704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2029 Results Found

704-841-2001

$14,500

POWERMATIC Shaper TS-29, with Sliding Table & Tilting SpindleSpecifications: -- 3/4", 1", & 1-1/4" Dia. interchangeable tilting spindle, 3/8" & 1/2" collet & router bit adapters, tilts 45° forward and 5° back, 7-1/2 HP - 3,600 RPM motor; 3,000 - 4,000 - 6,000 - 8,000 - 10,000 RPM spindle speeds via 4-step V-pulley with "quick release". -- 4-3/4" Cap. under nut when using the 1-1/4" spindle, 7-1/16" spindle travel; 51-1/2" x 33-1/2" extra thick cast iron main table, (3) removable table inserts 2-1/2" - 5-1/2" & 5-7/8" x 4-3/16" (oval).Complete with: -- Large scale "ACCU Fence" with integrated 4" dust collection shroud, reversing switch, AMBI-TECH electronic brake, cutter-head guard, clamping miter gauge & magnetic control; incl. owners manual & parts list. Actual Model # PM9-1791284

POWERMATIC Shaper PM 2700 Spindle Shaper 5 HP, 3 Phase, Single Spindle ShaperSpecifications & Features: -- Digital readout gives the use of exact spindle height and allows for 0.001" adjustments. -- 4" Spindle travel. -- 5 HP Motor -- Heavy-duty 30" x 40" precision ground tabletop for smooth stock feeding and Heavy-duty cast iron base. Includes: -- 3/4" and 1-1/4" spindles -- Independently adjustable fence sides. -- Micro-adjust control knobs allow for precision adjustment for the fence. -- Integrated casters can be raised and lowered to mobilize shaper. -- Superior clear cutter guard promotes safety, allows observation of the entire cut. -- Table predrilled and tapped for Power Feeder mounting.Dust Collection Minimum CFM Required (CFM) 600; 4"Dust Port Outside Diameter

$3,649

20" Dia. dynamically balanced aluminum disc, 3 HP - 1,740 RPM direct drive motor; 15" x 27-1/4" table w/miter gage slot, tilts 30° upward & lowers 45° downward, 90° positive table stop; rack mechanism for raising & lowering table by hand crank, heavy bolt-down steel base. Complete with reversing switch and miter gauge. Also available in Single-phase in 2 HP motor.

$12,950

POWERMATIC - WB-25, ...Wide Belt Sander1-Head; 25" width capacity; 1/8" to 6" thickness capacity.Combination sanding head with: 4" Dia. rubber-covered contact roll; 2" wide polishing platen; micro-adjust platen; steel abrasive belt tension roll; steel idler roll: 25" x 75" Abrasive belt capacity.Equipped with: -- 15 HP 3-Phase main motor; 1 HP variable feed motor, 15 - 49 FPM. -- 1/4 HP Table raising & lowering motor with: Auto adjust thickness assist; 1/8" to 6" opening with (4) screw jacks. -- Double infeed & outfeed rubber covered holddown rolls. -- Complete with: -- Digital readout; air eye belt sensing; limit switch overtravel protection; magnetic starter; overload protection; load meter; emergency brake.Includes: Owner's manual & parts list.

$1,800

POWERMATIC - 26, ...Single Spindle Shaper -- Specifications: 5 HP (3.7 kW) - 3,600 RPM Belt drive motor; 7,000 & 10,000 RPM spindle speeds via 2-speed step pulley; reversing switch. -- 1" Dia. solid interchangeable spindle featuring 3-7/8" cap. under the nut; 3" spindle travel w/handwheel adjustment -- Complete with:24" x 26" Cast iron table; miter slot; 7" insert opening; adjustable fence; magnetic controls. -- Actual Model is: POWERMATIC 26

$7,750

POWERMATIC - RB-37, ...Single Head Wide Belt Sander1-Head, 36" width cap., combination sanding head. -- Includes: 4" Dia. contact roll & 2" wide polishing platen, micro-adjust platen; 15 HP main motor. -- Abrasive belt size: 37" x 60"; with air tensioning, air jet abrasive belt tracking. -- 1 HP Feed drive; variable feed speed of 15 - 30 FPM conveyor speed. -- 0" - 5-1/4" Opening with: (4) Screw jacks; double infeed & outfeed rubber-covered hold-down rolls. -- Complete with: Magnetic starter; overload protection; load meter; emergency brake.

$11,500

POWERMATIC WP 2510 PLANERThe POWERMATIC "WP 2510" Planer with a 15 HP motor has a solid steel helical cutterhead with four-sided carbide knife inserts that require no adjustments when changing. With a digital readout and simple PC controller, setting up table heights is quick and easy. -- The frame is machined from heavy cast iron and has extra wide side panels that offer rigid bed support and ensure accurate alignment. -- The planer's segmented, serrated infeed roll with segmented chip breakers has an independent yield of 1/4". Its automatically adjusting, chain drive gear box powers the 3" dia. infeed rollers, solid pressure bar and dual outfeed rollers for precise feeding of stock. -- The 3-speed feed selector gives woodworkers flexibility by changing feed rates quickly and easily. -- The "WP 2510" Planer has a large 32-3/16" x 26" precision-ground table which contains two adjustable table rollers for smooth feeding of uneven stock. The planer has a Quick-Set micro-adjustable lever that easily raises and lowers the table rollers from 0 to 0.05". The hood features a built-in 5" diameter dust chute. -- SPECIFICATIONS: -- Max. planing 25", max. planing thickness 9", max. full width depth of Cut 1/8", max. depth of cut ¼". -- Min. Planing length 10", cutterhead dia. 3-3/8", cutterhead speed 5,000 RPM, cuts per minute 30,000; 15 HP motor. -- Feed Rate 20, 25 and 30 FPM, Outfeed Roller Diameter 3 "; number of Knives: (174) Four-sided inserts. -- Table Size: 32 3/16" x 26"; dust port diameter 5 ", dust collection CFM Required (600) CFM. -- Bed Rollers adjustable from front fom 0" to 0.05"; Readout Scale: inch/ metric; Table Height adjust manual with 1 Turn = 1/32", (2) column for bed support, 2-1/2" column dia.; (1) infeed and (2) outfeed rollers; includes Tool Kit.

$1,150

Powermatic Vertical Chain MotiserSpecifications -- 3/4" Chain width cap., -- 1.5 HP direct drive motor, -- 4" max. depth of cut; -- Table size 5" x 72"Equipped with & Features -- Cast iron main table, -- Rack & pinion table tilts 45ø right or left, -- 14" vertical adjustment, -- 4" lateral (in & out) adjustment, 12" longitudinal adjustment. .Note from the seller : Machine runs great condition. It has 2 fairly new chains (1/4 x 1": 3/8 x 1 3/4") Both chains, sprockets and bars are close to new.

$2,080

Powermatic DDS-225 Drum SanderSpecifications: -- 5 HP Main motor, durometer rubber-coated steel drums, independently adjustable rear drum for fine tuning. The Cast Iron table incorporates (4) jack screws with chain drive timing to keep it level. -- Features: Heavy-duty poly conveyor belt, 0.25 HP feed motor coupled to 2-speed forward/reverse gearbox for 8 or 10 SFPM, and dual dust collection ports with directional baffles.

POWERMATIC - 075: Dust Collector3 HP Freestanding Collector; 1,900 CMF; (2) 20" dia. x 48" upper cloth filter bags; (2) 20" dia. x 34" lower cloth collector bags with: 10 Cu/feet cap. -- Unit mounted on common base; comes with: (1) 8", (1) 6", and (3) 4" dia. outlets. -- Equipped with: Push-button starter switch; base mounted on: (4) Swivel casters: 96" x 26" x 60" height overall.

Call for Price

POWERMATIC PF-41 4-Roll Power FeederFeatures: -- Cast Iron construction. -- Continuous duty motors transfer power from the gearbox to the feed rollers. -- Moveable universal joints and locking mechanisms lock the feeder in horizontal, vertical, or angle feed positions. -- Roller chain and sprocket design provide positive feeding for all types of materials. -- Rollers can be changed out easily and quickly; Smart roller system allows for the tires to be replaces without replacing the assembly. -- Solid cast iron construction of body pieces and base. -- The support column is fully adjustable for horizontal, vertical or angled feeder position. -- Universal joints provide stability for vibration-free feedingSpecifications: -- Swing 360°. -- Motor Power 1 HP. -- (4) Feed speed rates at 13 / 36 / 43 / 108. -- Max. Height of Rollers Parallel to Tabletop 8-1/2".

$2,025

POWERMATIC 100 Single Sided PlanerSpecifications: -- 12" Cap. with 1/16" to 5" thickness opening -- 5 HP motor - 5,300 RPM -- 3-knife cutterhead with high speed steel knives -- 3-1/8" dia. head; 18 FPM fixed feed speed. -- Solid infeed rolls; 12" x 24" precision ground cast iron table. -- 1/4" max. depth of cut -- 7-1/2" min. stock length (unbutted). -- Complete with: Magnetic controls, cutterhead guard with dust chute on enclosed steel stand. -- Belt driven head

Call for Price

PRESTO XL36-20 Scissor Lift2,000 Lbs load capacity for evenly balanced load. -- 7-1/4" Lowered height. -- 36" Travel to raised height of 43". -- 17 Seconds travel time. -- Hinged platform for access to cylinders and internal power unit in collapsed position. -- 24" x 48" standard platform size. -- 3/4" Steel plate scissor legs. -- Heavy Duty hydraulic cylinders with chrome plated rams. -- Lifetime lubricated bearings on all rollers and pivot points. -- Electro-hydraulic 1 HP motor. -- Standard hand control pendant. -- Standard safety velocity fuses. -- Safety maintenance device.

ROBUST SD 60E Low Noise Vertical GrinderFeatures: -- One-piece machined cutterhead without welding for increased accuracy in knife fastening. -- The inserts can be used on their four (4) sides, which reduces operating and tooling costs. -- Overload protection. -- Several dimensions of HARDOX Screen available according to your requisitions.Technical Specifications: -- Motor (18.5KW) - 25CV/600V/60C/3Ph -- Top opening 946 mm x 567 mm (37" X 22.3") -- Cutterhead diameter 222 mm -- Cutterhead speed 80 à 120 RPM -- Quantity of TCT tips 14 ( + 2 latéral) -- Productiion capacity 3 à 4 m3/hour The capacity varies according to the dimensions of the grill, the type of wood and its humidity rate . -- Rear screen dimensions of holes 10 à 30 mm -- Dust hood 160 mm -- Machine dimensions 1881(L) x 1115(W) x 1670(H) (70" X 44" X 65.7")

ROBUST SD 70 Low Noise Vertical Wood Waste GrinderBasic machine features: -- BOVER_BASIC intelligent control system -- Power set (electric motor, reduction gear, and belt transmission) -- Vertical hopper -- Hydraulic pressure unit -- Robust and adjustable -- Hardened knives with four cutting edges with an extended service life -- Hardened cleaning knives -- Hardened cutting racks -- HARDOX sieve -- The motor start-up is controlled by the star/triangle systemTechnical Specifications: -- Main motor 30 kW (40 HP) -- Top Opening: 1445 mm × 1345mm ( 56.8" X 53") -- Rotor working length: 650 mm -- Rotor diameter: 270 mm -- Number of knives: 28 -- Screen hole diameter 10 - 50 mm -- Production capacity: 3 - 5 Cubic meter -- Weight : 1,750 Kg (3,850 Lbs) -- OAL 1973 mm X 1548 mm (77.6" X 61")

ROCKWELL/DELTA 16-RAS, 16" Radial Arm SawSpecifications: -- Blade dia. 16";; base size 37" x 37 x 31"; H; approx. 18" crosscut cap.; approx. 42"; out & 26"; rip cap.Equipped with: -- 5 HP - 3,450 RPM Motor; 34-1/2" table height sitting on mobile base; 32-1/2" without. Includes: -- (5) Sharpened blades.

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i5w 2 HP Motor, belt driven to saw arbor, 10" blade cap., 5/8" dia. tilting arbor, tilts 0° - 45°; 36" x 27" table. 18" left of the blade. Complete with: 2-3/4" x 33" Rip Fence with approx. 25" travel. NOTE: The above specs are taken from literature and considered accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

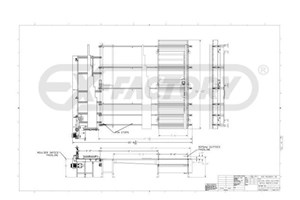

ROSE MACHINERY LCFCMS14 PANEL RIPPER TO MOULDER TRANSFER SYSTEM OUTFEED ROLLCASE: -- Outfeed Rollcase receives material from the LHI Panel Ripper at 47 1/4"; elevation and drops down to place the lumber onto the Transfer Chains at 42"; elevation. 66"; wide rolls are 2-12"; diameter steel rolls, snap in style on 12"; centers. Rolls are powered by a line shaft using round Eagle Belts and a 1-1/2 HP gear-motor. The conveyor will be fabricated from tubular and sheet steel and designed to interface with the Transfer Chains. The conveyor speed is 80-120 FPM to create a gap between courses exiting the Panel Ripper. The drop will be triggered when a photocell detects the leading end of the boards, creating a far side lumber line. A pneumatic cylinder provides lifting power. When the transferred boards clear the rolls, another photocell triggers the rolls to return to the up position. Stock length handled by the Outfeed Rollcase is from 6’ to 16’. Elevation adjustment is +/- 1";.TRANSFER CHAINS: -- Transfer Chains receive material from the Outfeed Rollcase. The Transfer Chains are fabricated from tubular and structural steel. There are (6) strands of 2060H conveyor chain approximately 17’-6"; CC long, leaving 11’ clear space to accumulate (2) layers of ripped strips. (2) sets of pin stops are incorporated to keep the layers separate. The conveyor is powered by a 1-1/2 HP gear motor. Conveyor speed is 90 FPM maximum. Elevation is 42"; +/- 1";. LATERAL CHAIN FEED TABLE (ROSE MODEL LCFCMS14): -- Standard duty low friction flat top steel infeed chains drive the stock to the fence. The fence is adjustable for alignment with downstream equipment such as a Moulder. (3) lower powered feed rolls are smooth steel and non-marking. The feed rolls and chains are controlled by adjustable frequency drives. (3) upper pinch rolls are 5"; diameter urethane. The first (2) rolls singulate pieces while (1) pinch roll keeps the board moving on the bridge. The pinch rolls are triggered by photocells. A PLC in the control cabinet cycles the outputs based on operator input. Operator controls allow for start and stop of the chains and rolls, the feed to be paused, the rolls to be reversed and speed controls. -- Fabricated structural steel frame -- Passline height 42"; +/- 1"; -- Stock width 2"; to 9"; -- Stock Thickness 1/4"; to 4"; -- Stock Length 6’ - 16’ -- Rolls include a variable feed rate from 60 to 300 FPM -- Feed roll drive is by a 3 HP gearmotor -- (6) infeed chains, each 50"; long, are driven by a 1-1/2 HP gearmotor -- Infeed chain's variable feed rate is 20 to 75 FPM -- 2-1/2"; bore air cylinders actuate the pinch rolls -- With 3/4"; fence adjustment. ELECTRICAL CONTROLS: -- Controls are incorporated in the LCF Cabinet for the above Transfer System. It consists of operator controls, (2) VFDs, and additional PLC I/O and programming. STARTUP: -- 2-days startup assistance is included. Travel expenses are billed se

ROSE MACHINERY TRANSFER SYSTEM: PANEL RIPPER TO MOULDER INFEED OUTFEED TRANSFERA Rollcase will carry stock away from a LHI 72" Panel Ripper. When the stock reaches the far end-stop, a 6-Strand Transfer Belt will pop up and take the stock to a Lateral Chain Feeder (supplied by others). The lifting mechanism is triggered by photocells and powered by an air bag using plant air. When the stock clears the Rollcase, the transfer will return to the down position to receive the next batch of strips. Rollcase Specs:17' 0" long; 76" between frame; 1.9" dia. X 12 gauge rollers. Galvanized rollers are set high on 3" centers. 5-1/2" x 1-1/2" x 12 gauge formed steel channel frames; welded construction. 120 FPM maximum. Dual shaft w/jump chain; underhung drive; timing belt driven; 1 HP, 575 volt/3ph/60hz motor; less controls. With (3) H-style leg supports; 34" top of roller; adjustable 32" to 38", with knee braces. Fixed angle end-stop. Frame is powder coated blue; guards powder coated yellow. Transfer Specs:B/17 purple power twist belt; 36" strand centers; 10'-0" long. UHMW chain track; airbag lifting style; thru frame; 36" top of chain. With 1/2 HP Boston 575 volt/3ph/60hz motor with Boston reducer for 120 FPM; less controller; proximity switches to detect carriage position are mounted only; solenoid valve, mounted and plumbed; filter/regulator - mounted and plumbed. With central bearing lube. Frame is powder coated blue; guards powder coated yellow Electrical Controls:ROSE provides an Electrical Control & Cabinet that will control the above Outfeed Transfer System. Electrical Control will incorporate a fused disconnect for incoming power, transformer and power supply for control voltage, (4) variable frequency drives for the motors, a PLC to read input devices and control output devices, and pushbuttons/switches for operator control. The panel will be mounted and wired to the enclosed devices. Incoming power and other field wiring is by others. Two days startup assistance is included. Travel expenses will be billed at cost separately.Conditions:All gear-motors, mechanical equipment, limit switches, sensors or photoelectric devices as required for each item of this quotation, will be supplied and mounted. All pneumatic cylinders or other pneumatic power devices and their valves will be supplied and mounted. They will have connecting hoses and fittings installed. Filter/Regulator units will be supplied, mounted and connected by hose to the valves. Compressed air service to equipment is by others.Exclusions:This proposal describes the machinery to be provided by Rose Machinery Inc.. The equipment supplied by Rose Machinery Inc. is specifically limited to the items actually described in the itemized details of this quotation. Unless specifically mentioned herein, all other items and services are the responsibility of the Buyer. State or local sales taxes, or any permit or other fees that may be required are not included. All field wiring, plumbing, and installat