704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1847 Results Found

704-841-2001

Call for Price

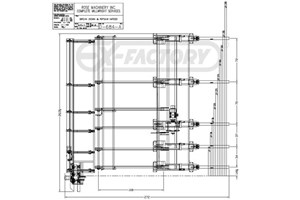

ROSE MACHINERY BDH/LC/LCFT Automated Infeed SystemAutomated, high speed Infeed System for Gang Rip Saws of all makes and models and other similar machines. -- 5-Arm Breakdown Hoist - Electric hoist accepts loads 4' wide x 4' high x 4' - 24' long; 10 HP gear motor (with brake) powers the hoist and holds the load. -- Hoist actuated through foot switches for up & down; limit switches provide max. up & down positions; (5) lifting arms tilt load at 50° allowing layers to spill onto the takeaway conveyor; 16,000 Lbs. max. lift cap. -- Landing Chain - Features: (6) Strands of roller chain; powered by a 5 HP gear motor at 60 FPM nominal rate. -- Tail end constructed with integral slide, stock transits from Breakdown Hoist; head shaft & gear motor supported by tubular steel frame with bolts to allow for leveling at installation. -- Material stops at the head end so the operator can flip & grade each piece. -- Chain races fabricated from steel, UHMW PE wear strips on the top race and on the return race; conveyor is 42' long. -- Magnetic motor starter with foot switch for operator to start & stop of the chain. -- Lateral Chain Feed Table "LCF2013-20": Feeds material 3" - 10" wide x 4' to 24' long x 1" to 3" thick; variable 50 - 200 FPM Feed rate; adjustable fence throughout 3/4" range for alignment with the Rip Saw (or other machines). -- (6) 30" long, low friction steel flattop infeed chains for long life non-marking transport; 1 HP gear motor. -- (3) Powered smooth steel & non-marking feed rolls, 2 HP gear motor; rolls & chains controlled by variable speed drives. -- (3) Overhead pinch rollers, 5" dia., urethane covered; 1st (2) pinch rollers powered by individual 2-1/2" bore air cylinders to singulate pieces onto a 2' bridge; 3rd roller keeps the board moving on the bridge; pinch rolls triggered by photoelectric cells. -- Note: Fabricated frames and appropriate parts of the items in this quotation will be painted with (1) coat of industrial grade Shady Lane Green enamel; guards and appropriate moving parts painted with Safety Orange. -- All gear motors, mechanical equipment, limit switches, sensors or photoelectric devices, as required for each item of this quotation, are supplied and mounted; all pneumatic cylinders or other pneumatic power devices and their valves supplied and mounted; connecting hoses & fittings installed. -- Filter/Regulator units supplied, mounted, and connected by hose to the valves; Note: Compressed air service to equipment is by others.

Call for Price

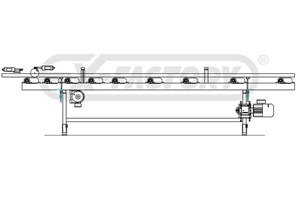

Ripsaw Feeder with 32" wide feed rolls on 18" thru 28" roll centers; will feed 3' thru 16' lumber. With 24" of in-out fence travel; feed speeds from 50 to 150 FPM; 3/4 HP feed roll drive and 3/4 HP fence drive via gear motor with brake. -- Fabricated frame of structural steel with boots that allow +/- 1" elevation adjustment. 3-1/2" dia. steel feed rolls driven by a variable frequency drive for speed adjustment; rolls are canted to aid in holding stock against the fence. -- Powered fence with 24" fence travel is easily shifted via joystick control for stock alignment with the sawblades. -- With pneumatic powered gate to keep material from feeding until the operator initiates the feed sequence. -- Urethane covered idler pinch roll is attached to the fence and is powered down at the start of the feed sequence. When a photocell detects the board is clear of the gate, the pinch roll and gate will return to their normal position. Electrical control panel ready for connection to the power supply.

Call for Price

ROSE MACHINERY HBR Horizontal Band RE-RIP SawThe Horizontal Band Re-Rip Saw is an effective and efficient means of ripping short blocks into as many as six (6) set rip widths. Rip widths are easily adjustable, as well as the setting for stock thickness.Advantages of the system: -- Compact, efficient use of floor space. -- Accurate cutting of rips with minimum tear-out. -- Short blocks, 4" minimum length, without taper problems. -- Straight through feed design, good for sorting. -- Minimum dust collection required. -- Single point scrap collection. -- One saw drive motor, requires less power. -- Safety, no kickback problems.Specifications: -- Five (5) rip widths - (6) optional -- 20 HP bandsaw drive -- 30" diameter band wheels, 2" wide face -- (2) 3/4 HP feed works drives -- 1-1/2 HP feed belt drive -- 1" to 6" rip width (independently adjustable in each lane) -- 10" maximum board width at maximum rip -- 4" maximum waste piece width -- 3/4" to 2" stock thickness (all lanes adjust together) -- 4" minimum stock length -- 36" maximum stock length -- 80 FPM feed speed -- 52" to 58" pass line height -- Motor starters and push buttons included, wired for 440 volt, 3 phase, 60 Hz (uses standard mag starters) -- An automatic band lubrication system is includedOptional Equipment: -- For SIX (6) LANES, add ...$5,600 (SORTER increases $3,700) -- Automatic machine grease lubrication system, add ...$ 9,200 -- Ergonomic overhead stock slide, add ...$ 5,600 -- Output conveyor and sorter for 5-LANEsingle side discharge, add ...$47,300 -- Output conveyor and sorter for 6-LANE single side discharge, add ...$51,100 -- Operator's platform, add ...$ 7,900 -- Optional voltage configuration: 220/380/440V, 50HZ, add ...$2,900 -- Start-up and training, add $1,000 per day plus expenses at costHorsepower Requirements: -- (1) @ 20 HP -- (1) @ 1-1/2 HP -- (2) @ 3/4 HPDust Collection: -- (2) outlets, 6" diameter, 5,200 FPM velocity @ 2,300 CFMCompressed Air Required: -- 90 PSI @ 1.4 CFM

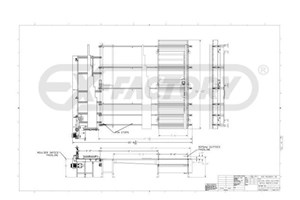

ROSE MACHINERY LCFCMS14 PANEL RIPPER TO MOULDER TRANSFER SYSTEM OUTFEED ROLLCASE: -- Outfeed Rollcase receives material from the LHI Panel Ripper at 47 1/4"; elevation and drops down to place the lumber onto the Transfer Chains at 42"; elevation. 66"; wide rolls are 2-12"; diameter steel rolls, snap in style on 12"; centers. Rolls are powered by a line shaft using round Eagle Belts and a 1-1/2 HP gear-motor. The conveyor will be fabricated from tubular and sheet steel and designed to interface with the Transfer Chains. The conveyor speed is 80-120 FPM to create a gap between courses exiting the Panel Ripper. The drop will be triggered when a photocell detects the leading end of the boards, creating a far side lumber line. A pneumatic cylinder provides lifting power. When the transferred boards clear the rolls, another photocell triggers the rolls to return to the up position. Stock length handled by the Outfeed Rollcase is from 6’ to 16’. Elevation adjustment is +/- 1";.TRANSFER CHAINS: -- Transfer Chains receive material from the Outfeed Rollcase. The Transfer Chains are fabricated from tubular and structural steel. There are (6) strands of 2060H conveyor chain approximately 17’-6"; CC long, leaving 11’ clear space to accumulate (2) layers of ripped strips. (2) sets of pin stops are incorporated to keep the layers separate. The conveyor is powered by a 1-1/2 HP gear motor. Conveyor speed is 90 FPM maximum. Elevation is 42"; +/- 1";. LATERAL CHAIN FEED TABLE (ROSE MODEL LCFCMS14): -- Standard duty low friction flat top steel infeed chains drive the stock to the fence. The fence is adjustable for alignment with downstream equipment such as a Moulder. (3) lower powered feed rolls are smooth steel and non-marking. The feed rolls and chains are controlled by adjustable frequency drives. (3) upper pinch rolls are 5"; diameter urethane. The first (2) rolls singulate pieces while (1) pinch roll keeps the board moving on the bridge. The pinch rolls are triggered by photocells. A PLC in the control cabinet cycles the outputs based on operator input. Operator controls allow for start and stop of the chains and rolls, the feed to be paused, the rolls to be reversed and speed controls. -- Fabricated structural steel frame -- Passline height 42"; +/- 1"; -- Stock width 2"; to 9"; -- Stock Thickness 1/4"; to 4"; -- Stock Length 6’ - 16’ -- Rolls include a variable feed rate from 60 to 300 FPM -- Feed roll drive is by a 3 HP gearmotor -- (6) infeed chains, each 50"; long, are driven by a 1-1/2 HP gearmotor -- Infeed chain's variable feed rate is 20 to 75 FPM -- 2-1/2"; bore air cylinders actuate the pinch rolls -- With 3/4"; fence adjustment. ELECTRICAL CONTROLS: -- Controls are incorporated in the LCF Cabinet for the above Transfer System. It consists of operator controls, (2) VFDs, and additional PLC I/O and programming. STARTUP: -- 2-days startup assistance is included. Travel expenses are billed se

ROSE MACHINERY TRANSFER SYSTEM: PANEL RIPPER TO MOULDER INFEED OUTFEED TRANSFERA Rollcase will carry stock away from a LHI 72" Panel Ripper. When the stock reaches the far end-stop, a 6-Strand Transfer Belt will pop up and take the stock to a Lateral Chain Feeder (supplied by others). The lifting mechanism is triggered by photocells and powered by an air bag using plant air. When the stock clears the Rollcase, the transfer will return to the down position to receive the next batch of strips. Rollcase Specs:17' 0" long; 76" between frame; 1.9" dia. X 12 gauge rollers. Galvanized rollers are set high on 3" centers. 5-1/2" x 1-1/2" x 12 gauge formed steel channel frames; welded construction. 120 FPM maximum. Dual shaft w/jump chain; underhung drive; timing belt driven; 1 HP, 575 volt/3ph/60hz motor; less controls. With (3) H-style leg supports; 34" top of roller; adjustable 32" to 38", with knee braces. Fixed angle end-stop. Frame is powder coated blue; guards powder coated yellow. Transfer Specs:B/17 purple power twist belt; 36" strand centers; 10'-0" long. UHMW chain track; airbag lifting style; thru frame; 36" top of chain. With 1/2 HP Boston 575 volt/3ph/60hz motor with Boston reducer for 120 FPM; less controller; proximity switches to detect carriage position are mounted only; solenoid valve, mounted and plumbed; filter/regulator - mounted and plumbed. With central bearing lube. Frame is powder coated blue; guards powder coated yellow Electrical Controls:ROSE provides an Electrical Control & Cabinet that will control the above Outfeed Transfer System. Electrical Control will incorporate a fused disconnect for incoming power, transformer and power supply for control voltage, (4) variable frequency drives for the motors, a PLC to read input devices and control output devices, and pushbuttons/switches for operator control. The panel will be mounted and wired to the enclosed devices. Incoming power and other field wiring is by others. Two days startup assistance is included. Travel expenses will be billed at cost separately.Conditions:All gear-motors, mechanical equipment, limit switches, sensors or photoelectric devices as required for each item of this quotation, will be supplied and mounted. All pneumatic cylinders or other pneumatic power devices and their valves will be supplied and mounted. They will have connecting hoses and fittings installed. Filter/Regulator units will be supplied, mounted and connected by hose to the valves. Compressed air service to equipment is by others.Exclusions:This proposal describes the machinery to be provided by Rose Machinery Inc.. The equipment supplied by Rose Machinery Inc. is specifically limited to the items actually described in the itemized details of this quotation. Unless specifically mentioned herein, all other items and services are the responsibility of the Buyer. State or local sales taxes, or any permit or other fees that may be required are not included. All field wiring, plumbing, and installat

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6s ROWLEY & HERMANCE Sash Sticking Machine Specifications: Table size 5” x 46”. Equipped with: 3 HP - 1,750 RPM Motor. (2) 2” Dia. x 2” W Serrated upper feed rollers.

Call for Price

// This item is up for Auction at exfactoryauctions.com // https://bit.ly/40zDLa2 RUVO Door Lite Cutout machine Model 9715W Specifications: 7' Max. door height x 3' max. door width; max. lite sizes in 3' door 30" x 60", 24" x 64", or 20" x 66"; lock sizes 1-1/2", 1-5/8" and 2-1/8". Deadbolt sizes 1-1/2", 1-5/8" and 2-1/8"; corner radius 1/4" for both lite and faceplates; backset switch selectable for 2-3/8" or 2-3/4". "Broken Arm" design for lite cut outs in wooden doors. Machines wood or steel doors (to 16 ga.) with 3 HP cutter head, 2-speed operation with 2,400 or 4,700 RPM; (2) horizontal stations, features door length adj. and end clamps. Equipped with: Boring for lock, deadbolt, and latch, (2) Back fences, steel hole template locating pin, template clamp, end clamp cylinders, flip stop assembly on the back fence. The 9700 control box provides the operator with exceptional versatility allowing independent operations for special house orders Recommended cutter head ONSRUD 15-05 cutting bit with reverse flute (interchangeable with EKSTROM-CARLSON bit 088-1680). Ruvo's 9700 Door Lite Cutter series machines are manufactured to last under heavy use and are the finest available to steel and wood door suppliers. The heavy-duty, easily operated cantilever cutting arm is key to the model's speed and efficiency. After the lite template and door are pneumatically clamped, its arm follows the template edge as a 1/2" cutter bores through the door.

Call for Price

RUVO 2260 Wedge Cutter. -- General Data: Wedge and glue-block cutter. Allows for 1" X and 2" X material in the same hopper. Cuts (2) wedges out of 1" X material and (1) wedge out of 2" X stock. -- Self diagnostic system, walk-away, hands free operation. -- If not reloaded, the machine has an auto-shut-off feature at the end of the stack to prevent the machine from cycling endlessly. --With capability to cut glue-blocks. -- Ports for dust collection.

$94,500

RUVO 505, ...Prehung Door Machine.Handles a wide range of door, jamb, and hinge sizes. - Bevels doors and door hinges. - Designed for efficient handling and operation. - Fast, accurate hinge and lock backset adjustment. - Residential, Commercial, Architectural, and Labeled Fire Doors.Features: Heavy duty powered 3° beveler/sizer. Routers to ease door edges. Accurate target scales. The 4-hinge and jamb route location changes fast and precisely. A similar system for the backset on hinges & locks. Provision for single and double-belled doors. Controls interlocked by a PLC. Auto door sizing is fast to adjust the lifter bar by digital input and servo control. Reliable, long-lasting non-contact sensors. Fast push-pull controls with a friendly touchscreen HMI. Hinge screw gun and pre-drill included.Technical Details: Max Door Height: 6’ - 9’ or ADA Specs 6’ - 8’. -- Door Width: 1'-6"’ to 4’. -- Door Thickness: 1-3/8"; to 2-1/4. -- Jamb Size and Styles: Up to 1-1/4"; x 10";, all styles. -- Number of hinges: Up to (4); Hinge Size: 3-1/2" to 5";; Hinge Radius 1/4" to 5/8". -- Hinge Backset: Scaled as required -- Lock Bore Sizes: 2-1/8"; Standard. -- Lock bore Backset: Scaled to 5";. -- Lock Bore Latch plate: Up to 1-1/4"; x 8";.Machine Size: 18’ x 3’ x 7’; Approx. Machine Weight: 3,200 Lbs; Electrical: 4-Wire, 230/3/60 and draws 25 Amps. Requires a 1/2" airline using 40 CFM @ 90 PSI.Options Include: -- Built-In Power Beveler Vacuum System......$ Please call. -- Screw Driver............................................... Included. -- Pre-Drill Kit.................................................. Included -- Digital Readout ..........................................$ Please call.RUVO 512, ...Heavy Duty Strike Jamb Mortising Machine.For Jam Sizes up to 1-1/4"; x 9"; x 10";. Strike Plate mortise to 6";. Compliments Jamb Preparation of the RUVO 505 and 405. Operated by one worker.Unit Includes: -- Adjustable Jamb Stops. -- Heavy Duty Construction. -- Foot Pedal Actuated Clamp. -- 120 Volt, 1-Phase, 20 Amps. -- 1/2" Airline needs 0.5 CFM @ 100 PSI. -- 1.5 HP Router.@ 23,000 RPM. Additional Cost for the RUVO 512 above ...$Please call.Material Handling for the Line:Loading Device..........................................$ Please call.Unloading Device.......................................$ Please call.

Call for Price

RUVO - 2200: Stair Stringer Route; Top/Bottom, Semi-automatic. -- Size capacity (nominal): 2" Thick x 12" - 15-3/4" wide stringer size; semi-automatic operation. -- (2) 5 HP - 25,000 RPM Router motors for top & bottom heads. T & B Heads are arranged to jump in & out; automatic pneumatic clamping of stringers, spring-loaded side pressure to keep stringers against the fence. -- Mirror image routing on: (1) Pair of stringers at one time; graduated template automatically sets up to stated tread & rise; cuts standard wedge taper for both treads and risers. -- Includes: Clamp, feed system, and safety covers. -- NOTE 1: Stair Router rebuilt in 2022 by BUILDERS AUTOMATION. Replaced 3 HP with new 5 HP routers. Reconditioned air cylinder pistons, air-over-oil booster, replaced air lines, etc.. Painted from green to Blue.

Call for Price

--In auction: https://exfactoryauctions.com/Detail/SA-231010/event/A122024$1 --No Reserve!-- RYE R 72 2-Spindle Automatic Rotary Copy Shaper Specifications: Cutting circle cap. 24" - 80", Max. square cap. 56", Max. rectangular shape cap. 71" x 35-1/2", & Max. length capacity 50". Table size 68" Dia. x 40-1/2" H. Table speeds 0.3 - 3 RPM. Spindle speed 9,000 RPM. Equipped with: (2) 1-1/8” Dia. High frequency floating spindles, with Frequency changer. 6-1/2” Dia. Center clamp plate.

$3,950

SAV S 53 S Single-Sided Planer20" Width x 1/8" to 12" opening; 6.6 HP motor, 4-knife 4-3/4" dia. cutter head rotates @ 5,000 RPM, max. cutting depth 5/16" -- (4) fixed feed speed settings 13 - 23 - 36 - 59 FPM. Equipped with: -- (1) Steel outfeed roller, (2) adjustable bed rollers, sectional infeed roller, sectional chip breaker, manual raise & lower w/mechanical digital readout; -- Table size 41" x 21". Complete with: -- Emergency stop, magnetic starter w/overload protection & 5-1/2" dia. dust hood.

Call for Price

PRO-EDGE TECHNOLOGY SQUEEZETIGHT CASE CLAMP (AUTOMATIC FEED THROUGH): -- Specifications:The SqueezeTight automatic hydraulic case clamp does the work for you. The vertical pressing system with motors & independently controlled crossbars move according to the size of the piece to be pressed, mobile parts slide along linear bearings and guides. -- Operating Cycle;Once the piece of furniture is assembled on the preparation bench the operator starts the automatic cycle and the carcass enters the machine.The reading devices automatically determine the length and height of the workpiece and send this information to the PLC which positions the mobile head and the conveyor and stops the carcass in position. The beam automatically moves to the preset position.Each of the mobile heads are fitted with: (2) RH & (2) LH Horizontal pressure beams + (4) stationary & (1) adjustable top pressure clamps.The Clamping Cycle is 100% programmable & pressing is by a 10 HP (7.5 kW) Hydraulic pump system.The in-out-cross transfer powered belt conveyors are driven by "SIEMENS" AC brushless motors. -- Working Capacity:9.8" - 89.7" (250 - 2,280 mm) working width/length, 9.8" - 42.9" (250 - 1,090 mm) working height, 9.8" - 25.9" (250 - 660 mm) working depth. -- Positioning Speed:32.8 - 131.3 FPM (10 - 40 MPM) Variable speed controlled by programmable inverter. -- The carcass transfer system is located at the bottom of the bed and consists of an electro-welded steel structure on which a closed loop belt is driven by an inverter-controlled "SIEMENS" motor. -- Operator Interface:Automatic cycle control from onboard "HMI" Touch Screen control + "DELTA" VFD's & PLC with adjustment for all clamping aspects. Clamping pressure strength up to 1,200 PSI over-all. -- Complete with:(1) 98" Long powered in-feed conveyor belt with alignment guideways, (1) 98" Long powered cross-feed conveyor belt with alignment guideways & (1) 98" Long powered out-feed conveyor belt. Parameter Safety Light Curtain System. -- NOT included:Cost for Delivery, installation, and training (please call for quotes). -- Actual Model is PRO-EDGE TECHNOLOGY SQUEEZETIGHT

$13,900

PROFILEMATIC 503 PROFILE SANDER3-Head feed through, sands from top at adjustable angles narrow moulding type parts as well profiled edges on panels.Equipped with: -- (3) Top VPS vibrating air-loaded sanding units, 0.5 HP vibrating motor ea., sanding heads have (2) pneumatic cylinders for sanding pressure control and oscillate with 1/2" stroke on dust-protected round guides, variable vibration speed from 200 - 1,800 RPM; adjustment range of 120ø to conform to profile, equipped with air shower to clean workpiece & sandpaper automatically. -- Part transport is achieved by a 4-1/2" wide linatex coated conveyor belt system, "quick adjustment" holddown wheels & fence system, variable feed speed 0 - 35 FPM powered by a 0.25 HP DC gear drive (forward & reverse feed mode). -- Each sanding head with its own controls for manual raise & lower, pressure control and vibrating speed. Profile width approx. 1/2" min. to 4" max., material feed through thickness up to 5"; support fences for up to 10" moulding width.

Call for Price

Make an offer - Machine is in an Ex-Factory Liquidation. 4-Station Profile Shaper Specifications: 6" Chain drive with non-marking rubber top pads traveling on a hardened and ground precision dia. 5/8" round rods, Top pressure beam driven, Heavy duty fabricated transporter frame, Forward and reverse mode and block mode for creating sanding tools Precision X & Y axis mounting stands, 60° rotating tilt on mounting stands with positive lock, Independent activation control at each station, Adjustable infeed fence system, All dust hoods and guards, 2 HP AC variable speed gear drive 5 to 60' per min. Workstation 1: 3.5 HP TEFC Saw Arbor Motor, 1" Dia. Spindle, Dust Hoods with 4" outlet, Mounted on precision X & Y slides Workstation 2 & 3 - Belt Sanding Unit: 2 HP AC motor drive, Air belt tension system, Independent belt tracking system, Air activated sanding pad with touch control, 2" sanding belt width, Guards and Dust hoods with 4" outlet Workstation 4 - Wheel Sanding Unit: 3" HP variable speed (0-3,400 RPM) AC TEFC drive motor, 1" or 1.25" arbor 3.5" long, Dust Hood with 4" dia. outlet, Mounted on precision X & Y slides SPECIAL NOTE: Needs New PLC or wire for traditional controls NOTE: Above specs are taken from literature and thought to be accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

4-Station Profile ShaperSpecifications: -- 6" Chain drive with non-marking rubber top pads traveling on a hardened and ground precision dia. 5/8" round rods, Top pressure beam driven, Heavy duty fabricated transporter frame, Forward and reverse mode and block mode for creating sanding tools -- Precision X & Y axis mounting stands, 60° rotating tilt on mounting stands with positive lock, Independent activation control at each station, Adjustable infeed fence system, All dust hoods and guards, 2 HP AC variable speed gear drive 5 to 60' per min.Workstation 1: 3.5 HP TEFC Saw Arbor Motor, 1" Dia. Spindle, Dust Hoods with 4" outlet, Mounted on precision X & Y slides Workstation 2 & 3 - Belt Sanding Unit: 2 HP AC motor drive, Air belt tension system, Independent belt tracking system, Air activated sanding pad with touch control, 2" sanding belt width, Guards and Dust hoods with 4" outlet Workstation 4 - Wheel Sanding Unit: 3" HP variable speed (0-3,400 RPM) AC TEFC drive motor, 1" or 1.25" arbor 3.5" long, Dust Hood with 4" dia. outlet, Mounted on precision X & Y slidesSPECIAL NOTE: Needs New PLC or wire for traditional controlsNOTE: Above specs are taken from literature and thought to be accurate.

Call for Price

PROFILEMATIC - BF-400: Solid Surface Sand/Buff -- FeaturesPatented Rotary Orbital Sanding/Buffing System. For sanding & buffing solid surface countertops up to 10' long x 40" wide; with or without sink bowls or cove backsplashes to a matt finish in approx. (3) minutes. -- Quickly programmed. Speed of the top through the machine; speed of the randomly orbiting sanding heads; stroke distance of the sanding heads. -- Operator places the workpiece on a feed through Conveyor System; top automatically feeds through the machine and is sanded with different grades of sandpaper or buffing material and exits the machine as a finished product. -- SpecificationsMaterial Width: 40″; material length: Unlimited; material thickness: 12″ +/-; (3) Sanding Stations; (18) sanding heads; sanding pad type: PSA. -- Equipped with(45) 5″ Diameter Sanding Discs; Infeed & Outfeed Conveyors; ALLEN-BRADLEY "PanelView 300" Controller. -- Actual model: PROFILEMATIC - SURFACE MASTER BF-400 & Made in the USA!

$1,550

PROGRESS PMC-264 Stroke SanderSpecifications: -- 8' x 30" Sliding table (on ball bearing steel rollers), 30" table travel; -- Manually operated stroker pad travels on ball bearings; large hand wheel for manual raise-and-lower of table for up to 24" vertical opening -- 5 HP - 1,750 RPM TEFC main motor. -- (2) 10" Dia. pulleys x 6-1/4" face, drive pulley rubber covered; -- 6" Wide x 264" long abrasive belt, abrasive belt speed 4,300 SFPM. -

PROGRESSIVE - Model SB/D 31, ...Dip Chain Gang Rip Saw.Specifications: -- 31" Cap. arbor with: Pneumatic arbor lock, 14" max. dia. tooling, -- 5" max. motorized thickness adjustment; 22" min. length for glue joint accuracy, 6" throat depth to fence side of blade. -- (1) 31-1/2" Saw sleeve with: Double-keys arranged for 3-1/8" bore saw blades. -- Equipped with: 75 HP - 3,600 RPM TEFC -- Direct drive motor, arbor with disc brake & load meter; 2-3/16" dia. turned, ground & polished saw arbor with outboard bearing; motorized vertical adjustment of arbor. -- Feed & chain: 34" Wide feed bed, -- 5 HP variable feed drive, feed speed from 30 - 150 FPM; adjustable jam protection. -- Dip bed carried on 2-1/2" pitch hardened double V-chain, extruded structural aluminum feed bed slats with replaceable Equipped with & Features -- "Safety Orange" polyurethane inserts; oil mist lubrication for extended chain life. -- (2) Infeed & (2) outfeed 4" dia. air loaded overhead pressure rolls; full width air loaded laminated bed holddown plate at saw arbor with +/- 1/4" thickness variation with pressure adjustment -- Pressure rolls & bed plate unit with manual height adjustment. -- Anti-kickback Finger System with: (1) Lower & (2) upper on infeed, (1) upper between feed rolls, and (1) upper assembly on outfeed. -- 5" Dia. dust outlet on upper infeed & 8" dia. dust outlet in upper outfeed; control panel mounted on infeed; saw sleeve and spacers. Note: Includes One Sleeve with a Collection of Spacers -- Owner's Manual Included -- Machine can be purchased As Is with a condition report (available on request), or you have it gone through ( As Is will be at a reduced price )

PTR - 2507-HD, ...2-1/2 Yard Stationary CompactorSpecifications: -- Charge box capacity: 2.5 Cu/Yd -- Clear top opening (L x W): 54-1/2" x 60" -- Total normal force: 59,376 Lbs -- Cylinder bore: 6" -- Cylinder rod: 3-1/2" -- Capacity per hour: 63 Cy/Hr -- Average cycle time: 57 SecEquipped with: -- Heavy-Duty structural steel components -- 3-Button controls