704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

40 Results Found

704-841-2001

Call for Price

MATH-EX - SUCTION CUP END TOOLING ARM FOR FANUC ROBOT -- Suction Type Pick Up Tooling Arm. -- Specially Designed for FANUC Robot. -- To Palletize Pillow Type Bag up to 75 Lbs. -- This Tooling will be Installed on a FANUC Robot. -- Loaded onto your truck.

MATH-EX BAG TURNER WITH CONVEYORSpecifications: -- Bag Turner/Knockdown Conveyor -- 5' Long x 24" Wide Smooth Top Belting -- Includes Turn Wheel -- 30" Stainless Steel Turn Plate and Adjustable Knockdown Bar -- 1/2 HP Motor at 90 FPMLoaded on your truck

Call for Price

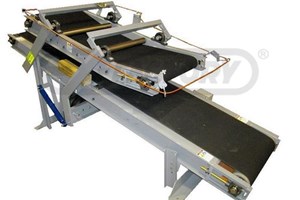

MATH-EX Bag FlattenerSpecifications: -- Standard Bag Flattener conveyors are 10' in length with a 15° incline. -- The system has an opposed 5-1/2 foot conveyor with parallel linkage and adjustable spacing for various bag thicknesses. -- The standard unit has a 12" inlet and 42" discharge. -- The lower conveyor has a 1-1/2 HP motor and the top conveyor has a 1 HP motor both with a speed of 90 FPM. -- Both conveyors come with 24" wide Roughtop black belt.Custom length bag flatteners are available in 2' increments from 10 feet to 24'. Mild steel construction with industrial powder coat finish is standard, however all stainless steel, corrosive resistance packages and hazardous location components are available as option.

$223,500

MOLLERS HSA Automatic Stretch Hooding SystemSpecifications: -- Max. pallet size: 48" x 48" x 120" -- Capacity: up to 120 units per hour (depending on load height and length) -- Main motor: 2 HPFeatures: -- Fully automatic -- Tubular film is automatically fed and stretched over the load -- Handles a variety of load heights automatically

Call for Price

MOLLERS HSA Automatic Stretch Hooding System with Corner Board ApplicatorSpecifications: -- Max. pallet size: 48" x 48" x 120" -- Capacity: up to 120 units per hour (depending on load height and length) -- Main motor: 5 HP -- Corner board system: -- Automates the process of placing 4 corner boards. -- Each corner board magazine can hold up to 30 corner boards. -- Carousel design, servo driven corner board applicator allows for precise positioning during corner board retrieval and for proper staging.Features: -- Fully automatic -- Tubular film is automatically fed and stretched over the load -- Handles a variety of load heights automaticallyApplications include: -- Pallets of smooth boxes or uneven containers that need to be secured on a pallet -- Cereal / grain based products -- Chemical / industrial -- Prepared / convenience foods -- Household goods -- Snack foods

Call for Price

COMPLETE FORM-FILL AND SEAL BAGGING LINEPREMIER TECH "FFS200" LOOSE BAGGING SYSTEM AND PALLETIZING SYSTEM PREMIER TECH MODEL "AP-425" INCLUDING THE FOLLOWING;Equipped with: -- RD-1520 Volumetric Hopper with Belt on Rollers ( 20yd³ / 15 m³) -- ORD-1019 Lump Breaker -- ORD-1032 Adjustable Front Gate with Crank -- ORD-1034 Transition ChuteINFEED CONVEYOR -- CM-9036 Troughed Belt on Flat Idler Rollers Conveyor 52' -- OCB-1050 Transition Chute -- Volumetric Feeder -- VF-2300 Volumetric Feeder with Live Chain Scrapers -- SVF-2001 Recommended Safety Device - Platform for Safe and Easy -- Access to Volumetric FeederFFS-200 Horizontal Form-Film and Seal Bagger -- OFS-2006 Dust Collecting Ports -- OFS-2022 Vertical Setting Device -- OFS-2070 Horizontal Fixed Roll Support -- OFS-2074 Bag Exit Dropping Arm -- OFS-2076 Product Infeed Line Controlled by FFS -- SFS-2000 Recommended Safety Device- Complete external Guards to Prevent Access Inside the FFS -- FFS Grow Bag Options -- X-Large Option Upgrade to FFS-200 for Wider than Normal Bag -- OFS-2010 Gusset Former -- OFS-2045 Corner Sealer for Gusseted Bag with Powered Adjustment System -- Bag Conveyor -- OFS-2099 FFS Outfeed Belt Conveyor with Adjustment System and Pivot 10' -- CF-5001 Horizontal Bag FlattenerROBOT -- AR-225 Robotic Bag Palletizing Cell -- ARR-M-4140 Fanuc Robot M-410iB/140H -- OAR-2006 Powered Slip Sheet Dispenser -- OAR-2207 Wire Mesh Trays and Cables -- OAR-2208 Fanuc NRTL 575V Brake Option -- OAR-2213 Palletizing Conveyor -- OAR-2050 VFD for AR Series Motor Speed Control -- CP-2010 Powered Roller Conveyor 7' -- DD Upgrade for Large Bag for Finger Gripper -- Additional Fingers Kit for Large Bag (Quick Connect)

PRESTO P3-AA ROUND PNEUMATIC AIRBAG LOAD LEVELERTurntable top with easy turning anti-friction bearings allows users to spin loads so they are always working from the near side without having to walk around the unit.Specifications: -- Automatic positions loads between 9-1/2" and 27-3/4" -- Small base allows workers to stand up close to the P3 at any position -- Stable design requires no floor lagging -- Build fork pockets for easy lagging, -- Load capacity 4,000 Lbs -- Raised height 27-3/4" -- Lowered height 9-1/2" -- Overall base 36" W x 36" L -- Turntable diameter 43-5/8" -- Shipping weight 450 Lbs

MOTORIZED PALLET CONVEYOR -- 48" X 10 Feet -- Motorized with 3/4 HP Motor -- To be use as an Accumulation Conveyor -- Loaded on your Truck

Call for Price

ONE-STATION COMPRESSION BAGGERSpecifications: -- Will Make Bags of 48" Wide x 48" Thick and 48" High Compressed -- Can Compress Multiple Types of Products Like; Peat Moss, Fibers, Wood Shaving, Alfalfa, etc.etc. -- This Unit is Installed on a 53-Foot Tridem Stepdeck or it could be loaded into containers -- Sides of Bagger Fold Down for TransportationReady to Go (and Roll).

$245,800

VERVILLE VP400SE 4-STATION BAGGERComplete 4-Station Bagging System -- Automatic Bag Placer -- Automatic Bag Sealer -- Bag Size 12" x 17" x up to 30" High -- Hydraulic System and Control -- Tube Height 130''Loading on Buyer's TruckNOTE: This machine requires 27' clearance inside a building.

VERVILLE VP424-S-CCW BAGGING SYSTEM4-Station Compression Bagging SystemSpecifications & Includes: -- High Tubes of 116" -- Bag Size 11" x17" up to 30" High -- Automatic Plastic Bag Sealer -- Oil Tank Heater and ModemLoaded on your Truck

Call for Price

VERVILLE 6-SCREW HOLDING BINSpecifications: -- (6) Motorized 14-1/2" Diameter Bottom Screw -- (1) Motorized 14-1/2" Diameter Exit Screw -- 11 Feet Long -- 16 Feet Wide -- 18 Feet High -- 12 Feet High Support LegsDismantled and Loaded on Truck

Call for Price

VERVILLE VP324CCW 3-STATION VERTICAL BAGGERSpecifications: -- 25 HP Motor -- High of Tubes 116" -- Bag Size 11" x 17" x Up to 30" Finish High -- Counterclockwise Rotation -- Includes Belt Feeding Conveyor -- Loaded on your Truck

Call for Price

VERVILLE VP300 3-Station Bagging SystemSpecifications: -- Main motor: 25 HP -- High of Tubes 116" -- Bag Size 11" x 17" x Up to 30" Finish HighNote: Bin and Infeed auger/conveyor is not included.

$44,500

VERVILLE 376 3-STAGE Bagging System with Conveyor and Stretch WrapperSpecifications: -- Bag size: 17.5"; X 12.5"; X 40" -- Number of stages: 3Equipped with: -- Surge tank -- Stretch Wrapper -- 25' conveyor

Call for Price

Something "Free" and "No Strings Attached"....Really. We can be your partner for providing you solution on your next expansion or modification project, we can save your time and money by helping you answer questions such as... -- What packaging equipment do I need ? -- What is the most cost efficient way of doing the same? -- Can my equipment be upgrade to re-use ? -- How much will a Turnkey project cost? -- Where do I start ? -- Don't do it alone. Put our specialized expertise to work for you as you plan your next project. -- At Ex-Factory we offer complete expertise and integrated solution for bulk solid packaging system, automation & warehouse management. -- Your satisfaction our commitment. -- Call us today for a FREE evaluation.

AMERI-MULCH COLORING SYSTEM -- 5 Yard Hopper -- Low Hours 1,550 -- Production of 60/80 Yards per Hour -- Good Working Machine -- Loaded on your Truck

Call for Price

CAROLINA BULK BAG FILLING MACHINECarolina Conveying filling stations are used to safely and efficiently load bulk bags. A filling head with inflatable seal is used for dust tight loading of the bulk bag, and bolts to the adjustable height framework. The inlet to the filling head is connected to the customer’s equipment above via a flexible tube. The bag spout is secured to the outlet with an inflatable seal. The seal inflation is controlled by a manual on/off spool valve, which pipes air to the unit. A cavity around the outerperimeter allows displaced air and dust to exit the filling head through a dust extraction nozzleSpecifications & Features: -- Rated for 5,000 Lbs Bag fill up to 4000 Lbs. -- Platform size 48" x 48" -- Bulk Bag Filler Stations are used to safely and efficiently load bulk bags. -- A filling head with an inflatable seal is used for dust-tight loading of the bulk bag, and bolts to the adjustable framework height. -- The inlet to the filling head is connected to the customer's equipment above via a flexible tube. -- The bag spout is secured to the outlet with an inflatable seal. -- The seal inflation is controlled by a manual on/off spool valve, which pipes air to the unit. -- A cavity around the outer perimeter allows displaced air and dust to exit the filling head through a dust extraction nozzle. -- Support frame with adjustable rack. -- Support arms; Four adjustable height arms for loop-type bags. -- Inlet 8" round flange, ASA 150 Bolt hole pattern. -- Inflatable seal; White seamless gum rubber tube. -- Dust spigot 3" o.d. tube -- Weight platform with Digital Scale -- Output for digital readout is includedOption 3Heavy Duty, Mild Steel, 48"; Square Vibrating Table with checkered plate top, pneumatic piston vibrator and four inflatable anti vibrationmounts. The vibrating table ensures that product in the bag is de-aerated and maximizes bag capacity: (Allow 12 – 15 weeks)

Call for Price

COMPLETE CHANTLAND 4234 LOOSE BAGGING SYSTEM4234 BELT-WEIGH BAGGER Including the following: -- Load Cell Weighing with "5511" Weighmeter Controller -- Color Touch Screen 5.4" size -- Single or Dual Set Point -- Calibration Routine -- Zero Tracking - Weigh Track -- Multiple Product Set-Up w/Quick Change over- (100) products -- RS-232, RS 422 Ethernet TCP/IP Connection -- NEMA 4X Poly Enclosure 16" x 14" -- Three Level Password Protection -- Requires Dedicated 120V /60 Cycles service -- Two Stage Variable Speed Control for Bulk Feed & Dribble Cut off by Weight Using VFD -- Flapper Style product Stop Gate for Positive Product Cut-Off -- Discharge Dust Collection Chute -- Spiked Agitator Above Inlet, with Drive, -- An Agitator Stirs the Product and Helps Deliver Product to the Belt. -- Surge Bin, Mounts to Flange of Packer, with Removable Lid, Inlet Flange and Dust Flange in Lid -- Approximately 10 Cubic Foot Capacity with Threated Ports for Customer Supplied Bin Level IndicatorsAP100 Automatic Bag Placer -- Bag Face 13-19 Inches -- Bag Length 24 Inches and up to 40 Inches Long -- Material of Bag Construction; Kraft Paper, Poly Plastic, Woven -- Gusseted Bags 5-1/2" Wide Gussets -- Upgrade to VEE Spout Clamp for AP10000FISCHBEIN "400NS" PLAIN SEWN CLOSURE SYSTEM -- This heavy-duty, state-of-the-art plain sewing system is designed for semi or fully automated bagging operations. -- The 400NS is specifically made for medium to high volume bagging applications that will require operating speeds up to 55 linear feet per minute @ 2.5 stitches per inch. -- This versatile unit will securely sew close woven polypropylene, multi-wall paper, and jute bags. -- Includes an infeed and standard unit is Right to Left travel.Standard features include: -- Empress model "100" two thread sewing head @ 2.5 stitches/inch -- Adjustable height high speed pedestal with casters. (31-56 inches) D4380 15" infeed -- Air thread pusher -- PLC controlled pneumatic actuators -- 24 VAC control circuit / 24 VDC solenoid valve controls,1HP, 1750 rpm motor 230 VAC single phase, or 230/380/460/575 VAC 3 PH -- NEMA 12 Electrical Components -- 180 Days System WarrantyNOTE: Minimum 6" of bag free top required

Call for Price

COMPLETE CHANTLAND 4234 LOOSE BAGGING SYSTEM4234 BELT-WEIGH BAGGER Including the following: -- Load Cell Weighing with "5511" Weighmeter Controller -- Color Touch Screen 5.4" size -- Single or Dual Set Point -- Calibration Routine -- Zero Tracking - Weigh Track -- Multiple Product Set-Up w/Quick Change over- (100) products -- RS-232, RS 422 Ethernet TCP/IP Connection -- NEMA 4X Poly Enclosure 16" x 14" -- Three Level Password Protection -- Requires Dedicated 120V / 60 Cycles service -- Two-Stage Variable Speed Control for Bulk Feed & Dribble Cut off by Weight Using VFD -- Flapper Style product Stop Gate for Positive Product Cut-Off -- Discharge Dust Collection Chute -- Spiked Agitator Above Inlet, with Drive, -- An Agitator Stirs the Product and Helps Deliver Product to the Belt. -- Surge Bin, Mounts to Flange of Packer, with Removable Lid, Inlet Flange and Dust Flange in Lid -- Approximately 10 Cubic Foot Capacity with Threaded Ports for Customer Supplied Bin Level IndicatorsAP100 Automatic Bag Placer -- Bag Face 13-19 Inches -- Bag Length 24 Inches and up to 40 Inches Long -- Material of Bag Construction; Kraft Paper, Poly Plastic, Woven -- Gusseted Bags 5-1/2" Wide Gussets -- Upgrade to VEE Spout Clamp for "AP10000" -- PLASTIC BAG IMPULSE SEALER