Woodworking Equipment For Sale

1739 Results Found

Call for Price

VITAP ALFA 21 21-Spindle Semi-Automatic Construction/Line Boring Machine21-Spindle Boring Head on 32 mm Centers.Specifications: -- Drills vertically from bottom up, Head rotates to horizontal position for edge boring, Head rotation is pneumatic with Switch control. -- 2-3/4" Max. drilling depth, 2.5 HP - 2,800 RPM Motor, Pneumatic drill head advance with Speed control. -- Head height adjustment with Mechanical digital readout. -- 34" x 20" Table size, Max. workpiece width 31-1/2".Equipped with: -- Left & right side fences for construction boring, (2) Pneumatic hold-down clamps, Line boring fence with flip stops. -- Pneumatic foot pedal control, Magnetic starter & Overload protection, (1) Set of quick-change chucks.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP BC-91 Contour Edgebander – Demo Model Never Used in ProductionDesigned for straight or curved (contour) edgebanding.Specifications: -- 0.3 - 3 mm (0.01" - 0.12") Edgebanding thickness. -- 10 - 60 mm (0.39" - 2.36") Panel thickness & Edgebanding height. -- 20 mm (0.79") Minimum radius with concave curve. -- 280 mm (11.02") Min. panel length.Equipped with: -- Compact "Quick heat-up" underneath worktable glue pot. -- Double roller glue applicator. -- Magazine for coil material or solid strips. -- Manual feeding of straight and/or contoured panels. Complete with: -- Program-controlled end cutoff for coil material, Coil dispensing table, Digital thermo-control for glue temperature. -- Single motor end trim with 1 HP - 10,500 RPM Motor. -- Magnetic push button starter.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP SMART Hot Melt Contour EdgebanderDesigned for straight, curved (contour) or beveled edgebanding, Unique design to allow banding of strips or rolled edging.Specifications: -- 0.3 - 3 mm (0.01" - 0.12") PVC Edgebanding thickness. -- 3/8" - 2-3/8" Edgebanding height. -- 20 mm (0.79") Minimum radius with concave curve.Equipped with: -- Hot Melt glue system applies adhesive to banding for softer flexible applications. -- Automatic advance of banding material by foot pedal activation. -- Digital temperature control for precise & easy temperature setting. -- Small glue pot for quick heat-up.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP SMART Hot Melt Contour EdgebanderDesigned for straight, curved (contour) or beveled edgebanding, Unique design to allow banding of strips or rolled edging.Specifications: -- 0.3 - 3 mm (0.01" - 0.12") PVC Edgebanding thickness. -- 3/8" - 2-3/8" Edgebanding height. -- 20 mm (0.79") Minimum radius with concave curve.Equipped with: -- Hot Melt glue system applies adhesive to banding for softer flexible applications. -- Automatic advance of banding material by foot pedal activation. -- Digital temperature control for precise & easy temperature setting. -- Small glue pot for quick heat-up.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP RC 92 Semi-Automatic Top & Bottom Edge TrimmerFor straight & curved edgebanded panels; (2) spindles (one top & one bottom) 0.75 HP - 12,000 RPM ea.Features: Large dia. guide bearings to ensure precise trimming of edges; panel thickness from 10 - 60 mm., Up to 3mm thick PVC banding material. Complete with precision ground table, table size of 31" x 27".NOTE: Sold "As-Is" Without Warranty!

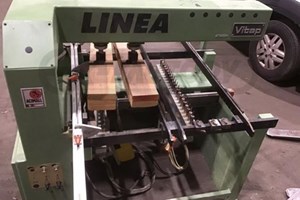

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

VITAP ALFA 21 CONSTRUCTION/LINE BORER21-Spindle boring head on 32 mm centers. -- Specifications: drills vertically from bottom up and head rotates to horizontal position for edge boring, head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth, 2.5 HP - 2,800 RPM motor, pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size, max. workpiece width 31-1/2". -- Equipped with: Left & right side fences for construction boring, (2) pneumatic holddown clamps, line boring fence w/flip stops, pneumatic foot pedal control, magnetic starter & overload protection, and (1) set of quick-change chucks.

$ 11,680

VITAP ALFA 35T Boring Machine (Construction/Line) Specifications: -- 35-Spindle boring head on 32 mm centers, drills vertically from bottom-up and head rotates to horizontal position for edge boring, head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth, 3 HP - 2,800 RPM motor, pneumatic drill head advance with speed control. -- Head height adjustment with mechanical digital readout; 34" x 20" table size, max. workpiece width 31-1/2". Equipped with: -- Left & right side fences for construction boring, (2) pneumatic holddown clamps, line boring fence w/flip stops. -- Pneumatic foot pedal control, magnetic starter & overload protection, and (1) set of quick-change chucks.

Call for Price

Vitap Forma Boring Machine 21 Vertical Spindles 21 Horizontal Spindles Approx $1000 worth of carbide bits DUAL LINE machine and there are (2) vertical lines of 21 spindles each for a total of 42 ...... PLUS an additional single line of 21 horizontal spindles!

$ 46,900

VALPATO LBK-150-ST 1 Feed Through Profile SanderTECHNICAL FEATURES: An added small needle type drum sander can be fitted with drum sanding aggregates of 25, ­30, ­35,­40, ­45 ­50 mm diameters which can be used for tighter curves and smaller radius sanding requirements. Storage compartments (2 in total) are located on each machine extremities, these are easily accessible and can be used for sanding belts and various tooling storage. Sanding belt motor power: 3 Kw Abrasive head motor power: 1.5 Kw Oscillation motor power: 0.38 Kw Feed motor power: 0.75 Kw Motor power for electrical adjustment of sanding group: 0.19 Kw Machine voltage: 480/3/60 Full Load Amps @ 480V: 15A Compressed air: Not required Dust collection requirement one (1) only 6" (150mm) port: 950 CFM Sanding belt speed: 14 Mt/sec Variable speed of the belt: from 5 to 25 m/min Sanding belt dimensions: 150 x 2640 mm Height of working table: 930 mm Dimensions of front working table: 1980 x 250 mm Machine dimensions: 2500 x 900 x 1600 mm Net weight: 1000 KMAIN FEATURES: User friendly PLC touch screen control panel is accessible from 360° by the operator, the control panel is centrally located on the infeed end of the machine. Factory installed variable feed drive (VFD), enables machine to run from 5 M/Min to 25M/min (+/­ 80 ft/Min). The entire sanding plenum rise and fall is motorized, it can be adjusted vertically in height to utilise the full height/width of the sanding belt. An oiling unit ensure long life of sanding plenum rise and fall master cylinder.

Call for Price

$ 16,750

VOORWOOD - A 515 GH, ...Arch Door Sander with Floating Head ARCH SANDER with: (4) 1.5 HP Motors for precision sanding; quality sanding using Disc sanding at continuous feed. Equipped with: -- (4) Floating Sanding Stations equipped with: 1.5 HP Precision balanced drive motors and quick change spindles. -- Infeed & outfeed (1st and last) spindles equipped with: Double collets and angular, horizontal & vertical adjustments with accurate and repeatable digital readouts. -- PLC Control with: Monitor at eye level height.Feedthrough Arch Machine capable of sanding arch profiles on cabinet door components, plus can do straight cuts.. .

$ 49,500

VOORWOODM 15 CNC Round End Tenoner & Mortiser --The "M15" Miter Machine is designed to rapidly make mortise and tenon cuts at 0°, 45°, and 90° degrees. Parts can be up to 1.5” thick and up to 4” wide, and of ANY length. --A primary application for this machine is for miter cabinet door frames. Parts can be quickly transferred from left to right. They are mortised on the left side of the machine and tenoned on the right. The machine can also mill the slots. --Specifications & Equipped with: -- The mortise station has (3) servo-controlled axes (X, Y, and Z) that are coordinated by the machine controller to achieve complex CNC motion. It is equipped with a collet-style router spindle for cutting. The tenon station uses the same X- and Y-servo-controlled axes as the mortise station and is configured for pneumatically actuated in-and-out movement along the Z-axis. The tenon station is equipped with a direct drive shaper spindle for cutting. -- -- Pneumatic clamping assemblies with non-marring urethane pads are mounted to the hold-down assembly to secure the parts during cutting and these can be adjusted to various locations over the cutting surface. -- -- M15 Miter Machine operator interface consists of a colored touch screen. For simplicity, the entire calibration, setup, and monitoring of the machine are accomplished using only four touchscreen displays. The program designs the depth and location of both the mortise and the tenon. When the design is complete, it is saved in a recipe format. Once this recipe is opened, the operation is as simple and boils down to feeding the substrate into the machine. -- -- The full-color touchscreen panel is located on the front of the machine to provide easy access for setting up or operating the machine. Clamping and shaping operations are controlled by operating lighted pushbutton switches. --Also Included: --÷Additional tooling (worth $3,500) --÷ Replacement motr (worth $975) --÷ Few small replacement parts

$ 17,900

WADKIN "GA-220" 5-Head Feed Through MoulderSpecifications: -- 5-Head, with 8-5/8" x 4-5/8" cutting capacity (220 mm x 120 mm) -- 40 mm Spindle diameter with cutterhead speed of 6,000 RPM. -- Head sequence: Bottom 10 HP, Right 7-1/2 HP, Left 7-1/2 HP, Top 15 HP, Bottom 10 HP motor. -- 2 HP variable feed speed 19 to 72 FPM, chain drive. -- Currently wired for 460 Volt, 3-Phase power.

Call for Price

7 Spindle Moulder with Manual Bed Lubrication 6000 RPM Spindle Speed 19-91 F/Min Feed Speed Will Take 7" x 5" Lumber Specs: 1ST BOTTOM--7.5 HP 1ST FENCE SIDE--7.5HP 1ST LH SIDE--10HP 2ND FENCE SIDE--7.5 HP 1ST TOP-15HP 2ND BOTTOM-10HP UNIVERSAL-7.5 HP FEED DRIVE--3 HP BEAM LIFT--.5 HP

$ 26,500

WADKIN - K 23, ...6-Head Feed Through Moulder Head Configuration --(B-R-L-T-T-B) with working capacity of 9-1/2" x 5".Specifications: -- Head sequence: Bottom 10 HP, Right & Left 20 HP, Top 15 HP, Top 20 HP, Bottom 15 HP motor. -- Spindle dia.: 1-13/16" at 6,000 RPM. -- Mechanical digital readouts on all heads. -- Top heads with MDR for chipbreakers and pressure elements.Equipped with & Features: -- Infeed Table: 2 M (6-1/2'), adjustable table plates for vertical spindles. Includes: Top driven feed rolls , motorized overhead feed beam with dual speed for rise-and-fall, full Cardan feed drive with independent adjustment to feed rollers after top head. -- Side pressure opposite right side head. -- Spindle locks for axial adjustment. --Manual bed lubrication. -- Feed drive: 4 HP Motor, variable feed speed from 20 - 75 FPM.

Call for Price

Manufacturer NV300 - With bilateral linear action providing profiling and straight knife grinding up to a max of 310 mm. Will shape and regrind moulder knives in the block and profile grind solid tipped heads. Suitable for HSS, Stellite and TCT. Max length of cutter profile 310 mm. Max dia of cutting circle 300 mm. Includes arbor, grinding wheel, stylus, 220 volt 3-phase

$ 4,950

WADKIN JTA Disc & Bobbin SanderCombination machine with Disc Sander & Vertical Spindle Sander mounted on a common base.Disc Sander Specifications: -- 30" Dia. cast aluminum disc, 4 HP motor, slotted steel side table 38-1/2" x 15", tilts 10° up and 45° down, move in-and-out & up-and-down by hand wheels. -- Equipped with: Magnetic controls, dust outlet and large hand wheels for easy adjustments on worm & rack.Vertical Spindle Sander Specifications: -- Heavy Duty 1-1/2 HP - 1,725 RPM oscillating spindle, 1-1/2" oscillation travel, (75) oscil./Min, mounted on large trunnions and integrated into a 24" x 24" cast iron table, table tilts 30° down & 10° up, 39" working height. -- Oscillation by Heavy Duty worm & gear mechanism.Equipped with: Precision ball bearing for quill, hand wheel table adjustment.

Call for Price

WADKIN GD 220 6-Head Feed Through MoulderSpecifications: -- Working capacity: 230 mm W x 130mm H (9.06" W x 5.12" H) Timber admitted, 220 mm W x 120 mm H (8.66" W x 4.72" H) Finished timber. -- Head Sequence: Bottom 7-1/2 HP, Right 7-1/2 HP, Left 7-1/2 HP, Top 15 HP, Bottom 10 HP, & Universal 7-1/2 HP. -- Spindle dia. 40 mm (1.57"), Spindle speed 6,000 RPM. -- Variable feed speeds 6 - 22 MPM (20 - 72 FPM).Equipped with: -- Right, Left & Top heads with Mechanical digital readouts. -- 1/2 HP Motorized feed beam, 2.2 kW Feed motor, 3 HP Cardan drive, Reverse feed, 5-1/2" Dia. Hardened & Chromed steel feed rollers up to top head, 2" x 2" Polyurethane feed rollers after top head, All feed & pressure rollers move with rise & fall of feed beam. -- 2 M (78.74") L Infeed straightening table. -- Manual bed lubrication. -- Sound enclosure.

Call for Price

Wadkin K23 5 Head Moulder Largest Motor is 20HP S/N 99/2093 440 Volt 3 Phase Electric Motors

.gif)