Equipment For Sale

9613 Results Found

CAM-WOOD TRS-805-H2X Multiple Round Pole MakerFeatures: Single to Multiple Round Pole Making with Flutes all in one passSpecification: -- Working Capacity (Maximum Working Size): 8"; Width, 4-¾";He right. -- Pole Making Length: Minimum10";, Maximum Unlimited. -- Spindle : Precision spindles are manufactured of SCM-4 tool steel (imported from MISHIBISHI Japan), heattreated to HR 46° (ROCKWELL CScale) and the 6,200 RPM spindle are fitted with class 6SKF match ball bearings per spindle then mated to precision machined spindle housings. -- Besides, the spindle body and whole bearing house (include the appearance and interior of the bearing house) has been completely burnished.So, the high hardness material, and high-class SKF ball bearings, and precise spindle-body and bearing house, finally by SHEN KO accurate combination technique. -- The spindle must meet every user’s requirements. -- Spindle tolerance is guaranteed included to (0.002mm / 0.00007") accuracy.Transmission (Drive) Belt: All spindles running are powered by V-shape- double belts (MITSUBISHI) without slipping problem Cutters: Arbor Size 40 mm • Cutting Cycle: 1stTop - 4";to 6-1/4"; Dia., 2nd Bottom - 4"; to 6-1/4"; Dia.Cutting Spindle Motor; 1stTop10 HP, 2nd Bottom 10 HP, Cutter Speed:6,200 RPM Equipped With And Features -- Top head and pressure roller power up & down by 1 HP motor -- Operating panel separate from control cabinet, easy to operate. -- Mechanical digital read-out. -- Mobile jog panel box for setting up. -- Central lubricating for spindles. -- Manual oil pump to remove the resin from table. -- Each table has (2) holes for lubrication.Include - ( 1 ) One size / set of the Cutters, Jig, -- Hold-Down Plate, -- Fence, spacer) -- Optional Round Pole Cutters $2,269.00 each size per set

$ 48,990

CAM-WOOD SFJ-300A End Matcher, 12" Performs tongue and groove, tenoning, mortising, and shaping at both ends of the boards; -- Includes 10'-6" Powered Infeed and 7' Non-Powered Outfeed Conveyors. -- Air-operated hold-downs keep material firmly in place during the machining process. -- Cutter heads move in and out while cutting a tongue on the trailing end of one part and a groove on the leading end of the following part.FEATURES: -- PLC controls combined with a touch-sensing screen for maximum convenience of operation. -- Each cutter head is driven by a separate motor driving the spindle at 7,500 RPM spindle speed. -- Accepts unlimited wood lengths via an automated conveyor for infeed and outfeed processing. -- Cutterheads feed thru the wood is controlled by a frequency inverter that permits speed changes to suit various cutting conditions. -- Pressure plates are actuated by air cylinders. -- Hard chrome-plated table features maximum wear resistance. -- Table rollers increase feed smoothness. -- Powered in feed roller conveyor is driven by a 1 HP motor. -- 3,400 mm in feed roller conveyor and 2,200 mm out feed conveyor table are standard equipment. -- Fully enclosed chip guards. -- Air-operated clamp holds stock firmly in place. After the workpiece is clamped, the cutter head moves in and performs the shaping operation. -- The spindle is precision constructed to cut accurately -- The spindle height adjustment is displayed on a dial gauge. -- CAM-WOOD’S 2-spindle design accommodates cutterhead dia. up to 6"; -- When end matching, one spindle cuts the tongue, and the second cutterhead machines the groove. SPECIFICATIONS: -- 1-1/2" To 12" width cap. -- 10-1/2"; min. length cap. -- Thickness 3/8" to 1 3/8" -- Unlimited length, no restriction. -- Material feed speeds up to 297 FPM; cutterhead travel speed of 79 FPM -- Cutting cycle time 1.5 second.and up to 20 cycle per minute -- (2) 5-1/2 HP Spindle motors and a 2 HP feed drive -- 1/2 HP motor for in/out cutterhead travel. -- 40 mm Dia. spindle -- Requires 1300 CFM dust collection.

CAM-WOOD 16' Pusher Type Cutoff Saw with Crayon Marking connected to a CAM-WOOD 12" wide End Matcher; System width capacity is 12" with a maximum inbound board length of 16' (as priced here). 8' and 12' Saws are also available. Call Jeff for price deduction.General Data: -- Cut-Off Saw is arranged to remove defects from Clear. Will chop for random length clear material OR optimize clear wood according to your cutlist, delivering either to the End Matcher. -- The line requires (1) man to mark and feed the Cutoff Saw and (1) man to offbear and stack finished work coming from the End Matcher. Price includes the following equipment and specifications: Defect Saw Features: -- 18" CAM-WOOD Model CS-18AAT-16' Automatic Cut Off Saw equipped with Automatic Pusher for increased automation and efficiency -- 16' Infeed table -- Works as an automatic pusher for defect removal and fixed length cutting when crayon marking -- PLC controlled automatic pusher device is driven by servo motor at feed speeds up to 200 FPMAutomatic Pusher Operation: -- Operator places crayon marks at the leading and trailing ends of a defect or waste zone (Optional) -- Pusher moves the board to the first crayon marked defect, automatically completes the cutting cycle, and continues to position and chop the board at each crayon mark, thereby removing all waste zones. When the board is finished, the pusher returns to its starting position at top speed and starts on the next board -- Super Pusher travels up to 200 FPM -- Sealed, long-life ball bearings -- Precision ground cast iron table with heavy metal stand -- Easy to operate in all operations -- Saw blade comes up from beneath the table and returns after cutting for safe operation -- Totally enclosed blade guard prevents danger during cutting cycle -- Includes magnetic starters with overload protectionCutting & Other Specifications: -- (45) Strokes/Min -- 18"; Saw Blade Diameter with 1"; Saw Arbor -- 10 HP Arbor Motor -- 3,200 RPM Blade Speed -- 90 PSI Compressed Air requirement with 1" Inlet -- (1) 4"; Dust Hood -- Machine Size (W x L), 30" X 28-1/2'Automatic Transfer between Defect Saw and End MatcherCAM-WOOD SFJ -300 End Matcher with the following Specifications: -- Machines tongue and groove at ends of random or fixed length boards as provided by the Defect Saw -- Includes powered conveyor for infeed and steel landing table at the outfeed -- Air operated hold downs keep material firmly in place during the machining process -- Cutter heads move in and out while cutting a tongue on the trailing end of one part and a groove on the leading end of the following pieceFeatures: -- PLC controls combined with touch-screen for maximum convenience of operation -- Each cutter head is powered by a separate motor driving the spindles at 7,500 RPM -- Accepts unlimited wood lengths via an automated conveyor for infeed and outfeed -- Cutterhead travel thru the wood is controlled by a VFD which permits automatic speed changes to suit various

CAM-WOOD BR-2732X Boring Machine32-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- (2) 2 HP - 3,400 RPM Motors. -- Cast iron 45" x 31-1/2" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: -- Magnetic starter, overload protection. -- Optional quick-change chucks $28.00 ea.

CAM-WOOD BR-50 Universal Boring MachineFeatures & Specifications: -- 3 HP Pneumatic Universal Boring Machine, all adjustments feature an index plate for accurate and convenient reading, workplace clamping. -- Vertical Base travel, 24". Horizontal Base travel 12". -- 0" - 4" Spindle stroke, 7/16" - 14-thread screw shank, 1/2" max. bit capacity. -- Table Size: 15" x 22". -- Complete with: Air operated overhead holddown clamp and foot pedal operated drill cycle. -- Drill Head can be swiveled 360° and Optional Multi-Spindle drill heads available.

CAM-WOOD BR 25 Horizontal DrillFeatures & Specifications: -- Single Spindle, 2 HP - 3450 RPM 3-phase motor, adjustable vertically and front to back. -- 5" Horizontal spindle travel (drilling depth) w/foot pedal control. -- 3-1/2" Vertical table adjustment. -- Pneumatic holddown clamp for up to 3" thickness. -- 12" x 10" Table size. -- 1/2" Drill chuck / 3/4" max. bit diameter.

CAM-WOOD BR 25 + 1 Horizontal and Vertical DrillFeatures & Specifications: The model BR-25+ 1 has the same features as the BR-25, except it's fitted with an additionaluniversal boring head, making it ideal for drilling holes on K/D furniture. -- The boring head can be swiveled 360 degrees for angular drilling, as desired -- Vercical Single Spindle, 2 HP - 3450 RPM 3-phase motor, adjustable vertically and front to back., spindle node threaded 7/16-14" -- Horizontal spindle 2 HP, 3450 RPM-3 phases motor, adjustable 360 degree, spindle nose threaded 7/16-14" -- 5" Horizontal spindle travel (drilling depth) w/foot pedal control. -- 3-1/2" Vertical table adjustment. -- Pneumatic holddown clamp for up to 3" thickness. -- 12" x 10" Table size.

CAM-WOOD BR-2132 Boring Machine21-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 3,400 RPM Motor. -- Cast iron 37-1/2" x 19-1/4" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: Magnetic starter, overload protection. -- Optional: Quick-change chucks $28.00 ea.

CAM-WOOD DC-102 Dust CollectorSmall radial-finned Dust Collector mounted on wheels for portability.Features & Specifications: -- Large 13-1/2" fan that produces 2,100 CFM. -- Heavy Duty 3 HP motor pre-wired at 230 Volts. -- Large capacity dual station cloth top bags of 31.2 sq. ft. total cloth filter area. -- Low sound level of 75 - 90 dB.

Call for Price

CAM-WOOD SET-46TS 6 Heads 48" Double End Tenoner: Soring, trimming and shapingCapacity: -- Max. 48" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Motorized opening with LED indicator; -- Single-post machine, single "dual-track" base, right side fixed, left side movable.Each side equipped -- Front of post: Bottom scoring unit, 2 HP - 3,600 RPM motor, 1" dia. arbor & up to 10" blade; -- Top trim head, 3 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade; (saw blade included) -- Back of post: Vertical shaping head, 5 HP - 7,200 RPM motor, 5-7/8" (150 mm) long & 1" dia. arbor, 8" max. dia. cutter-head. -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads and dogs at 6" center, --Spring loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Cross transfer system with transfer line 4' X 8' transfer table with rollers (additional $41,400) -- Hopper feed magazine (additional $4,990)Extended infeed 42" (additional $5,625) -- Sound enclosure additional $ 8,625 -- Pneumatic jump control on scoring or shaping unit -- Same machine with 8' opening

$ 121,200

CAM-WOOD - SET-48TS-CH 45 , ...8 Heads Double End Tenoner for Chevron & Herringbone FlooringSpecial design Servo Control for Chevron & Herringbone Double End TenonerFeatures: -- Servo Control for +45° or –45° and 90° cutting. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 12 - 52 FPM. -- Feed chain with dogs at 10" center distance. -- Suitable for mass production of woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- Possibility for: Scoring Saw, Trim Saw, Jump Coping, Shaper, Coping. -- Total (4) stations at each side. -- Reversed direction cutting jump shaper head with sensor for automatic move in and out for perfect cutting to prevent tearing at end edge. -- HMI Plus PLC controller for user-friendly easy setting and operation. -- Powerful machine is great for heavy-duty production. In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of sizes for tolerance within 0.004";. -- Variable speed, through feed, wide rubber pad, and spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of wide width Conveyor to hold the material tight to prevent sliding during the cutting process. -- The Shaper head can be moved up & down, forward & backward. -- Equipped with: Industrial motors for full power cutting capacity. Specifications: -- Width from 30 mm to 125 mm (1.18" to 4.9") -- Max. working thickness: 2";. -- Max. working length: 45° is 49";. -- Max. working length: 90° is 48". -- Min. working length: 45° is 18". -- Min. working length: 90° is 13-3/4". -- Scoring/Main saw blade (dia.): 10" x 1". -- Shaper cutter (dia.): 6" - 8" x 1" -- Feed speed 12' - 52', variable power 3 PH - 220/440 Volt. -- V-Scoring saw: 3 HP x 2. -- Trim saw: 3 HP x 2. -- Jump Shaper: 5 HP x 2 Stationary. -- Shaper: 5 HP x 2. -- Feed motor by Servo: 1 kW x 1; Width setting by Servo 0.75 kW x 1.Available Options: -- Total sound enclosure cover: Add ...$9,875 -- Infeed Hopper Magazine: Add ...$6,250.

$ 135,740

CAM-WOOD - SET-48TS-CH 3045 , ...8 Heads Double End Tenoner for Chevron & Herringbone FlooringSpecial design Servo Control for Chevron & Herringbone Double End TenonerFeatures: -- Servo Control for + 30°,45° and 90° cutting. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 12 - 52 FPM. -- Feed chain with dogs at 12" center distance. -- Suitable for mass production of woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- Possibility for: Scoring Saw, Trim Saw, Jump Coping, Shaper, Coping. -- Total (4) stations at each side. -- Reversed direction cutting jump shaper head with sensor for automatic move in and out for perfect cutting to prevent tearing at end edge. -- HMI Plus PLC controller for user-friendly easy setting and operation. -- Powerful machine is great for heavy-duty production. In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of sizes for tolerance within 0.004";. -- Variable speed, through feed, wide rubber pad, and spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of wide width Conveyor to hold the material tight to prevent sliding during the cutting process. -- The Shaper head can be moved up & down, forward & backward. -- Equipped with: Industrial motors for full power cutting capacity. Specifications: -- Width from 30 mm to 305 mm (1.18" to 12") -- Max. working thickness: 2"; -- Working Lenght for 8" wide: 30° 30 1/4" to 33 7/8". -- Working length for 12" wide: 45° is 26" to 41" -- Working length for 12" wide: 90° is 13 3/4" to 49". -- Min. working length: 90° is 13-3/4". -- Scoring/Main saw blade (dia.): 10" x 1". -- Shaper cutter (dia.): 6" - 8" x 1" -- Feed speed 12' - 52', variable power 3 PH - 220/440 Volt. -- V-Scoring saw: 3 HP x 2. -- Trim saw: 3 HP x 2. -- Jump Shaper: 5 HP x 2 Stationary. -- Shaper: 5 HP x 2. -- Feed motor by Servo: 2 kW x 1; Width setting by Servo 0.75 kW x 2.Available Options: -- Total sound enclosure cover: Add ...$9,875 -- Infeed Hopper Magazine: Add ...$6,250.

$ 31,000

CAM-WOOD - VPS I +: Vertical Panel Saw (76" x 122" w/Scoring); Vertical/Horizontal Digital Readouts & Auto-Lock SystemTop to Bottom cutting height : 2,000 mm (76") with or without: Scoring; saw head w/motor rotates 90° for rip or crosscutting; cutting length 3,100 mm; cuts single or stacked panels up to 60 mm (2.36") in thickness.Standard Features -- 4.0 HP Motor (5-1/2 HP Option) with: 250 mm (10") dia. 80-teeth main saw blade. -- Separate 80 mm (3.15") dia. scoring blade; belt driven at 7,800 RPM; single-screw adjustment for side-to-side and depth. -- Auto shifting material back support grid; shifting away from the saw blade cutline prevents cutting into the grid support strips while rip cutting horizontally; senses the blade/cutter position & automatically shifts away. Equipped with: -- Precision ground bottom edge steel support rollers to facilitate easy loading & positioning of the larger or heavy panels; both standard inch & metric preset "beam lock" stations. -- Vertical Cutting Stations: Spaced at 40" or 1,000 mm increments to lock in the saw beam for vertical crosscuts. -- (2) Adjustable flip stops on inch (metric available) measuring scales: (1) Located on the lower rail & the other on the foldout shelf at the middle of the frame. -- Repeat Rip Gauge for duplicating multiple horizontal cuts. -- Retractable Material Support Shelves throughout the entire length of the machine frame allow ergonomic cutting of smaller parts, at any cutting station without the need for the Operator to bend down.Includes: Vertical/Horizontal Digital Readouts; Pneumatic Lock System; Repeat Cutting Device; (1) 250 mm (10") dia. 80-tooth; 30 mm bore main blade; (1) 80 mm (3.14") dia. 24-tooth; 20 mm bore scoring blade.Optional Equipment available. Built-in Dust Collector: Please add ...$ 1,250.

$ 60,000

CAM-WOOD "DYNAMIC" CNC Routers w/ATC for "Nested Base Manufacturing" including Cabinets, Three-Dimensional Wood Processing, Wooden Doors, Furniture & Window Processing; as well as Plastic Processing and Engraving.SERIES 408: $ 60,090SERIES 510: $ 63,800SERIES 512: $ 65,080Models Include (Table Sizes): 408 (4' x 8'), 510 (5' x 10'), 510 (5' x 12')General Specs: Machine Gantry X Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Y Axis Square Rails Parallel Vertical Accuracy 0.001"; (0.03mm), Z Axis Ball Screw Parallel Vertical Accuracy 0.001"; (0.03mm), Re-Position Accuracy 0.001"; (0.02mm), Working Accuracy 0.004"; (0.10mm), Grating Ruler Travel Accuracy 0.002"; (0.05mm).Control System: SYNTEC Control SystemSpindle: 9.0kW (12.8Hp) HSD Air-Cooled Spindle - 6,000 - 24,000 rpmBed Frame: Heavy-Duty Metal WeldingTable: (6) Zone Vacuum TableDriving System: YASKAWA Servo Drive and MotorY Axis Driving System: Helical Rack & PinionX & Z Axis Driving System: HIWIN Ball-screw Axis Square Rail: HIWIN Linear Square RailATC: Rotary (12) Tools ISO30, ER32Inverter: 11 kWLimit Switch: OMRONElectrical Wiring: SIEMENSControl Switch: MOELLERTool Length Device: AutomaticVacuum Pump: OptionalDrill Bank: Includes (9) Tools HSDCAD/CAM Software: OptionalWorking Size:SERIES 408: 51’’ (X) x 98’’ (Y) x 7-3/4’’ (Z)SERIES 510: 63’’ (X) x 126’’ (Y) x 7-3/4’’ (Z)SERIES 512: 63’’ (X) x 150’’ (Y) x 7-3/4’’ (Z)Machine Size (L x W x H):SERIES 408: 87’’ (X) x 122’’ (Y) x 71’’ (Z)SERIES 510: 99’’ (X) x 149’’ (Y) x 71’’ (Z)SERIES 512: 99’’ (X) x 173’’ (Y) x 71’’ (Z)Max Travel Speed: 2 350 IPMMax Working Speed: 1 100 IPMMachine Net Weight: SERIES 408: 3,960 lbs / SERIES 510: 4,480 lbs / SERIES 512: 4,970 lbsFeatures Include: --Automatic (12) Tool Rotary Type Auto-Tool Changer for Increased Productivity. --All “Servo Motor"; Driving System: All Axes are Driven by Brush-Less Type, High Torque AC Servo Motors. --DSP CNC Controller is Setup to Accept Standard G-Code Programming Formats along with On-Board Conversational Applications. --Optional CAD/CAM System can Create and Edit Part Programs then Send to Machine for Easy Cutting. DXF Files can be Imported, Modified and Edited from here to Create a G-Code. --DNC is no Longer Required as the PC Directly Stores all Part Programs in a Text Editable File. --Machine Designed Ready for 3-D Cutting Usage and Superior Performance. --Moving Gantry Construction for Space Saving. --The Rigid Steel Frame Construction has been Stress-Relieved Prior to Finish Machining to Provide Repeatability and Accuracy. --Automatic Frequency Brake for the Spindle Allows Rapid Deceleration Resulting in Faster Tool Changes. --Linear Guides and Sliding Blocks are Pre-Loaded with Recirculation Bearings to Ensure Maximum Rapid Trav

CAM-WOOD TRS-2216 -- 16" Single Blade Bottom Cut Straight Line Rip Saw;Precision fence ensures absolute accuracy between blade & fence, with a precision gauge.Equipped with and Features: -- Double anti-kickback fingers mounted at the infeed end provides maximum safety protection. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage. -- The variable feed speed enables the machine to suit different wood species and work applications. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain running smoothly. -- Precision built saw head ensures accuracy for straight line rip saw operations. -- Four bearing spindle mount ensures rigidity & long life. -- Anti-kick finger, two long rollers, in front of saw blade, 4 x 2 = 8 short rollers at side of saw blade, two long roller at out feed. -- The auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil. Specifications: -- Max. cutting depth: 3-1/8". -- Arbor dia.: 2". -- Saw blade size: 16". -- Spindle speed: 3,300 RPM. -- Feed speed 21 - 85 FPM. -- Throat to blade depth 16". -- Main motor: 10 HP. -- Feed motor 2 HP. -- Min. work piece length: 8". -- Dust Collection Hood dia. 4".Options- LA-6000 LASER BEAM LIGHT ...$980.00

$ 39,990

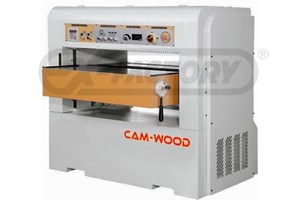

CAM-WOOD WP-1010H 40"; Heavy Duty Planer with S.C.H.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- Maximum thickness capacity 8" -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planing with low noise levels. -- With (4) each 4" diameter dust outlets -- 20 HP Main drive motor. -- 3 HP Variable feed speed 10 to 50 FPM. -- Maximum depth of cut 1/4". -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 40" -- Max. Cut Thickness 8" -- Max. Cut Depth ¼" -- Min. Cut Length 9" -- Cutting Speed 3600 RPM -- Table Size (W x L) 43" x 55" -- Main Motor 20 HP, 3 Ph -- Feed Motor 3 HP -- Table Raising Motor 1 HP -- Feed Rate (Variable) FPM 10 ~ 50 -- Net Weight 4,750 Lbs -- Shipping weight 5,500 LbsFOR UPGRADE TO 25 HP ADD ...$900.00

$ 14,990

CAM-WOOD BX-1212BEEX Single Bottom Head Band Resaw.Can be used to cut boards, cants, or reclaim slabs; Specifications: -- Can process up to 12" H x 12" W; 5/16" - 5-1/4" from blade to conveyor. -- 2 HP Electric motor controlled variable speed from 12 - 80 FPM. -- This Model BX-1212BEE is equipped with: -- 20 HP Saw Motor, 28" x 1" band wheels, 168" x 1" band saw blade (not included). Features: -- Hand-wheel blade tensioning; manual elevation adjustment; 2 HP hydraulic system pump motor. Complete with: -- Spring-loaded steel and rubber upper-pressure rolls; 11" X 215" conveyor belt.

CAM-WOOD BX-1212HR-1 Single-Head Band Resaw w/30° Bevel CuttingCan be used to cut boards, cants, or reclaim slabs; Specifications: -- Max. working height up to 12" H under pressure roller x 12" W; 1/4" - 10-5/8" between blade and conveyor; -- VFD controlled variable speed from 0 - 60 FPM. Equipped with: -- 20 HP Saw Motor, 24" x 2" dynamically balanced cast iron band wheels, 184" x 1" to 1-1/2" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Tilting 10-5/8" x 165-1/2" infeed conveyor from 0° - 30° with side support for bevel cutting; 3 HP drive motor; variable feed speed 0 - 60 FPM; return gravity roller conveyor.Complete with: -- Programmable Digital Controller for convenient and accurate thickness setting; -- 1/4 HP Blade elevation motor moves blade and saw head; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. Includes: Operators' & Parts Manual and covered by (1) Year Warranty.

$ 39,890

CAM-WOOD BX-2410HR Single-Head Band Resaw w/30° Bevel CuttingCan be used to cut boards, cants, or reclaim slabs; max. working height up to 10" H under pressure roller x 24" W; 5/32" - 10" between blade and conveyor; VFD controlled variable speed from 0 - 82 FPM.Equipped with: -- 30 HP Saw Motor, 28" x 2" dynamically balanced cast iron band wheels, 195-1/2" x 2-1/8" x 3/64" band saw blade (not included); hand wheel adjustment for blade tension with tensioning scale. -- Tilting 23" x 215" infeed conveyor from 0° - 30° with side support for bevel cutting; hydraulic infeed and outfeed conveyor drive motor; variable feed speed 0 - 82 FPM; return gravity roller conveyor. -- Complete with: -- Digital controller for convenient and accurate thickness setting; 1/4 HP blade elevation motor; infeed and outfeed spring-loaded pressure rolls, easily adjusted by gear rack. -- Includes: -- Operators' & Parts Manual and covered by (1) Year Warranty.

Call for Price

CAM-WOOD SET-410-SHJJA 50" Double End Tenoner with Sanding(10) Heads Double End TenonerFeatures: -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 66 FPM. -- Suitable for mass production in woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most universally satisfying machines for bulk production in lumber-processing factories. -- The specially designed numeric controller allows quick setting of length sizes for tolerance within 0.004". -- Variable speed, through feed, wide rubber pad, spring-loaded dogs at 16" center conveyor for the best finish selections. -- Heavy-duty powered pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting and sanding process. -- Shaper head can be moved up & down, forward & backward. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Two sanding heads can use brush, flap wheel or profile disc for fine finish with one pass. -- Trim saws and sanding heads can be tilted for different angular setup. -- Heavy cast iron base for durability usage.SPECIFICATIONS: -- Material Thickness: ½" to 4". -- Material Length: 10" to 50". -- Scoring Saw Blade: 12" x 1" Dia. -- Hogging Saw Blade: 8" x 40 mm dia. arbor. -- Shaper Cutter: 6" - 10" x 40 mm dia. arbor. -- Feed Speed: 20' - 66' Variable, Motor 3 PH, 220/440 V. -- Trim Saw 5 HP x 2. -- Hogging saw blade 10 HP x 2. -- Jump Shaper 15 HP x 2. -- Jump Shaper 15 HP x 2. -- Brush/Disc Sanding 2 HP x 2 with inverter for variable RPM. -- Feed Drive 3 HP x 1. -- Width Setting 1HP x 1. Option: -- Sound enclosure $ 8,900 -- Hopper feed magazine $ 3,900 -- 42" extend infeed conveyor before top hold down $ 4,900

.gif)