704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1853 Results Found

704-841-2001

WEEKE ABD 060 CNC BORE, GLUE & DOWEL INSERTER: -- Specifications:(1) Horizontal drilling head with (3) Independent spindles on 32 mm centers, with servo control of "X", "Y" & "Z" Axis; (1) glue & dowel injector with glue flow control; (1) vibrating hopper dowel feeder. -- Working Capacity:Material size from 20 mm - 1,250 mm (.75" - 49") long, 50 mm - 800 mm (1.97" - 31.5") wide, 10 mm - 60 mm (0.4" - 2.4") thick.Machine is currently set up for 8 mm Dia., 30 or 35 mm long dowels (additional dowel sizes are optional). -- Work Area(2) Separate working fields with (4) pneumatic top clamps can process up to (4) parts independently on the left-hand, right-hand or center stops.Work can be loaded in (1) field while being machined in the other to allow fast production of varying parts. -- Operator Interface:PC Front-end with Homag Power Control PC 85T, WoodWOP 5.0 operating system with graphic programming & error messaging.17" TFT flat screen monitor, CD-RW drive, 1.44MB floppy drive, standard keyboard & mouse; Software allows program design with automatic mirror-image by use of an active center stop located 600 mm (23.6") from zero. -- Complete with: All manuals, documentation & program disk provided with machine. -- Actual Model is WEEKE ABD 060/12/NA.

Call for Price

WEEKE - VENTURE 230 L: CNC Machining Center (w/ATC/Boring/C-Axis) -- Specifications: Working Capacity: "X" Axis is 180" (4,500 mm); "Y" axis is 60" (1,500 mm) for boring; 64" (1,600 mm) for routing; "Z" axis stroke is 7.2" (185 mm); max. material thickness 4.9" (125 mm). -- Positioning Speed"X & "Y" Axes travel speed: 361 FPM (110 MPM); "Z" Axis travel speed: 66 FPM (20 MPM).Machine head travels on: THK linear motion guides on all axes. -- Worktable(8) Movable K-Table support rails with: (6) Side mounted raise-and-lower panel feeding rails; (2) vacuum pods per rail; (8) pneumatic backstops: (2) Pneumatic side stops create (2) working zones.Setup assistance through LED displays on the support rails for precise rail & vacuum pod positioning. -- Boring Unit3 HP (2.2 kW) Motor; variable speed from 1,500 - 7,500 RPM; (21) vertical drill spindles: (11) Spindles in "X" axis & (10) in "Y" axis. (10) Horizontal spindles with: (3 + 3) In "X" axis & (2 + 2) in "Y" axis.(1) NC Controlled 0° - 90° "X" / "Y" grooving saw; 125 mm dia. saw blade. -- Machining(1) 16 HP (12 kW) Air-Cooled electrospindle router with: HSK F63 Adaptor; programmable 1,250 - 24,000 RPM; constant torque from: 9,000 - 24,000 RPM; RH or LH rotation; powered by a frequency inverter.(1) NC Controlled "C" axis for: 360° Horizontal processing.(28) Total ATC positions with: (1) 14-Position Rotary ATC tool changer magazine at the back of the machine head; for "on the fly" ATC.(1) 14-Position Rotary ATC tool changer magazine mounted on the RH side of the machine. -- Operator InterfaceWEEKE IPC "PC 85 Power Control" + Windows "XP" + WoodWOP 6.0 Operating System; "BECKOFF" PLC for: (3/4) Axes linear; Circular & Helical interpolation.15" TFT Monitor; industrial keyboard for data entry; CD R/W; 1.44 MB floppy drives; modem; USB slot; RS-232 serial interface for possible simple PC connection; all mounted in separate free-standing control panel. -- Complete with:(2) 100 m³/Hr Vacuum Pumps; 2-zone safety mats (will stop machine if operator enters work area); safety fences; scrap conveyor; handheld pendant controller. -- Actual Model: WEEKE VENTURE 230 L

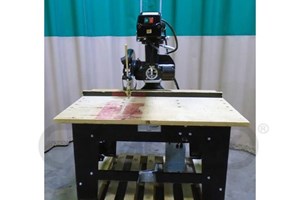

ORIGINAL 3546 RADIAL ARM SAW (Heavy Duty Series)The Heavy Duty Series is a very precise machine made for the rigors of every day industrial use. Straight, miter, bevel and compound bevel cutting in a heavy gauge steel powder coated frame & legs. Specifications: 5 HP TEFC Saw motor; 16" dia. blade; 1" x 2-3/16" saw arbor; 4-15/16" thickness cap. @ 90°, 2" @ 45°; 24" crosscut cap.; 15-1/2" max. miter cut @ 45°; 37-7/8" rip capacity. Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and automatic spring return; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. Complete with: -- 42-1/2" x 31-1/4" MDF table; sturdy powder coated cast iron frame; heavy gauge steel base and support legs. Optional: -- 16" x 60-Tooth x 1" Bore saw blade; pneumatic clamping systems; power carriage feed; 14" & 22" wide roller tables.

ORIGINAL 3558 RADIAL ARM SAW (Super Duty Series)The Super Duty Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy-duty cast and ductile iron for vibration-free operation. Specifications: -- 7.5 HP TEFC Saw motor; 20" dia. blade; 1" x 3-1/8" saw arbor; 6-1/4" thickness cap. @ 90°, 3-1/4" @ 45°; 32" crosscut cap.; 21-5/8" max. miter cut @ 45°; 48-3/4" rip cap. Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and automatic spring return; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. Complete with: 58" x 50" MDF table; sturdy powder coated cast iron frame; heavy gauge steel base and support legs. Optional: -- 20" x 60-Tooth x 1" Bore saw blade; pneumatic clamping systems; power carriage feed; 14" & 22" wide roller tables.

ORIGINAL 3579-20L Metal Cutting Radial Arm Saw (Super Duty Series)The Super Duty Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy duty cast and ductile iron for vibration free operation. Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel. Specifications: -- 7.5 HP TEFC Saw motor; 20" dia. blade; 1" x 3-1/8" saw arbor; 7" thickness cap. @ 90°, 3-3/8" @ 45° bevel; 32" crosscut cap. with 1" stock; 21-5/8" max. miter cut @ 45°. -- Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; indexing yoke to 90° for rip cutting panels; saw head with automatic motor brake and manual chain feed assembly; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. -- Complete with: -- The Metal Cutting Series comes with the standard t-slot aluminum extruded top, allowing easy to attach aluminum fence, clamping systems, table surface options, as well as your own clamping jigs or cutting fixtures. These all come mounted to a extruded leveling frame for easy leveling of the entire table assembly throughout the life of the machine. -- Available Options: -- Power feed saw head; pneumatic clamping systems; Mist Coolant System (manual for non-ferrous cutting); blade.

ORIGINAL 3579-22L Metal Cutting Radial Arm Saw (SD Series)SD Series is the ultimate workhorse of the industry, capable of operating 2 to 3 shifts per day. Miter & bevel cutting, compound miters and dado operations. Constructed of heavy duty cast and ductile iron for vibration free operation. Aluminum, Brass, Bronze, Copper, Fiberglass, Lead Sheets, Plastic, Steel. Specifications: -- 7.5 HP TEFC Saw motor; 22.5" dia. blade; 1" x 3-1/8" saw arbor; 8" thickness cap.; 4" @ 45° bevel; 24" crosscut cap. with 3/4" stock; 21-5/8" max. miter @ 45°. -- Features: -- Swivel arm for miter cuts, swivel motor for bevel cuts; saw head features VFD technology; which increases the start-up speed of the blade by over 8 seconds with a slower, smoother start-up that slows and stops the saw over approximately 25 seconds to allow for consistent braking times; positive locking device for tilting; upper and lower blade guards with anti-kickback attachment. -- Complete with: -- The Metal Cutting Series comes with the standard t-slot aluminum extruded top, allowing easy to attach aluminum fence, clamping systems, table surface options, as well as your own clamping jigs or cutting fixtures. These all come mounted to an extruded leveling frame for easy leveling of the entire table assembly throughout the life of the machine. -- Available Options: -- Power feed saw head; pneumatic clamping systems; Mist Coolant System (manual for non-ferrous cutting); blade.

$7,160

ORIGINAL - 3551, ...Radial Arm SawThe "Original" Radial Arm with: Full 24" crosscut capability. -- Sturdy cast iron frame for saw head and arm.Equipped with: -- 5 HP Single-phase motor with: Magnetic starter and overload protection. -- Saw head with: Automatic motor brake and automatic return. -- Positive locking device for tilting. -- Large 49" x 50" MDF table. -- 16" Blade cap. with: 4-3/8" Material thickness at 90°. -- Features: -- Heavy gauge steel base & legs for solid support. -- Complete upper & lower blade guards and anti-kickback attachment.

$14,795

ORIGINAL 3691-03 Overhead Rail Panel SawSpecifications: -- Sturdy welded steel frame for saw head and beam arm; 7.5 HP motor; 1" dia. arbor; 1-3/8" long arbor; saw head with automatic electro-mechanical motor brake. -- 20" Max. blade dia.; 7" max. cutting depth @ 90°; 3-1/2" @ 45°; 62" long x 1", 4" & 6" thick max. crosscut cap. -- Complete with: -- 36" x 60" MDF table; heavy gauge steel base & legs for solid support. -- Includes: -- Upper & lower blade guards; magnetic starter and overload protection. -- Single-phase option available for;...$ 250.

ORIGINAL 3691-01-7 Overhead Rail Panel SawSpecifications: -- Sturdy welded steel frame for saw head and beam arm; 7.5 HP motor; 1" dia. arbor; 1-3/8" long arbor; saw head with automatic electro-mechanical motor brake. -- 20-1/2" Max. blade dia.; 8" max. cutting depth @ 90°; 4" @ 45°; 60" long x 1" max. crosscut cap. -- Complete with: -- 36" x 60" MDF table; heavy gauge steel base & legs for solid support. -- Includes: -- Upper & lower blade guards; magnetic starter and overload protection.

$9,810

ORTON - TYPE F, ...Ship Shaper/RouterORTON Type "F" Ship Shaper/Router with: 40" x 60" Table Size. -- 5 HP - 230 Volt, 3-Phase. -- Oil Mist Lubrication. -- Machine "Completely Restored". -- Can be used as a Shaper or Router. -- Comes with: Mandrel with Top Bearing Attachment so the machine can be used as a Tilting Spindle Shaper. -- Also used as a Tilting Spindle Router with: Collet Chuck attachment with: 1" HSS spiral cutter and template guide. -- Heavy-Duty spindle with: BROWN & SHARPE "#11 Tapered Socket" in Spindle. -- Spindle tilts: 30° forward and 45° backward. -- Includes: BROOKS Frequency changer to increase 60-Cycles to 250-Cycles to increase speed of routers to 4,700 RPM. -- Great for cutting changing bevels. -- Approx. weight 3,000 Lbs. -- Lamp & cord NOT included. 5 HP - 230 Volts, 3-phase; in "Excellent Condition." Routers come with: 4 Ft x 14 ft table for clamping down work with patterns.

Call for Price

OSAMA SP/RSI-1600 1600 mm (63") Top & Bottom Brush Panel CleanerSpecifications: -- Min. panel length 430 mm (16.93"), Panel thickness 0 - 100 mm (3.94"). -- Feed speed 22 MPM (72 FPM).Equipped with: -- 290 mm (11.42") Dia. Top & bottom brush rolls, with 0.6 mm (0.02") Dia. Black nylon bristles.Available at additional cost: -- Spare pair of brushes.NOTE: This machine is also being offered for sale as a part of a Feed Through White Glue Laminating Line (EXF #LA-011187).

Call for Price

OSAMA S2R-1600 1600 mm (63") Top & Bottom Glue SpreaderSpecifications: -- Panel thickness 0 - 100 mm (3.94"). -- Pass line height 800 mm (31.50"). -- Feed speed 18 MPM (59 FPM).Equipped with: -- 185 mm (7.28") Dia. x 64" L Grooved anti-acid rubber-covered top & bottom applicator rolls, each with Manual brush washer, Side glue wipers. -- 21-3/4"; x 72"; x 2-3/4"; D Removable stainless steel bottom pan. -- Front & rear safety fences.NOTE: This machine is also being offered for sale as a part of a Feed Through White Glue Laminating Line (EXF #LA-011187).

Complete OSAMA Feed Through White Glue Laminating Line, with MIDWEST AUTOMATION Laminate Indexing/Lay-up Table & HMT Laminator Specifications: Line was designed to use the HMT Laminator as a pinch roller with heaters for large quantity runs. The HMT Laminator was used as a stand-alone machine for small quantity runs. Max. panel size 60" x 120" (Based on current outfeed scissor lift platform size. With a 60" x 144" or larger scissor lift, 144" L panels could be run.) Consisting of the following machines as late as 2016: AREDON 48" x 96" Electric/Hydraulic Scissor Lift Platform. 2007 OSAMA SP/RSI-1600 1600 mm (63") Top & Bottom Brush Panel Cleaner, S/N 8103, Min. panel length 430 mm (16.93"), Panel thickness 0 - 100 mm (3.94"), Feed speed 22 MPM (72 FPM), with 290 mm (11.42") Dia. Top & bottom brush rolls with 0.6 mm (0.02") Dia. Black nylon bristles, Spare pair of brushes, 460 V, 60 Cy, 3 Ph., Dimensions 108" X 36" X 70" H, Weight 1,100 Lbs. 2006 OSAMA S2R-1600 1600 mm (63") Top & Bottom Glue Spreader, S/N 20944, Panel thickness 0 - 100 mm (3.94"), Pass line height 800 mm (31.50"), Feed speed 18 MPM (59 FPM), with 185 mm (7.28") Dia. x 64" L Grooved anti-acid rubber-covered top & bottom applicator rolls, each with Manual brush washer, Side glue wipers, Removeable bottom pan, Front & rear safety fences, 230 V, 60 Cy, 3 Ph., Dimensions 90" x 30" x 60" H, Weight 1,500 Lbs. MIDWEST AUTOMATION LT 500 60” x 144” Laminate Indexing/Lay-up Table. 2016 HMT ADVANTAGE PLUS 61" Laminator, S/N 5A391, with 10.5 kW Heatbank, 208 V, 60 Cy, 1 Ph., Dimensions 120" x 83" x 55" H, Weight 1,400 Lbs., NOTE: This machine is also being offered for sale separately (EXF #LA-011186). SOUTHWORTH 5,000 Lb. Capacity 60” x 120” Electric/Hydraulic Scissor Lift Platform, with Gravity roller conveyor top. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

OSI SM-450 Side Matcher LineSide Matcher:FEATURES -- Directly opposing heads (Side-Matcher): Enhances width tolerance and eliminates pistol grip -- Guarantee machining accuracy of +/- 0.002"; (0.05 mm) on width and on tongue/groove position -- Through feed system in both machines: work boards as short as 9"; (229 mm) out of the defecting station; can be processed directly into the Side-Matcher -- Process twisted, crooked and bowed boards -- Hydro-lock collars on all axis -- Feed wheels on independent suspension -- Very low friction -- High precision spindle -- Very short setup time Easy and quick width adjustment -- Easy opening for tool replacement -- Hydraulic unjammingSpecifications: -- Pre-Milling top and bottom with (2) 15 HP motor -- Feed speed 200 to 450 FPM -- Board width 1 1/2" to 8" -- Board thickness: 1/2" to 1 1/2" -- Board length: minimum of 9" trough feed -- Tooling: (2) X 8", RPM 6,000 -- Spindle drive: (2) X 30 HP -- Feed wheels: (2) rows of (4) wheels on top driven by (2) 3 HP motors -- Feed rolls: (3) chromed rolls on bottom driven by (3) 2 HP motor -- Axis movement: on linear bearings

Call for Price

OSI GA 220 High Speed 6 heads Moulder6 Head, 9" X 4-3/4" cap.Bottom,Top,Side,Side,TopHead sequence: -- bottom, 7.5 HP, right 7.5 HP, left 7.5 HP, top 10 HP, top 10 HP, bottom 10 HP. Top/bottom spindles 50 mm diameter, Side spindle 40 mm diameter at 6,000 RPM, -- Hydraulic variable feed speed up to 300 FPM. Hydraulic drive unit with 30 HP drive motor Complete with: -- Digital read out on spindle adjustments, motorized feed beam, automatic bed lubrication, -- Pneumatic hold downs, -- ISO long infeed table, -- Large assortment of cutter heads, -- ISO PLC Control system with Motor starter, Amp meter and report displayNote: Machine still under power until December 06 2025

OverBuilt - Baler/Logger: "NEW" in 2023OverBuilt Baler/Loggers are: The fastest, most efficient Baler/Loggers any scrap recycler can own.Compressing scrap metal & vehicles into denser, stackable forms results in more efficient loading &transport. Approx (4,000) hours.Specifications -- Charge box open: 20’ x 8’-5";. -- Closed: 240"; L x 40"; W x 26"; H. -- Bale Size: 40"; x 26"; x Variable. -- Min. variable distance: 22";. -- Bale density: 25 - 80 Lbs/CF. -- Main compression cylinders: 2. -- Logging force (per side): 175 Tons. -- Charge box door cylinders: 6. -- Baling force (per door): 255 Tons.

OverBuilt - Baler/Logger.OverBuilt Baler/Loggers are: The fastest, most efficient Baler/Loggers any scrap recycler can own. Machine does not have boom. Compressing scrap metal & vehicles into denser, stackable forms results in more efficient loading &transport. - Approx (1,500) hours.Specifications -- Charge box open: 20’ x 8’-5";. -- Closed: 240"; L x 40"; W x 26"; H. -- Bale Size: 40"; x 26"; x Variable. -- Min. variable distance: 22";. -- Bale density: 25 - 80 Lbs/CF. -- Main compression cylinders: 2. -- Logging force (per side): 175 Tons. -- Charge box door cylinders: 6. -- Baling force (per door): 255 Tons.

OverBuilt - Baler/LoggerOverBuilt Baler/Loggers are: The fastest, most efficient Baler/Loggers any scrap recycler can own.Compressing scrap metal & vehicles into denser, stackable forms results in more efficient loading &transport. Approx (5,500) hours.Specifications -- Charge box open: 20’ x 8’-5";. -- Closed: 240"; L x 40"; W x 26"; H. -- Bale Size: 40"; x 26"; x Variable. -- Min. variable distance: 22";. -- Bale density: 25 - 80 Lbs/ft³. -- Main compression cylinders: 2. -- Logging force (per side): 175 Tons. -- Charge box door cylinders: 6. -- Baling force (per door): 255 Tons.

$10,980

PANHANS - 436, ...24'' Single Surface Planer -- Specifications24.8" (630 mm) Width x 1/8" to 10" opening; 10 HP Motor; 4-knife - 4-3/4" dia. cutterhead belt driven @ 5,000 RPM; max. cutting depth: 5/16". -- 1 HP Feed motor with: (2) Feed speeds: 22 - 44 FPM. Segmented rubber-covered infeed and outfeed rollers, sectional chip breaker, motorized raise-and-lower of bed w/LED readout, table size 43" x 21". -- Options Include: (16) Cutter knives: Power lift up & down. -- Complete with: Emergency stop;, magnetic starter w/overload protection; knife setting gauge: & 5-1/2" dia. dust hood; includes: Operations manual; parts list; tool kit.

Call for Price

PAUL K34V/1000 RIP SYSTEM WITH (1) SHIFTING BLADE39.3" (1000 mm) max. cutting width x 4.1" (105 mm) max. thickness cap. -- Specifications: Bottom arbor design; (6) powered bottom and (6) powered top feed rolls propel lumber from the infeed system thru the Ripsaw.50 HP (37 kW) Main motor, 2,900 RPM driving a 2.362" (60 mm) dia. arbor with (1) moveable blade. Moveable saw has a shift-able range of 400mm.Moveable blade and fixed fence positions indicated by 15mw laser lights that project 16' lines down inbound boards. Arbor is removable on a slide system; -- Feed Works: 49 - 262 FPM (15 - 80 MPM) Variable feed speed feed drive; hydraulic drive to (3) sets of smooth top and corrugated bottom feed rolls before and (3) sets of smooth top and corrugated bottom feed rolls after the blades and individually controlled pressure to the feed rollers. With (3) sets of anti-kickback fingers. -- Equipped with: Automatic oiler, push-button station, upper dust hood and upper and lower dust chutes. In-feed roller table 980 mm with (7) rollers; universal type mounted to the machine. -- Operator Interface: 1 NCD control, VGA color monitor, features 10-width lists with 200 items (8 variable-width lists, 2 set-up lists for long bush fitted for fixed blades.) -- Machine is under power but not in production.