704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Sawmill

747 Results Found

704-841-2001

Call for Price

KUFO LS-500E Self-contained Dust CollectorDesigned for use in industrial environments for extracting different kinds of dust and dry shavings from single or multiple dust sources. It can be installed directly without any additional fire or explosion protection measures.Features: -- 5 HP Direct drive blower with backwardly curved blades and 2,649 CFM air flow rating; Inlet dia. 10". -- The blower is located on the clean air side. -- Noise reduction cover to reduce from 82 dB. to 76 dB. -- Fire control system with built-in Fire Sprinkler featuring auto-temperature activation (requires a water line hook-up). -- Pulse-jet filter cleaning with compressed air. -- (1) Dust collection tank container.Options: -- Built-in Fire Extinguisher with auto temperature activation -- "Y" Adapter with 9-3/4" inlet opening with 4" x (5) fitting -- Noise Reduction option (76 dB from 82 dB without).

L & L 400HP Belt Driven DensifierSpecifications: -- Main motor: 400 HP -- Densifier tank thickness: 3/4" Wall -- Tank dimensions: 50" Dia. x 48"Equipped with: -- Funnel-top lid with interlocked limit switch -- Heavy-Duty operator platform with stairway -- Soft Start -- Infeed Conveyor -- Mezzanine -- Was used to process PE film scrapNOTE: Unit has seen very little use.

Call for Price

LAWECO HEAVY DUTY Scissor LiftSpecifications: Very Heavy Duty hydraulic Scissors Lift with 12,000 Lbs. capacity. -- (2) 6" lifting/lowering cylinders. -- Platform size 64" x 142", approx. 19" lowered and approx. 85" raised height. -- No hydraulic unit or controls.(2) Units available, chain conveyor on one can be removed @ N/C

Call for Price

LEADERMAC LMC-101-900 HD 36" HD Multi-Blade "Roll Feed" RIP SAWSpecifications: -- Working width: 0.6” – 36” -- Working thickness: 0.4” – 4” -- Up & Down motor: 1 HP -- Feed motor: 7-1/2 HP with VFD -- Spindle HP: 75 HP, larger motors optional -- Spindle diameter: 3.15” double keyed -- Spindle RPM: Std. 4,000 RPM, 5,000 RPM optional -- Saw Blade Diameter, 14” diameter -- Feed speed, infinitely variable: 20 – 50 FPM, 100 or 200 FPM optionalStandard Features: -- Extra Heavy Main Frame – Stress Relieved -- Sound & Safety enclosure included – with internal strobe-free lighting -- High Precision Spindle - Double Keyed assembly with Hydro-Lock outboard bearing assembly on outboard side -- Spindle assembly slides out on support for Quick, Easy and Precision Saw Setting & Changing -- Hardened & Hard Chromed Feed Tables -- (7) Sets of Top Power Driven Rolls – full width -- (5) Bottom Power Driven Rolls – full width -- Infinitely Variable Pneumatic Pressure to Top Feed Rolls -- Top & Bottom Feed Rolls driven by Cardan Shaft Drive with HD Gearboxes Interconnected -- 1st Top & 1st Bottom Powered Roll Combination and then (2) Rows Anti Kick Back Finger Units Full Width and then to the rest of the Powered Top & Bottom Rolls provide the best Feeding Capability with excellent safety features -- HD VFD – 7-1/2 HP Feed System – Infinitely Variable -- Main motor has Wye-Delta low amperage soft start -- Electrics are 230, 450 or 575 volts 3/60 with all controls to CSA/UL Specifications -- Documentation: Maintenance manual, Operation manual, Electrical diagrams, Parts list & Tool Box (Electronic Version on Request) -- (8) Dust outlets consisting of (4) top & (4) bottom 6” diameter dust hoods -- Saws, Dado Heads &/or cutterhead(s) and spacers optional extra Options Included In Price: -- Hanging Control Panel – in lieu of Control std. setup as shown in machine photo, Included -- Moveable Main Electrical Panel with 10 ft. of main cable, Included -- Amp Meter for the Arbor Motor, Included -- 4” Thickness capacity in lieu of standard 2” thickness, Included Available Options: -- To 3" Thickness Capacity – using 12” blades, P.O.R. -- To 3” or 4” thickness Capacity – using 14” blades, P.O.R. -- To 100 FPM Top Feed Speed – Infinitely Variable – 4” Thickness Capacity, POR -- To 200 FPM Top Feed Speed – Infinitely Variable – 2” max. Thickness, P.O.R. -- 100 HP saw spindle motor, P.O.R. -- 125 HP saw spindle motor, P.O.R. -- 150 HP saw spindle motor, P.O.R. -- Front or Rear 10 HP Side Heads (Please discuss if interested), P.O.R. -- 15 HP or 20 HP Side Head motors in lieu of 10 HP, P.O.R. -- Adjustment of the Rear guide with digital readout from the front of the machine (only desirable if Side Heads are supplied), P.O.R. -- Scoring Saw Arbor ahead of main saws if desired, P.O.R. -- Saw Spacers fo

Call for Price

LEADERMAC MODEL LMC-1600M - 63” GANG RIPSAW Specifications: -- Width capacity: 0.6” to 63” -- Thickness capacity: 0.4” to 2” (thicker material processing is available as an option) -- Up & down motor: 1 HP -- Feed motor: 15 HP HD VFD -- Feed speed, infinitely variable: 20 - 200 FPM. -- Feed direction from Right to Left is standard -- Saw Spindle HP: 150 HP, Wye-Delta low amperage soft start (larger motors are available as an option) -- Saw Spindle diameter: 3.15” (80 mm) double keyed -- Saw blade Diameter 12” diameter for 2” thick material -- Spindle RPM: Std. 4,000 RPM. 5,000 RPM optional with 10” Blade capacity Standard Features & Equipment: -- Extra Heavy Main Frame – Stress Relieved -- Sound & Safety enclosure included – with internal strobe-free lighting -- High Precision Spindle - Double Keyed assembly with Hydro-Loc outboard bearing assembly on outboard side -- Entire Spindle assembly slides out on support for Quick, Easy and Precision Saw Setting & Changing -- Hardened & Hard Chromed Infeed Table -- (7) Sets of Top Power Driven Rolls – full width -- (5) Sets Bottom Power Driven Rolls – full width -- Infinitely Variable Pneumatic Pressure to Top Feed Rolls -- Top & Bottom Feed Rolls are all Driven by Cardan Shaft Drive with HD Gearboxes interconnected -- 1st Top & 1st Bottom Powered Roll Combination and then 2 Rows Anti Kick Back Finger Units – Full Width and then to the rest of the Powered Top & Bottom Rolls giving you the best Feeding Capability with good safety Features -- HD VFD – 15 HP Feed System – Infinitely Variable -- Main motor has Wye-Delta low amperage soft start -- Electrics are 460 volts 3/60 with all controls to CSA/UL Specifications -- Documentation: Maintenance manual, Operation manual, Electrical diagrams, Parts list & Tool Box (Electronic Version on Request) -- (8 - 4) Top & (4) Bottom 6” Dust hoods included -- Saws, Dado Heads &/or cutterhead(s) and spacers are optional at extra cost.Price Includes: -- Pedestal for all controls, on a 11 meter long cable to get around the front right (infeed side) of the ripsaw -- Moveable Main Electrical Panel with 10 ft. (3m) of main cable -- 150HP Saw Arbor Spindle motor in lieu of std. 75HP -- Pneumatic hold over on infeed table to hold wide, and allow holding over of narrow boards up to the fence -- Increased Feed Speed to 200FPM (60mpm) includes Heavier gearboxes and drive components) with 15 HP VFD -- Amp Meter for the Arbor Motor -- Faster removal speed for the arbor assembly (50% faster than standard machine) -- 1 Spare complete New Design Spindle Assembly including Drive Side Bearing Assembly with support slide and roller transfer support assembly per photo for preloaded saws Extended length per discussion.(1 only unit included in price of machine, this is for a 2nd cart and spindle assembly- total of (2) will come with the machine – additional units available, see

Call for Price

LEADERMAC MODEL LMC-1300M – 51” GANG RIPSAW -- Specifications: -- Width capacity: 0.6” to 51” -- Thickness capacity: 0.4” to 4” -- Up & Down motor: 1 HP -- Feed motor: 7-1/2 HP with VFD -- Saw Spindle HP: 75 HP, larger motors are optional - see below -- Saw Spindle diameter: 3.15” (80mm) double keyed -- Spindle RPM: Std. 4,000 RPM. 5,000 RPM optional with 10” Blade capacity -- Saw blade Diameter 12” diameter for 4” thick material -- Feed speed, Infinitely variable: 20 To 50 FPM. 100 or 200 FPM optional -- Standard Features & Equipment: -- Extra Heavy Main Frame – Stress Relieved -- Sound & Safety enclosure included – with internal strobe-free lighting -- High Precision Spindle - Double Keyed assembly with Hydro-Loc outboard bearing assembly on outboard side -- Entire Spindle assembly slides out on support for Quick, Easy and Precision Saw Setting & Changing -- Hardened & Hard Chromed Infeed Table -- (7) Sets of Top Power Driven Rolls – full width -- (5) Sets Bottom Power Driven Rolls – full width -- Infinitely Variable Pneumatic Pressure to Top Feed Rolls -- Top & Bottom Feed Rolls are all Driven by Cardan Shaft Drive with HD Gearboxes interconnected -- 1st Top & 1st Bottom Powered Roll Combination and then 2 Rows Anti Kick Back Finger Units – Full Width and then to the rest of the Powered Top & Bottom Rolls giving you the best Feeding Capability with good safety Features -- HD VFD – 7.5 HP Feed System – Infinitely Variable -- Main motor has Wye-Delta low amperage soft start -- Electrics are 230, 450 or 575 volts 3/60 with all controls to CSA/UL Specifications -- Documentation: Maintenance manual, Operation manual, Electrical diagrams, Parts list & Tool Box (Electronic Version on Request) -- (4) Top & (4) Bottom 6” Dust hoods included -- Saws, Dado Heads &/or cutterhead(s) and spacers optional extra -- Price Includes: -- Hanging Control Panel – in lieu of Control standard setup as shown in machine photo -- Moveable Main Electrical Panel with 10 ft. of main cable -- Amp Meter for the Arbor Motor -- 4” thickness Capacity – using 12” or 14” diameter blades Available at extra cost: -- Adjustment of the Rear guide with digital readout from the front of the machine (only desirable if Side Heads are supplied) -- Additional Side Pressure Roller System on the Infeed Table of the Machine -- 100 HP saw spindle motor -- 125 HP saw spindle motor -- 150 HP saw spindle motor -- Scoring Saw Arbor ahead of main saws if desired -- Saw Spacers for Main Arbor quick Setup -- Mechanical Quick Lock Saw collars if desired for independent saw setting -- Spare Spindle Assembly, complete, including Drive Side Bearing Assembly with support slide and roller transfer support assembly per photo for preloaded saws, add $ 13,045 -- Questions? Call Jeff @ Ext 349!

Call for Price

LEADERMAC SYC 300M Heavy Duty Roll Feed Ripsaw: Features & General Description: -- Cast Iron base with easily accessed Anchor Bolts; lift up sound enclosure with light for quieter and safer operation; Hydro-Loc Outboard Bearing System for best gang sawing shaft support, includes grease gun; HD Cardan shaft feed (chainless) drive throughout. -- (6) Full width, close coupled driven top feed rollers; (4) full width driven bed rollers; top rolls are air tensioned; variable pressure controls on top feed rolls; motorized lift to top rolls; infeed table is hard chromed with approx. 0.012” - 0.014” chrome. -- Easily adjusted roll holdover on the infeed table; saw spindle has motorized lift and lowering; multiple HD V-belt driven saw spindle with special HD belt tensioner; saw blades cut from below, hence better dust removal and a heavier sturdier design. -- Saws are pre-mounted on a slip-on sleeve for quick change; (3) sets of anti-kickback devices included; central lube system; pneumatic pressure controller safety switch – if air pressure to the top rolls drops below the set to run level, the feed will automatically stop. -- Controls include: VFD Control to feed speeds and Digital Speed Readout in FPM or MPM; TECO-WESTINGHOUSE main electric motor; I.E.C. – TELEMECANIQUE-SQUARE-D Electricals meet or exceed UL/CSA Standards. -- Machine is equipped with WYE-DELTA Soft-Start (low Amperage) starters & main disconnect, multiple “E-Stops" operate at low amperageSPECIFICATIONS: -- Max. thickness, 5.1” (130 mm); Note – to 4-1/2” with std. 14” diameter blades; to 5.1” with optional 16” Blades. -- Saw sleeve usable length of 12.3” (312 mm) - max. dist. between outside saws; minimum length material, 10” (250 mm) – at slower speeds. -- Saw Blades with 10” min. to 14” max dia. x 70 mm Bore (double key), 16” (400 mm) optional – no charge; Saw spindle with 50 mm dia. runs at 3,200 RPM; Saw sleeve – included, 70 mm OD with double keyways. - Includes (1) set of spacers. -- Main Motor – 75 HP (50, 60, or 100 HP optional); top feed rolls – rise & fall, 1 HP; Feed Drive of 7.5 HP with VFD infinitely variable speed control, 20 to 165 FPM (6 to 50 MPM) to 200 FPM – 60 MPM – optional). -- (4) 150 mm Dust collection outlets; approx. weight – net, 5,060 Lbs.; WYE-DELTA – low Amperage - Soft Start for main motor starter; electrics to UL/CSA Standards and wired to 230/460 or 575/3/60. - Note: Stock machines are with 50 HP – 460/3/60 electrics machine and can be easily and inexpensively transformed to other voltages.Optional Extras. -- 75 KVA Auto Transformer to run machine on 230/3/60 electrics, please add ...$ 2,045. -- 16” (400 mm) Dia. blade with 5.1” max. Thickness N/C; NOTE: – Contact us to see if stock machine has this capacity. -- Extra Saw Sleeve, add ...$ 995. -- Additional Sets of space

L&B High Strain 6' Bandmill complete with the following components: --Motorized top wheel hoist. --Pneumatic tilting hood. --Blade lube system. --150 HP Electric Motor and V-belts. --New slat bed. --This type is ideal for a left-hand headrig or right-hand resaw operations.

$88,500

LHI MODEL RFPR ROLL FEED PANEL RIP SAWWith the following Standard and Optional Equipment: -- Roll Feed Panel Rip Saw - 72" Arbor - 50 HP motor -- 10 to 80 FPM (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- 10" Dia. blades (thickness-1/8" to 1-1/4") Infeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) 2” x 3” support tubes for fork access -- 110 VAC / 1-Ph power unit -- Foot pedal control -- Automatic up-indexingOutfeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) Support ramp/cross-bars to allow for access -- Auto down indexing -- 110 VAC / 1 Ph power unit -- Foot pedal controlSawblades: -- (10) 10" x 40T x 4-3/16 Bore, TGC Blades -- (10) Blade Collars, 3-15/16" ID x 4.18" bore x 1.25" wide Quick-change arbor setup with the second arbor: -- Arbor change cart (included with the arbor setup that comes with the saw to allow roll-out) Second Arbor Setup Includes: -- Cart -- Blade Box -- Arbor, Bearing -- Sheave -- Throat Plate Rack -- (6) Throat Plates Quick Change Kit: -- Belt Guide -- Belt Tensioner -- Hyd. Arbor Lock Quick Change Kit permits the operator to release the belt and unlock the arbor from the front side of the machine. Without the kit, the operator must open the rear guard to remove the belt and unlock the arbor -- (10) Blades for the second setup -- (10) Collars for the second setup 16-week ESTIMATED delivery: -- Delivery assumes order and down payment are received within (1) week of the date of quotation. Installation technical assistance for $115/Hr plus travel time and expenses Customer responsible for rigging Quote assumes customer will deliver material for testing (if required) Warranty: (1) Year mechanical parts (electrical controls excluded) This quotation is valid for 30 days. ESTIMATED DELIVERY DATE:The delivery date is quoted as 'estimated' because the equipment we manufacture is built to order and to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$84,714

LHI MODEL RFPR ROLL FEED PANEL RIP SAW WITH THE FOLLOWING STANDARD AND SPECIAL EQUIPMENT: Specifications: -- 72" Useable Arbor and 50 HP Arbor Motor -- 14 - 80 FPM Variable Speed Feed Rate (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- Arranged for 14" dia. blades and 4” max cutting thickness -- Single Point Thickness Adjustment from 1/2" to 4" -- Arbor Quick-Change KitComplete with: -- Additional Arbor Setup, Includes: Cart, Blade Box, Arbor, Bearings, Sheave, Throat Plate Rack, and (6) Throat Plates -- (15) Blade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide -- (15) 14" Carbide Tipped Blades: 40 Tooth with 4.188 bore -- Delivery ESTIMATED at (14) weeks; assumes order and down payment are received within (30) days of the date of this quotation. -- Technical Installation assistance - $125/Hr plus travel time and expenses -- Buyer is responsible for rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1 Year mechanical parts (electrical controls excluded) -- This quotation is valid for 30 days.

$52,733

LHI PIGTAIL Crosscut saw with conveyor and air stopSpecifications -- 62" Cut width --Saw motor 5 HP -- 14 FT gravity conveyor cutting surface -- Cam Lock adjustable stop -- Power feed wheel for rip saw infeed assist -- Blade dia. 12"Equipped with and Features -- 4,500 lb lift with loading ramps 1 HP, 30" X 72" platform -- 4,500 lb Outfeed lift with 3 ramps, 48" X 96" Platform, Auto down indexing -- 10" X 40T X 4-3/16" , 30 Blades -- 3-15/16" ID x 4.18" bore x 1.25" wide 30 collars -- 32 Throat Plates

$186,709

LHI 72" RFPR Wide Arbor Roll Feed Gang Panel Ripper with Custom 5' x 16' Automated Infeed -- Specifications: -- Panel Ripper with 30 HP Arbor Motor; 1/8" min. to 1-1/4" max. material thickness and 72" cutting width. -- Machine configured for arbor removal from the right side of the Saw when facing the Saw's Infeed (opposite of standard) -- Electricals arranged for 600-volt/60-cycle/3-Phase operation -- 10" Dia. blade design will cut thru max. 1-1/4" thickness; -- 3-15/16" dia. arbor with 72" of usable width cutting capacity, min. panel length 30". -- 1-15/16" FAFNIR arbor bearings; with (8) steel feed rollers on 6" centers; fixed feed speed of 80 FPM -- 47-1/4" working (passline) height -- (1) Arbor Cart is included -- (2) 4" Dia. dust collection ports on top and (1) 8" dust collection port on bottom. Recommended 1,500 CFM Includes the Following Optional Items: -- 5-Strand powered Chain Deck; 12' long; arranged to feed 5' x 16' packages onto the Scissors Lift. Complete with controls for forward, reverse, and jog. -- 5-Sections of Gravity Rollers on Scissors Lift Deck -- 8,000 lbs. Infeed Tandem Scissors Lift with 5' x 17' Deck and 2-HP, 3-Phase Motor. Lift includes a backstop for initial alignment at the Rake Feeder -- (8) Polyurethane Feed Rollers on 6" centers -- Variable Feed Speeds from 10 to 80 FPM. -- Rake Feeder for 16' long panels -- Auto-cycle for Rake Feeder. -- 6' Line Up Conveyor with Fence and Powered Pinch Roll Included Tooling: -- (36) Standard Saw Collars for Ripping -- (72) Standard 10" Sawblades for Ripping (Includes a spare set) -- (37) Standard Throat Plates for RippingQuick Setup Kit Included, Contains the Following -- Belt guide -- Belt Tensioner -- Hydraulic Arbor LockAdditional Arbor Setup Included. Contains the Following: -- Includes cart, blade box, arbor, bearing, sheave, throat plate rack, and(6) throat plates -- Blade Box -- Arbor -- Bearings -- Sheave -- Throat Plate Rack -- (6) Throat Plates SYSTEM TOTAL ............….……$174,495 7% ($12,214) materials surcharge on $174,495 = $186,709

$132,700

LHI RFPR ROLL FEED PANEL RIPPER - "BUILT TO ORDER SYSTEM" with the following equipment: -- Ripsaw: -- 72" Arbor - 50 HP arbore motor and 14 to 80 FPM Variable Speed Feed Rate (4-speed programmable via VFD) -- (8) Polyurethane Feed Rollers -- Arranged for 10" dia. blades to rip panel thickness from 1/8" to 1-1/2” -- Single Point Thickness Adjustment -- Quick-Change Arbor Kit Additional Arbor Setup Including: -- (1) Arbor Cart, (1) Blade Box, (1) Arbor Shaft, (1 set) Bearings, (1) Arbor Sheave, and (1) Throat Plate Rack Automatic Infeed System: -- 4,500 Lbs. Capacity Hydraulic Scissors Lift with (4) loading ramps to feed and align 4’ x 8’ sheets into Panel Saw -- 110VAC/1PH Scissors Lift power unit -- Auto-Cycling Rake Feeder -- 6’ Line-Up Conveyor With Power Pinch WheelOutfeed Scissors Lift: -- 4,500 Lb. Capacity Hydraulic Scissors Lift with 4' x 8' top, (3) support ramps/cross-bars to allow fork access -- 110VAC / 1Phase power unit -- Auto Down Indexing -- Auxiliary Foot Pedal Control Blades, Collars and Throat Plates: 10" x 40T x 4 3/16 Bore, TGC, $105 eachBlade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide, $135 eachAluminum Throat Plates, $35 each TERMS AND CONDITIONS: -- Delivery: 16-18 Week ESTIMATED delivery date assumes your order is received within one week of date of this quotation. -- A 5% Tooling & Steel Surcharge to be added to the machinery price when the total is known -- Installation technical assistance, $125/hr. plus travel time and expenses (if required) -- Customer responsible for own rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1-year mechanical parts (electrical controls excluded) -- FOB: Shannon, MS 38868. ESTIMATED SHIPPING DATE: 16 TO 18-WEEKS --The delivery date is quoted as “estimated” because the equipment manufactured is built to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. -- LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

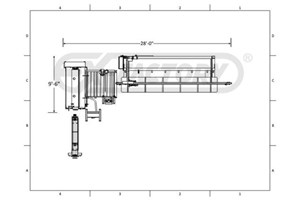

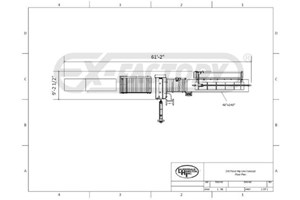

LHI 4,500 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 4,500 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

LHI 6,000 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 6,000 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$29,800

LHI MBR-10 ROLL FEED GANG RIPSAW: Saw arbor with 25 HP arbor motor (30 HP and 40 HP available, see Options for pricing).Specifications: -- 1-15/16" Saw arbor bearings and 10" usable arbor. 12" useable arbor available. Uses 12" dia. x 1-3/4" bore saw blades. -- 1/8" to 2" Max. cutting depth on hardwoods and softwoods; 18" minimum stock length; 17" maximum stock width; removable and replaceable phenolic throat plates. -- Unique “swing down arbor frame” for easy and fast blade changing. Blades are positioned using spacers.Feed system with: -- (2) 1 HP Feed motors with constant feed speed to be determined from thickness of wood, type of wood, and maximum number blades (average speed is set at 80 FPM). -- (6) Non-marking steel drive rollers; top and bottom rolls are powered for superior feeding capabilities; hand crank for easy feed roll height adjustment. -- Includes safe, fully enclosed belt and chain guards and double anti-kickback device. Features: -- Simple design, low cost, high performance. -- High production, fast setup, workhorse. -- Off-The-Shelf Parts are found locally for ease of maintenance.Options: -- 30 HP arbor motor & starter, add $1,150, -- 40 HP arbor motor and starter, add $2,300, -- Variable Speed Drive with speeds from 10 to 100 FPM, add $2,450. -- 12" Useable arbor space, add $2,950. -- 12" x 24T Blade,1.75" Bore, $115 each. -- 12" x 30T Blade,1.75" Bore, $165NOTE: PRICING DOES NOT REFLECT Mfg's 7% MATERIALS SURCHARGE

$167,985

LHI 72" RFPR Wide Arbor Roll Feed Gang Panel Ripper with Custom 5' x 16' Automated Infeed -- Specifications: -- 30 HP Arbor Motor; 1/8" min. to 1-1/4" max. material thickness and 72" cutting width. -- 10" Dia. blade design cuts thru max. 2" thickness; -- 3-15/16" dia. arbor with 72" of usable width cutting capacity, min. panel length 30". -- 1-15/16" FAFNIR arbor bearings; with (8) steel feed rollers on 6" centers; fixed feed speed of 80 FPM -- 47-1/4" working height -- (1) Arbor Cart is included -- (2) 4" Dia. dust collection ports on top and (1) 8" dust collection port on bottom. Recommended 1,500 CFM Includes the Following Optional Items: -- 5-Strand powered Chain Deck; 12' long; arranged to feed 5' x 16' packages onto the Scissors Lift. Complete with controls for forward, reverse, and jog. -- 5-Sections of Gravity Rollers on Scissors Lift Deck -- 8,000 lbs. Infeed Tandem Scissors Lift with 5' x 17' Deck and 2-HP, 3-Phase Motor. Lift includes a backstop for initial alignment at the Rake Feeder -- (8) Polyurethane Rollers on 6" centers -- Variable Feed Speeds from 10 to 80 FPM. -- Rake Feeder for 16' long panels -- Auto-cycle for Rake Feeder. -- 6' Line Up Conveyor with Fence and Powered Pinch Roll Included Tooling: -- (36) Standard Saw Collars for Ripping -- (72) Standard 10" Sawblades for Ripping (Includes a spare set) -- (37) Standard Throat Plates for RippingQuick Setup Kit Included, Contains the Following -- Belt guide -- Belt Tensioner -- Hydraulic Arbor LockAdditional Arbor Setup Included. Contains the Following: -- Arbor Cart -- Cart -- Blade Box -- Arbor -- Bearings -- Sheave -- Throat Plate Rack -- (6) Throat Plates PRICE REFLECTS FACTORY'S 7% MATERIALS SURCHARGE ON $156,995, OR $10,990

Call for Price

LHI MODEL RFPR AUTOMATED PANEL RIP SYSTEM --Arranged for up to 5/8” Thick x 52” Wide x 18’ Long Panels as follows: AUTOIMATIC INFEED SYSTEM, INCLUDES: --Rake Feeder for up to 18’ Long Sheets --Automated Feed Cycle Controls --Turnkey Controls, Plug it in and Run --1 HP, 3-Phase, 460-Volt Operation 6’ ALIGNMENT CONVEYOR, INCLUDES: --Gravity Roller Frame with 60” Wide Rollers --Alignment Fence --Spring Loaded “Feather” to Keep Sheets Tight to the Alignment Fence --Powered Feed Wheel to Push Sheets into the Ripsaw --2 HP, 3-Phase, 460-Volt Operation TANDEM INFEED SCISSORS LIFT --8,000 LBS. Capacity --30” x 204” Platform With 62” Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62” x 204” Useable Deck Size. --Automatically Raised and Lowered by Signals from the Sheet Feeder --2 HP, 3-Phase, 460-Volt Operation TANDEM OUTFEED SCISSORS LIFT --8,000 LBS. Capacity --30” x 204” Platform With 62” Long Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62” x 204” Useable Deck Size. --Automatically Lowers by Signals from Auto-Down Index Control Unit --2 HP, 3-Phase, 460-Volt Operation --OPTIONAL: 4-Sided “Accordion Skirts” for each Tandem Lift Table, add $2.650 per lift RFPR" ROLL FEED PANEL GANG RIP SAW --50 HP Main Arbor Motor --1/8" Min. To 1-1/4" Max. Material Thickness x 72" Cutting Width --10" Dia Blade Design; 3-15/16" Dia. Arbor with 72" of Usable Width Cutting Capacity --Min. Panel Length 30". --1-15/16" FAFNIR Arbor Bearings --(8) Polyurethane Feed Rollers on 6" Centers --Variable Feed Speeds Via VFD --(1) Quick Blade Change-Out Kit --(1) Additional Arbor Cart --(2) 4" Dia. Dust Collection Ports on Top and (1) 8" Dust Collection Port on Bottom. Total Recommended 1,500 CFM. TOOLING: --(20) Saw Collars, Mount Directly to the Arbor with a Set Screw --(20) Saw Blades Configured for Clean Cuts on Your Panels

LHI RFPR 72/12 "HEAVY DUTY" MULTI-BLADE PANEL SAWSpecifications -- (1) 50 HP main arbor motor for 1/8" min. - 2" max. material thickness; 12" Dia max. blade capacity with 1.25" minimum spacing between the blades; Minimum panel length 30" & 72" of usable width cutting capacity. -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; positive powered steel contact feed rollers with (8) Polyurethane drive rollers; variable feed speed to max 80 FPM. -- (1) "Quick Change" arbor cart trolley and blade box for 9 1/2" cutsOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.Available Options: -- Blade Box Arbor Cart and Trolley $ 12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $ 700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $ 3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $ 14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $ 16,390.00 eachTooling Cost: -- Carbide Tip Blades 12" x 40T x 4 3/16 bore with TCG and 3 pin holes $ 125.00 each -- Saw Blade Tooling Collars $ 125.00 each -- Actual Model is LAUDERDALE-HAMILTON RFPR "HEAVY DUTY" 12 Panel Rip SawNOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$239,800

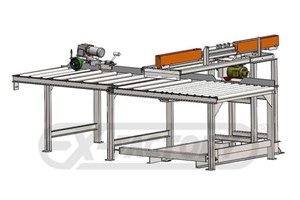

LHI 96" x 60" ANGULAR TYPE RIP & CROSS-CUT SYSTEM: Specifications: -- Automatic Angular Rip & Crosscut 5-Position System; max. panel size of 8' (96") long x 5' (60") wide x 1" - 4" thick; 1.25" minimum spacing between the blades; variable feed speed from 0 - 150 FPM. This system will process a unit of material in approx. (7) Min. -- Pos. # 1: LHI Automatic Staging/Infeed/Transfer & Panel Rake Feeding System: 10' (120") Long, powered 3-chain staging conveyor; (2) units can be preloaded while (1) unit is in process. Automatic up-indexing 4,500 Lbs capacity Scissors Lift with auto. rake infeed system: infeed rake system designed with a thin material device that can automatically load material as thin a 1/8". -- Pos. # 2: LHI "72": 72" Arbor length designed for panels up to max. of 5' (60") wide, min. panel length 30"; 40 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation. 2-3/4" Dia. arbor with 1-15/16" "Fafnir" arbor bearings; positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia. vertical dust outlets with an easy access strip separator box. -- Pos. # 3: LHI Cross-Transfer System: Transfer conveyor with panel hold-down & chain drive system to change direction 90° & automatically feed LHI 102". -- Pos. # 4: LHI "102": 102" Arbor length designed for panels up to max. 8' (96") long; 30 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation; 2-3/4" dia. arbor with 1-15/16" "Fafnir" arbor bearings. Positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia vertical dust outlets with an easy access strip separator box. -- Pos. # 5: LHI Stacking & Outfeed Transfer System: Auto. down-indexing 4,500 Lbs cap. Scissor Lift; (4) adjustable alignment posts & (4) bin separators to keep processed stacks square. 98' (96") Long outfeed gravity conveyor.Operating System: -- (1) LHI ALLEN-BRADLEY "Inter-Link" PLC for simple single-operator management of the entire system from (1) central control.NOTE: ...Attached description & pictures are for INFO purposes only; ...a NEW System can be modified to your exact specifications!NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE