704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1859 Results Found

704-841-2001

Call for Price

EMC FLEXY 1350 2RP Finishing Sander with (2) Sanding Heads, Roller and Segmented Finishing PadUseful working width 1,350 mm (53"). Working thickness min./max. 3 - 180 mm (1/8" - 7-1/16"). Head configuration:1st Head: Roller "R" Belt dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 250 mm (10"). -- Roller rubber hardness 85 Shore. Constant control to any position with accuracy 0.02 mm. -- Electronic motorized roller pressure adjustment "grit-set system". -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (15 HP). Automatic star-delta starter. -- Abrasive belt cutting speed: 18 m/Sec (59 FPS). Oscillating abrasive belt blower for the roller unit.2nd Head: Segmented Finishing Pad "P" Electronic PAD segmented in (50) sections. -- Belt dimensions: 2.620 x 1.370 mm (103" x 54"). -- Width of the segmented element (section): 27.0 mm (1-1/16"). -- Rotation: Against feed (clockwise). -- Timed oscillating abrasive belt blower. -- Motor power: 11 kW (15 HP) with electronic inverter variable abrasive belt speed 3 to 18 m/Sec (9.8 - 59 FPS).Feed system:Constant pass line, 900 mm (35.4") from floor ● Vacuum conveyor bed, 4 kW Vacuum unit for holddown of smaller parts, mounted inside of the machine base. ● Idle table rollers support in infeed and outfeed. ● Rubber covered presser rollers, grooved. ● Variable feed belt speed, adjustable from 3 to 18 m/Min (9.8 - 59 FPM) Inverter Controlled. ● Large diameter screws on machined guides with columns and pistons. ● Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized "grit set" system; control from touch screen for each working group (head).Electronic programmable color TOUCH SCREEN display, 10" wide ● PLC with micro-processor of latest generation, modular and expandable ● Connection USB, RS232, Ethernet 10/100/1000 ● Memory capacity: 100 working programs or more ● Graphic synoptic to facilitate programmingSoftware facilities: -- Automatic motor sequence starting. -- Display report and reset of alarms (self diagnostic) with memory records. -- Command, programming and display for:● all electronic pad functions● thickness● feeding● all inverters and for selected groups (heads).● blowers, including compressed air saving function.Centralized Control Cabinet: IP 54 protection against dust & moisture. Analog ammeter on main control cabinet. Table lifting-lowering thickness system electrically controlled. AUTOMATIC Delta - Star starter on abrasive belt motors. Centralized Independent Pneumatic Control Cabinet: IP 54 protection. Pneumatic air filter with automatic water-drain system. Pneumatic adjustment for "Grit set system". Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI) Options Available: Tampico Brush natural fiber brush for cleaning of

Call for Price

EMC VENUS 1300 1K ... Finishing Sander with (1) Sanding Head: Combination Head.Useful working width 1,300 mm (51"). Working thickness min/max mm 3 - 170 (1/8" - 6-5/8").Working Unit: Combination Roller & Pad. -- Roller diameter 142 mm (5-5/8"). Rubber covered hardness 85 Shore. Roller pressure adjustment control & "Grit-set system". Main Motor On Off Selector control with pneumatic piston to select roller, 22 kW (30 HP) Automatic star-delta starter Rotating cutting speed: 18 m/Sec (59 FPS). -- PNEUMATIC Controlled Flexible Sanding Pad Including On-Off Selector: Quick Change System: Removable pad with felt, rubber and graphite. Rotating cutting speed 18 m/Sec (55.8 FPS). Abrasive belts oscillation by means of electronic photocell sensor.Feed system:CONSTANT PASS LINE - fixed infeed height 900 mm (35") from floorIdle table rollers support in infeed and outfeedRubber covered presser rollers, groovedVariable feed belt speed, adjustable from 3 to 19 m/Min (9.8 - 62 FPM). Inverter ControlledLarge diameter screws on machined guides with columns and pistonsAutomatic feed belt centering deviceElectronic digital display for working thicknessGeneral Machine Features: -- Analog ammeters on main control cabinet. -- Electronic motorized grit set system, control from touch screen.Electronical Panel: -- Check Control Self Diagnostics with Alarm Control. -- Analog Ammeter on the main control cabinet. -- Infeed table thickness system electrically controlled. -- Independent Overload protection.Safety: -- Infeed front emergency swinging bar for oversized panels. -- Infeed protection pressing blade to avoid pieces to go back to operator. -- Rear and front emergency push buttons. -- Automatic brake on abrasive belts motors. -- Automatic emergency stop and alarm display in case of: ● Low Air Pressure. ● Doors opened ("easy maintenance and inspection"). ● Electric motors overloading. ● Emergency detector for over thickness material cut. ● No tension on abrasive belt. ● Abrasive belt lateral mistracking. ● Abrasive belt broken.Idle table rollers support in infeed and outfeedCentralized Control Cabinet: ● IP 54 protection against dust & moisture. ● Analog ammeter on main control cabinet. ● Table lifting-lowering thickness system electrically controlled. ● AUTOMATIC Delta - Star starter on abrasive belts motors. Centralized independent pneumatic control cabinet: ● IP 54 protection against dust & moisture. ● Pneumatic air filter with automatic water-drain system. ● Pneumatic adjustment for "Grit set system". ● Pneumatic plant working without lubrication. ● Compressed air pressure 6 bar (85 PSI). Options Available: Tampico Brush natural fiber brush for cleaning of the pieces, diameter 150 mm (6"). Motor Power 1.1 kW (1.5 HP). $3,950

EMC EXPLORER 1100 2RK ... Wide Belt Sander with (2) Sanding Heads; Roller and Combination head roller/pad.Versatile, medium duty machine, ideal for cabinet shops etc.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 1,900 mm (75") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Head configuration:1st Head: Steel Contact Roller -- Roller diameter 142 mm (6") -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. -- Motor power 11 kW (15 HP). -- Automatic Star-delta starter. -- Speed rotation: 18 m/Sec (59 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (6"). -- Rubber covered roller with hardness 45 Shore. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. Flexible sanding pad. Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 17 m/Sec (55.8 FPS). --Driven by same main motor.Abrasive belts oscillation by means of electronic photocell sensor.Feed System: -- Working thickness min./max. mm 3 - 190 (1/8" - 7-1/2"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt, machined. Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Centralized Control Cabinet: -- Control panel with self-diagnostics alarm control unit. -- Analog load meters on main control cabinet. -- Table lifting-lowering thickness system, electrically controlled. -- AUTOMATIC Delta - Star starter on main motor and IP 54 protection against dust & moisture. Centralized Independent Pneumatic Control Cabinet: -- Pneumatic air filter with automatic water-drain system. -- Pneumatic adjustment for "Grit set system". --Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). IP 54 protection against dust & moisture. Safety Features: -- Anti-kickback infeed protection. -- Oversized parts infeed protection by swinging bar. -- Emergency push buttons front & rear. --Automatic brakes on main motor. -- Automatic emergency stop and alarm displayOption: TAMPICO Cleaning Brush, 150 mm (6") diameter. Please add ...$3,400USA UL or Canada CSA Safety Features

Call for Price

EMC GIANT 1350 3WRF Abrasive Planer with (3) Heads, Planer Head, Roller and Superfinishing PadTop of the line Heavy Duty Abrasive Planer from EMC. The series of GIANT machines are available in many configurations. Abrasive Planer has a helicoidal head with insert tooling.Useful working width 1,350 mm (53"). Working thickness min/max mm 3 - 170 (1/8" - 6-5/8"). Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 180 mm (7-1/16"). -- Shaft for helicoidal position knives with (512) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 24 independent segments. -- Anti kickback protection made of 72 independent elements. -- On-Off pneumatic cylinder for planer group in working position. Working pressure adjustment. -- Motor power 30 kW (40 HP), Star-delta starter.Speed rotation: 35 m/Sec (115 FPS).2nd Head: Roller "R" Belts dimensions: 3,250 x 1,370 mm (128" x 54"). -- Roller diameter: 250 mm (9-13/16"). -- Roller rubber hardness 60-65 Shore. Constant control to any position with accuracy 0.02 mm. -- On-Off pneumatic piston, controlled from the electrical panel. -- "Grit-set system". -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (30 HP) Automatic star-delta starter. Rotating cutting speed: 21 m/Sec (99 FPS). Blower for the roller unit.3rd Head: SUPERFINISHING PAD "F" Electronic PAD segmented in (75) sections. -- Belts dimensions: 3,250 x 1.370 mm (127-15/16" x 54"). -- Width of a single element (section): 18 mm (11/16"). -- APC - Automatic Programmable Control and setting of the air pressure. -- Electronic motorized roller pressure adjustment "grit-set system". -- Rotation: Against feed (clockwise). -- Timed oscillating abrasive belt "air jets" cleaning. -- Motor power: 18,5 kW (25 HP) with electronic inverter variable abrasive belt speed 3 to 18 m/Sec (9.8 - 59 FPS).Feed system: -- Constant pass line, 900 mm (35.4") from floor (In line machine). -- Vacuum bed, 4 kW (5,5 HP) for hold down of smaller parts, mounted inside of the machine base. -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 20 m/Min (9.8 - 65.6 FPM). Inverter Controlled. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each working group.Electronic programmable color TOUCH SCREEN display, 7" widePLC with micro-processor of latest generation, modular and expandableConnection USB, RS232, Ethernet 10/100/1000Memory capacity: 100 working programs or moreGraphic synoptic to facilitate programmingSoftware facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, program

Call for Price

EMC EXPLORER 1100 SUPER WK Abrasive Planer / Wide Belt Sander with (2) Sanding Heads; Planer Head, Combination head roller/pad.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 2,200 mm (86.6") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 63 FPM). Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 142 mm (5-9/16"). -- Shaft for helicoidal position knives with (316) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 20 independent segments. -- Anti kickback protection made of 60 independent elements. -- On-Off pneumatic cylinder for planer group in working position. -- Working pressure adjustment. -- Motor power 15 kW (20 HP). -- Automatic Star-delta starter. -- Speed rotation: 30 m/Sec (97.5 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (5-9/16"). Rubber covered hardness 45 Shore. Automatic abrasive belt grit compensation with "Grit-Set System". On Off Selector control for 2° roller incl. pneumatic piston -- Pneumatic elastic pad high resistance with quick changing system; extractable felt, rubber & graphite. . Complete with On-Off Selector and Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 18 m/Sec (59.1 FPS). -- Motor power 15 kW (20 HP). Belt blowers, oscillating, for cleaning of abrasive belt. Abrasive belts oscillation by means of electronic photocell sensor. -- Cleaning Brush: -- Tampico brushing unit for panel cleaning, at outfeed, 150 mm diameterFeed system: -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt machined. -- Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). -- Idle table rollers support in infeed and outfeed.Centralized Control Cabinet: Analog ammeters on main control cabinet. Table lifting-lowering thickness system electrically controlled. AUTOMATIC Delta - Star starter on main motors and IP 54 protection against dust & moisture. Centralized independent pneumatic control cabinet: Pneumatic air filter with automatic water-drain system. Pneumatic adjustment for "Grit set system". Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). Features: -- Control panel with self-diagnostics alarm control unit. -- Telemetry computer remote diagnostics control. Direct connection with EMC via internet for assistance.USA UL or Canada CSA Safety Features

GRIZZLY G4185 BORING (HORIZONTAL) ---Price Negotiable---Make an Offer!--- 3-Spindle Horizontal Boring Machine, Will Accept 2-Spindle Boring Head - Maximum stock width 7-1/2” - Table size 9-3/4” x 15-3/4”, Maximum table height 35”, Table height adjustment 3-1/2” - Maximum bit capacity 9/16” (Right-hand threaded), Spindle travel adjustment 3”, Spindle speed 4,000 RPM, Maximum speed 12 SPM at 90 PSI - Hold-down force 600 Lbs. - 2 HP 3,450 RPM TEFC Direct drive motor - Pneumatic spindle travel - 2-1/4” Pneumatic hold-down - Pneumatic foot pedal control - Steel stand - Includes: GRIZZLY "G5953/3C-W20" 3-Spindle Boring Head, Maximum bit capacity 15 mm (0.59"), Bit threads 7/16 - 14 TPI Right-hand, Spindle speed 4,000 RPM

$1,800

15" Width cap. with 1/4" - 8" thickness opening, 1/16" max. depth of cut; 3 HP single-phase motor belt drives 3-knife, 3-15/64" dia. cutterhead at 5,000 RPM; head with high speed steel knives, max. thickness 8", min. 3/16"; dual feed speed of either 16 or 30 FPM; 16" x 42" cast iron table, table extentions on infeed/outfeed. Complete with: Magnetic controls, 2" dia. metal infeed & outfeed rollers, open fabricated steel base, and large hand wheel for cutterhead assembly adjustment.

GRIZZLY G4185 2-Spindle Horizontal Boring Machine, Will Accept 3-Spindle Boring HeadSpecifications: -- Max. stock width 7-1/2";. -- Table size 9-3/4"; x 15-3/4";, Max. table height 35";, Table height adjustment 3-1/2";. -- Max. bit cap. 9/16"; (Right-hand threaded), Spindle travel adjustment 3";, Spindle speed 4,000 RPM, Max. speed 12 SPM at 90 PSI. -- Hold-down force 600 Lbs.Equipped with: -- 2 HP 3,450 RPM TEFC Direct drive motor. -- Pneumatic spindle travel. -- 2-1/4"; Pneumatic hold-down. -- Pneumatic foot pedal control. -- Steel stand.Complete with: -- GRIZZLY "G5952"; 2C-W19"; 2-Spindle Boring Head, Max. bit cap. 5/8";, Bit threads 7/16 - 14 TPI Right-hand, Spindle speed 4,000 RPM.

GS - HEAVY-DUTY 34 KVA, ...Transformer.SCR Drive Transformer. -- Cat # DT631H34S. -- High voltage 575 Volts Delta; Low voltage 230 Y/133.

GUIDETTI - WIRE 415, ...Copper & Wire Chopper with Pre-Shredder -- Currently Disassembled.Specifications: -- Feed size of material; 1,310 x 2,140 mm. -- Load pusher stroke: 600 mm. -- Rotor diameter: 220 mm. -- Rotor rotation speed: 82 RPM. -- Hydraulic power: 0.75 kW. -- Grid hole diameter: 40 mm. -- Rotating blades: 23 + 4 External. -- Low hours; 2,300 Hrs.GUIDETTI Pre-Shredder New in 2012. -- Model: PM6N 600/200 -- Low hours: 1,700 -- Loaded onto your truck.

Call for Price

HAAS - 2000XL 2.0, ...Mobile ShredderLow Hours; 2018 YMFG.Specifications & Features: -- Can be used at any location (comfortable transport measurements). -- Easy & quick positioning thanks to crawler track and radio remote control. -- Shreds different materials with just (1) tool configuration. -- High throughput capacity of up to 100 tons/Hr. -- Resistant against foreign bodies. -- Low wear cost and long lifetime. -- Service and maintenance friendly. -- No wrappings; self-cleaning. -- Quiet main drive.

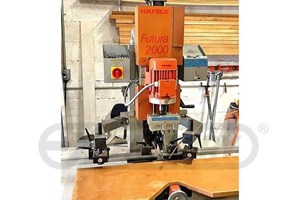

Rafix Hinge Boring & Inserting Machine with 1.5 HP motor.Specifications: -- High-quality air cylinder (80 mm bore with 650 ft lbs of pressure @ 90 PSI) rated for 3.5 million 3" strokes. A skilled operator can bore and insert in 3 to 4 seconds. -- Features: Two types of boring depth adjustment: drawbar style for quick and easy adjustment and a solid stop adjustment for the changing of door thickness applications. This allows for changing of the door thickness and still bore the same depth without adjustment! -- Fixed table with adjustable back rail to control the tab location. -- Enclosed cutting area for better chip removal with blow-off nozzle to assist in chip evacuation and adjustable 2" and 4" vacuum hook-up. -- Pneumatic drilling unit with push button control. -- Includes: adjustable cutting speed control, indicator light, reset thermal circuit breaker, emergency stop button, drill and insert buttons (two hand activation for operator safety), rotary switch for pair of pneumatic hold down clamps, 600 mm ruler and (4) flip stops.

$2,990

HALSTY 136 WIDE BELT SANDER1-Head Sander with 36" width cap. and 6" thickness cap. -- Combination sanding head with 5-1/4" dia. contact roll, 2-1/2" wide polishing platen; 20 HP 3-Ph motor. 37" x 75" Abrasive belt, electronic tracking. -- Variable feed drive for conveyor belt with speeds of 0 - 18 FPM, 2" dia. infeed & outfeed rubber covered holddown rolls. -- 0" - 6" Thickness cap. with motorized adjustment via (4) 1" Acme thread jackscrews.

HAMMER 2080FFS Loose Pack Line with Bag SealerFeatures: -- Perfect for Free Flowing Material -- Uses V- Plastic Film -- Capacity of up to (25) Bags Per Minute -- Scale Design (no scale)Application: An advanced, reliable system, the Model 2080 forms bags from economical centerfold roll stock film, then fills and seals them accurately at rates up to 30 bags per minute. Vent holes are punched to varying sizes and pattern specifications. Conveyor easily adjusts to accommodate different bag sizes. Microprocessor-controlled operation ensures reliability and consistent performance. Corrosion restraint, heavy-duty construction for ease of cleaning, and long-lasting service.It was running wood pellets previously so no major corrosion issues. The operating manual is included and there are some spare parts including belts, pulley motor etcIt was running wood pellets previously so no major corrosion issues.

HARMONY T60-XDRC Vertical BalerSpecifications: -- Motor: 20 HP -- Large 10" Cylinder with Twin Torque Tubes -- Bale Size: 30" x 60" x 48" -- Feed Opening: 25" x 60" -- Ram Force: 235,620 LbsEquipped with: -- Conveyor Over the Back: 48" -- Loaded on your Truck!

Call for Price

(4) HARMONY - M60-CB, ...Vertical Balers with (1) PTR 3400-HD. ...Vertical BalerLot of (5) Vertical Balers; with free loading onto your truck.Specifications:Cylinder: 6"Power unit: 10 HP

(8) HARMONY - M60-CB, ...Vertical BalersLot of (8) Balers: Loaded on your truck!Specifications: -- Bale size: 60" x 30" x 48" -- Cylinder: 6" x 48" -- Motor: 5 HP -- Hi/Lo Power Unit

HARRIS HRB-8/NF Two-Ram Horizontal Baler with ConveyorSpecifications: -- Cylinder: 12" -- Main motor: 100 HP -- Ejection cylinder: 8" -- Bale size: 45";W x 31";H x 64";L -- Charge box opening: 57";W x 110";L -- Hopper Opening: 74";W x 132";L -- In-feed belt conveyor width: 72"Equipped with: -- Upgraded PLC (Allen Bradley) with optical sensors -- Wide Steel Belt in-feed conveyor 72" wide

HARRIS PIRANHA Full Closed Door Horizontal BalerSpecifications: -- Cylinder: 10" -- Main motor: 20 HP -- Feed opening: 56" x 36"Equipped with: -- Full Pen

HARRIS HLO-608-AR30 Auto-Tie Horizontal BalerSpecifications: -- Cylinder: 8" -- Feed opening: 60" x 45" -- Main motor: 30 HP -- Bale size: 48" x 40" x VariableEquipped with: -- Auto-Tie system -- Automatic cycle