704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1696 Results Found

704-841-2001

CEMCO MBV 54 Vertical Boring Machine54" x 15" Cast iron table with wooden top,Equipped With:(2) Universal spindles with movable spindle supports,(3) 2 HP - 1,725 RPM direct drive spindle motors,36" Stationary table height; 6" Max. vertical stroke, spindles advance hydraulically at 0 - 30 strokes/Min;Foot pedal actuated w/single cycle & continuous automatic modes;2 HP hydraulic feed pump, 12-gal. hydraulic pump system;Note: Riggers are required for loading

$8,950

CEMCO - URF-3352, ...3-Head Wide Belt Sander.53" Width cap. Drum, Drum Combination Head.Head Configuration:1st Head: Rubber-covered contact roll, 10" dia., 65 shores (to be verified), adjustable with a dial indicator, 50 HP motor.2nd Head: Rubber-covered contact roll, 10" dia., 65 shores (to be verified), adjustable with a dial indicator, 40 HP motor.3rd Head: Combination Head, (2) 5-1/2" finishing Drums & Platen.4th Station: Panel Brush.Specifications: -- 6" Max. working thickness. -- 1 HP Variable speed feed. -- 53" x 75" Abrasive belt size. -- Power raise & lower of feed bed. -- Numerical digital readout of thickness. -- Spring-loaded holddown rollers through machine. -- 36" Infeed table, 30" outfeed table; feed speeds from 5 - 60 FPM, 3 HP inverter. -- Load meters. -- (2) 8" Dia. dust outlets. Equipped with & Features: -- Belt Tracking (Electric Eye). -- Constant Pass-Line machine.Some spec's need to be verified.

$16,950

CEMCO - 4000, ...2-Head Wide Belt Sander38" Width cap. - Drum, Platen configuration.Head Configuration:1st Head: 40 HP -1,780 RPM rubber contact drum head.2nd Head: 30 HP - 1,775 RPM platen style head.Specifications: -- 3 HP 230/460/60/3 Feed motor with TOSHIBA VFD controls. -- 15 - 60 FPM Conveyor feed speed . -- 30 HP - 3,525 RPM Vacuum blower. -- Vacuum type rubber conveyor feed belt. -- Push button controls and amp meters. -- Electric ProScale digital thickness readout. -- YASKAWA Varispeed F7.Equipped with & Features: -- VFD abrasive belt drive system. -- Outfeed workpiece dust cleaning enclosure.Includes: Replacement abrasive belts and belt racks.

Call for Price

CENTAURO TC-1200 Copy Lathe;47-1/4" Max. between centers. -- 4-3/4" Height of centers over bed. -- Max. copy dia. 6" (4-1/8"). -- Max. dia. permitted by traveling steady 3-1/2" (2-1/2"). -- 4 HP main motor, 900 - 1,500 - 2,200 & 3,540 RPM spindle speeds. -- 1 HP hydraulic variable speed carriage with tool post and revolving steady rest. -- (2) Independent gouges working in conjunction with the traveling steady rest. -- Variable speed hydraulic saddle movement. Standard Equipment & Specs: -- Drive center with (2) interchangeable heads 1" and 1-3/4". -- Tailstock revolving center 1/2". -- Traveling steady rest max. 3-1/2" (square 2-1/2" x 2-1/2") with reduction bushing. -- (2) Vertical Tantung gouges, radius 1.2 mm and (1) precutting tool. -- Work-piece centering device. -- Tool support rest for hand turning. -- (2) Dust extraction ports 4" dia. -- Motor protection switch. -- Emergency push button. -- Front sliding safety guard. -- Standard: Service tool kit and Abrasive stone for cutting edge dressing.

Call for Price

CENTAURO T5E -1600 Semi-Automatic Hydraulic Copy Lathe with two copier heads. -- General data: 63" (1600 mm) Max. between centers and 8-5/16" height of center over the bed, 5.5 HP main motor with saddle advance using a lead screw with precision recirculating balls for max. accuracy.Automatic work cycle sequencing with electronic control capable of up to (5) different programmable cycles. -- Drives/Controller: Programmable saddle with variable feed speed; 900 - 1,500 - 1,800 - 2,250 - 3,000 & 4,500 RPM spindle speeds; 1.5 HP hydraulic variable speed carriage, 0 - 39-1/2 FPM, carriage return speed 39-1/2 FPM. CENTAURO "EM-12" Programmable Controller. -- Equipped with: (2) Hydraulic tracing units and revolving steady rest attachment; 3-1/2" max. square part size with revolving steady rest, 5" dia. max. with copying unit, 5.8" stroke of copying unit. 19-5/8" max. length for manual turning. -- 9.8" (250mm) Max copy dia., 6.8" (175 mm) Max. square section without steady rest.. -- Includes: Drive center, revolving tailstock center with 12 mm dia. tip, and automatic double pass system for finishing center. -- Note this machine has no top Back Knife for plunging with form tool. -- Machine manual included.

Call for Price

CENTAURO T5-1600 Hydraulic Copy Lathe with (2) back knives; Specifications: -- 63" (1,600 mm) Max. between centers, 4/5.5 HP main motor, two speed selector switch, 900 - 1,500 - 1,800 - 2,250 - 3,000 and 4,500 RPM spindle speeds. -- 1 HP Hydraulic power pack for variable speed carriage 0 - 19 FPM carriage; return speed 24 FPM, hydraulic tailstock with Pressure Reducing Valve (PRV) for fine control of pressure, especially helpful for small and/or slender turnings. Equipped with: -- (2) Independent copying units, (1) for roughing and (1) for finish cutting. 1st, 2nd pass & auto feature with 2nd pass active it will cut the pattern 2 times automatically and sequence the tools between cuts. -- Revolving steady rest, max. dia. 140/100 mm square ( 5.5"/3.9"), and for max. dia. 90/65 mm max. square billet size. -- 9.8" (250mm) Max copy dia., 6.8" (175 mm) Max. square section without steady rest.. Includes: -- (2) Back slides manually operated with knives for making dowel ends; 45/26 mm drive center for headstock and 12 mm center for tailstock, (2) V-type gouges with 0.6 & 3.5 mm cut radii.NOTE: Ex-Factory handles import/export to just about any country in the world.

Call for Price

EMC MERCURY 1100 3WRK Abrasive Planer / Wide Belt Sander with (3) Heads; Planer Head, Contact Roller, and Combination Head.Useful working width 1,100 mm (43"). Working thickness min./max. 3 - 170 mm (1/8" - 6-11/16"). The machines uses abrasive belts 2,620 x 1,120 mm (103" x 44-1/16") for longer life of the sanding belts.Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 140 mm (5-1/2"). -- Shaft for helicoidal position knives with (316) Interchangeable knives with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 20 independent segments. -- Anti kickback protection made of 60 independent elements. -- On-Off pneumatic cylinder for planer. group in working position. -- Working pressure adjustment. -- Motor power: 15 kW (20 HP). -- Automatic Star-delta starter. -- Speed rotation: 35 m/Sec (115 FPS). -- Soft starter for slow starting2nd Head: Steel Roller "R", Belts dimensions: 2,620 x 1,120 mm (103" x 44"). -- Roller diameter: 180 mm (7"), spirally grooved. -- Electronic motorized roller pressure adjustment "Grit-set system". -- On-Off selector switch control for roller. -- Constant control to any position with accuracy 0.02 mm. -- Rotation: Against feed (clockwise). -- Motor power: 11 kW (15 HP) with Automatic star-delta starter. -- Abrasive Belt cutting speed: 18 m/Sec (59 FPS). -- Timing oscillating cleaning abrasive belt blower located at the bottom 3rd Head: COMBINATION Unit "K", Belt dimensions: 2,620 x 1,120 mm (103" x 44"). -- Roller diameter: 140 mm (5-1/2"). -- Roller rubber hardness 45 Shore, Constant control to any position with accuracy 0.02 mm. -- On-Off selector switch control for 3rd roller including pneumatic piston -- Pneumatic Aluminum PAD , lamina 40 mm, On-Off. -- Quick changing system, extractable blade with felt, rubber and graphite. -- Rotation: Against feed (clockwise). -- Motor power: 11 kW (15 HP) with automatic star-delta starter. Abrasive Belt cutting speed:18 m/Sec (59 FPS).Feed system: -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 17 m/Min (9.8 - 55 FPM) Inverter Controlled. -- Automatic feed belt centering device. General Machine Features: -- Large diameter screws on machined guides with columns and pistons. -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each (head) working group. Electronic programmable color TOUCH SCREEN display, 7" wide -- PLC with micro-processor of latest generation, modular and expandable. -- Connection USB, RS232, Ethernet 10/100/1000. -- Memory capacity: 100 working programs or more. -- Graphic synoptic to facilitate programming.Software facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, programming and display for t

Call for Price

EMC EXPLORER 1100 SUPER WK Abrasive Planer / Wide Belt Sander with (2) Sanding Heads; Planer Head, Combination head roller/pad.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 2,200 mm (86.6") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 63 FPM). Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 142 mm (5-9/16"). -- Shaft for helicoidal position knives with (316) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 20 independent segments. -- Anti kickback protection made of 60 independent elements. -- On-Off pneumatic cylinder for planer group in working position. -- Working pressure adjustment. -- Motor power 15 kW (20 HP). -- Automatic Star-delta starter. -- Speed rotation: 30 m/Sec (97.5 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (5-9/16"). Rubber covered hardness 45 Shore. Automatic abrasive belt grit compensation with "Grit-Set System". On Off Selector control for 2° roller incl. pneumatic piston -- Pneumatic elastic pad high resistance with quick changing system; extractable felt, rubber & graphite. . Complete with On-Off Selector and Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 18 m/Sec (59.1 FPS). -- Motor power 15 kW (20 HP). Belt blowers, oscillating, for cleaning of abrasive belt. Abrasive belts oscillation by means of electronic photocell sensor. -- Cleaning Brush: -- Tampico brushing unit for panel cleaning, at outfeed, 150 mm diameterFeed system: -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt machined. -- Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). -- Idle table rollers support in infeed and outfeed.Centralized Control Cabinet: Analog ammeters on main control cabinet. Table lifting-lowering thickness system electrically controlled. AUTOMATIC Delta - Star starter on main motors and IP 54 protection against dust & moisture. Centralized independent pneumatic control cabinet: Pneumatic air filter with automatic water-drain system. Pneumatic adjustment for "Grit set system". Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). Features: -- Control panel with self-diagnostics alarm control unit. -- Telemetry computer remote diagnostics control. Direct connection with EMC via internet for assistance.USA UL or Canada CSA Safety Features

Call for Price

EMC FLEXY 1350 3WRR Finishing Sander with (3) Sanding Heads; Planer Head, Roller, Roller.Useful working width 1,350 mm (53"). Working thickness min./max. 3 - 190 mm (1/8" - 7-1/2"). Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 140 mm (5-1/2"). -- Shaft for helicoidal position knives with (380) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 24 independent segments. -- Anti kickback protection made of 70 independent elements. -- On-Off pneumatic cylinder for planer. group in working position. -- Working pressure adjustment. -- Motor power 22 kW (30 HP). -- Automatic Star-delta starter. -- Speed rotation: 35 m/Sec (115 FPS).2nd Head: Steel Roller "R", Belts dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 250 mm (10"), spirally grooved. -- Electronic motorized roller pressure adjustment "Grit-set system". -- Constant control to any position with accuracy 0.02 mm. -- Rotation: Against feed (clockwise). -- Motor power: 15 kW (20 HP) with Automatic star-delta starter. -- Abrasive Belt cutting speed: 18 m/Sec (59 FPS). -- Air Jet Blower for abrasive belt cleaning.3rd Head: Roller "R", Belts dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 250 mm (10"). -- Roller rubber hardness 85 Shore. -- Constant control to any position with accuracy 0.02 mm. -- Rotation: Against feed (clockwise). -- Motor power: 15 kW (20 HP) with Automatic star-delta starter. -- Abrasive Belt cutting speed: 18 m/Sec (59 FPS). -- Air Jet Blower for abrasive belt cleaning.Feed system:Constant pass line, 900 mm (35.4") from floor -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 18 m/Min (9.8 - 59 FPM) Inverter Controlled. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each (head) working group. Electronic programmable color TOUCH SCREEN display, 7" wide -- PLC with micro-processor of latest generation, modular and expandable. -- Connection USB, RS232, Ethernet 10/100/1000. -- Memory capacity: 100 working programs or more. -- Graphic synoptic to facilitate programming.Software facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, programming and display for thickness. -- Command, programming and display for feeding. -- Command, programming and display for all inverters. -- Command, programming and display for selected groups. -- Command, programming and display for blowers, including compressed air saving function. -- Display report and reset of alarms (self diagnostic) with memory records.Options Included: -- Vacuum bed

Call for Price

EMC VENUS 1300 1K ... Finishing Sander with (1) Sanding Head: Combination Head.Useful working width 1,300 mm (51"). Working thickness min/max mm 3 - 170 (1/8" - 6-5/8").Working Unit: Combination Roller & Pad. -- Roller diameter 142 mm (5-5/8"). Rubber covered hardness 85 Shore. Roller pressure adjustment control & "Grit-set system". Main Motor On Off Selector control with pneumatic piston to select roller, 22 kW (30 HP) Automatic star-delta starter Rotating cutting speed: 18 m/Sec (59 FPS). -- PNEUMATIC Controlled Flexible Sanding Pad Including On-Off Selector: Quick Change System: Removable pad with felt, rubber and graphite. Rotating cutting speed 18 m/Sec (55.8 FPS). Abrasive belts oscillation by means of electronic photocell sensor.Feed system:CONSTANT PASS LINE - fixed infeed height 900 mm (35") from floorIdle table rollers support in infeed and outfeedRubber covered presser rollers, groovedVariable feed belt speed, adjustable from 3 to 19 m/Min (9.8 - 62 FPM). Inverter ControlledLarge diameter screws on machined guides with columns and pistonsAutomatic feed belt centering deviceElectronic digital display for working thicknessGeneral Machine Features: -- Analog ammeters on main control cabinet. -- Electronic motorized grit set system, control from touch screen.Electronical Panel: -- Check Control Self Diagnostics with Alarm Control. -- Analog Ammeter on the main control cabinet. -- Infeed table thickness system electrically controlled. -- Independent Overload protection.Safety: -- Infeed front emergency swinging bar for oversized panels. -- Infeed protection pressing blade to avoid pieces to go back to operator. -- Rear and front emergency push buttons. -- Automatic brake on abrasive belts motors. -- Automatic emergency stop and alarm display in case of: ● Low Air Pressure. ● Doors opened ("easy maintenance and inspection"). ● Electric motors overloading. ● Emergency detector for over thickness material cut. ● No tension on abrasive belt. ● Abrasive belt lateral mistracking. ● Abrasive belt broken.Idle table rollers support in infeed and outfeedCentralized Control Cabinet: ● IP 54 protection against dust & moisture. ● Analog ammeter on main control cabinet. ● Table lifting-lowering thickness system electrically controlled. ● AUTOMATIC Delta - Star starter on abrasive belts motors. Centralized independent pneumatic control cabinet: ● IP 54 protection against dust & moisture. ● Pneumatic air filter with automatic water-drain system. ● Pneumatic adjustment for "Grit set system". ● Pneumatic plant working without lubrication. ● Compressed air pressure 6 bar (85 PSI). Options Available: Tampico Brush natural fiber brush for cleaning of the pieces, diameter 150 mm (6"). Motor Power 1.1 kW (1.5 HP). $3,950

$235,000

EMC R-evo Z 1350 Sanding & Polishing Center for multi-directional Superfinishing - Award-winning system!Superfinishing obtained by combining electronically controlled, segmented sanding pads with the continuous rotation of the entire sanding head assembly (carousel). This revolutionary system is equally effective as regular wide belt sanders with 4 heads!The carousel rotation is servo-controlled, and can also be operated at standstill in any angular position. The revolving sanding head provides a much more consistent overall finish, and better use of the entire abrasive sanding belt.Motorized doors, sliding and foldaway. Useful working width 1,350 mm (53"). Working thickness min./max. 5 - 180 mm (0.2" - 7"); Constant pass line.Part/Panel Reading unit with Electronic Segments: -- RB-75 Panel reading at infeed, (75) segments with electronic feeler pads. -- Electronic commands activated by magnetic switches. -- Panel detection by large diameter rubber wheels. -- Integrated electronic system.Machine Specifications: -- Hyper finishing abrasive belt 4,960 x 1,430 mm (195.3" x 56-5/16"). -- Chevron belt (inside) length 4,560 mm (179.5"). -- Carousel rotating speed infinitely variable 0.1 - 40 RPM. -- Two electronically controlled segmented sanding pads. Both with 75 segments, each 18 mm wide. -- APC - Automatic Programmable Control and setting of the air pressure for the electronic pads. -- Sanding pads pressure controllable from 0 - 4 bar (0 - 58 PSI). -- Main motor 11 kW (15 HP), Inverter Controlled for infinitely variable abrasive belt speeds 3 - 18 m/Sec (10 - 59 FPS). -- Double oscillating blowers for parts & feed belt cleaning. Activated by part size. -- Motorized linear sliding doors, total stroke 2,100 mm (82.7"). -- Including abrasive belt loading trolley for easy exchange of the sanding belt. -- At outfeed: TAMPICO brush roller for part cleaning, diameter 150 mm (6"), and TAMPICO brush roller for feed belt cleaning, diameter 150 mm (6").Feed System: -- Constant pass line, 900 mm (35-7/16") from floor. -- P.A. Automatic thickness caliper with radio frequency remote control. -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Vacuum conveyor bed assembly, fan mounted inside the machine. Inverter controlled 4 kW (5,5 HP) motor. -- Variable feed belt speed, adjustable from 2,5 to 16 m/Min (8 - 52 FPM), Inverter Controlled. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device.Machine Management System: -- Electronic programmable color TSD TOUCH SCREEN DISPLAY, 15,4" wide. -- PLC Power Logic Control for high speed data transmitting. CPU Pentium Intel Atom Z510; 1,1 GHz, DDR2 RAM 512MB expandable. -- Connection 3x USB, 1x RS232, 1x Ethernet 10/100/1000. -- Memory capacity of (200) working programs. -- Operating system Microsoft Windows 7. -- Graphic synoptic to facilitate programming. -- Software and connections prepa

EMC ROTOPLUS 1350 – LUC (1)5 + BRILL 15 Polishing & Buffing LineHeavy Duty Automatic Polishing & Buffing line for high gloss lacquered panels, consisting of: -- Infeed Conveyor -- ROTOPLUS 1350 LUC 5+1 - Polishing and Wax Application machine -- Intermediate Conveyor -- ROTOPLUS 1350 BRILL 15x - Buffing Polishing machine -- Outfeed Conveyor -- Synchronization of feed speed of all equipment in the line, the Rotoplus machines including all conveyorsFollowing are the full specifications: -- Infeed Conveyor, 1.500 x 1.350 mm (59" x 53") Constant pass line 900 mm (35") +/- 40 mm (1-9/16"). Variable feed speed inverter controlled and electronically controlled for synchronized speed and transfer with all other machines of the line.Feed speeds from 0,4 to 8 m/Min (1,3 - 26 FPM). -- ROTOPLUS 1350 LUC 5+1Polishing and Wax application machine for high gloss lacquered wood panels for Polyurethane lacquer or brilliant straight, brushes adjustable at different angles. Equipped with (1) longitudinal Brush Head plus (5) rotating brushes on carousel.1st STATION - Longitudinal Polishing Brush:Cleaning polishing cotton brush diameter 275 mm (10-13/16").Length of the brush 1,420 mm (55-5/16").Brush inclined 3° in respect to the parallel 180°.Automatic low pressure Spraying Gun.Longitudinal chain rail system for gun movement.Electric adjustment of the working pressure, operated from main touch screen control unit.Main motor power 7,5 kW (10 HP).Rotating speed adjustable from 260 to 960 RPM by means of inverter 7,5 kW (10 HP). 2nd STATION - Polishing Carousel: CAROUSEL with (5) Brushes.Max. Brush diameter: 350 mm (13-3/4").Spindle diameter 80 mm (3-1/8").Spindle length: 400 mm (15-3/4").(5) Independent motors, 5,5 kW (7,5 HP) each, with counter bearing supports.The working angle of the brushes is adjustable.Variable speed adjustable from 3 to 36 RPM by means of electronic inverter, driven by 4 kW (5,5 HP) motor.Clockwise and anti-clockwise direction of rotation.Programmable speed control operated from main electronic touch screen display. (5) Special shafts for brushes support EXTRA in addition to the standard ones.(5) Cotton rags 350 mm (13-3/4") to fit the shafts.Automatic System for Abrasive Wax application:Pressurized tank (50) liters for liquid abrasives, with automatic miscellaneous bottom exit and pressure regulator for gun.Low pressure spraying gun for liquid abrasives.Electronic valve for spray gun control.Infrared high precision photocell to detect the panels and activate the spraying gun.Adjustable support for spraying gun positioning.Software and graphic control, programmable through PLC and touch screen. Software and Plug for Telemetry. Computer remote diagnostics control: Direct computer connection between EMC and customer, for online support. -- Intermediate Conveyor, 1.500 x 1.350 mm (59" x 53"), Constant pass line 900 mm (35") +/- 40 mm (1-9/16"). Variable feed speed inve

Call for Price

EMC FLEXY 1350 2RP Finishing Sander with (2) Sanding Heads, Roller and Segmented Finishing PadUseful working width 1,350 mm (53"). Working thickness min./max. 3 - 180 mm (1/8" - 7-1/16"). Head configuration:1st Head: Roller "R" Belt dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 250 mm (10"). -- Roller rubber hardness 85 Shore. Constant control to any position with accuracy 0.02 mm. -- Electronic motorized roller pressure adjustment "grit-set system". -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (15 HP). Automatic star-delta starter. -- Abrasive belt cutting speed: 18 m/Sec (59 FPS). Oscillating abrasive belt blower for the roller unit.2nd Head: Segmented Finishing Pad "P" Electronic PAD segmented in (50) sections. -- Belt dimensions: 2.620 x 1.370 mm (103" x 54"). -- Width of the segmented element (section): 27.0 mm (1-1/16"). -- Rotation: Against feed (clockwise). -- Timed oscillating abrasive belt blower. -- Motor power: 11 kW (15 HP) with electronic inverter variable abrasive belt speed 3 to 18 m/Sec (9.8 - 59 FPS).Feed system:Constant pass line, 900 mm (35.4") from floor ● Vacuum conveyor bed, 4 kW Vacuum unit for holddown of smaller parts, mounted inside of the machine base. ● Idle table rollers support in infeed and outfeed. ● Rubber covered presser rollers, grooved. ● Variable feed belt speed, adjustable from 3 to 18 m/Min (9.8 - 59 FPM) Inverter Controlled. ● Large diameter screws on machined guides with columns and pistons. ● Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized "grit set" system; control from touch screen for each working group (head).Electronic programmable color TOUCH SCREEN display, 10" wide ● PLC with micro-processor of latest generation, modular and expandable ● Connection USB, RS232, Ethernet 10/100/1000 ● Memory capacity: 100 working programs or more ● Graphic synoptic to facilitate programmingSoftware facilities: -- Automatic motor sequence starting. -- Display report and reset of alarms (self diagnostic) with memory records. -- Command, programming and display for:● all electronic pad functions● thickness● feeding● all inverters and for selected groups (heads).● blowers, including compressed air saving function.Centralized Control Cabinet: IP 54 protection against dust & moisture. Analog ammeter on main control cabinet. Table lifting-lowering thickness system electrically controlled. AUTOMATIC Delta - Star starter on abrasive belt motors. Centralized Independent Pneumatic Control Cabinet: IP 54 protection. Pneumatic air filter with automatic water-drain system. Pneumatic adjustment for "Grit set system". Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI) Options Available: Tampico Brush natural fiber brush for cleaning of

$177,500

EMC UNDERTOP 1300 2+2 - Wide Belt Sanding Line Top + Bottom, both with (2) Sanding Heads; Steel Roller, Rubber covered Roller.This machine is equipped to process cement fibers!Useful working width 1,300 mm (51"). Working thickness min./max. 3 - 160 mm (1/8" - 6-5/16"). Both Bottom + Top units are equipped as follows:1st Head: Steel Roller "R", Belt dimensions: 1,900 x 1,320 mm (74" x 52"). -- Roller diameter:190 mm (7-1/2"), spirally grooved. -- Constant control to any position with accuracy 0.02 mm. -- "Grit-set system" for sanding belt grit compensation. -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (30 HP) with Automatic star-delta starter. -- Abrasive Belt cutting speed: 21 m/Sec (69 FPS). -- Air Jet Blower for abrasive belt cleaning.2nd Head: Roller "R", Rubber covered, spirally grooved. Belt dimensions: 1,900 x 1,320 mm (74" x 52"). -- Roller diameter:190 mm (7-1/2"). Shore hardness 85. -- Constant control to any position with accuracy 0.02 mm. -- "Grit-set system" for sanding belt grit compensation. -- Rotation: Against feed (clockwise). -- Motor power: 15 kW (20 HP) with Automatic star-delta starter. -- Abrasive Belt cutting speed: 21 m/Sec (69 FPS). -- Air Jet Blower for abrasive belt cleaning. Feed system: -- Constant pass line, 980 mm (38-9/16") from floor. -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 19 m/Min (9.8 - 62 FPM), Inverter Controlled, synchronized feed speed between both machines. -- Motorized height adjustment on (4) precision screws. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device. -- Pre-welded machined working table. -- Pneumatic air floating pressure holddown shoes at infeed, in middle position, and in outfeed position. These pressure holddown shoes are chrome hardened for processing of cement fibers!General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each (head) working group. Electronic programmable color TOUCH SCREEN LCD display, 7" wide -- Resolution 640 x 480 pixels. -- PLC with micro-processor of latest generation, modular and expandable. -- Memory capacity: (100) working programs or more. -- Graphic synoptic to facilitate programming. Front protection IP 65 against dust & moisture.Software facilities: -- Automatic motor sequence starting. -- Display report and reset of alarms (self diagnostic) with memory records. -- Command, programming and display for: ● all electronic pad functions. ● thickness. ● feeding. ● all speed control inverters. ● selected groups. ● blowers, including compressed air saving function. Options Included: -- Vacuum beds both on top + bottom, 4 kw (5,5 HP) each. Vacuum unit for holddown of smaller parts, mounted inside o

EMC EXPLORER 1100 2RK ... Wide Belt Sander with (2) Sanding Heads; Roller and Combination head roller/pad.Versatile, medium duty machine, ideal for cabinet shops etc.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 1,900 mm (75") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Head configuration:1st Head: Steel Contact Roller -- Roller diameter 142 mm (6") -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. -- Motor power 11 kW (15 HP). -- Automatic Star-delta starter. -- Speed rotation: 18 m/Sec (59 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (6"). -- Rubber covered roller with hardness 45 Shore. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. Flexible sanding pad. Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 17 m/Sec (55.8 FPS). --Driven by same main motor.Abrasive belts oscillation by means of electronic photocell sensor.Feed System: -- Working thickness min./max. mm 3 - 190 (1/8" - 7-1/2"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt, machined. Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Centralized Control Cabinet: -- Control panel with self-diagnostics alarm control unit. -- Analog load meters on main control cabinet. -- Table lifting-lowering thickness system, electrically controlled. -- AUTOMATIC Delta - Star starter on main motor and IP 54 protection against dust & moisture. Centralized Independent Pneumatic Control Cabinet: -- Pneumatic air filter with automatic water-drain system. -- Pneumatic adjustment for "Grit set system". --Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). IP 54 protection against dust & moisture. Safety Features: -- Anti-kickback infeed protection. -- Oversized parts infeed protection by swinging bar. -- Emergency push buttons front & rear. --Automatic brakes on main motor. -- Automatic emergency stop and alarm displayOption: TAMPICO Cleaning Brush, 150 mm (6") diameter. Please add ...$3,400USA UL or Canada CSA Safety Features

Call for Price

EMC MERCURY 1350 2RK ... Wide Belt Sander with (2) Sanding Heads; Roller and Combination head roller/pneumatic pad.Versatile, medium duty machine, ideal for cabinet shops etc.TECHNICAL DATA: -- Useful working width 1,350 mm (53"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 2,200 mm (86-5/8") x (width) 1,320 mm (52"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). Head configuration:1st Head: Steel Contact Roller -- Roller diameter 180 mm (7"), spirally grooved. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- Motor power 11 kW (15 HP) driving both heads, with soft starter. -- On/Off Selector control with pneumatic piston to select roller. -- Automatic Star-delta starter. -- Speed rotation: 18 m/Sec (59 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 140 mm (5-1/2"). -- Rubber covered roller with hardness 45 Shore. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. -- New pneumatic aluminium sanding pad, lamina 40 mm. With On/Off selector. -- Quick Change System for removable pad with felt, rubber and graphite. -- Rotating cutting speed 18 m/Sec (59 FPS). -- Driven by same main motor, with soft starter.Abrasive belts oscillation by means of electronic photocell sensor.Feed System: -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt, machined. Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). -- Table rollers. Extension supports with idle rollers in infeed & outfeed.Centralized Control Cabinet: -- Control panel with self-diagnostics alarm control unit. -- Analog load meter on main control cabinet. -- Table lifting-lowering thickness system, electrically controlled. -- AUTOMATIC Delta - Star starter on main motor and IP 54 protection against dust & moisture. Centralized Independent Pneumatic Control Cabinet: -- Pneumatic air filter with automatic water-drain system. -- Pneumatic adjustment for "Grit set system". -- Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). IP 54 protection against dust & moisture. Safety Features: -- Anti-kickback infeed protection. -- Oversized parts infeed protection by swinging bar. -- Emergency push buttons front & rear. --Automatic brake on main motor. -- Automatic emergency stop and alarm displayUSA UL or Canada CSA Safety Features

Call for Price

Plant Boiler System for up to 60,000 pounds of steam production per hour (1790 HP) with the following features and main components: -- (2) ENGLISH BOILER AND TUBE, INC. Boilers each rated for 20,700 pounds of steam per hour each. However, manufacturer specified they can be operated at 30,000 pounds per hour with dry wood or bark fuel (12 percent moisture). -- 250 PSI operating pressure ratings on each Boiler. -- VFD Drives on all main Motors. (The plant uses a maximum 75 HP for each boiler.) -- Electrical Controls. -- (1) Boiler has an Oil Burner for operating optionally on oil if sawdust or wood chips is not available. -- Chemical Water Conditioning System and Pumping System. -- De-aerator and Condensate Tank. -- Multi-clones for particle emissions reduction and abatement. -- (2) Fuel Storage Silos (25’x40’ & 20’x38’) with LAIDIG Model 243 Track-Driven Unloaders. -- Fuel Transfer Conveyors. -- The Silos also are included at the price shown and are available individually. See our listings DB-010162 and DB-010163 for details and individual pricing. -- Boilers can be purchased individually or as a pair. -- Professional removal and installation services are available.

Industrial Grade EUROVAC I Cyclone Separator & Cartridge Dust Collector Combination. -- Primary Separator: Cyclone on support stand and barrel waste collection: (A Rotary Air Lock with a larger waste bin can be added). Cyclonic action can remove up to 99% of dust and particles. -- SYS-030 Secondary Dust collection: Remaining 1% of dust collected using Cartridge Filter which are automatically cleaned by Pulse Jet cleaning using compressed air housed in a separate compressed air storage tank. -- Vacuum Producer: Heavy Duty cast iron turbine type pump with 10 HP energy efficient squirrel cage motors designed to run continuously all day. built-in thermal heat protection device, and overload protection in Control Panel. High 85" WC vacuum level. -- Control panel house pump starter controls with hand/auto selector for on demand starting. -- Features: Quiet operation with built sound deadening. Diaphragm valves for pulse jet cleaning. -- Approximate dimensions: 180" long x 70" wide x 72" high.

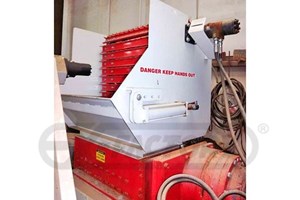

EVASHRED EV60E Dual Shaft Shredder with Infeed ConveyorEvashred is a well-known brand of commercial mobile and stationery shredders for solid waste designed and manufactured by F.V. Evans and Sons also known as Evans Engineering.Every type of shredder is designed specifically to shred a particular type of solid waste including Documents, Car & Truck Tyres, E-scrap (Hard Drives, Computers, Printers known as E-waste and e-scrap), Plastic, Foam rubber, Green Waste, Building Waste even Hospital WasteSpecifications: --30 kW / 40 HP Maximum Power --28-30 RPM Cutter Speed Rotation --Width 640 mm x 37 5mm Cutting Chamber Opening

$1,250

Used for the accurate radius measuring of cutterheads; allows for speedy tool changes on moulder. 12" Long x 6-1/2" base, 1-1/2" dia. arbor will handle up to 9-1/4" long tool body. -- Digital caliper rides up and down on precision machined octagonal bar. -- Options: T-bushings for 1-13/16" dia. & 40mm dia., please specify.