704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1718 Results Found

704-841-2001

Call for Price

PUTSCH EBP 950PMCR EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): Specifications: -- Edge material thickness 0.4 - 3 mm coil & up to 5 mm strips.Min./max. panel thickness "all units" 8 - 50 mm (0.39" - 1.97"). Max. material thickness when using CR unit is 1.77" (45 mm). Min. panel width: 95 mm (3.7") & 110 mm (4.3") min. length.Fixed feed speed of 9 MPM (29.5 FPM).Equipped with: -- Automatic coil feed magazine with an oscillatory cutting shear for uninterrupted edge feed. -- Gluing Unit: Teflon coated glue tank, approx. 10-minute heat-up time. -- Side Pressure Unit: 3-roll pressure unit w/1st roller power driven via clutch with pneumatic in & out positioning, (2) idler rollers.Workstations: -- Pre-Milling Unit: (2) 2.0 HP (1.5 kW) motors with (2) opposing 60 mm diamond cutters that are micro-adjustable to mill up to 2 mm from the panel edge for optimal, chip-free glue application. -- End Trimming Unit:(1) 0.3 HP (0.2 kW) - 12,000 RPM Motor, automatic single motor end trim unit with (2) 80 mm blades. -- Top & Bottom Trimming Unit: (2) 0.5 HP (0.37 kW) - 12,000 RPM ea. Motor with 75 mm cutters (with disposable knives) that offer a straight 2 mm radius / 15° bevel.The flush trim unit also includes 120 mm scratch-resistant vertical disc copiers that are ideal for delicate finishes. -- Corner Rounding Unit: NOTE: When using CR unit, the max. material thickness is 1.77" (45 mm) & min. panel length is 7.78" (200 mm).(1) 0.3 HP (0.2 kW) - 12,000 RPM Single motor Corner Rounding unit for leading & trailing edges. The corner rounding unit is fixed to the frame crossbeam on double linear guides and features 50 mm cutter blocks, as well as vertical/horizontal 50 mm diameter copiers for profiling straight, curved, and beveled edges. -- Edge Scraping Unit: Top & Bottom PVC Scraper for up to 3 mm radius, complete with 3 mm scrape shaving collection box. Programmable, pneumatic exclusion on/off. -- Buffing Unit:Top & bottom buffing unit (2 x 0.2 HP - 1,400 RPM motor each), tilting range 8°.Controller: "ETOUCH" Touch Screen Control for the "EBP 950" Series; the ETOUCH touch screen control is a 7-inch color programmable display.Operators can store up to (99) working programs and connect to an optional network to read statistical data, diagnostic messages and online updates.The Control permits the operator to engage or disable specific work operations, while also providing immediate access to diagnostic messages and statistical data such as hours of operation and length of coil used.Complete with:Track Drive Chain feed speed 9 MPM (29.5 FPM).(2) Rows of upper pressure wheels in holddown beam.Adjustable material support outrigger.Sound & Safety Hoods.Used Tooling -- Actual Model is PUTSCH EBP 950PMCR.

Call for Price

CASADEI (PUTSCH-BRANDED) EBP-320 Compact Edgebander – New, Never Used!NOTE: If Buyer desires, our technicians can convert machine from 3-Phase to Single-Phase power for additional cost.Specifications: -- Edgebanding thickness 0.4 to 2 mm (0.02" - 0.08"). -- Max. coil dia. 600 mm (23.62"). -- Panel thickness 10 - 45 mm (0.39" - 1.77"), Min. panel width 110 mm (4.33"), Min. panel length 220 mm (8.66"). -- Feed speed 7 MPM (22 FPM).Equipped with: -- 3-Position Infeed fence, 0 mm, 1 mm, & 2 mm. -- 1 kg (2.2 Lbs.) Cap. Teflon-coated glue pot, (6) Heating elements, & Thermostatic glue control with Automatic standby & Temperature display. -- Pneumatic guillotine. -- Pressure section, (1) Silicone roll & (2) Nylon rolls. -- 0.8 HP Feed belt motor. -- PLC Control, with Backlit LCD display & Touchpad. -- Sound enclosure, Outrigger panel support.Workstations: -- Front & Rear End Trim Unit. -- Top & Bottom Flush Trim Unit, with (2) 0.37" kW (1/2 HP) - 10,300 RPM Motors, Straight or Bevel cutters, & 75 mm (2.95") Dia. Cutterheads with Knife inserts for 2 mm (0.08") Radius or 15° Bevel.Complete with: -- Instruction & Maintenance Manual.NOTE: Sold "As-Is" Without Warranty!

Call for Price

CASADEI (PUTSCH-BRANDED) EBP-320 Compact Edgebander – New, Never Used! – 3-PhaseSpecifications: -- Edgebanding thickness 0.4 to 2 mm (0.02" - 0.08"). -- Max. coil dia. 600 mm (23.62"). -- Panel thickness 10 - 45 mm (0.39" - 1.77"), Min. panel width 110 mm (4.33"), Min. panel length 220 mm (8.66"). -- Feed speed 7 MPM (22 FPM).Equipped with: -- 3-Position Infeed fence, 0 mm, 1 mm, & 2 mm. -- 1 kg (2.2 Lbs.) Cap. Teflon-coated glue pot, (6) Heating elements, & Thermostatic glue control with Automatic standby & Temperature display. -- Pneumatic guillotine. -- Pressure section, (1) Silicone roll & (2) Nylon rolls. -- 0.8 HP Feed belt motor. -- PLC Control, with Backlit LCD display & Touchpad. -- Sound enclosure, Outrigger panel support.Workstations: -- Front & Rear End Trim Unit. -- Top & Bottom Flush Trim Unit, with (2) 0.37" kW (1/2 HP) - 10,300 RPM Motors, Straight or Bevel cutters, & 75 mm (2.95") Dia. Cutterheads with Knife inserts for 2 mm (0.08") Radius or 15° Bevel.NOTE: Sold "As-Is" Without Warranty!

Call for Price

CASADEI (PUTSCH-BRANDED) EBP 420 PMVR Compact Edgebander – New, Never Used!Specifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual Feed. -- Max. coil dia. 800 mm (31.50"). -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), Min. panel length 210 mm (8.27"). -- Feed speed 7 MPM (22 FPM).Equipped with: -- Pre-mill unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-adherence spraying unit, with PLC-Controlled spray function, Lower & Upper Sprayer, and Liquid tank. -- 1 kg (2.2 Lbs.) Cap. Teflon-coated glue pot, with (6) Heating elements, & Thermostatic glue control with Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section. -- Feed chain pads, with Replaceable rubberized surface inserts. -- Rubberized hold-down rollers. -- PLC Control, with Backlit LCD display & Touchpad. -- Safety enclosure.Workstations: -- VR Front & Rear End Trim Unit, with 0.22 kW (0.3 HP) - 2,700 RPM Motor, Vertical rounding function, & (2) Processing modes: Straight (thin edges & wooden strips) & Radius (ABS & PVC thick edges). -- Top & Bottom Flush Trim Unit, with (2) 0.22 kW (0.3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutterheads, & 2 - 3 mm (0.08" - .012") Radii. -- Edge Scraping Unit, with Box. -- Top & Bottom Scraping Unit (Flush Trim Unit), with 120 mm (4.72") Vertical disc copier. NOTE: Sold "As-Is" Without Warranty!

Call for Price

CASADEI (PUTSCH-BRANDED) EBP-320 Compact Edgebander – New, Never Used! – Single-PhaseSpecifications: -- Edgebanding thickness 0.4 to 2 mm (0.02" - 0.08"). -- Max. coil dia. 600 mm (23.62"). -- Panel thickness 10 - 45 mm (0.39" - 1.77"), Min. panel width 110 mm (4.33"), Min. panel length 220 mm (8.66"). -- Feed speed 7 MPM (22 FPM).Equipped with: -- 3-Position Infeed fence, 0 mm, 1 mm, & 2 mm. -- 1 kg (2.2 Lbs.) Cap. Teflon-coated glue pot, (6) Heating elements, & Thermostatic glue control with Automatic standby & Temperature display. -- Pneumatic guillotine. -- Pressure section, (1) Silicone roll & (2) Nylon rolls. -- 0.8 HP Feed belt motor. -- PLC Control, with Backlit LCD display & Touchpad. -- Sound enclosure, Outrigger panel support.Workstations: -- Front & Rear End Trim Unit. -- Top & Bottom Flush Trim Unit, with (2) 0.37" kW (1/2 HP) - 10,300 RPM Motors, Straight or Bevel cutters, & 75 mm (2.95") Dia. Cutterheads with Knife inserts for 2 mm (0.08") Radius or 15° Bevel.NOTE: Sold "As-Is" Without Warranty!

Call for Price

QUICK N-P50 Fixed Daylight Opening Air Pod PressThis Pod Press can produce a maximum 50 PSI platen pressure over the entire surface at 100 PSI supply air pressure. Press has a fixed vertical daylight opening of 44". The (18) 12.8" max. diameter air pods have 5.9" stroke.Material conveyance is via automatically extending and retracting (via pneumatic cylinders) non-powered roller tracks. A cycle timer provides visual and audible signals at the end of each cycle if desired, and also automatically releases platen air pressure at the end of each cycle, if desired.Specifications: -- Maximum platen pressure: 50 PSI at 100 PSI supply pressure. -- Lower platen dimensions: 4' x 8' -- End-loading or Side-loading: End-loading -- Number of upper platens: 1 -- Upper platen(s) dimensions: 4' x 8' -- Vertical opening: Fixed at 44" -- Lower platen Non-powered roller tracks. -- (18) 12.8" diameter, 5.9" stroke air pods. -- Number of air pressure zones: 1Lead Time: Approximately (12) weeks from time of order.Actual Model: N-P50-04-08-EL-1PL-F-44-R-1ZNOTE: Please let us know of any "Special or Specific" safety equipment requirements that you may have prior to order

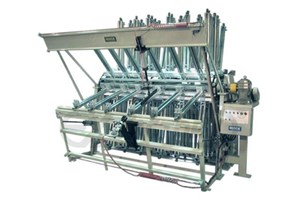

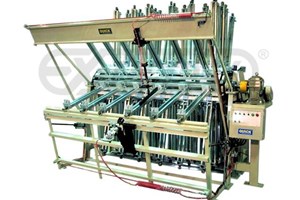

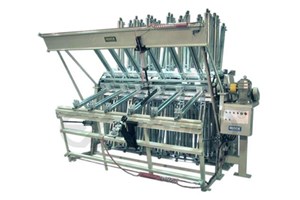

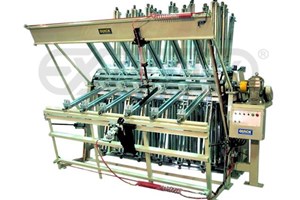

Quick Hydraulic Clamp Carrier with 20-sections and 12-1/2' width capacity.This special "thick stock" frame accepts (12) Heavy Duty zinc plated clamps per section. Includes: -- 240 clamps with 36" openings and 6" high x 4-3/4" wide jaws with 1° inward draft. -- Integral hydraulic overhead panel flattener. -- Automatic hydraulic clamp tightener with adjustable torque limiter. -- Single button automatic electric motor rotation cycle with indexing. -- The machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

Call for Price

Quick Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section with 52" opening. -- Includes 160 clamps with 52" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener riding along with tightener -- Semi-Automatic Pneumatic clamp tightener . -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

Quick Heavy Duty 14-Section Hydraulic Clamp Carrier, 16-1/2' Wide -- 14-Section Clamp Carrier 16-1/2' width cap.. -- (12) Heavy Duty zinc plated clamps per section for (168) total clamps. -- 38" opening on clamps; jaw sizes on clamps are 3-1/2" high x 4-3/4" wide with 1° inward draft. Equipped with: -- Dual Overhead Pneumatic Panel Flatteners for (2) operators -- Dual Hydraulic Clamp Tighteners for (2) operators -- Automatic Electric Motor Rotation with Indexing. -- Standard features include: Foot levelers, coiled air lines where used and flexible conduit for wires.

QUICK 14-Section Pneumatic Clamp Carrier with 8-1/2' width capacity With (6) Standard zinc plated clamps per section (84 clamps total), 32" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. The automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- 14-Section Clamp will produce 300 panels per shift; 20-Section machine, 500 panels per shift.

QUICK 6-Section Pneumatic Clamp Carrier with 20-1/2' width cap. & Dual Operator's Stations, -- (16) Heavy Duty zinc plated clamps per section (96) clamps total), 50" opening on clamps. Jaw sizes of clamps is 3-1/2" high x 4-3/4" wide, with 1° inward draft. Equipped with DUAL OPERATOR'S STATIONS including: -- (2) Pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners -- Semi-automatic rotation via electric motor drive; with separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In.Standard Supply includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

QUICK 6-SECTION, 12-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp, typically produces (144) high-quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (9) clamps per section and 12-1/2' width capacity. -- (54) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- Rocker Plates are available as optional equipment for face gluing. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy-to-use controls. -- Pneumatic Clamp Tightener with a 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; the 2-handed, trigger-activated tightener is more confidence-inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, and automatic air line oiler; -- High-quality Urethane finish coating, and tool box with spare parts & tools.Floor space requirement: 195"W X 125" H X 127"D

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

QUICK 14-Section Heavy Duty Hydraulic Clamp Carrier with 20-1/2' width capacity With (16) Standard zinc plated clamps per section (224) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Pneumatic Panel Flattener with easy to use controls. -- Pneumatic panel flattener for second operator -- Hydraulic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic clamp tightener for second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. -- NOTE: Clamp Carrier can be expanded to (14) or (20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

Call for Price

QUICK 20 Section Automatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 32" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Pneumatic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 16-1/2' width capacity and Glue applicatorWith (15) Standard zinc plated clamps per section (210 clamps total), 48" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment (2) Panel Flattener with easy to use controls.(2) Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.14-Section Clamp will produce 300 panels

QUICK 40 Section 10.5' Heavy Duty Hydraulic Clamp Carrier: -- Clamp Carrier: (40) Sections with 10-1/2' width cap., -- (10) heavy duty zinc plated clamps per section (400 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment.Equipped with: -- (1) Hydraulic clamp tightener for 10.5' -- (1) Hydraulic clamp tightener 10.5' for second operator -- (1) Pneumatic Panel Flatteners for 10.5' wide -- (1) pneumatic panel fattener 10.5' wide for second operatior -- Electric Motor Drive with fully Automatic Carrier Rotation Cycle.Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quiet -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.Note: this machine has 2 hydraulic tightener and 2 Pneumatic panel flattener for (2) operator)If one operator is fine the machine price could be reduce by $3,600