704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1837 Results Found

704-841-2001

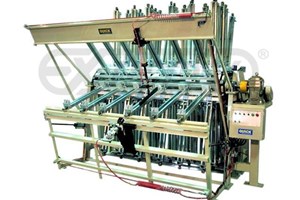

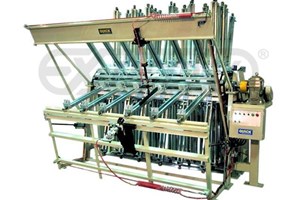

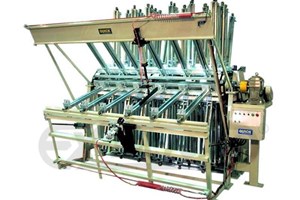

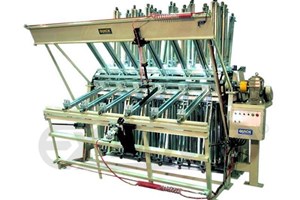

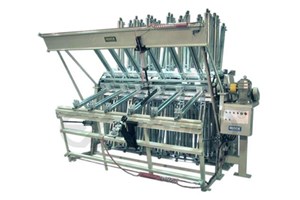

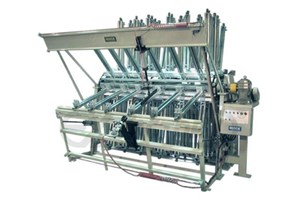

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

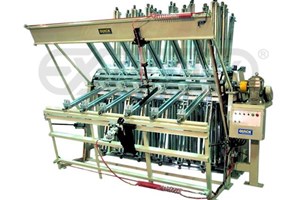

²QUICK 14-Section Pneumatic Clamp Carrier with 10-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. -- Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- A 14-Section Clamp will produce approx. 300 panels

QUICK 6-SECTION, 12-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp, typically produces (144) high-quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (9) clamps per section and 12-1/2' width capacity. -- (54) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- Rocker Plates are available as optional equipment for face gluing. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy-to-use controls. -- Pneumatic Clamp Tightener with a 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; the 2-handed, trigger-activated tightener is more confidence-inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, and automatic air line oiler; -- High-quality Urethane finish coating, and tool box with spare parts & tools.Floor space requirement: 195"W X 125" H X 127"D

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

Quick Heavy Duty Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- (10) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- Includes 180 clamps with 44" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener along with tightener -- Pneumatic panel flattener for second operator -- Semi-Automatic Pneumatic clamp tightener . -- Semi-Automatic panel tightener for second operator -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

QUICK 14-Section Heavy Duty Hydraulic Clamp Carrier with 20-1/2' width capacity With (16) Standard zinc plated clamps per section (224) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Pneumatic Panel Flattener with easy to use controls. -- Pneumatic panel flattener for second operator -- Hydraulic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic clamp tightener for second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

Quick Heavy Duty 14-Section Hydraulic Clamp Carrier, 16-1/2' Wide -- 14-Section Clamp Carrier 16-1/2' width cap.. -- (12) Heavy Duty zinc plated clamps per section for (168) total clamps. -- 38" opening on clamps; jaw sizes on clamps are 3-1/2" high x 4-3/4" wide with 1° inward draft. Equipped with: -- Dual Overhead Pneumatic Panel Flatteners for (2) operators -- Dual Hydraulic Clamp Tighteners for (2) operators -- Automatic Electric Motor Rotation with Indexing. -- Standard features include: Foot levelers, coiled air lines where used and flexible conduit for wires.

²QUICK 14-Section Pneumatic Clamp Carrier with 12-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment Panel Flattener with easy to use controls.Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

Call for Price

SCHELLING FH4-330/310 FRONT LOAD, AUTOMATIC PANEL SAW: -- Specifications: 130" (3,330 mm) Rip Cutting cap. & 130" (3,300 mm) pull back; 4.1" (105 mm) saw blade projection; 3.5" (90 mm) Max book height; 24 HP (18 kW) - 3.800 RPM main motor, 3 HP (2.2 kW) - 5,500 RPM scoring motor. -- Saw Carriage: Variable saw carriage travel speed from 16 - 525 FPM (5 - 160 MPM), constant return of 525 FPM (160 MPM). -- Pusher Fence: Programmable overhead program fence, rack & pinion driven on both sides; forward speed from 0 - 262 FPM (0 - 80 MPM), constant return speed of 262 FPM (80 MPM).Pusher fence with (8) material gripper clamps with double clamping fingers, clamps open to 3.5" (90 mm).Operator & Machine Control:PC Front-end controller with SCHELLING "MCS" Evolution + "HPO" Optimizing System + "Windows XP" operating system.17" Color screen displays cutting dimensions & patterns with "REAL TIME" moving graphics, self-diagnostic, data input by keyboard or direct downloading from office PC. -- Complete with:90.5" (2,300 mm) Long crosscut fence (front-to-back), (2) side/crosscut aligners, (1) in front & (1) back of the cut-line, up to 87" (2,210 mm) cross-cutting cap.Electronic scorer adjustment, from the machine control, (3) Front-mounted air float tables with (1) central fan, 24" x 83" (600 x 2,100 mm) each, of which (2) are movable.Fully enclosed for safety with a man-height wire screen fence with access doors. -- Includes:Original Docs, Manuals, tools & tooling as pictured. -- Actual Model is SCHELLING FH4 330/310

SCHMALZ VCBL-K 2 125x75x100 Q VACUUM PODS: -- Specifications: Quantity: (35) NEW, never been used SCHMALZ Vacuum Pods. -- Dimensions: 125 mm long x 75 mm wide x 100 mm height with crossways clamping arrangement. -- Prefixation to console by means of vacuum. -- Sealing edges and friction surfaces tailored for wooden surfaces with high dimensional accuracy. -- Hose-free vacuum clamping system for CNC Machining Centers with console table (2-circuit system). -- The vacuum blocks are prefixed to the consoles and secured against movement during setup. -- Safe and precise clamping of the workpiece and the vacuum blocks on the console with the second vacuum. -- Damage-free clamping with the highest precision and holding force -- Actual Model is SCHMALZ - VCBL-K 2 125x75x100 Q.

Call for Price

SCHUTTE 280.100 HAMMERMILL -- Type 13100P -- Rotor 24" dia. x 48" wide -- Housing 3/4" thick -- Shaft speed 3,600 rpm -- Heavy duty, statically and dynamically balanced rotor -- (96) Standard notched heat treated hammers 3/8" thick -- Also included; two screens -- Motor 125 HP -- Applications; Planer shavings, dry wood chips, etc. etc.

SCHUTTE PULVERIZER COMPANY - Model 40 HZF, ...HammermillComplete with the following major components & features: -- Integrated 18", 4,000 CFM Blower. -- WEBSTER Horizontal Feeder. -- Control Panel. -- Main drive motor: 75 HP - 3,540 RPM; originally 220V but switched to 460 Volt. -- Hammer width approx. 1-1/4" wide. -- 3-1/4" Shaft. -- 24" Dia. Rotor and a tip speed of 22,600. -- 17-1/2" Rotor width. -- 3/4" Main chamber steel.MANUFACTURER'S STATED KEY FEATURES:● Heavy-Duty plate construction with replaceable liner plates. ● Heavy-Duty grates available in a variety of sizes. ● Heavy-Duty rotor assembly. ● 24" dia. x 3" thick flywheel. ● Built-in fan conveys material up to 50' vertically and 100' horizontally.● Reversible anvil. ● 2-Way reversible "raked" hammers pull wood in without feed rolls. NOTES: ● Dates to early 1990s. ● The" HZF Series" Horizontal Trim Scrap Grinder is a high-speed, high production Grinder designed specifically for processing longer lengths of wood scrap such as: Rippings, edging, and trim blocks. Available in (4) standard sizes from 10" to 36" wide.● Each model features a built-in fan driven off of the main mill shaft, saving energy and valuable floor space while also significantly increasing production.

SCHUTTE PULVERIZER COMPANY - Model 40 HZF, ...HammermillComplete with the following major components & features: -- Integrated 18", 4,000 CFM Blower. -- WEBSTER 16 Ft. Horizontal Vibrating Conveyor. -- Motor Controls. -- Main drive motor, 75 HP - 3,540 RPM. -- Hammer width is approximately 1-1/4 in. wide. -- 3-1/4" Shaft. -- 24" Dia. Rotor and a tip speed of 22,600. -- 17-1/2" Rotor width. -- 3/4" Main chamber steel. -- Factory Frame.MANUFACTURER'S STATED KEY FEATURES:● Heavy-Duty plate construction with replaceable liner plates. ● Heavy-Duty grates available in a variety of sizes. ● Heavy-Duty rotor assembly. ● 24" Dia. x 3" thick flywheel. ● Built-in fan conveys material up to 50' vertically and 100' horizontally.● Reversible anvil. ● 2-Way reversible "raked" hammers pull wood in without feed rolls. NOTES: ● The HZF Series Horizontal Trim Scrap Grinder is a high-speed, high production Grinder designed specifically for processing longer lengths of wood scrap such as rippings, edging, and trim blocks.● Available in (4) standard sizes from 10" to 36" wide.

Call for Price

SCHUTTE-BUFFALO 15 Series, Model 15300 Wood Grinder;Complete with the following components and features: --Carbon Steel Construction. --Rotor approximate 44" diameter x 72" wide. --Approximately 3" wide Swinging Hammers, tip speed 20,700. --Top feed, bottom discharge. --Bottom screen approximate 5040 square inch area. --Clam shell housing. --500 HP, TEFC, 3/60/460 volt, 1785 RPM drive Motor with coupling and shaft guard. --Mounted on a heavy-duty steel Factory Frame. --NOTES: Largest model of the 15 Series. ● Machine weight 16,000 Lbs.

$25,000

SCMI OLIMPIC K 800 T-FR2 EDGEBANDER EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): Specifications: -- Edge Capacity, 0.4 to 8 mm (0.016 to 5/16") for strip feeding. -- Panel Capacity, min. width 65 mm and 140 mm min. length, (2-3/8" and 5-1/2"). Panel thickness min./max. 8 - 60 mm (3/8" - 2-3/8"). Equipped With: -- Adjustable In-feed Fence: Manually pre-set with digital indicator and pneumatic panel spacing device. -- Pre-Milling Station, RT-E: Spindles 2 x 3.0 HP, 12,000 RPM, (1) with PLC controlled jump action and manual digital indicators positioning. -- Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils. -- Gluing Station: For EVA (Hot Melt) with Teflon coated glue tank and quick disconnect to change glue tanks fast if needed. Heat-up time approx. 10 Min. -- Pressure Section: Servo motor positioning, (4) pressure rollers, first larger, Teflon coated and powered. Workstations: -- End Trimming Station K-SEL: Front & rear 2 x 0.5 HP, 12,000 RPM motors mounted on THK guides, swivels 0ø - 15ø, rapid set up between straight and angled cutting with the automatic swivel cylinder. -- Flush Trimming Unit: Top/Bottom, 2 x 1.0 HP, 12,000 RPM with 2 pre-set pneumatic positions, flush and overhang, remote pneumatic in/out positioning. -- Bevel/Radius Trimming Unit: Programmable, servo motor positioning, 2 x 1.0 HP - 12.000 RPM motors for change-over on the fly. -- Corner Rounding / Trimming Unit: For additional top & bottom trimming of linear an/or vertical leading & trailing corner when edgebanding all (4) sides, 2 x 0.8 HP - 12,000 RPM motor. -- Profile Scraping Unit "RAS/1000": Top/Bottom with (2) indexed manual pre-sets. Large dia. copy wheels for max. accuracy and pneumatic in/out positioning. -- Glue Scraping Unit, "RC-V": Top/bottom flat glue scraper with pneumatic positioning through controller and air-blow off nozzle to keep the knifes clean. -- Buffing Unit "SPN": Top/bottom, oscillating 2 x 0.25 HP - 3,000 RPM motors, tilting up to 12°. -- Hot Air Unit: Single blower with adjustable heat range and directional heat shield for top/bottom coverage. Restores color luster on thick pvc edging materials that my be lost during the edge scraping process.Controls: -- Startouch Controller, 12" color touch screen, swivels 270° at in-feed of machine. Capable to store (100) programs, (6) at the touch of a single key. Graphical display of all working units. Tracks production data, diagnostic information and monitors maintenance schedules. Complete With & Features: -- Feed-speed, 36/52 FPM, 1 x 2.5 HP feed drive motor, 200 Hz frequency inverter for all trimming units. -- Electronic, programmable hold-down pressure beam positioning, lighted safety/sound enclosure cover and outboard panel support. -- Options Include: Dust Manifold as pictured. -- Actual Model: OLIMPIC K 800 T-FR2

$1,750

SCM MINIMAX T-3 SHAPER3/4" Dia. solid spindle, 3 HP motor,(3) spindle speeds of 4,000 - 7,000 & 9,500 RPM; table size 22" x 37" with table insert openings. -- Complete with: Adjustable fence, magnetic starter w/overload protection, reversing switch and 5" dia. dust outlet.

$64,000

SCMI OLIMPIC K 560TE EDGEBANDER (W/PRE-MILLING): -- Specifications: Edge Capacity: 0.4 to 6 mm (0.016 to 1/4") for strip feeding. -- Panel Capacity: Min. panel width: 60 mm (2.375"); min. panel length: 140 mm (5-1/2").Min./max. Panel thickness: 8 - 54 mm (0.375" - 2.125"); min. distance between panels: 600 mm (24").Equipped with: -- Pre-milling Station: (2) 2.0 HP (1.5 kW) motors; rectifies/cleans panels already sized. -- Adjustable Infeed Fence: Manually preset with digital indicator; pneumatic in/out positioning. -- Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils. -- Gluing Station: For EVA (Hot Melt) with: Quick change/disconnect Teflon glue pot for fast glue tanks change if needed; Heat up time approx. (10) Min. -- Pressure Section: Manual digital positioning; Teflon coated pneumatic driven roller & (2) spring loaded idle rollers.Workstations: -- End Trimming Station: (2) Front & rear 1/2 HP - 12,000 RPM motors mounted on THK guides; swivels 0° - 15° for straight & angle cutting. -- Top & Bottom Trimming Unit: (2) 0.7 HP - 12.000 RPM Motors; capable of tilting & pneumatic positioning for (3) settings, flush/bevel/radius trimming for quick setup. -- Top & Bottom Profile Scraping Unit with: Digital indicators; large dia. copy wheels for max. accuracy and pneumatic in/out positioning. -- Glue scraping Unit: Eliminates any excess glue. -- Buffing Unit: (2)Top/bottom 1/4 HP - 2,800 RPM motors; tilting up to 12°.Operator & Machine Control: -- "STARTOUCH" Controller with: 12" Touchscreen display; capable of storing (100) programs. -- Machine automation by PLC function and encoder positioned in the panel feed track pinion. -- Diagnostics for a quick solution to errors: Process statistics data (i.e., number of pieces/edges) and track feeding.Features & Complete with: -- 2-Speed feed speed of 40 & 60 FPM (12 & 18 MPM); (1) 2-1/2 HP feed drive motor. -- 200 Hz frequency inverter for all trimming units. -- Manual adjustable top hold-down pressure beam. -- Full sound enclosure cover and outboard panel support. -- Actual Model is: SCM OLIMPIC K 560TE

SCMI K 208E SINGLE SIDED EDGEBANDER5/16" (8 mm) Max. edge cap., 1-3/4" max. banding height, 2-3/8" min. panel width and 6-/14" min. length. Equipped with: Automatic strip & coil feed magazine, Teflon coated glue pot (heat up time 10 Min), upgraded to Heavy Duty 3 mm PVC cap. guillotine, 3-roll pressure unit w/pneumatic controls. 42 FPM Fixed feed speed via 1 HP drive.Workstations: -- Double motor front & rear end trim (0.3 HP - 12,000 RPM motor ea.), tilts 0° - 15°, End trimmer mounted on 45° THK guides. -- Top & bottom trim station (0.8 HP - 12.000 RPM motor ea.), bevels 0° - 15°. -- Top & bottom PVC scraper for up to 5 mm radius; -- Top & bottom buffing unit (0.33 HP - 2,800 RPM motors). Complete with: Swivel control panel, pneumatic positioning of super finish, full cover sound enclosure, 200 Cy - 5 kW frequency converter & tooling.

$27,600

SCM DMC TC 1350 RKP Wide Belt Sander ( 3 ) HeadsWidth cap. 53" , Drum, Combination Head, PlatenHead Configuration1st Head: 35 hp 9″ Spiral Drum2nd Head: 24 hp/30 hp dual RPM 7″ Spiral Drum/Combination Head W/Segmented Platen,3rd Head: 15 hp VFD driven multi speed Segmented Platen4th Station: Panel CleanerSpecifications -- 53″ working width, 656 hours of operation, --. Yes, it has (2) segmented platens. It’s from a custom shop and was utilized for very specific custom work and nothing else. -- 6.5″ thickness capacityEquipped with & Features -- Auto thickness calibration, -- Vacuum bed, -- 5 hp vfd controlled feed speed, and multiple modes. -- There is also a manual and (4) spare platens.Note: Only issue found , are lines on the LCD Screen (see pictures).