704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1832 Results Found

704-841-2001

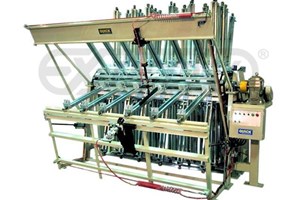

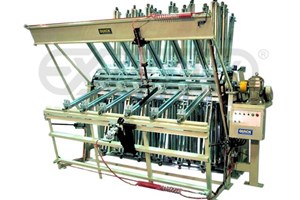

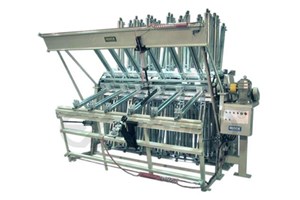

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

QUICK 6-Section Pneumatic Clamp Carrier with 20-1/2' width cap. & Dual Operator's Stations, -- (16) Heavy Duty zinc plated clamps per section (96) clamps total), 50" opening on clamps. Jaw sizes of clamps is 3-1/2" high x 4-3/4" wide, with 1° inward draft. Equipped with DUAL OPERATOR'S STATIONS including: -- (2) Pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners -- Semi-automatic rotation via electric motor drive; with separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In.Standard Supply includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

QUICK 6-Section Clamp Carrier with 16-1/2' width capacity6-Section Pneumatic Clamp Carrier with 16-1/2' width cap. -- (12) Heavy Duty zinc plated clamps per section (72 clamps total); 52" opening on clamps. -- Jaw size of clamps are 3-1/2" high x 4-3/4" wide, with 1° inward draft.Equipped with: -- Pneumatic overhead panel flattener 16-1/2' wide. -- Pneumatic clamp tightener -- Semi-automatic rotation via electric motor drive; -- Separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In. -- Flexible conduit for electric wires.Features & Includes: -- Automatic air line oiler; -- High quality urethane finish coating. -- Toolbox with spare parts & tools.Floor space requirement: 236" W X 131"D X 148" H

QUICK 6-SECTION Clamp Carrier; (6) Sections, (6) clamps per section, and 8-1/2' width capacity. -- (36) Clamps total with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. -- 8 1/2 feet wide with easy to use controls.Equipped with: -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Pneumatic Panel Flattener -- Electric motor drive for Carrier rotation.Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler. -- Hhigh quality Urethane finish coating, and tool box with spare parts & tools. NOTE: -- 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). -- Clamp can be expanded to (14 or 20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. -- NOTE: Clamp Carrier can be expanded to (14) or (20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

QUICK 6-SECTION, 12-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp, typically produces (144) high-quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (9) clamps per section and 12-1/2' width capacity. -- (54) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- Rocker Plates are available as optional equipment for face gluing. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy-to-use controls. -- Pneumatic Clamp Tightener with a 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; the 2-handed, trigger-activated tightener is more confidence-inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, and automatic air line oiler; -- High-quality Urethane finish coating, and tool box with spare parts & tools.Floor space requirement: 195"W X 125" H X 127"D

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

Call for Price

14 Section Hydraulic Clamp Carrier with 8-1/2' width capacity. -- This special "thick stock" frame accepts (8) Heavy Duty zinc plated clamps per section. -- Includes 112 clamps with 36" openings and 6" high x 4-3/4" wide jaws with 1° inward draft. -- Integral pneumatic overhead panel flattener. -- Automatic hydraulic clamp tightener with adjustable torque limiter. -- Single button automatic electric motor rotation cycle with indexing. -- The machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes: foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools. -- Call your FactoryNew sales specialist for details on all of "QUICK'S" popular clamps ranging from 30" to 52" openings. Many other base frames are available in hydraulic and pneumatic operation.

QUICK 14-Section Heavy Duty Hydraulic Clamp Carrier with 20-1/2' width capacity With (16) Standard zinc plated clamps per section (224) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Pneumatic Panel Flattener with easy to use controls. -- Pneumatic panel flattener for second operator -- Hydraulic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic clamp tightener for second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

$4,950

SCMI T-130 ShaperSolid Heavy Duty Shaper with 1-1/4" Dia. fixed spindle. Specifications: -- 8 HP belt drive motor with (5) spindle speeds of 3,000 - 4,500 - 6,000 - 7,000 & 10,000 RPM. -- 6" Max. cap. under nut. -- 47" x 28-1/2" Cast Iron table

$1,750

SCM MINIMAX T-3 SHAPER3/4" Dia. solid spindle, 3 HP motor,(3) spindle speeds of 4,000 - 7,000 & 9,500 RPM; table size 22" x 37" with table insert openings. -- Complete with: Adjustable fence, magnetic starter w/overload protection, reversing switch and 5" dia. dust outlet.

$15,000

SCM TECH Z 30 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working Field "X" axis 120" (3,050 mm); "Y" axis 52.7" (1,340 mm) for routing & 44" (1,118 mm) for boring; "Z" axis stroke 7.8" (200 mm); max. material thickness 3.9" (100 mm). -- Positioning Speed:"X" & "Y" Axes are 197 FPM (60 MPM); "Z" axis is 72 FPM (22 MPM).Axes positioning by: AC Brushless motors and YASKAWA drives; high precision ball screw drive system in "X", "Y". "Z" Axes;All axes ride on prismatic guideways & sliding blocks. -- Worktable:(6) "TV" Tubeless mobile support rails, (2) vacuum pods per rail; (4) pneumatic lifter rails for heavy panels.(6) Pneumatic pop-up backstops, (6) pneumatic pop-up front stops; (2) pneumatic pop-up side stops.LED Display positioning assistance for the support rails & vacuum pods; (2) independent working fields. -- Boring Head:3 HP (2.2 kW) motor - 4,000 RPM; (15) independent vertical spindles: (8) Spindles in "X" & (7) spindles in "Y".(6) Horizontal spindles (2 + 2) in "X" & (1 + 1) in "Y-axis".(1) X-axis grooving saw with 100 mm dia. blade - 6,000 RPM. -- Machining:(1) 10 HP (7.5 kW) Electro-spindle router with: HSK F63 Adaptor; variable speed from 1,000 - 24,000 RPM, max. torque achieved at 12,000 RPM.Static inverter for stepless speed & rapid shutdown rotation.(1) 6-Position ATC tool plate mounted on the on the machine for "on the fly" ATC; max. tool weight is 8 kG (17.6 Lbs). -- Operator & Machine Control:PC Front-End with: SCM "UNIVERSAL K2" + "Xilog Plus" + Windows "XP" Pro Operating System; 15" CRT color display, CELERON 2 GHz processor, enclosed in air-conditioned cabinet. -- Complete with:(1) 100 m³/Hr Vacuum Pump; automatic lubrication system; "BUMP STOP" safety system. -- Actual Model is SCM TECH Z30 R6

SCM STARTECH 23 BORING MACH. (CONSTR. & LINE BORING):Specifications: -- 23-Spindle boring head (aluminum alloy single block), drills vertically from top & horizontally from rear. -- Manual tilt with gas shock cylinder assist, positive stop at 45° for boring at an angle; 3 HP - 3,400 RPM motor. Equipped with: -- 6-Position turret depth stop, 2-3/8" boring head stroke with digital readout setting, hydraulic brake for vertical "through boring". -- (2) Air hold-down clamps, foot pedal operated. -- Index pins for line boring, side fences. -- Actual Model is SCM STARTECH 23

SCMI STARTECH/23 23-Spindle Construction Boring Machine.Specifications: -- Distance between spindles 32 mm (1.26"), Maximum drilling head distance 704 mm (27.72"), Maximum drilling depth 45 mm (1.77"). -- Panel thickness 10 - 75 mm (0.39" - 2.95"), Maximum panel width under bridge 1,000 mm (39.37"). -- Maximum panel size:270 mm(10.63") (with vertical head), 130 mm (5.12") (with horizontal head). -- Drilling head stroke 63 mm (2.48"), Tool diameter 5 - 10 mm (0.20" - 0.39"), Tool length 55 - 75 mm (2.17" - 2.95"). -- 26-1/4" x 40" x 33-1/2" H Table, 2.64 kW (3-1/2 HP) 3,390 RPM Motor.Equipped with: -- 23-Spindle Boring head (Aluminum alloy single block), Drills vertically from top & horizontally from rear. -- Manual tilt with Gas shock cylinder assist, Positive stop at 45° for boring at angle. -- 6-Position Turret depth stop. -- (2) 3" Diameter Air hold-down clamps, Foot pedal operated. -- Index pins for line boring, 15-1/4" L x 1-1/2" H Side fences.Complete with: Operation & Maintenance Manual & SHOP FOX Mobile Base with Swivel Casters. -- Dimensions: 58" x 48" x 46" H. Weight: 1,100 Lbs.

$16,900

SCMI - SIGMA 90 Plus, ...Front-Load Auto. Panel SawSpecifications: -- 126" Max. rip cut cap.; 126" max. front/back; 2-9/16" cutting height; 15 HP main saw motor; 4,600 RPM main blade speed; 2 HP scoring motor, 6,200 RPM score blade speed. -- Hydraulic feed speed variator for saw carriage, 50 - 100 FPM, return speed 100 FPM, automatic saw carriage lubrication, balanced on hardened cylindrical guides, external score saw adjustment. -- THK guides for vertical saw movement; programmable rear fence with (5) material grippers, rack & pinion movement, 26 FPM forward and reverse; grippers fit into a slotted pressure beam for positive material control during the final cut. -- Rear support rails with rollers; (1) front fixed Bakelite-coated air table 59" x 20" and (2) movable 59" x 20" air tables. -- Complete with: -- Automatic crosscut side aligner to 72-3/4"; plastic safety sectors & emergency bar surround cutting area. -- Specifications subject to verification.

SCM - SIGMA IMPACT 85K, ...CNC Front-Load Panel SawSpecifications: -- 126" (3,200 mm) Max. rip cut cap., 126" (3,200 mm) max. front/back (85 mm), max. saw blade projection 3.35"; 18 HP main saw motor, 13.78" (350 mm) dia. - 3,900 RPM main blade; 2 HP scoring motor, 6.3" (160 mm) dia. - 6,300 RPM score blade; external score saw adjustment.Feed speed variator for saw carriage, 0 - 443 FPM; return speed 443 FPM; automatic saw carriage lubrication, travels on precision round and hardened guides; THK guides for vertical saw movement. -- Equipped with: -- Programmable rear fence with: (6) Material grippers, rack & pinion movement, 230 FPM forward and 230 FPM reverse; grippers fit into a slotted pressure beam for positive material control during the final cut. -- "PC" Front-End with 15" Color monitor display with: (32) Key standard PC type keypad, (2) axes positioning readout (saw carriage and pusher). -- Automatic/semi-automatic modes interruptible for blade changes; dynamic (1,000) line memory, RS-232 serial port for PC connection; diagnostic readout of malfunctions, positioning errors, and command errors. -- Includes: -- Rear support rails with rollers; (1) front fixed air table 98" x 24", and (2) movable 59" x 15-3/4" air tables; automatic crosscut side aligner from 2.36" out to 47.24", plastic safety segmented curtain & emergency bar surround cutting area. Dust requirements 2700 CFM with (2) outlets 120 mm, (1) 150 mm in diameter.

SCM SIGMA SZ 110 PLAST Automatic Panel Saw;This machine is Ideal for Plastic Materials. -- Specifications: Working cap. 149.6" (3,800 mm) Max. rip cut cap. 149.6" (3,800 mm) pusher stroke; 4.5" (115 mm) max. saw blade projection.24 HP (17.8 KW) main saw motor Inverter controlled for various plastics, variable speed from 0 - 3,900 RPM; 2 HP (1.5 kW) scoring saw motor (4,200 RPM).Main blade diameter: 15.75" (400 mm), Main blade arbor diameter: 80 mm; Scoring blade diameter: 7.87" (200 mm), Scoring blade arbor diameter: 80 mm.Manual scoring blade adjustment with digital indicator. Automatic exclusion of scoring unit when motor is in off position. -- Saw carriage: Feed speed 0 - 442 FPM (0 - 134 MPM), return speed 442 FPM (134 MPM),Automatic saw carriage lubrication, balanced on hardened cylindrical guides; external score saw adjustment, THK guides for vertical saw movement. -- Pusher Fence Feed Speed 0 - 230 FPM (0 - 70 MPM) forward speed, 230 FPM (70 MPM) reverse speed.Programmable rear fence with (9) material gripper clamps with twin fingers for thin materials, rack & pinion movement,Grippers fit into a slotted pressure beam for positive material control during the final cut. -- Operator & Machine Control:PC front-end with SCM Real-time "WinCut" + Windows "7" operating system; Pentium 300 MHz, 6.4 GB hard drive, 64 MB RAM,17" Color VGA flat panel Touchscreen monitor, on-screen diagnostics & production reports; (2) serial ports & (1) parallel port, spacing available for networking cards. "Cutty" optimization software is included which allows for (2) different sheet sizes and (22) different parts, each part is allowed a max. quantity of 300. -- Complete with: Side alignment device: Min. part width 2.8"; Max. part width 47.24". Rear support rails with rollers.(1) Front fixed air table 98" x 23" (2,500 x 584 mm), (2) Adjustable air tables 98" x 23" (2,500 x 584 mm).Plastic safety guards, emergency stop bar; enclosed cutting area; triple dust collector outlet.Actual model is SCM SIGMA SZ 110 PLAST.

$12,750

SCMI MINI-MAX ME 25 EDGEBANDER, SINGLE SIDED SINGLE PHASE0.4 mm to 3 mm (1/8") Max. edge thickness cap. and 1.96" max. panel thickness; semi-automatic strip & coil feed magazine (feeds coil material automatically and strips one at the time); Teflon coated glue pot w/fast (8-10) Minute heat-up time, 1.2 mm cap. guillotine.Workstations: -- "ME 25" 2-Head -- Single motor end trim (0.8 HP - 12,000 RPM motor) -- Top & bottom flush trims (0.8 HP - 12,000 RPM ea. motor), straight or bevel cutters. -- Top & bottom scraping station. -- Top & bottom buffing, 3,000 RPM motors.22 FPM Fixed feed speed with 0.8 HP drive.Complete with: Sound enclosure, out rigger panel support, frequency converter, and used tooling on the stations.Features: Control Panel on machine infeed side Machine frame made of high rigidity ribbed steel to guarantee excellent support Top thick steel pressure beam with rubber coated wheels Manual adjustment of top beam with Auto positioning of operating units Numeric indicator of selected panel thickness Glue smoke-specific exhaust outlet; centralized extraction of the dust Panel support roller which can be extended the entire length of the machine

$36,000

SCM M3 Multi-Blade Dip Chain Gang Rip SawSpecifications: -- 300 mm (11.81") Width cap. -- 110 mm (4.33") Max. depth of cut. -- 8-3/4" Throat depth. -- 390 mm (15.35") Min. stock length. -- 200 - 350 mm (7.87" - 13.78") Blade diameter. -- Arbor dia. 70 mm (2.76"). -- Table size 750 x 1,530 x 750 mm H (29-1/2" x 60.24" x 29-1/2" H). -- Blade speed 4,200 RPM. -- Feed speeds 6 - 48 MPM (19 - 157 FPM).Equipped with: -- 44 kW (60 HP) - 3,554 RPM Blade motor. -- Variable speed drive feed chain motor. (2) Upper infeed & (2) Upper outfeed 4" Dia. rollers, Automatic chain lubrication. -- Top & bottom anti-kickback fingers. -- Main dust hood, with 200 mm (7.87") Dia. outlet. -- 40” x 2-3/4” H Adjustable infeed fence. -- Motor load meter.Complete with: -- Operation & Maintenance Manual. -- Tooling (As pictured).

$10,700

SCM P-170 Feed Through Moulder5-Head, 6-5/8" x 4-3/4" capacity. Specifications: -- Head sequence: Bottom 6.5 HP, right 6.5, left 6.5 HP, top 9 HP, Universal 9 HP motor; -- 1-13/16" Dia. spindles at 6,000 RPM, spindles equipped with high cap. precision bearings, all set-up adjustments on front side of machine. -- 15 - 85 FPM Feed speed, 3.6 HP Cardan (chainless) feed drive, motorized feed beam with air-loaded feed wheels.Complete with: -- 84" Long infeed table with quick lever thickness adjustment for stock removal, manual Waxilit bed lubrication. -- Note: No cutterheads or tooling included.