704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1847 Results Found

704-841-2001

MAREN - 72-OE-76, ...Auto-Tie Horizontal BalerSpecifications: -- Cylinder: 6" -- Bale size: 30" x 38" x Variable -- Feed opening: 29" x 27" -- Power unit: 30 HP -- Tensioner cylinder: 3" x 12" -- Ram thrust: 78; 340 Lbs -- Cycle time: 20 Sec -- Operating pressure: 2,700 PSI

Call for Price

MARCUS TRANSFORMER 15 KVA, 3-Ph, Auto, 600/480 V Transformer with tap for 440 V.15 KVA Auto-ventilated "dry type" transformer 600 V in (primary); 480 V out (secondary) with tap on secondary for 440V at full capacity. -- Manufactured with grain oriented silicon steel is used. -- Coil windings with high quality magnet wire and the enclosure is made of heavy gauge steel w/ventilation openings. -- UL and CSA approved.

Call for Price

--In auction: https://exfactoryauctions.com/Detail/SH-230492/event/A122024$1 --NO RESERVE!-- MARTIN T 23 Tilting Spindle Shaper, with 30 mm (1.18") Interchangeable Spindle & Power Feeder Specifications: Table size 940 x 1100 x 850 mm (37.01” x 43.31” x 33.46”) H, with Table insert dia. 90, 130, 205, 305, & 480 (3.54”, 5.12", 8.07”, 12.01”, & 18.90”). Spindle tilt 0° to 45°. Maximum capacity under nut 7". Vertical spindle adjustment 145 mm (5.71"). Spindle speeds 3000, 4,500, 6,000, & 90,000 RPM. Equipped with: 6.4/7.8 HP Motor. "MK5" Spindle shaft. Mechanical spindle brake, with Foot pedal. Hand spindle lock. Complete with: 11-1/2” x 4-3/4” Left & Right Fences, with 21” x 6” H Left & Right Wood fences. 1996 CO-MATIC 1 HP 4-Speed 4-Roll Power Feeder, with Speeds 13, 26, 26, & 72 FPM. Dimensions with Power Feeder: 42" x 42" x 63” H.

Call for Price

MARUNAKA Model RD – 8J WIDE Single Deck Veneer Roll Dryer;Complete with the following features: -- 1988 - year of manufacture. --Working width – 51"; --Length of the dryer – 24 Ft (4 Sections) --Type of heating - Steam --Operational in 2018 when mill closed --Professional rigging and loading available.

Call for Price

MARUNAKA Model RD-3UB/RD-6UB (Connected) Single Deck Veneer Roll Dryer;Complete with the following features: -- (3) 3 HP circulating fans with (1) 3 HP exhaust blower thru the ceiling. -- Optional heat source: electric (7) Elements/Zones, computer controlled thermocouples in addition to (2) Natural gas burners (OEM).. Both dryers have a 100amp circuit breaker with 100amp fuses. The RD 8 operates with 4 fan motors and 4 heaters. The RD 6 has 3 fan motors and 3 heaters";.. -- Capable of temperatures to 120° Celsius (250° Fahrenheit). -- Working width 1000 mm or about 39 inches. Veneer is fed endo.Please Note: -- Dryer is (2) separate units; all equipment will fit into a 40' container for shipment from Eastern USA. -- All equipment is in good working condition including all fans and blower, temperature control works properly; feed roll drive works well. -- Rolls have been nickel treated to minimize corrosion/oxidation. -- This dryer equipment is still in place. -- MARUNAKA (2) Models: RD-3UB and RD-6UB currently connected to increase capacity. Can easily be separated.NOTE: Refurbished in 2005, operated from 2005 - 2012. Still operational ready to work!

Call for Price

MASTER MACHINERY MC-MDS-1 Single Spindle ShaperSpecifications: -- Table size: 27.5" x 32" -- Spindle speed: 7500 - 10,000 RPM -- Main motor: 3 HP

MASTERWOOD PROJECT 313 CNC MACHINING CENTER (W/ACT/BORING): -- Specifications:Working Capacity:"X" Axis 3,080 mm (121"), "Y" axis 1,100 mm (43") width; -- Positioning Speed:Programming speed in X-axis 197 FPM (60 MPM), Y-axis 162 FPM (49 MPM), Z-axis 58 FPM (18 MPM). -- Boring unit:(13) independent vertical spindles, (9) in X-axis, (5) in Y-axis; (4) horizontal spindles with (1 + 1) in X-axis for edge boring in the left- & right-hand panel edges. -- Machining:(1) 7.5 HP (5.6 kW) high speed router (1,000 - 24,000 RPM) by frequency inverter; 1.5 HP (1.1 kW), 6,000 RPM grooving saw with manual rotation for X-axis or Y-axis; -- Work Table: (6) moveable support rails with (2) vacuum cups ea., double zero settings, (6) pneumatic backstops and (2) pneumatic side stops creating (2) working zones. -- Operator & Machine Control:TECNOSUD "K68800" Microprocessor control for (3) axis, lineal, circular, and helical interpolation. Equipped with 14" color video graphic monitor, keyboard for data entry, 1.44 MB floppy disk drive, 64K RAM, RS-232 for possible connection to office PC, all mounted in separate free-standing control cabinet; features to run CPL/Parametric "TRIG" programming and "Spline" CAD/CAM. -- Complete with: Dual zone vacuum pump. Ontario Hydro approved electrics. -- Actual Model is MASTERWOOD PROJECT 313

MASTERWOOD OMB1CN3-TF Horizontal Slot Mortiser. One NC working head (3) axis with a programmable microprocessor. Machines a sequence of slots on windows, doors, shutters, or cabinets without moving the workpiece. Continuous cycles with loading/unloading. -- Equipped with: (1) MAKA style chisel mortising unit, (1) Vertical routing unit, and (1) TF Horizontal routing unit. High-frequency drilling - routing with controlled axis, DC motors, and ball screw is driven. -- Max Mortise workpiece size 150x110x2800 mm length (5.9"x4.3"x110.2"). Vertical and horizontal routers 142"; length. -- Max slot depth 130 mm (5.1"). Max vertical head stroke 140 mm (5.5"). -- Features: Pneumatic hold-downs bar mounted above table. Flip-up pneumatic pressure beam for additional support when needed. Free-standing control and electrical cabinets house computer monitor and keyboard. Master universal electronic system controller (MW CN10 Centromac) -- Vertical routing assembly: 4HP, 220/380v 3 PH, 9,000 RPM -- Horizontal routing assembly 5"; 220/380v, 3 PH, 9,000 RPM -- Memory for 50 cycles. Mirror imaging with preset tool speed (over-writeable knob). -- Total load 21 KVA -- Overall dimensions 4200mm long x1600x1600mm (166"x63x63"). Electrical cabinet 1,000 high x 450x950mm (40"x 18"x38"). Approx. weight 3800 Kg (8,400 Lbs.).

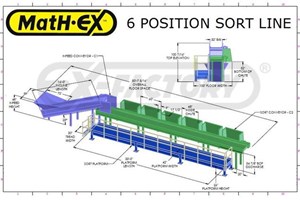

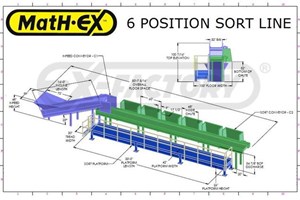

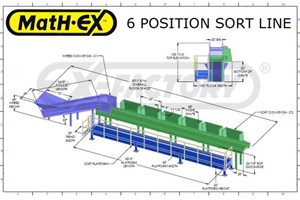

MATH-EX (6) PERSON BASIC RECYCLING SORT LINESpecifications: -- 16 Feet x 32" Inclined feed conveyor with 48" high hopper and 2" high cleats @ 36" centers. -- 36 Feet x 32" Sort conveyor with infeed transition guides and Belly rest skirt on one side. -- Sort platform with OSHA stair and handrail. -- (6) Sort chutes with 52" of clearance. -- 1-1/2 HP, 460 volts 3-phase drives.Custom order your Sorting Line with approx. 7 to 8 week lead time for delivery.

MATH-EX (6) Position (Person) Basic Recycling Sort Line Specifications: -- 16 Feet x 32" Inclined feed conveyor with 48" high hopper and 2" high cleats @ 36" centers. -- 36 Feet x 32" Sort conveyor with infeed transition guides and Belly rest skirt one side. -- Sort platform with OSHA stair and handrail. -- (6) Sort chutes with 52" of clearance. -- 1-1/2 HP, 460 volt, 3-phase drives. -- (2) VFD Controllers mounted in control panel -- Pedestal style stand. -- Emergency pull cord stop or-E-stop for sort conveyor -- Motor wire and flex conduit for (2) conveyors shipped loose. -- (1) 6" Diameter Ceramic Drive Pulley -- (1) Stainless steel Back ChuteOptional Equipment: -- (2) VFD Controllers mounted in control panel -- Pedastal style stand -- Emergency pull cord stop or E-Stops for sort -- More wire and flex conduit for (2) conveyors

MATH-EX (6) PERSON BASIC RECYCLING SORT LINE -- 16 Feet x 32" Inclined feed conveyor with 48" high hopper and 2" high cleats @ 36" centers. -- 36 Feet x 32" Sort conveyor with infeed transition guides and Belly rest skirt one side. -- Sort platform with OSHA stair and handrail. -- (6) Sort chutes with 52" of clearance. -- 1-1/2 HP 460 volts 3 phases drives. -- (2) VFD Controllers mounted in control panel -- Pedestal style stand. -- Emergency pull cord stop or-E-stop for sort conveyor -- Motor wire and flex conduit for (2) conveyors shipped loose. -- BRAND NEW WITH WARRANTY -- ALLOWS 7 TO 8 WEEKS DELIVERY -- LOADED ON YOUR TRUCK

MATH-EX 4-Position (Person) Basic Recycling Sort Line SLIDER BED BELT CONVEYOR: (MODEL 600, STYLE B) FRAME CONSTRUCTION:Specifications: --10 GAUGE, BOLT TOGETHER PULLEY DIAMETER --6" DIAMETER CONVEYOR LENGTH --16' 0" ANGLE OF INCLINE: 25° --EFFECTIVE WIDTH: 32" BELT: --BLACK PVC120 COS ENDURA-CLEAT: 2" HIGH @ 48" CENTERS SIDE SKIRTS --12" HIGH (TOB), 12 GAUGE BELT RETURNS: BOTTOM PANS BELT SPEED: 60 FPM DRIVE MOUNT/SIDE: SHAFT MOUNT -- RIGHT HAND SIDE MOTOR: 1 HP, 460V/3PH LIVE LOAD CAPACITY: 394 LBS. (FIXED SPEED) CONTROLS: START/STOP CONTROL - (2) E-STOPS - --MOUNTED AND WIRED INFEED HEIGHT: 0" BOF DISCHARGE HEIGHT: 83" BOF SUPPORTS: -- PROVIDED INCLUDED FEATURES: - BLACK SIDE GUIDES - BOTTOM PANS - INFEED HOPPER - TRANSITION GUIDES --MAGNETIC HEAD PULLEY (CERAMIC) OVERALL FLOOR LENGTH: 174" (END TO END) -- APPROXIMATE SHIPPING WEIGHT: 1876 LBS. PLUS PACKAGING --FRAME CONSTRUCTION: 10 GAUGE, BOLT TOGETHER --PULLEY DIAMETER: 6" DIAMETER CONVEYOR LENGTH: 26' 0" ANGLE OF INCLINE: 0° EFFECTIVE WIDTH: 32" BELT: --BLACK PVC120 COS SIDE SKIRTS 6" HIGH (TOB)12 GAUGE BELT RETURNS --RETURN ROLLERS BELT SPEED: 60 FPM DRIVE MOUNT/SIDE: SHAFT MOUNT --RIGHT HAND SIDE MOTOR: 1 HP, 460V/3PH -- LIVE LOAD CAPACITY: 922 LBS. --(FIXED SPEED) CONTROLS --AC VFD CONTROL (2) E-STOPS --MOUNTED AND WIRED INFEED HEIGHT: 52" BOF DISCHARGE HEIGHT: 54" BOF SUPPORTS: --PROVIDED INCLUDED FEATURES: - BLACK SIDE GUIDES - SORT SKIRTS -- (4) SORT CHUTES OVERALL FLOOR LENGTH: 312" (END TO END) --APPROXIMATE SHIPPING WEIGHT: 2059 LBS. PLUS PACKAGING --4P SORT PLATFORM: LENGTH: 23' WIDTH: 42" HEIGHT: 26" ADDITIONAL FEATURES: - SAFETY RAILINGS4K DUMPER TO FEED LINE-1 (INLINE) - Extra $16,500 --CONTAINER DUMPER: 4BD-60-5248 LIFT CAPACITY: 4000LBS. DUMP HEIGHT: 60" ROTATING DRUM SIZE: 52" WIDE X 48" DEEP MAX. CONTAINER HEIGHT: 48" OVERALL HEIGHT: 150" (APPROXIMATELY) FRAME: REINFORCED FORMED STEEL CUSTOMER CONTAINER SIZE: 48" L. X 40" W. X 48" H. POWER UNIT: 2HP, TEFC - LEFT HAND PUMP MOUNT VOLTAGE: 460 VOLT, 3 PHASE, 60 HERTZ CONTROLS: PUSHBUTTON CONTROLS - LEFT HAND MOUNTED CONTROLS - 120V CONTROL C IRCUIT --OPTIONAL FEATURE: GATED ENCLOSURE: Extra - $5,950- WELDED CONSTRUCTION WITH EXPANDED METAL - PUSHBUTTON CONTROL STATION - NON-CONTACT DOOR SENSOR INCLUDED - ENCLOSED BACK COVERS --OPTIONAL FEATURE: AUTO-RUN CONTROLS: Extra - $4,200 - SELECTOR SWITCH FOR AUTO-RUN OR MANUAL MODE - KEY SWITCH AND EMERGENCY STOP BUTTON INCLUDED - ALL SENSORS AND CONTROLS PRE-WIRED REQUIRES SAFETY ENCLOSURE LINE ABOVE --OPTIONAL FEATURE:Extra - $1,200 - FASTER LIFT TIME - 5HP DRIVE - 27 SEC LIFT

MATTEI OPTIMA 30, 40 HP Variable-Speed Rotary Vane Compressor (89-189 CFM @ 102-145 PSIG)RELIABLE ROTARY VANE AIRENDSThe inverter adjusts the motor’s rotational speed, adapting the air delivered by the compressor to the actual air demand. OPTIMA can save up to 35% of the annual operating costs. Ideal for automotive, commercial and industrial applications.Features: -- MATTEI Optima Series Air Compressors quiet cabinet constant-duty Rotary Vane Compressors feature an inverter to match their operation to suit the load profile required by the compressed air system to ensure maximum energy savings under varying air demands.Equipped with: -- 40 HP TEFC motor, 89-189 CFM @ 102-145 PSIG; MaestroXS microprocessor control and protection system, AC inverter, premium efficient TEFC motors, quiet acoustic enclosure, air-cooled aftercooler, intelligent timed electronic condensate drain and separator kit and are filled with Mattei Rotoroil 8000 F2 synthetic oil; 2" NPT outlet.Includes: -- “W"; Version includes water-cooled oil and after cooler, add;...$ 1,463

MATTEI OPTIMA 45, 60HP Variable-Speed Rotary Vane Compressor (102-145 CFM @ 102-145 PSIG)RELIABLE ROTARY VANE AIRENDSThe inverter adjusts the motor’s rotational speed, adapting the air delivered by the compressor to the actual air demand. OPTIMA can save up to 35% of the annual operating costs. Ideal for automotive, commercial and industrial applications.Features: -- MATTEI Optima Series Air Compressors quiet cabinet constant-duty Rotary Vane Compressors feature an inverter to match their operation to suit the load profile required by the compressed air system to ensure maximum energy savings under varying air demands.Equipped with: -- 60 HP TEFC motor, 102-145 CFM @ 102-145 PSIG; MaestroXS microprocessor control and protection system, AC inverter, premium efficient TEFC motors, quiet acoustic enclosure, air-cooled After Cooler. -- Intelligent timed electronic condensate drain and separator kit and are filled with Mattei Rotoroil 8000 F2 synthetic oil; 2" NPT outlet.

MATTEI BLADE 18 LX, 25 HP Direct-Drive Rotary Vane Compressor (112 CFM @ 116 PSIG)Direct-Drive Air Compressors combine legendary vane technology with traditional shaft-to-shaft coupling to provide industry leading performance at affordable prices. As quiet as 66 dB(A), all models turn at a slow 1,800 RPM. -- Equipped with: 25 HP Premium efficient TEFC motor; Wye-delta starter; quiet acoustic enclosure, 67 dB(A); air-cooled after cooler; protection system MaestroXS. -- Features: MAESTRO XB controller with expansion module allowing real time clock and daily/weekly programming, Continuous and Automatic operating modes with standard load/unload operation on all models, moisture separator & zero-loss electronic condensate drain (shipped loose); phase reversal protection; network ready. -- Includes: (3) Year parts warranty, (10) years on Air-End. Add Optional Refrigerated Air Dryer AC-300295

MATTEI BLADE 22i, 30 HP Direct-Drive VSD Rotary Vane Compressor (71 - 112 CFM @ 102 - 145 PSIG)Direct-Drive Air Compressors combine legendary vane technology with traditional shaft-to-shaft coupling to provide industry leading performance at affordable prices. As quiet as 66 dB(A), all models turn at a slow 1,800 RPM.Equipped with: -- 30 HP Premium efficient TEFC motor; VSD Drive; quiet acoustic enclosure, 67 dB(A); air-cooled after cooler; protection system MaestroXS. -- Features: -- MAESTRO XB controller with expansion module allowing real time clock and daily/weekly programming, Continuous and Automatic operating modes with standard load/unload operation on all models, moisture separator & zero-loss electronic condensate drain (shipped loose); phase reversal protection; network ready. -- Includes: -- (3) Year parts warranty, (10) years on Air-End.

MATTEI BLADE 7 LX-TM-SE, 10 HP Tank-Mounted Rotary Vane Compressor w/Refrigerated Air Dryer ( 39 CFM @ 115 PSIG) RELIABLE ROTARY VANE AIRENDSBLADE features proprietary single-rotor stator unit (RSU) that incorporates MATTEI's legendary white metal Babbitt bushings on the back and now an oversized radial ball bearing on the front to address the side load created by the belts. MATTEI BLADE compressors are engineered for 24 hours/day service with exclusive Meehanite® iron blades, designed to last 100,000 hours.Features: -- MATTEI BLADE Series Air Compressors combine vane technology with dual "V" belt transmission to provide industry leading performance at affordable prices. -- As quiet as 61 dB(A), with speeds as low as 1,050 RPM, and operating pressures from 115 PSI to 175 PSI, BLADE is the ideal solution for small woodworking cabinet shops and manufacturers, body shops, mechanical shops, and other manufacturers.Equipped with: -- 10 HP TEFC motor, 39 CFM @ 115 PSIG; full-voltage motor starter, air-cooled Aftercooler, MAESTRO XB controller with Continuous and Automatic operating modes with standard load/unload operation on all models; MATTEI Rotor Oil 8000 F2 synthetic oil.Includes: -- 80-Gallon ASME Air Receiver Tank; Refrigerated Air Dryer, Pressure Gauge, Safety Valve, Filter, Oil Separator.

MATTEI ERC 1018L, 25 HP Rotary Vane Compressor (105 CFM @ 125 PSI)Features: -- No wear on compressor's moving mechanical parts; pulse-free air; low oil volume and consumption. -- Direct-coupled compressor and motor; slow 1,800 RPM; compact, quiet design with 81 dB (A) in an open-frame design.Equipped with: -- Bearingless air-ends; rotor stator unit (RSU) is the rotor which is simply supported by (2) white metal Babbitt bushings that routinely deliver > 100,000 Hours of life. -- 25 HP ODP Motor; 105 CFM @ 125 PSIG; air cooled aftercooler with 18° F approach temperature'; 3-stage oil separator produces 3 PPM in compressed air, automatic drain valve; cleanable filter.Complete with: -- Efficient oil injection system guarantees a perfect holding among the moving parts, cooling, and lubrication. -- An oil film on the stator's inside surface prevents the moving parts from wearing by avoiding a direct contact with the blades. -- Automatic load/no load, load matching modulation; automatic with modulation; 1" dia. air outlet.

MATTEI ERC 507L 10 HP Rotary Vane Compressor (43 CFM @ 125 PSI)Features: -- No wear on compressor's moving mechanical parts; pulse-free air; low oil volume and consumption. -- Direct-coupled compressor and motor; slow 1,800 RPM; compact, quiet design - 77 dB (A) in an open-frame design.Equipped with: -- Bearingless air-ends - rotor stator unit (RSU) is the rotor which is simply supported by two (2) white metal Babbitt bushings that routinely deliver >100,000 hours of life. -- 10 HP ODP motor; 43 CFM @ 125 PSIG; air cooled aftercooler with 18°F approach temperature, 3-stage oil separator produces 3 ppm in compressed air. automatic drain valve; cleanable filter.Complete with: -- Efficient oil injection system guarantees a perfect holding among the moving parts, cooling and lubrication. An oil film on the stator's inside surface prevents the moving parts from wearing by avoiding a direct contact with the blades. -- Automatic load/no load, load matching modulation, automatic with modulation; 1" dia. air outlet.

$12,187

MATTISON - 202, ...Straight Line Rip SawSpecifications: -- 15 HP - 3,400 RPM Saw arbor motor, 9" - 14" max. blade capacity, 1-1/2" diameter arbor, overhead arbor design. -- 4" Max. depth of cut, 13" min. stock length, 24" max. rip capacity to the right of the blade, 77" x 65" table size.Equipped with & Features: --Overhead holddown with: (6) Pressure rollers, (3) front and (3) back; 2 HP feed drive, (4) feed speeds of 56 - 84 - 112 & 168 FPM (fixed at 25 FPM ).