle powered with a 30 HP motor. -- Bottom Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 12“(305 mm). -- Maximum Cutterhead diameter, 6.3“(160 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 295 FPM (10 ~90 m/Min). -- Outfeed cut-off saw motor, 10 HP. -- Cut-off sawblade, 24“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Outfeed conveyor, (2) 2 HP drives. -- Top outfeed feed rolls powered with (2) 2 HP motors. -- Lower outfeed feed rolls powered with (2) 2HP motors. -- Out-feed Inverter with (2) 7.5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. (glue pump not included) -- Hydraulic oil tank with 150-gal capacity (oil not included)Outfeed options: -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for the finger jointer (we can provide a quote) -- Gluing system with pump and nozzle Optional Cross Infeed Conveyor System:Optional Automatic 20 ft Cross InfeedPower Conveyor System Working size L = 1000 MM ~ 6000 MM, W= 50 ~ 305 MM, T=25 ~ 110 MM (Length 39" - 236" X Width 2" -12", Thickness: 1" to 43.3")Infeed roller Conveyor 3 HP1Cross feeding system 3 HP1Feeding speed of 15 M/min (48'/Min.)Storage area width 2500 mmAdditional cost: $61,990Glue Pump Option: -- Graco 1K PUR Glue SystemAdditional cost: $ 48,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 KG/cm² – 8 BAR --Electri

Call for Price

CAM-WOOD IAT 620-100HX INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6" X 16.5 feet long medium capacity Finger Jointing SystemIncoming Block Specifications: -- Incoming block lengths from 6"; to 31.5"; -- Blocks must be at least 50% longer than their width. -- Block thickness from 1/2"; to 3" -- Block width from 1"; to 6" -- Assembled lengths from 10’ to 16’ (Options 20’ or 24’) -- For use with PVAC adhesives (glue pump and nozzle not included) -- Works equally well with soft and hardwoods. -- Moisture content from 8 to 12% -- Blocks to be surfaced on (4) sides through a Moulder or 4-sided Planer to ± 0.2 mm with 90° right angle corners.Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. The conveyor is controlled by the operating system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width -- 1/2" to 3" thickness -- Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3"; (160 mm) maximum shaper cutterhead diameter (cutter head not included) -- 5 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyor powered by 1/2 HP motor. -- Table movement is inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles per minute. Motor senses load and varies travel as needed. TC-62 Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width. -- 1/2" to 4" thickness -- A 20 HP motor drives shaper spindle. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3" (160 mm) Maximum shaper cutterhead diameter (cutter head not included). -- 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP motor scoring saw, running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyer powered by 1/2 HP motor. -- Table movement is Inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses the load and varies travel as needed. Speed is controlled by system criteria. Included Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without a messy runoff. 4" Comb height is standard. -- Finger pitch 4 mm, 10 - 12 mm finger length is standard equipm

CAM-WOOD FJ-17 (FM) 6" X 16' Long Semi-Automatic Finger Jointer System(4) Version possible on this model. Choose the one that suits your needsTechnical Specifications:Incoming Block Requirements: -- Incoming block lengths No Limit (Manual Loaded). Blocks must be at least 50% longer than their width. -- Block thickness from 1/2"; to 3" -- Block width from 1"; to 6" -- Assembled lengths from 8’ to maximum 16’ or (20’ Options Add Extra ...$5,675.00) or 24’ (Options Add Extra ...$11,450.00) -- For use with PVAC adhesives Glue pump is not included -- Works equally well with soft and hardwood Blocks. Moisture content from 8 to 12% -- Blocks to be surfaced (4) sides through a Moulder or 4-sided Planer to ±0.2mm with 90° right angle cornersThis semi-automatic system is offered in (4) different versionsVersion 1: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) The price: $82,900.001. Semi-Auto Finger Shaper Process the finger at one side 2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual blush applied the glue,4. Semi-Automatic finger jointer press The price: $92,150.00Version2: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Manual Gluer (FSH-150) + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual Glue Spreader applied the glue,4. Semi-Automatic finger jointer pressThe price: $103,250Version 3: -- Finger Shaper with Gluer (FSM-621) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Automatic Glue Spreader applied the glue at the second finger process,4. Semi-Automatic finger jointer press The price: ...$116,600.00Version 4:Finger Shaper (FSM-460A) + RO-62 x 3 + Finger Shaper with Gluer (FSM-621) + Assembly Press (FJ-500A)1. Semi-Auto Finger Shaper Process the finger at one side.2. Push to the next (2nd) Semi-automatic finger shaper with Auto Glue Spreader and applied the glue at the other side,3. Semi-Automatic finger jointer pressThe price: ...$ 159,900Description of Each Unit:FSM-460A Semi-auto finger shaper (Air-hydraulic type) -- Working timber width (Horizontal Direction); 1"; to 6"; -- Maximum timber total width fit on working table 18"; -- Maximum working height (Vertical direction); 4"; -- Maximum timber thickness (Height feed into assembly press); 3"; -- Working timber length; No Limit (Timber length must be at least 50% longer than the timber width to be processed.) -- Trim saw/Hogging blade 180 mm x 50T x 5 mm x 1 pcs. Trim/Hogging saw speed; 2,850 RPM -- Trim/Hogging saw motor 5 HP x 1 -- Finger shaper motor; 10 HP x 1 . Finger spindle Speed; 5,500 RPM. Spindle size; 50 mm, OD of finger cutter; OD160 mm -- Table movement by pneumatic–hydraulic cylinder -- Cycle time

Call for Price

CAM-WOOD HSTC-62 HIGH SPEED LONG BOARD VERTICAL FINGER JOINTER with the following Specifications: Technical Specifications: -- Infeed lenght 1000 mm to 5,000 mm (39" to 16') -- Working width 50mm - 300 mm (1.9" to 11.9") -- Working thickness 25 mm tp 100 mm (1" to 3.9")HSTC-62A Infeed Belt Conveyor: -- Working dimension: 24"; wide x 16’ long -- Speed at 110 FPM -- One 3 HP Inverter Drive Motor SHAPER #1: DFSR-62I - Left Side Heavy Duty Finger Joint Shaper -- Working dimension: 24"; wide x 2"; to 12"; high x 39"; to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7"; diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12"; diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4"; -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Table cycle speed from (1) to (4) cycles per minute (depends on work)HSTC-62A HEAVY SINGLE TABLE OUTFEED TRANSFER CONVEYOR -- Working dimension: 24"; wide X 16’ long -- Speed at 110 FPM -- One 3 HP Inverter DriveHSTC-62A SINGLE TABLE INFEED TRANSFER CONVEYOR -- Working dimension: 24"; wide X 16' long -- Speed at 110 FPM -- One 3 HP Inverter DriveSHAPER #2: DFSR-62I - RIGHT SIDE HEAVY DUTY FINGER JOINT SHAPER WITH GLUE APPLICATOR -- Working dimension: 24"; wide x 1"; to 10"; high x 8"; to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7"; diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12"; diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4"; -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Injection type adhesive spreader with standard glue height of 10"; -- Glue system included is for PVAC. (glue pump not included) -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra priceHSTC-62B OUTFEED CONVEYOR WITH BELT CLEANER -- Working dimension 24"; long X 16’ wide -- Speed at 115 FPM -- (1) 3 HP Inverter Drive -- (1) 1/2 HP motor for conveyor cleaning device HSCB-62 TIPPING CONVEYOR W/NARROW CONVEYOR -- Flips boards from vertical to horizontal for automatic feed to the Press -- Working dimensions: -- (1) Conveyor at 24"; wide x 16’ long -- (1) Conveyor at 12"; wide x 16’ long -- Speed 110 FPM -- 3 HP Inverter Drive UFJ-600 FINGER JOINT CONTINOUS ASSEMBLY MACHINE FOR INFINITE LENGTHS -- Working dimension 1-3/8"; to 12" wide X 1"; to 4"; thick by unlimited lengths -- In-feed speed from 100 to 165 FPM -- Cut-Off Saw: 7-1/2

CAM-WOOD SFJ-3800-205-FM-FAH HIGH SPEED, LONG BOARD, HORIZONTAL JOINT, FINGER JOINTER: Specifications: -- Double Chain & Slat Type Shaper Section designed for long incoming boards -- Manual infeed; Slat Bed Feed Chain runs at up to 75 FPM; lugs on 30" centers. Slat Bed powered with a 15 HP gear motor with 1:40 gear ratio. -- Table Transfer Conveyor (Powered), even ends boards to the Right and Left Shaper Fences: powered by (2) 7-1/2 HP motors -- Power raising and lowering of the holddown assemblies on both Shaper Sections; Powered with (2) 2 HP motors -- (1) Pair Scoring Saws with 2 HP motors, 50mm arbor, 2,850 RPM, scoring blade size of 7"; x 50 tooth, (4) Blades included -- (1) Pair Trim Saws with 10 HP motors, 50mm arbor, 4,275 RPM, trim saw blade size of 10"; x 100 tooth. (2) Blades included -- (1) Pair Vertical Hogging Shaper Spindles with 10 HP motors, 50mm arbor, 4,375 RPM, hogging blade size of 9.4"; x 50-tooth. (2) Blades included -- (1) Pair Vertical Finish Shaper Spindles with 20 HP motors, 50mm diameter spindles, 5,300 RPM. For -- 50mm bore x 160mm dia. cutterheads; finger length of 1.122";; cutterheads and knife profile to buyer’s specification -- Extrusion Type Glue Application System for PVAC Glues; mounted on Right Side Shaper Section. Includes glue pump, valves, and glue injection thru the applicator comb machined to buyer's specifications. -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra price -- Deduct $5,200 if provided without a Glue SystemSCC-20 TRANSFER CONVEYOR -- Conveyor between Shaper Section to the Press Section -- Working dimension: from 1"; to 8"; wide x 12"; to 12’-6"; long -- Speed 230 FPM -- Powered by (1) 3 HP HSC-65 HIGH-SPEED PRE-PRESS ASSEMBLY SECTION -- Working dimensions: 1"; to 8"; wide x 3/4"; to 2-1/4"; high x up to 21’ long -- (2) 5 HP motors drive the double flat-top chains -- Feed speeds from 32 to 295 FPM -- Includes (1) 15 HP Frequency Converter to power the feed chain motors at speeds determined by incoming boards lengths NFJ-1500 50’ HEAVY-DUTY AUTOMATIC ASSEMBLY PRESS -- Working dimension: 1"; to 8"; wide x 3/4"; to 2-1/4"; high x up to 50’ long -- Power of upper rollers: (2) 3 HP motors with a 1:10 gear ratio -- Power of lower roller: (1) 5 HP motor with a 1:10 gear ratio -- In-feed Inverter: (1) 15 HP motor -- In-feed speed: From 32 to 295 FPM -- Cut-off saw: With 7.5 HP motor driving the arbor at 2,850 RPM -- Sawblade: 14"; Diameter x 120 tooth -- Hydraulic power to the Pressing Cylinders: (2) 20HP with high-speed oil tank -- Hydraulic pressure output: 1,700 PSI at the joint -- Capacity (1) to (4) 50’ assembled boards per minute -- Machine comes arranged with equipment to assemble (3) sizes of material cross sections according to buyer’s specifications for width within +/-3/16"; width toleranceSYSTEM REQUIREMENTS FOR INCOMING BOARDS -- Incoming lumber length: 1’ to 12

Cam-Wood TRS-MR-1300 X 75mm Roll Feed Gang Rip SawSpecifications -- Working thickness: 10 - 100mm • -- Working width: 530 - 1300 mm • -- Working thickness : 10 – 75 mm / 100 mm • -- Saw Blade 14", • Washer Diameter 110mm • -- Minimum length of work piece when feeding consecutively: 600mm • -- Number of spindle : 1 • Equipped with & Features -- Up & down motor : 1 HP x 1 • -- Feed speed : 6 - 15 M/ min. • -- Feed motor: 7.5 HP x 1 with Inverter • -- Multiple rip saw spindle motor:150 HP / 200 HP • -- Spindle diameter : 80 mm with two key-ways 10 mm5 mm • -- Spindle R.P.M.: 4,000 R.P.M. • -- Movable 1300 mm Saw Shaft Support for easy saw blade replacement.

Cam-Wood TRS-MR-1300 X 100mm Roll Feed Gang Rip SawSpecifications -- Working thickness: 10 - 100mm • -- Working width: 530 - 1300 mm • -- Working thickness : 10 – 75 mm / 100 mm • -- Saw Blade 14", • Washer Diameter 110mm • -- Minimum length of work piece when feeding consecutively: 600mm • -- Number of spindle : 1 • Equipped with & Features -- Up & down motor : 1 HP x 1 • -- Feed speed : 6 - 15 M/ min. • -- Feed motor: 7.5 HP x 1 with Inverter • -- Multiple rip saw spindle motor:150 HP / 200 HP • -- Spindle diameter : 80 mm with two key-ways 10 mm5 mm • -- Spindle R.P.M.: 4,000 R.P.M. • -- Movable 1300 mm Saw Shaft Support for easy saw blade replacement.

$ 64,500

CAM-WOOD INFEED AND OUTFEED PLANER TRANSFER LINE: 20"; Wide X 20’ Long Roller Conveyors with 6,000 lbs capacity and Consisting of the following: NON POWERED IDLE INFEED RIGHT ANGLE ROLLER TRANSFER CONVEYORS -- (4) Conveyor Sections, each 14"; Wide X 8’ Long (SEE DRAWING). -- 2-11/64"; Roller Diameter -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 6,000 lbsPOWERED INFEED CANTED ROLLER CONVEYOR -- With VFD Drive with speed feed 18' to 70 FPM -- 22"; Wide X 20’ Long -- Heavy Duty 3-11/32"; Roll Diameter -- (9) Rolls on 36"; Centers -- (5) Pneumatic jumped transfer roll -- Back Side Adjustable FencePOWERED OUTFEED STRAIGHT ROLLER CONVEYOR -- With VFD Drive with speed feed 18' to 70 FPM -- 22"; Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32"; Roll Diameter -- Rolls on 36"; Centers -- Includes (4) Sections of Pneumatically Jumped Skate Rolls -- Heavy Duty Type, Sections are 6"; Wide X 20"; Long NON POWERED IDLE OUTFEED RIGHT ANGLE TRANSFER ROLLER CONVEYORS (SEE DRAWING) -- (4) Conveyor Sections, each 14"; Wide X 8’ Long. -- 2-11/64"; Roller Diameter. -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 6,000 Lbs.

CAM-WOOD XCL-59 Auto Copy Lathe. via a template. SPECIFICATIONS: --Max. Between Center: 59". --Max. Finish Product Dia: 4-1/4". --Spindle Speed: 2,000 ~ 6,000 RPM. --Main Motor: 7.5 HP. --Hydraulic Motor: 3 HP. --Template Copier: One. --Model Copier: One. --Max. Copier Travel: 3-1/8". --Total Cutting Knives: 4 (including top plunging knives) --Feed Speed: Variable. --Includes (2) top plunging knives which can hold profiled or flat knives for dowel ends, etc. --Operation Modes: Manual Semi-auto, Auto. --Gross Weight: 3,400 Lbs, Net Weight: 2,900 Lbs.FEATURES: • Suitable for small quantity and multiple style production uses.• Can use sample or template for duplicate productions.• Cutter carriage forward and backward movements are hydraulically operated with feed.speed control, providing a smooth motion and stable cutting performance.• Adopts the precision hydraulic copy unit, most forms can be duplicated.• Easy to operate and lower maintenance costs.• There is a tongue shaving knife to pre-cut and guide ring to support the workpiece whencutting. This enables the cutting performance to be stable and more accurate.• Equipped with two sets of copying devices; one is copying device, which is driven by links andadopts U-Cutting tools. The other one is sample copy device by hydraulic system and adopts V-Cuttingtools.• Equipped with material center setup rack and automatic lubricator to lubricate the slide waysand keeps the slide ways in the optimal lubricated condition.• Industrial full power motor for maximum cutting capacity.• Precision sealed long-life bearing.• Heavy cast iron frame and table for durability usage.

$ 191,200

CAM-WOOD SM-545 HS 5-Heads High-Speed Trough Feed /Planer/Moulder(5) Heads (B-R-L-T-T), working cap. 450 mm X 160 mm (17-7" x 6-1/4").Specifications: -- Max/Min working width 17.7" - 3/4" -- Max/Min thickness 6 1/4" - 5/16" -- Minimum length 9-1/2" -- Head sequence: Bottom 15 HP, right 15 HP, left 15 HP, top 20 HP, and top or bottom 20 HP . -- All Horizontal spindles have outboard bearings -- Spindle dia. 50 mm with cutterhead speed of 6,200 RPM. -- All spindles are equipped with mechanical digital readouts, "Dual mechanical" readouts on the left and top spindles. Mechanical readouts for pressure elements and chipbreakers; all chipbreakers and pressure elements with pneumatics. -- Feed works: Inverter driven 15 HP feed system with feed speeds of 20 - 260 FPM. -- Infeed table 2M (6'6"), chromed tables, and fences. Side pressure roller mounted at infeed. Features and complete with: -- Feed speeds ranging from 20' ~ 260' per minute are a standard feature. -- The full safety enclosure also works as a chip guard and helps to reduce noise. -- Table surface is hard chrome-plated for maximum wear resistance. -- All manually adjusted turning parts are housed in dry bearings for oil-free lubrication. -- One piece cast iron machine frame and table is especially normalization heat treated for maximum stability and rigidity. -- Fence adjustment is quickly accomplished by a quick-setting lever. -- The three independent section pneumatic pressure for the infeed rollers, in-process rollers and outfeed rollers can be set with individual pressure allowing for consistent feeding results and outstanding effect. -- All control levers for the spindles are located at the front of the machine for convenient adjustment. -- Each spindle is provided with a mechanical digital readout, giving accurate adjustment. -- Vertical spindle adjustment up to 80 mm, allows fitting several tools on the vertical spindle, eliminating troublesome cutter change. -- Separate adjustment of vertical spindle and insert table permits the table to be positioned extremely close to the cutterheads for added cutting stability. -- An individual motor drives each spindle and is separately mounted to eliminate spindle chattering during high-speed running. -- Centralized lubrication system Available options: -- Digital (electronic) display for X and Y axis for each head add $ 3,200 /per head -- NC Automatic positioning control system. This option consists of motorized adjustment of the head control from the main screen of the machine.This option include: -- 15" HMI (1000 memory setting), -- Servo motor positioning, Simple and easy to operate. -- Width and thickness quickly & auto set-up -- Tools management system -- Lateral chain feeder (quoted with customer material specifications)

$ 198,900

CAM-WOOD WP-16L- V5HX 4 Sided 5 Heads High Speed Planer Designed for furniture, cabinet, flooring, intermittent planning mill work, and other industrial uses. Perfect Planer for S2S and S4S planning, tongue & groove flooring, wall paneling, etc. up to approximately 180 FPM depending on depth of cuts and dimensions of partsSpecifications: -- Width: ¾"; to 16"; -- Height: 3/8"; to 4"; -- Length: Maximum Unlimited, Minimum 70";. -- Maximum Cutting Depth; 8 mm -- Feed Rate 40 to 180 fpmFeatures:Horizontal Top & Bottom with Slip-On Spiral Head or Optional Profile cutter head, Tooling Information. -- Standard supply with Slip-On HAR Series Profile / Spiral Cutter head, Profile Knives combined with Carbide Insert 15 x 15 x 2,5 mm. Max depth of cut 8 mm each side (Standard 7"; O.D. Shaft 46 mm): Vertical with Helical or Optional Profile cutter heads -- Left & Right Side/ Standard HAR Series Vertical profile heads. -- Max depth of cut 8mm, 7"; OD, Spindle arbor diameter: 40 mm, -- Left & Right-side Heads can be profile work with owner provided tooling. Fifth head for moulding or sawing -- 15 HP Top Saw Head, raise/lower power digital by HMIQuality Features: -- Simple touch screen with Digital Positioning Controllers for width, thickness adjustment and variable feed speed. -- Hard Chrome plated table for long life -- Automatic top spindle – cutter head height adjustments entered via HMI touch screen control with PLC. -- Floating bottom infeed rolls for smooth, positive feeding -- Variable feed speeds by VFD. Controlled from touch screen. -- Heavy-duty spindle assemblies for durability & smooth finishes. -- Overhead assembly travels up/down and positions via touch screen control, Assembly is support by (4) hard chromed, polished posts and precision screws. -- Tables, fences, etc. are precision ground, polished and hard chromed to provide long life and smooth feeding. -- Massive, heavy-duty sheet metal frame for vibration absorbing finishes and extra-long bearing life. Compact construction with exclusive see-through top guard. -- Motor Control Center with under voltage and overload protection. UL and CSA labeled electric components.Motor Sizes and Feed Works: -- Top and Bottom Cutter Heads Motors each: 30 HP, 5,000 RPM -- Right & Left Side Cutter Motors each: 25 HP, 5,000 RPM -- Second top head for Top saw head, raised and lowered motorized digitally by HMI, drive motor 15 HP -- Variable Feed speeds from 40 to 180 FPM by VFD (invertor) -- Feed is powered by (2) each 5 HP VFD feed motors, (1) motor drives the top infeed and (1) Motor drives the top outfeed feed rolls. Top powered feed rolls are air cylinder loaded / Floating. (4) idle bottom infeed feed rolls and (4) idle bottom outfeed rolls.Overall dimensions: 167" X 71" X 73".

$ 62,900

CAM-WOOD WS-NDA 1300 3-Head Planer Sander[Equipped with Planer, Drum and combi head]Features: -- This machine is especially designed for removing heavy material such as glued-up panels, bent boards, and rough lumber. -- The first station is a knife planer head, followed by a combi head with drum and platen at the second station and a finishing platen head at the third station. -- Head configuration can be made to meet customer’s requirements. -- The spiral planer cutter head is fitted with 14 x 14 MM, four-edge throwaway Tungsten Carbide knife inserts, providing a superior chip removal rate, minimum noise, and an extremely smooth cutting effect. -- Changing knife inserts is convenient without removing the cutter head. The spiral cutter head is precision machined from special aluminum alloy steel, tempered, and precision ground by a CNC machine center. -- Anti-kickback fingers, mounted at the infeed of the machine, this anti-kickback finger gives a safety guard for the operator. -- Insufficient pressure protection: If inadequate working air pressure occurs, the machine brakes automatically for safety guard. -- The irreversible running of the pressure roller runs in a single direction only, giving an additional safety guard for panel kickback. -- Automatic elevation of conveyor table (micro-computer controlled with digital readout): it accurately displays the position of the conveyor table. It automatically moves to the setting thickness for planning and sanding. -- Panel cleaning brush roller: built at the outfeed end of the machine, this cleaning brush roller cleans the powder on the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Specifications: -- First head Planer with 40 HP motor -- Second head combi drum & platen with 30 HP motor -- Third head finishing platen with 30 HP motor -- Panel cleaning brush at outfeed with 1/2 HP motor -- Working width: 52" -- Working thickness up to 6 1/4" -- Minimum working length: 21" -- Feed speed 10 FPM to 90FPM inverted driven by 5.5 HP motor -- Table hoist motor 1 HP -- Sanding belt size 52" X 75" -- Floor space requirement: 107" X 103" X 80", weight 12,300 Lbs

$ 10,900

CAM-WOOD TX-P3200SAX Sliding Table Panel Saw w/Motorized Raise & Lower.Heavy-duty construction, vibration-free operation. Easy to set up and quickly adjusts. High accuracy, free movement sliding table without wear resistance.Specially designed double rollers carriage made by aluminum profile. Stable, torsion-free cross slides with easy running swinging arm.Features: -- 126" Cutting length w/scoring; 126" x 17" Anodized sliding table that locks in any position for easy loading. -- Motorized Saw blade up or down movement by 1/4 HP electric servo motor; tilting by manual handle wheel. -- Scoring unit for clean, accurate chip-free cutting, ready for edge banding. Specifications: -- 7.5 HP Main saw motor; 45° tilting (30 mm) main saw arbor; 14" Main blade dia.; 3,000/4,000 & 5,600 RPM arbor speed. -- 5.3" Max. material thickness at 90°; 3.1" at 45°. -- 1 HP Scoring saw motor, 5" dia. scoring blade; 8,000 RPM. -- Equipped with: 49" Max. ripping cap.; micro-adjustable rip fence and extendable crosscut fence to 10' with (2) flip stops. -- Articulating overarm protection guard; outboard and rear extension tables. -- Includes: Saw Blade(s), Maintenance Tools, Operators' & Parts Manual and covered by (1) Year Warranty.

$ 174,900

CAM-WOOD SM-632 HS 6-Heads High-Speed Through Feed Moulder(6) Heads (B-R-L-T-T-B), working cap. 12-1/2" x 6-1/4"".Specifications: -- Max/Min working width 12 " - 3/4" -- Max/Min thickness 6" - 5/16" -- Minimum length 9-1/2" -- Head sequence: Bottom 15 HP, right 15 HP, left 15 HP, top 20 HP, top 20 HP and bottom 20 HP motor. -- All Horizontal spindles have outboard bearings -- Spindle dia. 50 mm with cutterhead speed of 6,200 RPM. -- All spindles are equipped with mechanical digital readouts, "Dual mechanical" readouts on the left and top spindles. Mechanical readouts for pressure elements and chipbreakers; all chipbreakers and pressure elements with pneumatics. -- Feed works: Inverter driven 15 HP feed system with feed speeds of 20 - 260 FPM. -- Infeed table 2M (6'6"), chromed tables, and fences. Side pressure roller mounted at infeed. Features and complete with: -- Feed speeds ranging from 20' ~ 260' per minute are a standard feature. -- The full safety enclosure also works as a chip guard and helps to reduce noise. -- Table surface is hard chrome-plated for maximum wear resistance. -- All manually adjusted turning parts are housed in dry bearings for oil-free lubrication. -- One piece cast iron machine frame and table is especially normalization heat treated for maximum stability and rigidity. -- Fence adjustment is quickly accomplished by a quick-setting lever. -- The three independent section pneumatic pressure for the infeed rollers, in-process rollers and outfeed rollers can be set with individual pressure allowing for consistent feeding results and outstanding effect. -- All control levers for the spindles are located at the front of the machine for convenient adjustment. -- Each spindle is provided with a mechanical digital readout, giving accurate adjustment. -- Vertical spindle adjustment up to 80 mm, allows fitting several tools on the vertical spindle, eliminating troublesome cutter change. -- Separate adjustment of vertical spindle and insert table permits the table to be positioned extremely close to the cutterheads for added cutting stability. -- An individual motor drives each spindle and is separately mounted to eliminate spindle chattering during high-speed running. -- Centralized lubrication system Available options: -- Automatic Jointer for all (6) heads add: ...$46,900 -- Digital (electronic) display for X and Y axis for each head add $ 3,200 /per head -- NC Automatic positioning control system. This option consists of motorized adjustment of the head control from the main screen of the machine.This option include: -- 15" HMI (1000 memory setting), -- Servo motor positioning, Simple and easy to operate. -- Width and thickness quickly & auto set-up -- Tools management system -- Lateral chain feeder (quoted with customer material specifications) -- For 6 heads machine add $82,800 -- For 7 heads machine add $ 90,600

$ 61,900

CAM-WOOD SM-167AX Lateral Chain FeederLateral Chain Feeder for up to 11.8"' X 16' long materialFeatures: -- The feed table is designed to be able to connect with any 4-sided Moulder, Multiple Blade Rip Saw, Straight Line Rip Saw and Planer -- Feed rollers are pneumatically actuated for quick clamping of wood. The feed speed of the front set of rollers is adjustable to match the moulder -- Hydraulic drive motors for each feed roller allow variable feed drive -- Centralized control panel, with push-button for start and stop, chain feed regulation and display, feed roller raising/lowering control -- Infeed fence, the infeed fence allows the material to be lined up properly with the feed roller -- Wood thickness limit. There are two adjustable thickness limits preventing over-thickness material to enter the moulderSpecifications: -- Working width 25 to 300 mm (1" to 11.8") -- Working thickness: 8 to 160 mm (0.315" to 6.3") -- Working lenght: 2,000 mm to 7,000 mm (78.7" to 275.6") -- Infeed table 5,425 mm L X 2,090 mm W X 1,920 mm H ( 213.5' L X 82.2" W X 75.5" H) -- Minimum working length: 1,000 mm (39") -- Feed speed: 10 - 120 MPM (32.5 FPM - 390 FPM) -- Feed motor drive for hydraulic motor: 5 HP -- Table feed motor: 2 HP with inverter control -- Feed roller diameter: 140 mm (5-1/2")

$ 126,900

CAM-WOOD SM-623-HS 6-Head High-Speed Trough Feed Moulder(6)-Heads (B-R-L-T-T-B), working cap. 9" x 6-1/4".Specifications: -- Max/Min working width 9-3/4" -- Max/Min thickness 6-1/4" - 5/16" -- Minimum length 9-1/2" -- Head sequence: Bottom 10 HP, right 10 HP, left 10 HP, top 15 HP, top 15 HP and bottom 15 HP motor. -- Spindle dia. 40 mm (or by request) with cutterhead speed of 6,200 RPM. -- Feed works: Inverter driven, 10 HP feed system with feed speeds of 20 - 260 FPM. -- Infeed table 2 M (6'6"), chromed tables, and fences. Side pressure roller mounted at the infeed. Features and complete with: -- SM-237-DG where the last bottom spindle can be used for cutter head or saws with inverter RPM control -- HMI Touch Screen Control for all the head positions -- Automatic setting from 2nd to 6th heads, (2) axis positions and thickness control by servo control movement -- 200 sets of memory (Extendable) -- Feed speeds ranging from 20' ~ 260' per minute are standard specifications. -- Hard chrome-plated table for maximum wear resistance. -- Full enclosure safety hood reduces noise and completely prevents chips from splashing. -- Anti-impact plate for over-width and over-thickness protection. -- Oversize top and bottom rollers run synchronized, ensuring smooth feeding. -- FRP plastic steel safety guard features maximum durability and is impact resistance. -- The three independent section pneumatic pressures for the infeed rollers, in-process rollers, and outfeed rollers canbe set with individual pressure allowing for consistent feeding results and outstanding effect. -- The smooth initial feeding of the stock is achieved by the independently powered infeed rollers. -- Exclusively designed template inserted pressure plate suits various stock thicknesses and profile variations. -- A special pressure plate with table feeding roller design, provides smooth and precise cutting of dry and wetwood, reducing the possibility of material jams. -- All control levers for the spindles are located at the front of the machine for convenient adjustment. -- Vertical spindle adjustment up to 80 mm, allows fitting several tools on the vertical spindle, eliminating troublesome cutter change. -- Separate adjustment of the vertical spindle and insert table permits the table to be positioned extremely close to the cutterhead for added cutting stability. -- An individual motor drives each spindle and is separately mounted to eliminate spindle chattering during high-speed running. -- Centralized lubrication system Available options: -- Automatic jointer head for all (6) heads add ...$ 58,500 -- Siko encoder with digital display for all axis add ...$ 4,200 per head -- Automatic lateral chain feeder P.O.R.

$ 201,200

CAM-WOOD SM-732 HS 7-Heads High-Speed Trough Feed Moulder(7) Heads (B-R-L-T-T- T-B), working cap. 111 13/16" x 6-1/4"".Specifications: -- Max/Min working width 11 13/16" - 3/4" -- Max/Min thickness 6 1/4" - 5/16" -- Minimum length 9-1/2" -- Head sequence: Bottom 20 HP, right 15 HP, left 15 HP, top 20 HP, top 20 HP, top 15 HP and bottom 15 HP motor. -- All Horizontal spindles have outboard bearings -- Spindle dia. 50 mm with cutterhead speed of 6,000 RPM. -- All spindles are equipped with mechanical digital readouts, "Dual mechanical" readouts on the left and top spindles. Mechanical readouts for pressure elements and chipbreakers; all chipbreakers and pressure elements with pneumatics. -- Feed works: Inverter driven 15 HP feed system with feed speeds of 20 - 260 FPM. -- Infeed table 2M (6'6"), chromed tables, and fences. Side pressure roller mounted at infeed. Features and complete with: -- PNEUMATIC LOAD INFEED SIDE PRESSUREWhile high speed feeding, the side pressure on infeed table ensures every timber close to the fence even under different width. It's convenient to adjust quickly. --OVER HEiGHT PROTECTIONIn case workpiece exceeds the rated maximum height, it will be restricted by the over height protection device provided at the workpiece infeed end. -- HYDRAULIC OUT-BOARD BEARING SUPPORT TOP AND BOTTOM SPINDLESpecially designed hydraulic supports on the top and bottom spindles assure maximum stability while performing high speed and heavy duty machining. -- PNEUMATIC LOAD SIDE PRESSURE WHEELS The front side air pressure wheel on left vertical spindle fully eliminates problem when feeding short or narrow stock not smoothly. The pressure plate is easy and quickly to adjust. -- PNEUMATIC LOAD TOP PRESSURE PLATEThe front pressure plate for top spindle is available to apply an air loading device ensuring maximum stability while performing high speed cutting -- CENTERAL LUBRICATION POINTThe lubrication point are located at the centralized plate for convenience. -- POWERED INFEED TABLE ROLLER The roller in the infeed table is powered, providing a smooth feeding effect for feed stock. -- VERTICAL SPINDLE AXIAL ADJUSTMENT UP TO 60MMIt allows fitting several tools on the vertical spindle, eliminating troublesome cutter change. The 60mm spindle adjustment provides full utilization for a single cutter. -- CENTRALIZED PRESSURE ADJUSTMENT• All pressure regulations for the entire pneumatic system are centralized at the front of the machine for added convenience in pressure adjustment, and sectional pressure adjustments for all pressure rollers ensure consistent pressure.• Clear numerical indicators are provided to correspond directly to the pneumatic mechanisms on the machine, allowing operators to make adjustments based on different processing requirementsAvailable options: -- Automatic Jointer for all (6) heads add: ...$45,600 -- Digital (electronic) display for X and Y axis for each head add $ 3,200 /per head -- NC Automatic positioning control sys

CAM-WOOD XCL-1000S 4-Spindle Auto Copy Lathe/Shaper w/Sanding of Asymmetrical parts .via a template. Shaping with (4) cupped cutters and sanding with individual belts.Specifications: -- Capacity: (4) Spindle duplicating/carving/copy heads with (4) copy belt sanders for asymmetrical parts. Working length 6-3/8"- 39.5" -- Working dia. 1-1/8" - 8-1/4". Cutter diameter approx. 1.4" -- Speeds: Spindle Speed : Variable 2000 - 6000 RPM. Cutting Circle 2 - 12 times/min. -- Features: (4) Spindles with pre-loading centering station and pneumatic clamping. -- Drives: Hydraulic carriage motor 3 HP; Cutter drive motor 7.5 KW (10 HP). Sanding heads motor 2 x 1 HP. -- Electrical controls: 220 V Relay style. -- Overall Dimensions: 120" long x 47" deep x 110" high -- Approx. net weight: 6,240 Lbs. -- NOTE 1: Larger diameters are possible by using every second carriage position, ie. (2) heads instead of four heads. -- NOTE 2: Version without Sanding, XCL-1006 is priced at

$ 74,990

CAM-WOOD SM-623L Moulder, Feed Through 6-Head (B-R-L-T-T-B), working cap. 9-3/4" x 5-1/4". Head sequence: -- Bottom 10 HP, right 10 HP, left 10 HP, top 20 HP, top 15 HP, and bottom 20 HP motor. -- Spindle dia. 40 mm with a cutter-head speed of 7,200 RPM. All spindles with mechanical digital readouts. -- Feed: Variable speed of 26 - 119 FPM, with 7-1/2 HP feed drive motor. Powered feed rollers top and bottom. -- Infeed Straightening table 2M (6'6"), with side pressure roller and table lubrication pump. -- Dust outlet Diameters are 5" X 6" outlets. Includes: -- Hard chrome-plated fences and table, -- Operator/spare parts manuals, -- Centralized control panel, -- Sound and safety enclosure, -- Short stock feeding mechanism (9 1/2" min length), -- Power elevation (1-1/2 HP beam.)Options:Training and installation, tooling & rigging are optional. -- SM-KFST Knife Setting Stand ...$1,970.00The machine base is one piece coated from high-quality cast iron (FC-25) for maximum stability of the structure. Base is machined by CNC machine equipment to ensure the utmost working accuracy. Net weight 11,220 Lbs Shipping weight 12,300 Lbs.

.gif)