Woodworking Equipment For Sale

1739 Results Found

$ 2,500

Baxter Whitney & Sons Planer model 32-A manufactured in mid 1940s. This planer was taken out of service in good working order about 8 years ago. I have not used it. There is one pulley that has a broken edge as seen in photo 9319. This was broken in transit and should not affect its function . This planer has a 15 hp, 3 ph main motor with a 3 hp feed motor. Dust hood included. It will need to be picked up with a roll body truck. It comes with the knife sharpener and the sharpener box. Call 800-459-2148 for more info.

Call for Price

$ 12,900

BECKER VTLF 2.400 Vacuum pump:Seller states the pump was only turned on a few times15 HP Oil-less (Dry) Rotary Vane vacuum pump system, rated @ 270 CFM open flow, max. 23.6" Hg; heavy duty construction, compact design, small foot print. -- 100% Oil-less vacuum pump is virtually maintenance free with built-in carbon vanes and built-in suction filters. Complete with: Vacuum regulating valve, secondary suction for additional cooling, blow-off valve/silencer, 4" BSP x 4" NPT Nipple; coupled to a 886 RPM TEFC motor.

$ 3,500

Becker VTLF 250 Vacuum Pump: 6.6 kW (8.8 HP) Oil-less (Dry) Rotary Vane Vacuum Pump System, 176 CFM, max. 25"Hg; Heavy Duty construction, compact design, small foot print. -- 100% Oil-less vacuum pump is virtually maintenance-free with built-in carbon vanes & built-in suction filters, vacuum regulating valve, secondary suction for additional cooling, blow off valve/silencer; 2-1/2" BSP x 2" NPT nipple coupled to a TFC; 1,150 RPM motor. -- Also available at extra cost! -- $2,800 for the ROW 25 HP phase converter -- $1,900 for the electrical control panels

$ 6,500

Becker VTLF 250 Vacuum Pump: 7.5 kW (10 HP) Oil-less (Dry) Rotary Vane Vacuum Pump System, 176 CFM, max. 25"Hg; Heavy Duty construction, compact design, small foot print. -- 100% Oil-less vacuum pump is virtually maintenance-free with built-in carbon vanes & built-in suction filters, vacuum regulating valve, secondary suction for additional cooling, blow off valve/silencer; 2-1/2" BSP x 2" NPT nipple coupled to a TEFC; 400/480V, 1,160 RPM motor

$ 3,900

BECKER KVT 3.100 3.6 Kw (5 HP) Vacuum pump:Oil-less (Dry) Rotary Vane Vacuum Pump System, rated at 69 CFM and 100 cm/Hr with max. 27"Hg; Heavy Duty construction, compact design, small foot print. -- 100% Oil-less vacuum pump is virtually maintenance-free with built-in carbon vanes & built-in suction filters, vacuum regulating valve, secondary suction for additional cooling, blowoff valve/silencer. -- Complete WithInlet vacuum air filter system.

$ 5,000

Berlin 4 head planer. Manufactured pre WW1. Electric motor with each head individually powered. Cap 14" x 20" surface. Call 800-459-2148 for more info.

Call for Price

Bertheson Press Platform size 51 Wide X 102 Long with 2 16 ft shuttle driven aluminum runner platforms. Pressure 2500 psi and we ran a temperature of 350 degrees for Tego and 165 degrees for plywood. The Press can laminate Tego Film glue or pva c glue. This press is a double shuttle and can laminate up to 14 ft by double pressing on shuttle. We can get the press operational if you are interested. We only have to hook up the power. Very good condition!

Biesse Rover B Edge semi automatic pod setting 4 coil magazine vertical and horizontal drill bank main spindle with U axis Milling X1: 5055 mm Y1: 1600 mm Edgebanding X2: 4100 mm Y2: 1600 mm Milling Module H74 - Z1: 245 mm Module H29 - Z2: 290 mm

Call for Price

2007 Biesse Rover B 7.40 R FTK - 61.22" (routing) - 75" (drilling) - Working field of machine in Z-axis - 5.9" X-axis stroke - 157.87" Y- axis stroke - 77.16" Z-axis stroke - 6.23" 61.22" x 145"

Call for Price

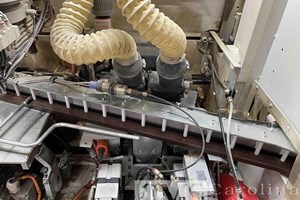

Machine Equipped as follows: NC 410 PC Based Controller Keyboard with Floppy Drive Automatic Strip Feed Magazine Belt Driven Top Pressure Beam Multi-Coiled Infeed Magazine RT63 Pre-Milling Unit SP20 Glue System w/ Pre-Melt Unit Hot Air Gluing system Automatic Infeed Pressure System T45 Front & Rear End Trimming Units w/Tilt RS10 Top & Bottom Rough Trimming Units RF30 Top & Bottom Fine Trimming Units AR10 4 Motor Corner Rounding Trimming Units RB30 Top & Bottom Profile Scraping Units RC10 Top & Bottom Glue Scraping Units SZ30 Top & Bottom Oscillating Buffing Units PH10 Top & Bottom Edge Heaters Specifications: Min. Panel Thickness:....................10mm? Max. Panel Thickness:....................60mm? Height of Edge-Band Material:…..15-65mm? Min. Banding Thickness:.................0.3mm ? Max. Banding Thickness:........ ...... 20mm? Min. Panel Length:...........................150mm? Min. Panel Width:............................ 100mm? Feed Speeds:.................................10-24m./min? Electrics: ......................................... 460-480V 3 Phase

Call for Price

Call for Price

The seller has confirmed that this Biesse Lato is in great working/running condition. This is ready to load! - User Friendly PLC Controller - Adjustable Pressure Beam - Quick Heat-Up Glue System with Dual Temperature Control and Auto Cool Down Feature when Machine is Idle. - Pneumatically Controlled Pressure System - Front & Rear End Trimming w/Tilt - Top & Bottom Edge Trimming Units - Top & Bottom Edge Profile Trimming Unit w/Tilt and Pneumatic ExclusionTop & Bottom Profile Scraping Unit with Pneumatic Exclusion - Top & Bottom Hot Air Blower - Top & Bottom Buffing Units - Specifications : - Min. Panel Thickness:.........10mm - Max. Panel Thickness:.........60mm - Height of Edge-Band Material: 14-64mm - Min. Banding Thickness:......0.4mm - Max. Banding Thickness:.....10mm - Min. Panel Length:................140mm - Min. Panel Width:.................. 50mm - 2 Feed Speeds:.....................12m./min & 18 m/min - Electrics : 230V, 3 Phase - Machine Dimensions: 174" L x 39" W x 57" H - Machine Weight: 1800 lbs

Call for Price

Biesse Akron 440 Edgebander Premill Top & Bottom Trim Corner Round Edge Scrape Glue Scrape Buffing Unit 12-18 m/min Feed Speed All work units are servo controlled

Call for Price

Manufacturer Specs premill hot glue end trim top/bottom trim corner rounding scraping buffing Computer interface

Call for Price

$ 35,200

BIESSE - ARTECH LEVIA 330, ...3-Head Wide Belt Sander43" Width cap. Drum, Drum, and Combination Head.Head Configuration: -- 1st Head: Rubber covered Contact Roll, 6" dia., 25 HP motor. -- 2nd Head: Steel Contact Roll, 6" dia., 25 HP motor. -- 3rd Head: Combination head with a rubber-covered Contact Roll and Finishing Platen.NOTE: There are (2) 25 HP motors; one drives the 1st head and the 2nd drives the other (2) heads.Specifications: -- 44" x 85" Abrasive belts, electronic abrasive belt tracking; all contact rolls with pneumatic seclusion; Head #3 with air belt cleaner. -- EASY PRO "2000 C" Processor with (200) programs, touchscreen for control of Sander functions, thickness opening, feed speed, sequential startup, contact roll seclusion, and abrasive belt cleaner. -- Conveyor belt feed, 11 - 66 FPM variable feed speed, 2 HP feed drive with inverter control. -- 1/8" - 7-7/8" Motorized thickness adjustment with LED readout; automatic part thickness setup.Equipped with & Features; -- Automatic conveyor belt tracking. -- Infeed & outfeed shoes or rubber-covered holddown rolls, infeed panel "over thickness" sensor. -- Electronic brakes on both sanding head motors. -- Infeed emergency stop, 3-roll infeed extension, and motor load meter.

Call for Price

BIESSE ROVER B 4.35 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working capacity: "X" Axis is 125.9" (3,200 mm) any unit; "Y" axis is 51.7" (1,315 mm); "Z" axis stroke 6.3" (160 mm) max. material thickness is 5.9" (150 mm). -- Positioning Speed:"X" & "Y" Axis is 262 FPM (80 MPM) & "Z" axis is 66 FPM (20 MPM). -- Worktable:(6) Panel support rails with: (3) Vacuum pods per panel support; (4) pneumatic lifting bars for heavy panels.(2) Independent working areas with: (6) Front & (1 + 1) side pneumatic pop-up locating pins for positioning of parts on the worktable.Prepared for (optional) "quick fit" vacuum outlets for optional clamping of small or awkward shaped parts; each work zone with: (1) "Quick Connect" vacuum outlet for custom vacuum fixtures. -- Boring Unit:(1) 2.3 HP (1.7 kW) - 4,000 RPM Motor: (12) Independent vertical boring spindles with (6) spindles in "X" axis & (6) spindles in "Y" axis.(6) Horizontal spindles with: (2 + 2) in "X" Axis & (1 + 1) in "Y" axis; (1) "X" axis grooving saw for max. 120 mm dia. blade. -- Machining Unit:(1) 10.2 HP (7.5 kW) Vertically mounted HSD "Electrospindle" Router with ISO 30adapter, inverter driven 1,000 - 20,000 RPM with max. torque from 12,000 - 20,000 RPM.(1) 10-Position ride-along ATC for "on the fly" tool change. -- Operator & Machine Control:PC Front-End with: BIESSE "XP 600" + "BiesseWORKS Advanced" + Windows "WRT" (Windows Real Time) operating system; INTEL "Celeron" 2.0 GHz processor; 4 GB Hard drive.15" Color monitor, international keyboard, soft touch keypad & industrial mouse, RS-232 serial port, USB ports, CD ROM & 1.44 MB disk drives.Separate Control Panel with: Built-in 1,500 W air conditioner for constant temperature & dust-free environment; 11 KVA Stabilized autotransformer for voltages between 200 - 600 Volts. -- Complete with:(1) 100 cbm/Hr Vacuum Pump; centralized manual lubrication system for guides & ball screw; emergency stop rope; safety light barrier & sound absorbing protective head enclosure with debris curtain around bottom edge; scrap belt conveyor. -- Actual model is: BIESSE - ROVER B 4.35.

Call for Price

BIESSE ROVER 20 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working field: "X" Axis 113.9" (2,893 mm); "Y" axis 37.4" (950 mm); "Z" axis stroke is 3.9" (100 mm), max. panel thickness 2-1/2" (65 mm). -- Positioning Speed:"X" Axis at 246 FPM (75 MPM); "Y" axis 147 FPM (45 MPM); "Z" axis 49 FPM (15 MPM)."X" Axis moves on high precision prismatic guides and ground helical rack; "Y" & "Z" axis via hardened ground ball screw. -- Worktable:(6) Pneumatically locked & manually positioned panel supports with (2) vacuum cups each.(2) Working zones with: (6) Pneumatic backstops; (2) pneumatic side & (2) center stops; stops raised & lowered automatically by start/stop of machining cycle. -- Boring Unit:(1) 2.3 HP - 5,135 RPM Motor; (10) vertical spindles independently operated with (6) in "X" axis & (4) in "Y" axis.(6) Horizontal spindles: (2 +2) in "X" Axis & (1 + 1) in "Y" axis; 2-1/2" (65 mm) max. boring depth.(1) "X" Axis grooving saw with: 120 mm Dia. blade - 5,200 RPM. -- Machining: Equipped with: (1) 9 HP (6.6 kW) Air-cooled "Quick Change" electro spindle with ISO 30 adaptor.Router is driven by: 10.2 HP (7.5 kW) Inverter for variable speed from 1,000 - 24,000 RPM; RH & LH rotation.(1) 3-Position automatic tool changer mounted at the back of the machine for "on the fly" ATC. -- Operator & Machine Control: Separate Control Console with: CNi "NC 410" Operating System housed in air-conditioned cabinet.8" LCD Monitor: Displays programming graphics, numerical & function keyboard; 512 KB RAM memory; (1) "UPGRADED" USB drive.RS-422 Serial port for PC and RS-425 port for inverter connection; EPROM for machine data & subroutines; machine runs production programs while programming and editing. -- Complete with:Stabilized autotransformer for voltages between 200 - 600 Volt 50/60 Hz; (1) 100 cbm/Hr Vacuum Pump; triple photocell barrier; assortment of misc. parts and tooling; Users operator/maintenance manuals & backup disks. -- Actual Model is: BIESSE - ROVER 20.

BIESSE ROVER 18 CNC MACHINING CENTER: -- Specifications: Working capacity: "X" Axis 91" (2,310 mm); "Y" axis 24-3/4" (928 mm); "Z" axis stroke is 3-1/2" (90 mm); max material thickness 2-1/2" (65 mm). -- Worktable(6) Stationary Panel Supports with: (2) Vacuum cups each. -- Positioning Speed "X" & "Y" Axis 328 FPM (100 MPM); "Z" axis 27 FPM (90 MPM). -- Boring Unit2.3 HP Motor - 4,000 RPM with: (12) Independent Vertical spindles with (7) spindles in "X" axis & (5) spindles in "Y" axis; all spacing on 32 mm centers.(4) Horizontal spindles with: (2 + 2) in "X" axis for boring top & bottom edges of panels.(1) "X" Axis grooving saw for max 120 mm (4.7") dia. blade. -- Machining(1) 10 HP (7.5 kW) Router; variable speed from 12,000 - 18,000 RPM for RH or LH rotation with 7.5 kW inverter. -- Operator & Machine Control:CNI "NC 481" CNC 3-Axis Controller; built-in 9" amber CRT; 32 KB memory; 3-1/2" floppy disk drive.Tool correction, circular & helical interpolation, feed speed override, user-friendly programming, and background editing. -- Complete with: (1) 40 cbm/Hr Vacuum Pump; 20 KVA Stabilized autotransformer, side & rear safety fencing, safety photocell barrier. -- Actual Model is: BIESSE - ROVER 18.

.gif)