704-288-1904

Carolina Machinery Sales (CMS) works in the sawmill, pallet and woodworking industries. In addition to the buying and selling of used equipment, we work as brokers and take in machines on consignment. Give us a call today!

Industry

Woodworking

628 Results Found

704-288-1904

Call for Price

Manufacturer Specs premill hot glue end trim top/bottom trim corner rounding scraping buffing Computer interface

Call for Price

Min. Panel Thickness: 0.39? Max Panel Thickness: 2.36? Height of Edge-Band Material: 0.55-2.51? Min. Banding Thickness: 0.01? Max Banding Thickness: 0.39? Min. Panel Length: 5.51? Min. Panel Width: 1.96? 2 Feed Speeds: 39ft/min & 59ft/min Electrical: 230V, 60Hz, 3Phase Equipped With Siemens TD200

Call for Price

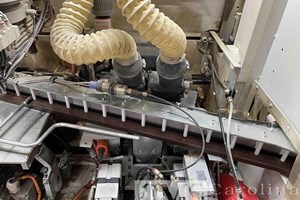

Machine Equipped as follows: NC 410 PC Based Controller Keyboard with Floppy Drive Automatic Strip Feed Magazine Belt Driven Top Pressure Beam Multi-Coiled Infeed Magazine RT63 Pre-Milling Unit SP20 Glue System w/ Pre-Melt Unit Hot Air Gluing system Automatic Infeed Pressure System T45 Front & Rear End Trimming Units w/Tilt RS10 Top & Bottom Rough Trimming Units RF30 Top & Bottom Fine Trimming Units AR10 4 Motor Corner Rounding Trimming Units RB30 Top & Bottom Profile Scraping Units RC10 Top & Bottom Glue Scraping Units SZ30 Top & Bottom Oscillating Buffing Units PH10 Top & Bottom Edge Heaters Specifications: Min. Panel Thickness:....................10mm? Max. Panel Thickness:....................60mm? Height of Edge-Band Material:…..15-65mm? Min. Banding Thickness:.................0.3mm ? Max. Banding Thickness:........ ...... 20mm? Min. Panel Length:...........................150mm? Min. Panel Width:............................ 100mm? Feed Speeds:.................................10-24m./min? Electrics: ......................................... 460-480V 3 Phase

Biesse Rover B Edge semi automatic pod setting 4 coil magazine vertical and horizontal drill bank main spindle with U axis Milling X1: 5055 mm Y1: 1600 mm Edgebanding X2: 4100 mm Y2: 1600 mm Milling Module H74 - Z1: 245 mm Module H29 - Z2: 290 mm

Call for Price

2007 Biesse Rover B 7.40 R FTK - 61.22" (routing) - 75" (drilling) - Working field of machine in Z-axis - 5.9" X-axis stroke - 157.87" Y- axis stroke - 77.16" Z-axis stroke - 6.23" 61.22" x 145"

Call for Price

Call for Price

Capacity overall cutting length 3200 mm (128"). Cutting height 100 mm saw blade projection. 18 HP main and 3.6 HP scoring motor. Modular roller rear machine table. Side aligning device for squaring ripped strips out to 74". Variable saw carriage travel speed 0-328 FPM. 328 FPM return. Electronically controlled overhead program fence. Rack & pinion driven. Forward speed 196 FPM. Return speed 196 FPM. 6 clamps (open up to 100 mm), of which (2) are closely spaced in crosscut area for strip handling and the other (4) are at equal distance in rip cut area. AC Servo motor drives on both saw carriage and pusher fence. "Gateway" PC controller w` monitor and >assist line> w`LED readout integrated into high tech look operator control panel (displays cutting dimensions & patterns). Data input by keyboard or direct downloading from office PC. Side Crosscut aligner. "Quick Change" saw blade replacement system. (3) front mounted air floatation tables with patented rounded front for moving panel from rip to crosscut position (24" x 79" each).

Call for Price

Carolina Machinery Sales (CMS) is proud to offer Thermo-Modification Technology from the Italian manufacturer Big on Dry. ????Big on Dry has improved the Thermo-Modification process with their THERMOWOOD (THW) line and provides complete "turn key" systems. The PLC control systems allow programming for a wide variety off wood applications. This allows the same systems to work with very delicate wood that is hard to treat to thicker wood that will be used for outdoor products. The THW system can also be used as a conventional kiln with steam. Basic systems include: - Kiln completely built with stainless steel and aluminum - Initial humidy of 10-15% is reduced to 5-6% - Loading options: Side or Trolley - Heating options: Gas or Wood Burner - Humidification: Combined Spraying System - Controls: Fully Automatic Controls with PLC - Interface & Software: Allows communication with Big on Dry technicians to provide online support - Complete installation and training in the USA Contact CMS to get a quote for your Thermal Modification system

Call for Price

Big on Dry Thermal Modification Kiln Optional Single or Double Units available! The photos on this listing show the latest kiln installed in the US. The wood treated was 12" wide pine at 190 degrees C. Contact CMS for more details! - Gas boiler system (optional oil or electric) - Quick, efficient installation provided by technicians! - Complete package includes shipping, installation and all drawings fro site preparation. - Approx 10,000-12,000 board foot capacity (depending on lumber size and bundle stacking) on the Double Kiln. - Customer support via internet connection.

Call for Price

Call for Price

Specification from owner 2007 Black Brothers 775-56” Top and Bottom Glue Spreader with an extra-large 12.5” opening designed for SIP (structural insulated panels) manufacturing. This machine is brand new and ready for immediate delivery. 575V, 3PH

Call for Price

Black Brothers 22D glue spreader Max working width 50"Max working thickness 3" 1/2 Hp, 230/460 volt three phase drive motor Table passline height 40" 7-1/4" diameter x 50-1/2" long top and bottom chrome doctor rollers 9" diameter x 50-1/2" long top and bottom rubber covered applicator rollers (Please note that the top doctor roller and top applicator roller is segmented) 11-3/4" long and 38" long top roller segments

- Black Brothers Model 22D-875, 68”Top & Bottom Glue Spreader - Width Capacity: 68” - Grooved, Rubber-Covered Applicator Rolls - Applicator Roll Diameters: 8.75" - Main Motor: 1.5 HP, 208-230/460v, 3ph - Hard Rubber-Covered Doctor Rolls - Bottom roll adjustment 575 volt, 3ph

Bliss Hammer Mill Model ED3840 250 HP Motor 1/4"- Screen Motor and machine have been gone through and checked.

Call for Price

Call for Price

Call for Price

50” width drum/drum/platen heads 480 volt 3-phase Bottom and top sanders can be sold separately Pictures coming for bottom sander

Call for Price

BolDesign Kiln that includes Future-Design Controls FDC-2010-K5C Small Kiln Features • Board Feet Capacity: 2,000 to 10,000 BF (Board Feet) • Expect a 6-9 Week Turn Around • Easy to Clean and Maintain • Built with Aluminum and Stainless Steel, The Same Aluminum that is food grade used in Commercial Kitchens • RH control results in less lumber damage, this leaves you with better, brighter colors These Kilns are Built for Forklifts • Pallet Stock Drying Kiln; Disassembled crated and ready to load. 1 truck

Call for Price

Brandt KF 76F Edgebander: Premil, top/bottom trim, buffing, extra glue pot Ligmatech ZHR 01/R/075 Return: 87”x84” crossover, 36”x19.5’ for the return conveyor belt