704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2036 Results Found

704-841-2001

$20,500

OLIVER 5385 Single Head Wide Belt SANDER (37") 1-Head and 37" belt width Combination Sanding Head with rubber covered contact roll and adjustable finishing platen, 1/8" - 5" Thickness capacity, 36" width capacity.Specifications: -- 20 HP Main drive motor. -- 1 HP Variable speed (15 to 45 FPM). -- 1/4 HP Power raising and lowering conveyor bed motor. -- 37" X 75"; Abrasive belts for longer life and less loading.Features; -- Central control panel features digital thickness set-up control for accurate stock height and removal. -- Four post lift design assures accurate consistent results. -- Oscillating belt is controlled by an air sensor to prevent sanding lines. -- Finishing Platen is fully adjustable and can be removed. -- Multiple dust ports for efficient dust management. -- Independent motors run the sanding belt, feed conveyor, and table elevation for maximum power to each operation.

$12,312

Oliver model M-5360.002 25″ double head wide belt sander.Head configuration1st Head; Drum2nd head: Combination HeadSpecifications -- 25" Width capacity -- Belt length is 75″.Equipped with & Features -- Operators manual, -- Misc supplies, and several extra belts.

Call for Price

OMAB GRU-100 (BACCI Style) 4-Spindle Copy Lathe/ShaperSpecifications: -- Capacity: (4) Spindle duplicating/carving/copy heads with (4) copy belt sanders for asymmetrical parts. Max. working height: 6.5" (165 mm), max length capacity 39.4" (1000 mm). -- Speeds: (3) Carriage speeds: 3 IPM (75 mm/Min)_up to 7.87 IPM (200 mm/Min). Spindle speeds: 25 minimum to 42 maximum RPM. Features: -- Carriage feed motor 1.8 HP. Cutter drive motor 2.2 KW (3.9 HP). Bell cutters 1.38" (35 mm), Minimum working radius 0.71" (18 mm). -- Comes with: Installed cup-style cutters. -- NOTE: Larger diameters are possible by using every second carriage position, i.e. (2) heads instead of four heads. -- Dimensions approx 94" long x 37" wide x 78" High . Weight about 2400 lbs NOTE: Specifications are from similar BACCI lathes and need to be verified prior to purchase.

OMAL - INSERT 1300 / Lock-Dowel HBD 1300: CNC Bore, Glue, and Dowel Inserter with: Lock-Dowel"; Processing + Laser Measuring System -- SpecificationsPLC Controlled automatically step-by-step: Boring, glue injection & dowel insertion into panel: Components, drawer parts, chair pieces, etc., at random spacing. -- Working Capacity1,300 mm (51.18") In the "X" axis work area; 40 mm (1.57") "Y" axis stroke with: Manual depth setting; 40 mm (1.57") "Z" axis stroke with: Manual vertical settings.10 mm to 30 mm (0.39" - 1.18") Material thickness capacity in the "Z" axis. -- Positioning Speed: Carriage travel speed: 164 FPM (50 MPM).Equipped with: Brushless motor; ball nut & ball screw for quick positioning. -- Work Areas15-1/2" x 50" x 33-1/2" H Table; (2) 23-1/2" Loading zones with: Cycle time of (1) second for each bore, glue, & dowel insertion when holes are on: 32 mm Intervals. -- Dowel Inserter(1) Dowel Vibrating Hopper feeding System with: (1) OMAL "SURE SHOT" Revolver system guarantees a dowel is inserted every time. 2-Spindle Drill Head on: 32 mm centers & (1) Dowel inserting unit with: 8 mm Diameter dowel capacity.Standard dowel dimension: 8 mm x 35 mm; Max. dowel length: 40 mm; max. dowel projection: 14 mm. -- Lock-Dowel Processing(1) "Lock-Dowel" Vibrating Hopper feeding system + (1) Manual “Lock-Dowel"; loading system; (2) Automatic “Lock-Dowel"; hopper feeders; (1) Automatic “Lock-Dowel"; inserting system. -- Laser SystemLaser automatically measures the part, populates the program list of parts width, and calculates all the inserting location for the part being processed. -- Operator & Machine Control17" Touchscreen Control for: Writing & storing programs and is programmable in the "X" axis.Graphics programming 2.5D with: Simultaneous working display; automatic mirror-Image (left & right) programming; parametric programming; gGraphical aids.Internal self-diagnosis; historical report of alarms -- Complete with:CNC Controlled retractable side & center stop fences for various part sizes; (1) 2-gal (8-Liter) cap. high pressure glue tank; (1) 2-gal. (8-liter) cap. water tank (for cleaning); (4) large 2-3/4" x 5-1/2" pneumatic holddown clamps; dual foot pedal controls. -- Options include: Handheld, Bar Code scanner/reader. Set up for (4) Working Zones, which can be excluded for larger panels. OMAL "Sure Shot" Revolver System (eliminates misfeeds). Laser measuring system..Actual Model: OMAL - INSERT 1300 / LOCK-DOWEL HBD 1300 OF

OMAL HBD 2500 CNC BORE, GLUE & DOWEL INSERTER: Specifications: -- NC Controlled, automatic step-by-step boring, glue injection & dowel insertion into panel components: Drawer parts, chair pieces, etc. at random spacing or automatic hole-spacing with simple what-if statement: i.e. parametric programming.Working Capacity: -- 2,500 mm (98.4") In the X-axis; 30 mm (1-1/4") stroke in the Y-axis; 10 mm - 40 mm (0.39" - 1.57") thickness capacity in the Z-axis. (4) Working zones: Center fence and both side fences dropdown for 2- or large 1-zone operation.Tool Plate Configuration: -- X-Axis rack & pinion drive CNC Controlled; carriage speed of 90 MPM (295 FPM); Y- & Z-axis: Manual ball screw with digital indicators.Equipped with: -- (1) Horizontal drilling unit with: 3/4 HP - 6,000 RPM Motor; (1) gluing & (1) dowel insertion unit.Control System: -- PC Numerical Control operating system; Windows/XP, color video flat screen monitor; 40 GB hard drive; keyboard & mouse. -- Graphic operator inter-phase, parametric programming standard; OMAL patented "SURE SHOT" Revolver System with fiber optic sensor to guaranty reliable dowel presence & insertion.Complete with: -- (1) 18-Liter (4-3/4 Gallon) cap.; high pressure glue tank. -- (1) 18-Liter (4-3/4 Gallon) cap.; water tank (for cleaning). -- (1) Vibratory Dowel Hopper, (6) pneumatic hold-down clamps; machine is setup for 8 mm dowels.

OMAL INSERT 900 CNC BORE, GLUE & DOWEL INSERTERSpecifications: -- Capacities: X-Axis 900 mm (35.44"); Y-Axis 40 mm (1.57") stroke; Z-Axis 10 - 40 mm (0.39" - 1.57") thickness. -- Table size; 15-5/8"; x 49"; x 35"; H; (4) working zones: (2) 450 mm (17.72") W. -- Max. dowel size: 8 mm Dia. x 30 mm L (0.31" dia. x 1.18" L). -- Max. dowel projection: 15 mm (0.59"). -- Spindle speed: 6,000 RPM. -- Cycle time: 0.8 Sec.Equipped with: -- (4) 2-1/4" Dia. pneumatic hold-downs. -- (1) Horizontal drilling unit with: 3/4 HP - 3,380 RPM TEFC Motor; (1) glue injection unit & (1) dowel insertion unit. -- PC-Based controller with: 12" Display; (2) foot pedal controls.Complete with: -- BROVIND VIBRATORI "OB 300 DC": 14" Dia. x 5-1/2"; D vibratory Bowl Feeder with: "NC-02M-50 DC" Variable Speed Controller. -- (1) 8 L Cap. High Pressure Glue Tank; (1) 8 L Cap. Water Tank.

Call for Price

OMAL VELOX 1300 CNC BORE, GLUE & DOWEL INSERTER + Optional LASER MEASURING DEVICE SpecificationsPLC Controlled automatic step-by-step boring, glue injection, & dowel insertion into panel components, drawer parts, chair pieces, etc. at random spacing. Features"Optional" Auto Laser measuring device with: Parametric Control and Touchscreen PLC Control. Working Capacity51" (1,300 mm) In "X" Axis work area; 1.57" "Y" Axis stroke with manual depth setting; 1.57" "Z" Axis stroke with manual vertical settings. -- 10 mm to 30 mm (0.39" - 1.18") Material thickness capacity in the "Z" axis. -- Machine is currently set up for 8 mm dia. x 30 mm long max. dowel dimension.Work Areas(2) Loading zones with: Cycle time of (1) second for each bore, glue and dowel insertion when holes are on 32 mm intervals. -- Equipped with: Brushless motor; ball nut and ball screw for quick positioning.Dowel InserterOMAL "SURE SHOT" Revolver system guarantees a dowel is inserted every time. (1) Dowel insertion unit with: 8 mm Diameter dowel capacity -- Standard dowel dimension: 8 mm x 35 mm; Maximum dowel length: 40 mm; Maximum dowel projection: 14 mm.Operator InterfaceTouchscreen Control for writing and storing programs & is programmable in the "X" Axis. -- Graphics programming 2.5D with: Simultaneous working display; Automatic Mirror Image (left & right) programming; Parametric programming; Graphical aid.Internal self-diagnosis; Historical report of alarms, Complete with:(2) Working zones, (1) horizontal drilling unit, (1) gluing, (1) dowel insertion unit.(1) 8-Liter cap. high pressure Glue Tank, (1) 8-liter cap. Water Tank (for cleaning), (1) Vibratory Dowel Hopper, (4) pneumatic Holddown Clamps, Dual foot Pedal controls. -- Actual Model is: OMAL VELOX 1300

QUICK 20" Wide Conveyorized Glue Applicator -- 20" Wide grooved rubber glue applicator roll with stainless steel doctor blade and glue reservoir. -- Features easy adjustment or removal of doctor blade, -- 18' Overall length, 8' infeed before the glue roller and 10' outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers, -- Heavy Duty crossbars, chain guard, high-quality anti-stick urethane finish, and owner & operator's manuals.

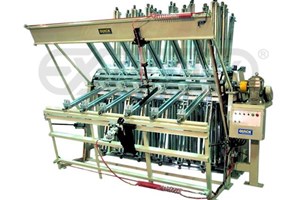

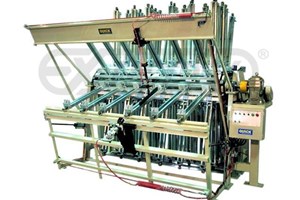

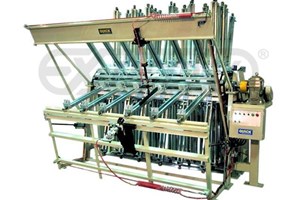

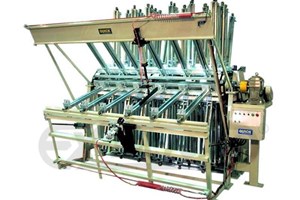

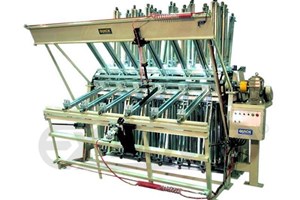

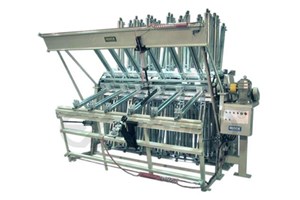

QUICK 30-Section Heavy Duty Clamp Carrier with 12-1/2' width capacity -- With (9) Standard zinc plated clamps per section (270 clamps total), 32" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls -- Second Panel Flattener for the second operator -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Second pneumatic Clamp tightener for the second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

²QUICK 14-Section Pneumatic Clamp Carrier with 12-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment Panel Flattener with easy to use controls.Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

QUICK 40-Section Heavy Duty Clamp Carrier 12.5' with Auto Clamp Loosener -- With (9) Standard zinc plated clamps per section (320 clamps total), 32" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- (2) Hydraulic Semi Automatic Clamp Tightener/Panel Flattener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic Upper Auto Clamp loosener for 12.5' wide -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Conveyorized glue spreader 20" wide with 10' infeed and 13' outfeed -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.

Call for Price

Quick Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section with 52" opening. -- Includes 160 clamps with 52" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener riding along with tightener -- Semi-Automatic Pneumatic clamp tightener . -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

Quick Hydraulic Clamp Carrier with 20-sections and 12-1/2' width capacity.This special "thick stock" frame accepts (12) Heavy Duty zinc plated clamps per section. Includes: -- 240 clamps with 36" openings and 6" high x 4-3/4" wide jaws with 1° inward draft. -- Integral hydraulic overhead panel flattener. -- (2) Hydraulic clamp tightener with adjustable torque limiter. -- (2) Pneumatic panel flattener -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.Note: Could be order with single tightener and panel flattener

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.OAL Dimensions are 163" W x 182" D x 125" H

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

²QUICK 14-Section Pneumatic Clamp Carrier with 10-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. -- Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- A 14-Section Clamp will produce approx. 300 panels

QUICK 6-SECTION, 12-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp, typically produces (144) high-quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (9) clamps per section and 12-1/2' width capacity. -- (54) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- Rocker Plates are available as optional equipment for face gluing. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy-to-use controls. -- Pneumatic Clamp Tightener with a 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; the 2-handed, trigger-activated tightener is more confidence-inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, and automatic air line oiler; -- High-quality Urethane finish coating, and tool box with spare parts & tools.Floor space requirement: 195"W X 125" H X 127"D

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (48) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

Quick Heavy Duty Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- (10) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- Includes 180 clamps with 44" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener along with tightener -- Pneumatic panel flattener for second operator -- Semi-Automatic Pneumatic clamp tightener . -- Semi-Automatic panel tightener for second operator -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

QUICK 14-Section Heavy Duty Hydraulic Clamp Carrier with 20-1/2' width capacity With (16) Standard zinc plated clamps per section (224) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Pneumatic Panel Flattener with easy to use controls. -- Pneumatic panel flattener for second operator -- Hydraulic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic clamp tightener for second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels