704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1859 Results Found

704-841-2001

Call for Price

DUST-EX HSAG-24 Packaged Safety Solution for a 23"x23" (24" dia. round equivalent. Suitable for up to 25" dia. ) Return Air Rated for max 12,850 CFM @ 3,500 FPM.. System for mitigating fire and explosions in combustible dust environments, for the woodworking industries. Generally includes Heavy Duty Abort Gate, Non -Return Valve and Spark Detection/Suppression Hardware and Controls as follows: -- 1.) VigiFlap Dust Sensor, Dirty Air 22": Sensor, dust level, adjustable capacitive for organic dust, requires intrinsic safety system (will not trigger combustion or ignition in gasses or fuels). -- 2.) VigiFlap Explosion Isolation Flap (Non-Return) Valve, EV-VF22 (EPDM); 22" diameter, flanged inlet and outlet, locking mechanism; welded steel construction, safety red painted finish, domed flap (stainless steel), inspection/access door, EPDM gasket, grounding straps, inductive shutdown sensor, normally open or closed flap orientation, certified ATEX EN 16447, NFPA 69 compliant. -- 3,) Control Panel, Intrinsically Safe, CP05 - single zone, allows for installation of (1) inlet and (1) outlet explosion isolation valve(s), (3) monitored inputs per zone (two programmable), (1) intrinsic circuit with barrier and physical separation (one per zone), outputs for system shut down and monitoring, NEMA 4 enclosure, 120 VAC or 24 VDC. -- 4,) SPARK DETECTION & EXTINGUISHING, SINGLE ZONE, KIT for pipe sizes 20?- 40? diameters; includes Raptor Spark RS-CUSP1L Control Panel, (2) Spark Detectors, Extinguishing Kit, Flexible hoses, Audible Alarm & Warning Light. Single zone spark detection and extinguishing kit for duct sizes of ?20" - 40" diameter, RS-KIT02, includes Raptor Spark RS-CUSP1L control panel, (1) RS-PDK-02 packaged detector kit with (2) spark detectors with mounting kits, (1) RS-PWE02 water extinguishing assembly with hose connections and spray nozzles, audible alarm, warning light, battery back up - ATEX certified, CE listed, FM approved. -- 5.) Packaged External Test Lamp Kit, RS-TLK02, duct sizes: 6" - 39" diameter, (2) RS-SD02 test lamps with (2) RS-MK02SD/TL mounting kits - IP 65 enclosure, ATEX certified, CE listed, FM approved. -- 6.) Optional Start up Service Assistance: a.) Start Up - Day Rate @ $1,750/day. b.) Travel Service: Day Rate @ $900/day. c.) Travel Expenses: Total $110/hr. - min. two hrs. required - total $220. c.) Start Up Service Hourly Rate is $160/hr. Min. (4) hrs. needed for a total $640. -- 7.) Heavy Duty High Speed Abort Gate, RGAG-23, magnetic , 23" x 23" flanged inlet and outlet (24" round equivalent), suitable for 21" - 25" dia., control panel for, magnet power with status lights and manual test button, gate position verification monitoring, manual reset lever, weather hood with bird screen. Maximum volume and velocity: 12,850 CFM @ 3,500 FPM, clean air installations only, NFPA compliant when installed with listed spark detection system. -- 8.) Packaged dust probe (broken bag detector) RS-PDP03, RS-MK02DP, etc. IP 65 encl

$475,000

EARTH CARE PRODUCTS, INC. 10½ Ft. x 32 Ft. Triple-pass Rotary Drum Dryer System with Gas Burner;Complete with the following major components: -- 10.5 Ft. x 32 Ft. (despite the model DB-1030) Triple-pass Insulated drum. -- Trunion Bases, and 30 HP Drum Drive. -- High efficiency Cyclone, Cyclone outlet Airlock. -- 100 HP Dryer Main Fan, and Ducting. -- 25 MM BTU Gas Burner complete with Refractory Lined Furnace and Gas Train. Notes: ● The Trunion Tracks and Trunion Wheels are in good condition as is the drum interior. The system was renovated in 2015 and not used much after the work was done. ● The equipment is still in-place.

$5,750

FRAVOL VSR TOP & BOTTOM TRIMMERSpecifications: -- Edgebanding thickness 0.4 mm to 3 mm, 16 mm (0.62") to 60 mm (2.36") panel thickness capacity. The rough trimming function uses vertical copy pads and one disc copier between the two cutters in a horizontal position, allowing 0.4 mm to 3mm radius edge rough trimming without replacing the cutters. Panel working height (thickness) is from 16 mm to 60 mm.Equipped with & Features: -- Two 12,000 RPM motors complete with braze welded hard metal cutters Ø 50x16- Z6. Your choice of profiles R1; R2; R3; 5°; 30°. -- The machine comes with a new, patented worktable that provides smooth panel sliding and extremely flexible edging without using jigs. -- Sliding on nylon blocks allows perfect cleaning of the panel melamine surfaces.

FRUILMAC RANDOMAT E - End Matcher; --For End Matching flooring or cabinet & entry door rails; the feed-thru system allows continuous feeding of random length parts with any kind of profile.Capacity & Description: -- Width cap. 1-3/16" x 9-7/8'; length cap. 6-5/16" x 137" length (longer lengths with additional support); 3/8" min. - 1-3/16" max. thickness cap. --÷ Approx. (10) cycles/Min depending on part length & width; -- Feed system with (2) 120" long x 10" wide powered infeed & outfeed belt conveyors, parts are automatically fed & positioned with sensors. -- Positive stop to the 1st vertical shaper head (a 2nd shaper head is next to the 1st one); cope cycle is automatic. -- Parts are conveyed past the 1st & 2nd shaper head, automatically reversed and positioned to a positive stop for the 2nd cut on the other end of the part. At the same time the 1st shaper head would be coping the 1st end of another part.Equipped with: --÷ Twin 7.5 HP - 7,500 RPM high-speed shaper motors which pneumatically traverse in tandem for each cutting cycle. --÷ Cutting station with overhead hold-down wheels and 4-point pneumatic clamping with (2) overhead & (2) horizontal clamps. --Controller & Operator Interface: Key Pad SIEMENS Controller, PLC controlled conveyor & shaper cut cycle for automatic operation, variable feed speed conveyor line, and shaper head advance with LED readout on the controls. --Includes Infeed and Outfeed Conveyors

FRUILMAC - RANDOMAT- E, ...End Matcher.For End Matching flooring or cabinet & entry door rails; the feed-thru system allows continuous feeding of random length parts with any kind of profile.Capacity & Description: -- Width cap. 1-3/16" x 9-7/8"; 6-5/16" x 137" length cap. (longer lengths with additional support); 3/8" min. - 1-3/16" max. thickness cap. -- Approx. (10) cycles/Min depending on part length & width. -- Feed system with: (2) 120" Long x 10" wide powered infeed & outfeed belt conveyors; parts are automatically fed & positioned with sensors. -- Positive stop to the 1st vertical shaper head (a 2nd shaper head is next to the 1st one); cope cycle is automatic. -- Parts are conveyed past the 1st & 2nd shaper head, automatically reversed and positioned to a positive stop for the 2nd cut on the other end of the part. - At the same time, the 1st shaper head is coping the 1st end of another part.Equipped with: -- Twin 7.5 HP - 7,500 RPM high-speed shaper motors, which pneumatically traverse in tandem for each cutting cycle. -- Cutting station with overhead holddown wheels and 4-point pneumatic clamping with (2) overhead & (2) horizontal clamps.Controller & Operator Interface: -- Keypad SIEMENS Controller, PLC controlled conveyor & shaper cut cycle for automatic operation; variable feed speed conveyor line and shaper head advance with LED readout on the controls.Includes Infeed Conveyors.

FRUILMAC RANDOMAT-E End Matcher;For end-matching flooring or cabinet & entry door rails; the feed-thru system allows continuous feeding of random-length parts with any kind of profile.Specifications: -- Width cap. of 1-3/16" to 9-7/8"; length cap. of 6-5/16" x 137" length (longer lengths with additional support); 3/8" min. - 1-3/16" max. thickness capacity. -- Approx. (10) cycles/Min depending on part length & width; -- Feed system with (2) 120" long x 10" wide powered infeed & outfeed belt conveyors, parts are automatically fed & positioned with sensors, and a positive stop to the 1st vertical shaper head (a 2nd shaper head is next to the 1st one); cope cycle is automatic. -- Parts are conveyed past the 1st & 2nd shaper head, automatically reversed, and positioned to a positive stop for the 2nd cut on the other end of the part. At the same time, the 1st shaper head would be coping the 1st end of another part.Equipped with: -- Twin 7.5 HP - 7,500 RPM high-speed shaper motors, which pneumatically traverse in tandem for each cutting cycle. -- Touch-screen SIEMENS Controller, PLC controlled conveyor & shaper cut cycle for automatic operation. -- Variable feed speed conveyor line; shaper head advance with led readout on the controls. -- Cutting station with overhead holddown wheels and 4-point pneumatic clamping with (2) overhead & (2) horizontal clamps.Includes:(4) set of used tooling

FRIULMAC Quadramat Single End TenonerSingle end tenoner with (4) heads with Jump cope, cope, disc sanding and disc sandingSpecifications: -- Workpiece Length: 125 - 1500mm -- Workpiece Width: 125-1500mm -- Workpiece Thickness: 13 - 40mm -- Configuration: Jump-Cope, Cope, Wheel-Sanding, Wheel-Sanding -- First Station: 7.4 HP Jump-Cope/Profiling Unit with 40mm Diameter Shaft, 6000 RPM Rotation -- Second Station: 7.4 HP Cope/Profiling with 40mm Diameter Shaft, 6000 RPM Rotation -- Thirds Station: 4.7 HP Sanding Wheel -- Fourth Station: 4.7 HP Sanding Wheel -- Variable Speed Control of Sanding Stations from 750 - 1400 RPM -- Feed Speed: 13 - 98 FPM

$28,900

FRIULMAC - Dual-Feed, ...Double End Cut-Off SawFor squaring workpieces and for transportation to a Planer or Moulder with a straightening table.Specifications: -- 79" Max. (2,000 mm) opening from Saw to Saw. Motorized opening with LED readout on the control panel; left-hand fixed with left-hand fence line. -- Hopper Magazine - material capacity: Min. length: 7.87" (200 mm), max.: 79" (2,000 mm); width: 1-1/8" (30 mm) to 6-3/4" (170 mm); and thickness: 0.59" (15 mm) min. up to 2-3/8" (60 mm) max.; hopper stack height: 23-1/2" (600 mm).Each side is equipped with: -- (2) Trim saw motors, 5.36 HP each; saw blade dia. 9.84" (250 mm). -- Hydraulic feed drive unit: 4 HP (3 kW) motor. -- Trimming & throughput capacity: Up to (55) pieces/Min.NOTE: Voltage transformer for 600 Volts available with the machine

$14,500

Sanding wheel shaper for the production of profiles on the sanding wheels. -- Template carrier holds metal or plexiglass template (same as can be used on the moulder knives). -- Spindle length 5" with 1" diameter arbor for wheel support. Handles 8" diameter wheels (3) included with the machine. -- X and Y axis on dovetail slide with lineal bearing support for smooth movement during the wheel grinding. Pneumatic clamping on grinding wheels. Depth of grinding 1.5" for raised panel. -- Tilt capabilities from 0 to + 30°. -- Grinds all types of varda wheels on 1 HP motor with speed of 1,750 RPM. --You can customize this machine to you needs.

G & P - EPN, ... Pump Sander (Double-Sided), Double-end direct-drive pneumatic Drum Sander.2 HP Motor - 3,600 RPM motor speed.(2) 1-1/4" Dia. x 10" long shafts.

GABBIANI GALAXY 125 PLM FRONT LOAD, AUTOMATIC PANEL SAW: -- Specifications:126" Overall cutting length; 4.9" (125 mm) max. saw blade projection.24 HP Main motor 3,800 RPM w/pneumatic saw blade "quick change" system, 2.4 HP scoring motor; 16.5" (420 mm) Max. main blade dia., 6.3" (160 mm) 7,600 RPM scoring blade with external adjustment. -- Saw carriage: -- Travel speed from 0 - 297 FPM; 297 FPM constant return speed; powered by TEFC AC brushless motor. -- Pusher fence: -- Variable pusher speed from 0 - 297 FPM; return 297 FPM, powered by TEFC AC brushless motor on rack & pinion system.Equipped with: -- (6) Material gripper clamps; (2) Prismatic THK guides with recirculating ball bearings and forced lubrication. -- Pressure beam: Alternate pressure beam for final trim cut; (2) automatic pneumatic side aligners with rollers on front & back of the cut line. -- Features: Optimized blade/Pressure beam stroke optimized according to book height thus obtaining better cuts and lower cut time; electronic scorer adjustment user settable via PC; Double independent side aligner crosscuts optimized, stroke 86.6" (2200 mm) by min. panel width of 2.8" (70 mm). -- Operator & Machine Control:PC Front with INTEL CELERON 2 GHz, 128 Mb RAM, 40 Gb hard disk 15" color monitor, industrial keyboard & mouse, 1.44MB & CD ROM 48X disk drives for data transfer, (2) RS-232 serial port 1 parallel, 6 USB and network card capable for downloading from the office.Includes: -- DISA dust collector shown in photos. Specifications subject to verification.

Call for Price

GABBIANI G2 115 38/38 FRONT LOAD, AUTOMATIC PANEL SAW: -- Specifications:Working capacity 149.6" (3,800 mm) Rip & Cross-cut pull-back. Main saw blade projection is 4.5" (115 mm).20 HP (15 kW) Inverter driven, variable RPM main motor & 2 HP (1.5 kW) scoring motor. Automatic exclusion of scoring unit. Pneumatic quick-change system for blades -- Saw carriage: Feed speed from 3 - 492 FPM (1 - 150 MPM), return speed of 492 FPM (150 MPM.Automatic cutting stack height & length limiter adjusts according to the program dimensions. Automatic saw carriage lubrication. -- Pusher Fence: 0 - 230 FPM (0 - 70 MPM) Forward positioning speed, 230 FPM (70 MPM) return speed.Rack & pinion movement on both sides to assure the pusher remains parallel. (8) Total Material gripper clamps, with (4) of the grippers in the cross-cut section independent & programmable according to the cutting pattern.All gripper clamps open to 4.5" (115 mm); -- Operator & Machine Control:PC Front-end controller with SCM Maestro "eye M" + Windows operating system.21" LCD "Touch Screen" monitor display with real-time graphics + function control keypad. Virtually unlimited program storage via USB ports; RS-232 serial port, keyboard, mouse.Maestro software features machine functions, programming, run time, diagnostics, production reports, imports, language and unit of measurement, optimization cut software (Maestro Pattern)Maestro Cut 3D editor: Label printing software, 3D simulator, graphic editor, panels editor, cutting editor for figured panels, semi-automatic macro.Easy Import: This software imports from an Excel file all data related to part of a cutting list previously selected by the user to Maestro Pattern, Diagnostic for errors or machine malfunction by means of an error signal code, incremental or absolute programming in mm or inches. All enclosed in an air-conditioned control cabinet -- Complete with: Automatic Side alignment device. Min. part width 2.36", Max. part width 149". Automatic saw blade height adjustment. "Quick-change" blade system. (4) Air support tables 98" x 24" (2,500 x 600 mm), with (1) common blower. -- General Features:Automatic high performance beam saws controlled by PC/PLC “PREMIUM"; control system, designed to cut to size solid wood panels, chipboards, MDF panels, multilayer panels, plywood panels and fiber panels. -- Base and Working Table:Base with a tubular steel structure with a “closed"; ring shape. Worktable in Reinforced Ribbed-Steel and Coated with Anti-Scratch Phenolic Material. No. 2 Cylindrical Guides for the Saw Carriage Movement Equipped with Sliding Wheels in Ground Steel. Squaring Fence Located on the Left Side. -- Options Include:Zebra label printer. -- Actual Model is GABBIANI G2 115 38/38

$19,800

GABBIANI S.Q.V. Double End Tenoner ● Double sided with Scoring, hogging, top/bottom cope, shaping, belt sanding, belt sanding ● 2,500 mm (102") Max. width and 235 mm (9-1/2") min., programmable motorized opening with LED readout.Specifications: -- 112 mm (4.72") max. part thickness. -- 900 mm (36") Load area in front of holddowns driven upper holddowns caterpillar type -- 235 mm (9-1/4") min. length, left side fixed right side moveable.Each side equipped with: -- 1st Station: Jump scoring, 2.4 Kw (3.2 HP) motor. -- 2nd Station: Hog/trim saw, 7.5 Kw (10HP) motor. -- 3rd station: Cope unit Top,5.5 Kw (7.5 HP) motor -- 4th Station:Cope unit bottom 5.5 Kw (7.5 HP) motor. -- 5th Station: Cope unit, 8 Kw (10.8 HP) motor -- 6th Station: Belt sanding unit with pneumatic 7.5ontrols. -- 7th Station: Belt sanding unit with pneumatic controls. -- Variable feed speed 0 - 36 m/Min (120 FPM), 7.5 HP feed drive, -- Feed chains with disappearing dogs, platform feed chain with rubber faced track pads and separate control panel with controler, contactors and overloads. - -- Full sound enclosures.

GANNOMAT COMBI 110 CONSTRUCTION LINE BORER(23) Spindle head, 2 HP - 2,800 motor, 31-1/2" max. working width, 3" drilling stroke, drills vertically from bottom and horizontally from rear, tilts pneumatically from lower to rear position with positive stop at 45° for angle drilling. -- Holddown clamp assembly tilts 90° for clamping short panels vertically for edge boring, no need to swivel boring head, hydraulic brake for through boring. -- Complete with: (4) Pneumatic holddowns, mirror imaging fences, 4,000 mm line boring fence w/stops and 1,500 mm butt joint fence with (2) flip stops.

GANNOMAT Elite 25 Construction & Line Hole Boring Machine --25-SpindleConstruction hole and Line hole32 mm Boring Machine. --Specification: -- 2 HP - 3,400 Motor, 31" (768 mm) max. working width up to 34.4" (900 mm) through feed width. -- Adjustable drilling stroke up to 3-7/8", line drilling up to 11-3/4" from edge. -- Drills vertically from bottom and horizontally from rear, pneumatic tilting of boring head from 0° - 90°, with pneumatically operated rear stop with selector switch. -- Features quick, removable side stops for conversion to line boring, mirror-image fence setting device. --Complete with: -- Side fences with micro-adjustment, optional line drilling fence, (3) flip-stops. -- Pneumatic holddown clamps, foot control, and emergency stop button.

GANNOMAT DB21 CONSTRUCTION/LINE BORINGVertical/horizontal drilling, (21) spindles.Specifications: -- Drills vertically from the bottom-up, horizontally from the back or any angle between 0° - 90°; tilting action of the boring head is pneumatically controlled. -- 21-Spindle head, 2 HP motor - 3,000 RPM spindles on 32 mm centers. -- Tilts pneumatically with switch control, graduated degree scale from 0° - 90°. Complete with: -- (4) Overhead holddown clamps, frontal top stops, 70" (1,800 mm) Left & right side fence, line boring fence, and 45° Miter set-up stop.

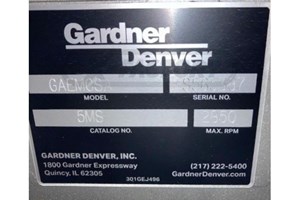

GARDNER DENVER - VS80A, ...Rotary Screw Compressor 100 HP, 436 ACFM @ 125 PSI, 125 PSI operating pressure (175 PSI max), 2" air outlet, and 71 dBA.Also included: -- Full sound enclosures. -- GARDNER DENVER Air Dryer model "RCD500A8". -- Air tank: 1,60 gallons, year 2002 -- Operating hours: 36,652Note: Specifications need to be confirmed..

Sutorbilt Legend 5M -- Standard, medium-pressure -- Diameter (inlet/outlet): 4" NPT -- Shaft size: 1.125" -- 2,350 Max RPM

GARDNER-DENVER 2BV5121 15 HP Liquid ring pump:11.4 kW (15 HP), Volume flow 360 CFM; operates at a low noise level of 74 dBA.Specifications: -- The "2BV5121" series are compact plug-and-play systems for easy on-site installation; pumps are air-cooled, 100% oil-free, and do not require additional water during operation. -- Due to contact-free compression, they are virtually wear-free in operation and require no periodic maintenance. -- The patented discharge-air cooling system ensures that the pumps will not heat up by more than 15K above room temperature; pumps work reliably in continuous operation and are steam resistant & insensitive to condensation of the pumped air. -- Vacuum power units of the "2BV5121" split type are standardized liquid ring pump circulation systems with patented exhaust air cooling for large volume flows. -- A considerable amount of the water contained in the cool exhaust air condenses, remains in the system, and is available as operating water; as a result, many applications no longer require additional operating water.(2) Available, buy both for less than $9,000.