704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1718 Results Found

704-841-2001

Call for Price

BELFAB NBM6-30 CHIP & DUST TRANSFER DUST COLLECTOR Patented Modular Technology and heavy-duty construction for exterior use. Heavy Duty construction designed for interior or exterior use.Specifications: -- Each "NBM" filter module is fitted with; (1) service door & (1) explosion door per NFPA safety regulations, and integrated compact hopper. -- Rated Capacity: Rated @ 9,000 CFM @ 9.5" static pressure, 7,600 CFM @ 10.4 static pressure. -- Equipped with: Direct drive centrifugal fan assembly with 30 HP "Hummer" blower motor, anti-spark cast aluminum impeller, 20" inlet diameter. Unit Includes: -- (6) "NBM" filter modules, each with (18) 7" x 60" Poly Twill cloth filter tubes; 990 sq. ft. total cloth area (165 sq. ft. per module) w/Continuous Dust Disposal Capacity. -- Pneumatic Chip / Dust Transfer System with (1) 7.5 HP and (1) 5 HP material handling blowers, continuously discharges chips and dust for re-cycling or disposal. -- (1) Electrical Control Panel w/ Shaker Mechanism to include; (4) Interlock Starters; (1) Soft start for the main blower, (2) for the Pneumatic Dust Transfer System and (1) for the shaker mechanism.Security System for Air Return: -- (1) 20" Explosion Back Draft Damper, (1) 24" Fire Damper with status signal, (1) 24" Derivation Tee, (1) 24" Abort Damper and (1) Single Zone Spark Detector. (Optional; pricing upon request)CALL FOR PRICING

YM-800 1 YARD 4 OR 5 TINE Orange Peel GrappleSpecifications: -- Operating Weight 2,400lbs -- Opening Width 71 1/8" -- 4 or 5 Tine in stock - Ready to ship -- Rotating -- Hanger for Extra Cost

Call for Price

BIESSE - Stream A 6.0. ... Edgebander (w/Premill & Corner Ronding), High Production w/NC Axis PackageFeatures: -- "NC Axis Package": The machine adapts to the process being executed based on the edge's thickness and material.Machine management ...100% touch with no need for external devices. - Intelligent language management.Easy program management and usability with rapid transition from one machining operation to the next. Specifications: -- Edgebanding Capacity: Edge thickness for strips: Min./max. 0.4 - 22 mm (0.02" - 0.87"); coiled material from 0.4 - 3 mm (0.02 - 0.12").Panel thickness from: 10 - 60 mm (0.39 - 2.36"); workpiece width: Min. of 85 mm (3.34"); workpiece length: min. 140 mm (5.51").Feed speeds of: 12 - 18 - 20 - 25 MPM (39 - 59 - 65 - 82 FPM).Machine Infeed Configuration: -- Premilling Station:(2) 1.8 kW (2.4 HP) - 12,000 RPM Motors; LH & RH Counter Rotating Spindles; NC (Servo) controlled with automatic intervention that guarantees a perfect base for gluing. -- Anti-Adhesive:Automatic Spray Unit with: Glue release agent preventing glue to adhere to workpiece's surfaces. -- Infrared Heating Lamp:Preheating workpiece edge to ensure best possible surface adhesion quality of edgebanding material. -- Edge Magazine: Automatic 2-coil/position magazine for processing coiled & strip edgebanding material in real time. -- Pressure Section:Servo Controlled programmable pressure section with: (1) Large driven roller and (4) idle rollers.Gluing System w/Premelter: -- EVA (Hot Melt), quick premelting granulate with: Glue roller applicator to cover conventional edgebanding material. Workstations: -- End Trimming: Front & Rear Linear end trimmer with: Tilt Function for high speeds with (2) 0.8 kW (1.0 HP) - 12,000 RPM motors. The machine axis movement on linear tracks allows the achievement of very high processing speeds.The copying & tracing system guarantees optimal finish quality; also on high gloss edges with film. -- Flush/Bevel Trimming Unit:Top & Bottom flush or bevel trims with: (2) "Quick Change" 0.65 kW (0.8 HP) - 12,000 RPM motors. -- Fine Trimming Unit: (2) 0.65 kW (0.8 HP) - 12,000 RPM Motors; (2) Servo motors for tool positioning (one for horizontal tool position, one for up/down tool position).Prepositioning of motors by pneumatic air cylinders while using a combination bevel/radius/flush insert knives.Absolute machining flexibility thanks to the full adjustment of the machine according to the required edge thickness. -- Corner Rounding Unit: (2) 0.65 kW (0.8 HP) - 12,000 RPM Motors for front/back corner and upper & lower edge profiling.The controlled axis on the Corner Rounding unit supports the management of infinite machining settings. -- Profile Scraping Unit:Top/Bottom 2-axis NC programmable knife positioning (i.e. 2 - 3 mm radius) for PVC edges. -- Glue Scraping Unit: Flat, top/bottom, digital positioning indicators, pneumatic controlled for in/out position. -- Buffing Station: Top & Bottom buffing motors:

$26,500

BIESSE - AKRON 440 AX Edgebander (w/Premill & Corner Rounding): -- Specifications: Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood. -- Edge & Workpiece Capacity: 0.4 - 3 mm (0.016 - 0.12") Edge; 10 - 60 mm (0.39 - 2.36") panel thickness; 140 mm (5-1/2") min. panel length, and 85 mm (3.3") min. width. -- Working Units:Premilling Station: (2) 3 kW (4 HP) - 150 Hz, 9,000 RPM Motors; equipped with panel blowoff device and SIKO digital counters for adjustments. -- EVA Gluing Unit: Edge Feeding & Pressing Unit; automatic loading of tape in rolls and strips; quick-change glue pot system. -- Pressure Section: (1) Large 150 mm dia. driven & (5) idle pressure rollers. -- Feed Speeds: Operating feed speeds 12 & 18 MPM (39 & 60 FPM). -- Workstations: Double Motor End Trim; tiltable from 0° - 15°; each motor 0.8 kW (1 HP) - 12,000 RPM; sliding in a slicing motion on a 45° precision guide bar with oversized bearing blocks. -- Top & Bottom Trimming: (2) Motors 0.65 kW (0.87 HP) each; "Pro-Nesting" copiers; cutters R=2 mm. -- Fine Trim/Corner Rounding Unit: (2) Motors; each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material, and wood edge banding up to 3 mm max. edge thickness. -- Top & Bottom Flat Glue Scrapper: To remove potential glue squeeze out. -- Buffing Station: Top & Bottom, (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM. -- Operator Interface:Operator Control Panel, "HDI" High-Definition touchscreen control, Windows XP based. -- User-friendly graphic user interface with diagnostic and assisted maintenance. -- USB and Ethernet port; 1.44 MB floppy drive, automatic or manual startup. -- Complete with:High frequency motors (200 HZ): Padded sound enclosure. -- Top pressure beam with staggered double-row holddown wheels mounted on ball bearings. -- Actual Model is: BIESSE AKRON 440 AX

Call for Price

BIESSE - JADE 240, ...Edgebander w/Premill & Corner Rounding -- Specifications: Edgebanding thickness: 0.4 - 8 mm (0.01" - 0.31"); Min. panel width 85 mm (3-1/2"); min. length 150 mm (5.9"); max. panel thickness 10 - 60 mm (0.39 - 2.36"). -- Premill Unit: (2) 1.8 kW (2.4 HP) - 12,000 RPM Motors; "AUTO-SET" device ensures optimum positioning of the cutters according to the thickness of the panel being machined; numerical readout; pneumatic exclusion when not needed. Workstations: -- End Trimming: Front & rear end trims: 0.8 kW (1.0 HP) - 12,000 RPM Motors; motors travel on 45° slides and pneumatic tilt 0° - 15° from the Control Panel. -- Flush/Bevel Trimming Unit: Top & bottom flush or bevel trims with: "Quick Change" Motors; 0.65 kW (0.8 HP) - 12,000 RPM motors; digital readouts for easy setup. -- Corner Rounding Unit: (2) Motors, 0.65 kW (0.8 HP) - 12,000 RPM for trimming leading & trailing upper & lower edge/corners with 2-position pneumatic set-up for corner rounding. -- Edge Scraping Unit: Finishing unit to eliminate previous machining imperfections; pneumatic exclusion from the machine control. -- Glue Scraping Unit:Top & Bottom scrapers for 3 mm thick PVC banding. -- Buffing Station: Top & Bottom.Operator & Machine Control: -- BIESSE "Smart Touch 7" + Windows Operating System: User-friendly touchscreen Control Panel for workstations; rotating Operator Control Panel w/keypad and LCD readout.Graphic 7" display touchscreen; high-resolution screen for defined and intuitive images and text; integrated 4 GB hard disk for filing media files and the programs back up.USB Port for managing in a simple and efficient way multimedia files, programs, and updates; Ethernet port for connecting the machine to the net.Complete with: -- Top pressure beam & motorized feed track with "anti-slip" "Quick Change" snap on 80 mm wide x 60 mm long rubber pads; low friction nylon graphite self-lubricating chain pads. -- Sound Enclosure & Panel Support: Over all trimming stations; industrial lights and viewing windows; extendable side panel support rail. -- Fixed feed speed at 39 FPM (12 MPM); 3 HP feed drive.Options include: -- Anti-Adhesive Unit:The unit applies an anti-adhesive liquid on the Top & Bottom surface of the panel. It is positioned before the Premilling Unit.The anti-adhesive liquid is applied with precision by means of injectors controlled by the machine control. -- Nesting Package:Allows trimming of premachined panels. -- Transformer:230 Volt autotransformer. -- Actual Model is BIESSE JADE 240

Call for Price

--at Auction, Seller Loading, Powered Inspection Available-- BIESSE AKRON 440 AX Edgebander, with Pre-Mill & Corner Rounding Specifications: - Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood. - Edge & Workpiece Capacity: 0.4 - 3 mm (0.016 - 0.12") Edge; 10 - 60 mm (0.39 - 2.36") panel thickness; 140 mm (5.5") min. panel length, and 85 mm (3.3") min. width. Working Units: - Pre-Milling Station: (2) 3 kW (4 HP) - 150 Hz, 9,000 RPM Motors; equipped with panel blow-off device and SIKO digital counters for adjustments. - EVA Gluing Unit: Edge Feeding and Pressing Unit; Automatic loading of tape in rolls and strips; Quick change glue pot system. - Pressure Section: (1) Large 150 mm dia. driven & (5) idle pressure rollers. - Feed Speeds: Operating feed speeds 12 & 18 MPM (39 & 60 FPM). Workstations: - Double Motor End Trim; Tiltable from 0° - 15°, each motor 0.8 kW (1 HP) - 12,000 RPM; sliding in a slicing motion on a 45° precision guide bar with oversized bearing blocks. - Top and Bottom Trimming; (2) Motors 0.65 KW (0.87 HP) each - "Pro-Nesting" copiers - Cutters R=2 mm. - Fine Trim/Corner Rounding Unit: (2) Motors, each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material and wood edge banding up to 3 mm max. edge thickness. - Top & Bottom Flat Glue Scrapper, to remove potential glue squeeze-out. - Buffing Station: Top & Bottom, (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM. Operator & Machine Control: - Operator control panel, "HDI" High-Definition touch screen control Windows XP based. - User-friendly graphic user interface with diagnostic and assisted maintenance. - USB and Ethernet port. 1.44 MB floppy drive, automatic or manual startup. Complete with: - High-frequency motors (200 HZ): Padded sound enclosure: - Top pressure beam with staggered double-row hold-down wheels mounted on ball bearings. NOTE: Includes new Glue Pot, extra knives & misc. parts.

Call for Price

--at Auction, Seller Loading, Under power & available for inspection!-- BIESSE ROVER 24 FTS CNC Flat Table Machining Center, with ATC & Boring - Specifications: 4' x 10' Flat table design for "Nested Base" processing: Working cap.: X-Axis is 122" (3,100 mm), Y-axis is 49" (1,250 mm), Z-axis is 6.1" (155 mm). - Worktable: Phenolic "MATRIX" grid vacuum table for FT "Nesting" or single part processing using (optional) pods or jigs; (2) side & (4) rear pop-up pins for easy material location. - Positioning Speed: X- & Y-axis 262 FPM (80 MPM), Z-axis 98 FPM (30 MPM); "X-axis uses a helical rack & pinion system, Y- & Z-axis use precision ball screws; all axes movement is on precision linear guides & ways & controlled by digital, brushless AC Servo motors; all motion components are maintained by an automatic lubrication system. - Boring Unit: (1) 4 HP (3.3 kW) - 4,000 RPM motor: (14) independent vertical spindles, (7) in X-axis & (7) in Y-axis; (6) horizontal drills with (2 + 2) in X-axis & (1 + 1) in Y-axis. - Machining: (1) 16 HP (12 kW) Liquid-cooled vertically mounted HSD electro-spindle router with HSK F63 adaptor, inverter driven 1,000 - 20,000 RPM with max. torque from 12,000 - 20,000 RPM; (1) 6-position "Ride Along" Automatic tool changer for "on-the-fly" ATC. - Operator & Machine Control: PC Front End with: BIESSE "XP600 + WINDOWS" XP-operating system; 15" color CRT; 40 GB hard drive; full keyboard & mouse; Ethernet connection capabilities; programs can be transferred via diskette or downloaded by wire; built-in 1,500 W air conditioner for constant temperature & dust-free environment. - Complete with: 11 KVA Stabilized autotransformer for voltages between 220 - 600 V; automatic "forced" lubrication system for guides & ball screw; emergency stop rope & pressure sensitive safety mats that will instantly place machine in "pause cycle" when stepped on; sound absorbing protective head enclosure with debris curtain around bottom edge. - NO Vacuum Pump is included but let us know if needed we can source a good used unit.

BUSELLATO JET 2 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working field: "X" Axis 120" (3,050 mm); "Y" axis 49.2" (1,250 mm); "Z" axis stroke 6.7" (170 mm); max. material thickness 4.7" (120 mm). -- Positioning Speeds:"X" Axis 197 FPM (60 MPM); "Y" axis 197 FPM (60 MPM); "Z" axis 66 FPM (20 MPM).Motion system utilizes Rack & Pinion and precision ball screws driven by AC Servo motors.The working head travels on high precision profile Guide Rail & Way Bearing System. -- Worktable:(6) Support rails with (4) panel lifters for heavy panels; (2) adjustable vacuum pods per rail. -- Boring Unit: 3 HP (2.2 kW) - 4,000 RPM motor; (12) independent vertical spindles: 7-Spindles in "X" axis, 5-spindles in "Y" axis.(6) Horizontal spindles: (2 + 2) Spindles in "X", (1 + 1) spindle in "Y". (1) "X" Axis grooving saw for max 120 mm dia. blade. -- Machining:(1) 10 HP (7.5 kW) Electro spindle with ISO 30 adaptor; variable spindle speed from 1,000 - 18,000 RPM. (1) 8-Position ATC tool plate for "on the fly ATC".(1) Additional 3 HP (2.2 kW) horizontal router mounted in "Y" axis. -- Operator & Machine Control:"PC" Front-End with: "TPA Genesis Evolution 2.2" + Windows 2000 Operating system; 32-bit INTEL Pentium III Processor - 1,000 MHz, 10 GB hard drive.15" Color monitor, international keyboard, soft touch keypad, & industrial mouse; (4) serial ports, (1) parallel port, (2) USB ports, (1) 1.44 MB floppy & (1) CD ROM disk drives. "Genesis Evolution" is a real-time multitask Processing System with data & error diagnostics; programs can be transferred via diskette or possible downloading by wire. -- Complete with:(1) 100 cbm/Hr BUSCH Vacuum Pump; scrap conveyor; safety mats; safety hood; all backup disk, documents, & manuals associated with this machine. -- Actual Model is: BUSELLATO JET 2.

Call for Price

BUSELLATO JET 4002 XL CNC MACHINING CENTER (W/ATC/BORING): -- Specifications Working Field "X" Axis of 168.1" (4,270 mm); "Y" axis of 47.2" (1,200 mm); "Z" axis stroke 9.8" (250 mm); 6.8" (175 mm) max. material thickness. -- Positioning Speed"X" Axis at 230 FPM (70 MPM); "Y" axis at 197 FPM (60 MPM); "Z" axis 49 FPM (15 MPM). -- Worktable(8) Pneumatic locking panel supports; (2) vacuum pods per support.(8) Pneumatic backstops; (2) pneumatic side stops & (2) pneumatic central stops.(4) Independent working zones; jig locking device on (2) work areas. -- Boring Head(1) 4 HP (3 kW) Motor - 4,000 RPM; (20) vertical spindles with (12) spindles in "X" axis & (8) spindles in "Y" axis. -- Machining(1) Vertically mounted 10 HP (7.5 kW) electro spindle with ISO-30 adaptor (0 - 18,000 RPM) with RH or LH rotation; (1) 6-position automatic tool changer.(1) Additional 5 HP (3.8 kW) vertical Routers; Routers are driven by an 11 kW digital Inverter. -- Operator & Machine ControlPC Front-End with: "GENESIS EVOLUTION" 2.2.1 + Windows "NT" Operating System; 15" color monitor; 1.44 MB floppy & 32X CD ROM drives; 8.4 GB hard disk; 64 MB RAM; (2) RS 232 serial ports; integrated modem; Ethernet card, all built into a protective cabinet enclosure.GENESIS Software is continuously online providing real-time information on tool position & error messages; visualization of RPM, current load meter, and more; positioning of panel supports and vacuum cups.Software Features: Automatic generation of G & M code, stop & restart, machine diagnostics, automatic optimization, and full graphic display with the possibility to associate up to (11) parameters and programming of up to (2,000) work lines per single program. -- Complete with:Front safety mats that will instantly place machine in "Pause Cycle" when operator steps onto the mats. -- Actual Model is BUSELLATO- Jet 4002 XL.

$8,750

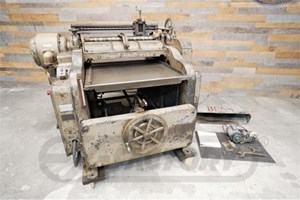

BUSS - 44, ...36" PlanerSpecifications: -- 36" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Knife Grinding/Jointing equipment. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$10,200

BUSS DL 30" X 8" Heavy Duty Wood Planer with GrinderModel DL, , Bed Capacity 30" W x 65" L x 8" H ,Specifications: -- (2) Large steel support rollers on bed, upper area: (1) steel roller -- One (1) cutter-head with (4) knives, one (1) grip-thru roller. -- Heavy duty spring tension adjustment on top of machine. -- Two (2) 15 HP, 3-PH motors; one connected to 20-ratio gear reducer variable feed speed drive and the other connected to the cutter head system. -- Upper cross frame attachment for knife grinder system ( Comes with grinder )Equipped with & Features -- Oil cup & grease fitting lube system. -- Power Raising and lowering of the Planer bed.

$18,200

BUSS DL TYPE Heavy Duty 50" x 8" Single Sided Wood Planer:Specifications: -- Belt-Driven 50" Straight Knife Cutter Head. -- 25Hp Cutter Head Motor. -- Dust hood with 12" Port. -- Chip Breakers -- Grooved Feed Rolls -- Smooth Pressure Roll After Cutter HeadEquipped with & Features -- Top Mounted Grinding Bar -- Manual Height Adjustment -- Leeson SpeedMaster - Adjustable Feed Speed Controller -- Push Button Controls -- Safety Guards

$19,750

BUSS 44-40 STRAIGHT KNIFE PLANER40" x 8" Cap., 30 HP - 3,600 RPM direct drive single top head,Specificatioins: -- 4-knife cutterhead w/high speed steel knives, top sectional -- infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. material thickness. Manual opening with indicator. -- Min. stock length 14" and 4" butted, manual table raise-and-lower; variable speed infeed 28 - 85 FPM. via REEVES power transmission -- Complete with: Knife grinding/jointing equipment, pressure lubricator, push button magnetic control & shaving hood.

$7,200

BUSS - 44, 26" PLANERSpecifications: -- 25" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$14,950

BUTFERING SKO-113-C WIDE BELT SANDER53" Width cap. Combination Head. Combination sanding head with steel contact roll & electronically controlled segmented platen.Specifications: -- Contact roll height position with programmable control. -- Platen consists of 35 mm wide segments designed to conform to part size to minimize sand throughs. -- 53" Wide vacuum bed with 3 kW vacuum pump motor assembly. -- 53" x 75" Abrasive belt with air tensioning and electronic abrasive belt tracking,Equipped with & Features: -- Out-feed rotary panel cleaning brush. -- Touch screen program control with storage up to (125) programs. -- Conveyor belt feed 2 HP motor, Variable feed drive from 8 - 43 FPM. -- Vacuum conveyor bed assembly with suction fan and motor assembly. -- Infeed & outfeed rubber-covered hold-down rolls. -- Programmable part thickness opening 1/8" - 5-7/8", automatic conveyor belt tracking -- Infeed roller extension, electric brake on abrasive belt, -- Emergency stop button, -- Motor load meter, and magnetic controls.

BUTFERING TSBC213 CCC/C Line wide belt sander53" Width cap , Combination Head, Combination HeadSpecifications -- Wide Belt Sander, Model Optimat SBC 213 CC/C-Line -- Sanding width: 1350mm -- Working height: 900mm constant pass -- Workpiece thickness. 150 mm -- Abrasive belt width: 1370 mm -- Abrasive belt length: 1900 mmHead Configuration1st Head -- Abrasive belt drive: ( Drum )1 speed 25.3 kW -- Abrasive belt speed:18 m/s -- Contact roller diameter 140mm -- 2nd Head -- Abrasive belt drive: 3 speed. 2.7/7.5/15 kw -- Abrasive belt speed: 4.5/9/18 m/s -- Contact roller diameter. 140mm Equipped with & Features -- Infeed drive infinitely variable 1,5 kW2.5-13 m/min. -- Cleaning brush

BUTFERING - OPTIMAT STO 311 RRL, ...3-Head Wide Belt Sander43" Width cap., Drum, Drum, and Platen.Head Configuration:1st Head: 7" Steel spiral contact drum, 29.5 HP motor.2nd Head: 7" Rubber covered drum, 25 HP motor.3rd Head: Combination Style Head with Grooved Rubber-Covered Drum and Air-Cushion Pad; 3rd Head Motor: 16.7/21.5 HP.Specifications: -- 43" x 75" Abrasive belts, electronic abrasive belt tracking. -- Conveyor belt feed with variable feed speed from 8 - 43 FPM. -- Automatic conveyor belt tracking. -- Infeed & outfeed spring-loaded rubberized holddown rolls. Equipped With & Features: -- 1/8" - 5-1/2" Motorized thickness adjustment, "quick-set" automatic thickness adjustment with LED readout. -- Infeed panel "over-thickness" sensor. -- Outfeed rotary panel cleaning brush Infeed & outfeed emergency stops. -- Safety interlocks on all doors. -- Roller infeed conveyor extension, -- Motor load meters and main motor electronic brakes.

BUTFERING - OPTIMAT SCO 413 RRRR, ...Top Head Wide Belt Sander (...part of line with SX-012681 Profiline 3-Head Bottom Sander)Top 4-Head, 53" Width Capacity Wide Belt Sander with (4) Drums (Rollers).Head Configuration: -- 1st Head: Steel Contact Roll, 240 mm (9-1/2") dia., 22 kW (30 HP) motor. -- 2nd Head: Rubber covered Contact Roll, 85 Shore, 240 mm (9-1/2") dia., 22 kW (30 HP) motor. -- 3rd Head: Rubber covered Contact Roll, 65 Shore, 320 mm (12-1/2") dia., 22 kW (30 HP) motor; Rotation with or against feed direction. -- 4th Head: Rubber covered Contact Roll, 35 Shore, 320 mm (12-1/2") dia., 18.5 kW (25 HP) motor. -- All Heads with servo positioning of Contact Roller via precision motor to 1/100 mm, with possibility to store different values in the Terminal.Features & Specifications: -- Outfeed Rotary Panel cleaning brush with abrasive grit, 5.5 kW (7.5 HP) motor; 950 mm (37") Section of free-standing power driven infeed roller track; 54" x 103" Abrasive belts and electronic abrasive belt tracking; all heads with Servo driven grit compensation and motorized positioning; Abrasive belt air-jet blowers on all heads; Automatic head locking for fast abrasive belt change. -- Vacuum Conveyor belt feed with variable feed speed 5 - 25 MPM (16-1/2 - 82 FPM); automatic conveyor belt tracking, infeed & outfeed spring loaded rubberized holddown rollers. -- Constant passline of 900 mm (35-1/2") by adjustment upper machine frame via (4) large dia. threaded spindles. -- Color touchscreen control with (1,000) programs, 1/8" - 5-1/2" motorized thickness adjustment, "quick-set" automatic thickness adjustment with LED readout; infeed panel "overthickness" sensor.Complete with: -- Infeed & outfeed emergency stops, safety interlocks on all doors, roller infeed Conveyor extension, motor load meters, and electronic brakes for all sanding head motors. -- Operator and Maintenance manuals (in Spanish); spare parts drawings, spare parts list, and wiring diagram.NOTE: -- BUTFERING "PROFILINE SUR" Bottom Sander and "OPTIMAT SCO" Top Sander [SX-012681] are: Offered as a Complete System/Line with Infeed & Transfer Connect; one common Control for both machines to operate as line. - Copy of original quote with detailed specifications is available upon request.Asking Price with this "SX-012684" listing is for the Top Head Sander only - Open to reasonable offers.

$26,950

BUTFERING - STO 211 RL, ...2-Head Wide Belt Sander.43" Width cap.; Drum & Combination Head.Head Configuration:1st Head: Grooved Steel Contact Drum, ~8"; dia. and 25 HP motor.2nd Head: Combination style, w/grooved rubber covered drum & platen, 20 HP motor.Specifications: -- 43" x 75" Abrasive belts, both heads with grit compensation. -- Electronic abrasive belt tracking. -- Conveyor belt feed with 2-speed control at 14 & 28 FPM. -- Automatic conveyor belt tracking. -- Infeed & outfeed spring-loaded rubber covered holddown rolls.Equipped with & Features: -- Automatic part thickness setup with index control. -- 1/8" - 5-1/2" Motorized thickness adjustment with joystick control and LED readout. -- Panel "over-thickness" sensor at infeed. -- Infeed & outfeed emergency stops, safety interlocks on all doors. -- Roller infeed conveyor extension. -- Motor load meters and main motor electronic brakes.

BUTFERING - Profiline SUR 313 RRR, ...Bottom Wide Belt Sander with Powered Infeed & Connect to Top Sander (...see SX-012684 - OPTIMAT SCO 413 RRRR, ...Top Head Wide Belt) Bottom 3-Head, 53" Width Capacity Wide Belt Sander.Head Configuration: -- 1st Head: Steel Contact Roll, 240 mm (9-1/2") dia., 22 kW (30 HP) motor. -- 2nd Head: Rubber covered Contact Roll, 65 Shore, 320 mm (12-1/2") dia., 22 kW (30 HP) motor; Rotation with or against feed direction. -- 3rd Head: Rubber covered Contact Roll, 55 Shore, 320 mm (12-1/2") dia., 18.5 kW (25 HP) motor; Rotation with or against feed direction.Features & Specifications: -- Outfeed Rotary Panel cleaning brush with: Abrasive grit, 5.5 kW (7.5 HP) motor. -- 950 mm (37") Section of free-standing power driven infeed roller track. -- 54" x 103" Abrasive belts, electronic abrasive belt tracking, and all heads with Servo driven grit compensation and motorized positioning. Abrasive belt Air Jet blowers on all heads. -- Vacuum conveyor belt feed with: Variable feed speed 5 - 25 MPM (16-1/2 - 82 FPM); automatic conveyor belt tracking; infeed & outfeed spring loaded rubberized holddown rollers; outfeed extension for linking to transfer conveyor, connecting Bottom head to Top head Sander. -- Constant pass line of 900 mm (35-1/2") by adjustment upper machine frame via (4) large dia. threaded spindles. -- Tie In conveyor: To connect to Top Head Sander; 1,500 mm (59"), 5 - 25 MPM (16-1/2" - 82 FPM), synchronized with machine bed conveyor speed. -- Color touch screen control with: (1,000) Programs, 1/8" - 5-1/2" motorized thickness adjustment; "quick-set" automatic thickness adjustment with LED readout; infeed panel "over-thickness" sensor.Complete with: -- Infeed & outfeed emergency stops; safety interlocks on all doors; roller infeed conveyor extension; motor load meters and electronic brakes for all sanding head motors. -- Operator and Maintenance manuals (in Spanish); spare parts drawings, spare parts list, and wiring diagram.NOTE: -- BUTFERING - PROFILINE SUR, ...Bottom Sander and OPTIMAT SCO, ...Top Sander are being offered as a "Complete System/Line" with Infeed & Transfer Connect; (1) Common Control for both machines to operate as a Line. Copy of original quote with detailed specifications is available upon request.Asking Price with this "SX-012681" listing is for the Bottom Head Sander only - Open to reasonable offers.