704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Sawmill

749 Results Found

704-841-2001

$54,780

LHI RFPR 102/10 MULTI-BLADE PANEL SAW: with 102" of usable width cutting capacity. Specifications: -- (1) 40 HP main arbor motor for 1/8" min. - 4-1/4" max. material thickness; min. panel length 30"; 102" of usable width cutting capacity. -- 12" Dia max. blade capacity; 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; -- Positive powered steel contact feed rollers with (8) Polyurethane drive rollers; fixed feed speed of 80 FPM. -- Includes (6) arbor collars - blades not included. -- Complete with:(2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM.Available Options: -- Blade Box & "Quick Change" Arbor Cart and Trolley $12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $16,390.00 each -- Drag Chain Feeder Conveyor - Roller conveyor transfers sheets to in-feed of saw and dog chains align and start the sheets into the saw feed rolls. Recommended with 102" wide machines, $18,800 Tooling Cost: -- Carbide Tip Blades 10" dia. x 40-tooth thin kerf blades $125.00 each -- Saw Blade Tooling Collars $125.00 eachOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

Call for Price

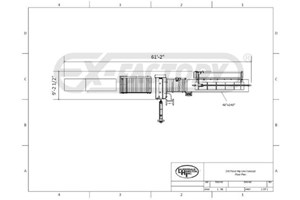

LHI MODEL RFPR AUTOMATED PANEL RIP SYSTEM --Arranged for up to 5/8"; Thick x 52"; Wide x 18’ Long Panels as follows: AUTOIMATIC INFEED SYSTEM, INCLUDES: --Rake Feeder for up to 18’ Long Sheets --Automated Feed Cycle Controls --Turnkey Controls, Plug it in and Run --1 HP, 3-Phase, 460-Volt Operation 6’ ALIGNMENT CONVEYOR, INCLUDES: --Gravity Roller Frame with 60"; Wide Rollers --Alignment Fence --Spring Loaded “Feather"; to Keep Sheets Tight to the Alignment Fence --Powered Feed Wheel to Push Sheets into the Ripsaw --2 HP, 3-Phase, 460-Volt Operation TANDEM INFEED SCISSORS LIFT --8,000 LBS. Capacity --30"; x 204"; Platform With 62"; Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62"; x 204"; Useable Deck Size. --Automatically Raised and Lowered by Signals from the Sheet Feeder --2 HP, 3-Phase, 460-Volt Operation TANDEM OUTFEED SCISSORS LIFT --8,000 LBS. Capacity --30"; x 204"; Platform With 62"; Long Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62"; x 204"; Useable Deck Size. --Automatically Lowers by Signals from Auto-Down Index Control Unit --2 HP, 3-Phase, 460-Volt Operation --OPTIONAL: 4-Sided “Accordion Skirts"; for each Tandem Lift Table, add $2.650 per lift RFPR" ROLL FEED PANEL GANG RIP SAW --50 HP Main Arbor Motor --1/8" Min. To 1-1/4" Max. Material Thickness x 72" Cutting Width --10" Dia Blade Design; 3-15/16" Dia. Arbor with 72" of Usable Width Cutting Capacity --Min. Panel Length 30". --1-15/16" FAFNIR Arbor Bearings --(8) Polyurethane Feed Rollers on 6" Centers --Variable Feed Speeds Via VFD --(1) Quick Blade Change-Out Kit --(1) Additional Arbor Cart --(2) 4" Dia. Dust Collection Ports on Top and (1) 8" Dust Collection Port on Bottom. Total Recommended 1,500 CFM. TOOLING: --(20) Saw Collars, Mount Directly to the Arbor with a Set Screw --(20) Saw Blades Configured for Clean Cuts on Your Panels

LHI 4,500 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 4,500 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$239,800

LHI 96" x 60" ANGULAR TYPE RIP & CROSS-CUT SYSTEM: Specifications: -- Automatic Angular Rip & Crosscut 5-Position System; max. panel size of 8' (96") long x 5' (60") wide x 1" - 4" thick; 1.25" minimum spacing between the blades; variable feed speed from 0 - 150 FPM. This system will process a unit of material in approx. (7) Min. -- Pos. # 1: LHI Automatic Staging/Infeed/Transfer & Panel Rake Feeding System: 10' (120") Long, powered 3-chain staging conveyor; (2) units can be preloaded while (1) unit is in process. Automatic up-indexing 4,500 Lbs capacity Scissors Lift with auto. rake infeed system: infeed rake system designed with a thin material device that can automatically load material as thin a 1/8". -- Pos. # 2: LHI "72": 72" Arbor length designed for panels up to max. of 5' (60") wide, min. panel length 30"; 40 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation. 2-3/4" Dia. arbor with 1-15/16" "Fafnir" arbor bearings; positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia. vertical dust outlets with an easy access strip separator box. -- Pos. # 3: LHI Cross-Transfer System: Transfer conveyor with panel hold-down & chain drive system to change direction 90° & automatically feed LHI 102". -- Pos. # 4: LHI "102": 102" Arbor length designed for panels up to max. 8' (96") long; 30 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation; 2-3/4" dia. arbor with 1-15/16" "Fafnir" arbor bearings. Positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia vertical dust outlets with an easy access strip separator box. -- Pos. # 5: LHI Stacking & Outfeed Transfer System: Auto. down-indexing 4,500 Lbs cap. Scissor Lift; (4) adjustable alignment posts & (4) bin separators to keep processed stacks square. 98' (96") Long outfeed gravity conveyor.Operating System: -- (1) LHI ALLEN-BRADLEY "Inter-Link" PLC for simple single-operator management of the entire system from (1) central control.NOTE: ...Attached description & pictures are for INFO purposes only; ...a NEW System can be modified to your exact specifications!NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

LHI RFPR 72/12 "HEAVY DUTY" MULTI-BLADE PANEL SAWSpecifications -- (1) 50 HP main arbor motor for 1/8" min. - 2" max. material thickness; 12" Dia max. blade capacity with 1.25" minimum spacing between the blades; Minimum panel length 30" & 72" of usable width cutting capacity. -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; positive powered steel contact feed rollers with (8) Polyurethane drive rollers; variable feed speed to max 80 FPM. -- (1) "Quick Change" arbor cart trolley and blade box for 9 1/2" cutsOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.Available Options: -- Blade Box Arbor Cart and Trolley $ 12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $ 700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $ 3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $ 14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $ 16,390.00 eachTooling Cost: -- Carbide Tip Blades 12" x 40T x 4 3/16 bore with TCG and 3 pin holes $ 125.00 each -- Saw Blade Tooling Collars $ 125.00 each -- Actual Model is LAUDERDALE-HAMILTON RFPR "HEAVY DUTY" 12 Panel Rip SawNOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$43,600

LHI RFPR-72/10 MULTI-BLADE PANEL SAW: Specifications: -- 40 HP main arbor motor; 1/8" min. - 1-1/4" max. material thickness; 10" dia blade with 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 72" of usable width cutting capacity, min. panel length 30"; -- 1-15/16" precision arbor bearings; positive powered steel contact feed rollers; -- Fixed feed speed of 80 FPM. Blades & collars: -- Thin kerf 10" dia x 40-tooth x 4.18" bore non-split blades with quick & easy setup for fast blade positioning/removal (blades not included). -- Blades & collars are sold separately & not included in the machine price; 10" dia. x 40-tooth thin kerf blades, please add ...$ 105 ea.;1.25" wide x 4.18" bore blade collars, add ...$ 145 each. Complete with: -- (2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM -- Actual Model is LHI RFPR-72/10 Roll Feed Panel Saw. Available Options at additional cost: -- 110 V Infeed Scissor Lift with foot pedal controls or automatic up-indexing; 110 V Outfeed Scissor Lift with automatic down-indexing;Assortment of blade thicknesses & diameters; Split blade & collar system; Additional Options Depending on application: -- Main motor power from 30 - 75 HP; 4" Max. cutting height (requires 75 HP motor); -- Variable feed speed; Non-marking Polyurethane contact feed rollers; -- Additional arbors; "QUICK CHANGE" arbor system (see video); -- "Pigtail" quick change Crosscut Saw System.Many more tooling & configuration options available upon requestThis machine will cut a bundle (42 sheets) of 3/4" Plywood. PB, MDF or OSB into narrow strips in (4) minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

LHI RFPR-72/16 "HEAVY DUTY" MULTI-BLADE PANEL RIP SAW (W/LOADING/UNLOADING): -- Specifications (1) 30 HP Main arbor motor for 1" min. - 5" max. material thickness;16" Dia max. blade capacity with 1.25" minimum spacing between the blades;Minimum panel length 30" with 72" of usable width cutting capacity.3-15/16" Dia. arbor with 1-15/16" precision arbor bearings;Positive powered steel contact feed rollers with (8) adjustable Polyurethane drive rollers;Variable feed speed to max 80 FPM.Available Options Include:Single point height adjustment for materials from 1" to 5" thickness using customer supplied 16" dia blades(note: Ripping widths can never be less than one-half the material thickness).(1) "Quick Change" arbor cart trolley and blade box for QC set ups.(12) Saw collars to attach the customer supplied 16" dia. diamond blades to the arbors(1) In-feed Scissors Lift with auto cycle controls(1) In-feed 6' conveyor with alignment fence and powered assist feed(1) Auto sheet feeder with auto cycle controls(1) Out-feed Scissors Lift with 4 x 8 roller top.Installation technical assistance for $125/Hr plus travel time and expenses, payable upon competition of services. NOTE:Quote is valid for 30-days;Quoted price is FOB, Factory;Customer is responsible for off-rigging cost at their facility;Customer is responsible for spotting the machine to its final resting place with adequate floor foundationCustomer is responsible for adequate electric, air & dust control supply upon technician's request:Warranty: 1-yr mechanical parts (electrical controls excluded);Delivery to Customer's facility is approx 17 weeks from receipt of funds;Quote assumes customer will deliver material for testing & run-off procedures (if required);NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

LHI 6,000 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 6,000 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$88,500

LHI MODEL RFPR ROLL FEED PANEL RIP SAWWith the following Standard and Optional Equipment: -- Roll Feed Panel Rip Saw - 72" Arbor - 50 HP motor -- 10 to 80 FPM (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- 10" Dia. blades (thickness-1/8" to 1-1/4") Infeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) 2"; x 3"; support tubes for fork access -- 110 VAC / 1-Ph power unit -- Foot pedal control -- Automatic up-indexingOutfeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) Support ramp/cross-bars to allow for access -- Auto down indexing -- 110 VAC / 1 Ph power unit -- Foot pedal controlSawblades: -- (10) 10" x 40T x 4-3/16 Bore, TGC Blades -- (10) Blade Collars, 3-15/16" ID x 4.18" bore x 1.25" wide Quick-change arbor setup with the second arbor: -- Arbor change cart (included with the arbor setup that comes with the saw to allow roll-out) Second Arbor Setup Includes: -- Cart -- Blade Box -- Arbor, Bearing -- Sheave -- Throat Plate Rack -- (6) Throat Plates Quick Change Kit: -- Belt Guide -- Belt Tensioner -- Hyd. Arbor Lock Quick Change Kit permits the operator to release the belt and unlock the arbor from the front side of the machine. Without the kit, the operator must open the rear guard to remove the belt and unlock the arbor -- (10) Blades for the second setup -- (10) Collars for the second setup 16-week ESTIMATED delivery: -- Delivery assumes order and down payment are received within (1) week of the date of quotation. Installation technical assistance for $115/Hr plus travel time and expenses Customer responsible for rigging Quote assumes customer will deliver material for testing (if required) Warranty: (1) Year mechanical parts (electrical controls excluded) This quotation is valid for 30 days. ESTIMATED DELIVERY DATE:The delivery date is quoted as 'estimated' because the equipment we manufacture is built to order and to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$17,950

RES 2500 25" Gas Powered Alligator Shear Description -- Approx 10 Hours --Blade Length 25.25" --Blade Opening Tip To Tip 14" --Motor Size 10 HP, 220v or 440v / 3ph --Jaw Fully Open 11 Cuts Per Minute --Jaw 1 1/2" Open 63 Cuts Per Minute --Dimensions (L x W x H) 72 1/2" x 32 3/4" x 45 1/4" --÷Weight 2500 lbs --Shear Height 32 1/8" --Foot Pedal Control Automatic/ Single Stroke --Maximum Cutting Force 110 Tons --Cutting Capacity Mild Steel --Round Bar 2 1/4" Dia. --Angles 3" x 3/8" --Flats 6" x 3/4" --T Section 3" x 3" x 3/8" --I Beams 4" x 1 3/4" x 5 1b. --Square Bar 1 3/4" --Channels 4" x 2" x 8 1b. --Plate 25" x 1/4"

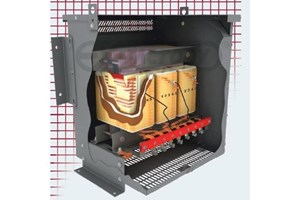

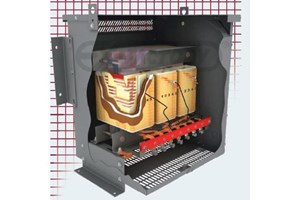

REX MFG. 200 KVA RC200C-F/N 240/380 Three-Phase Auto TransformerSpecifications & Features: -- 200 KVA Auto-ventilated "dry type", 3-phase Auto Transformer. -- 240 Volt primary, 380 Volt secondary. -- Manufactured with 3-legged cores and high quality, grain oriented silicon steel; core steel is precision cut and stacked for reduced noise and losses; cores clamped with heavy steel brackets. -- The 75-460/600 Transformer coil windings have high quality copper magnet wire; Class 220° C insulation is utilized througout the coil winding process; coil is impregnated and baked in Polyester resin varnish. -- Complete with: -- Substantial cooling ducts for effective cooling. -- NEMA 3R rated Heavy Gauge steel enclosure w/ventilation openings; sprinkler proof. -- UL & CSA approved. -- Includes: -- Delivery anywhere in the Continental USA.

REX MFG. 200 KVA RC200H-G1/50 480/400 Three-Phase Auto TransformerSpecifications & Features: -- 200 KVA Auto-ventilated "dry type", 3-phase Auto Transformer. -- 480 Volt primary, 400 Volt secondary. -- Manufactured with 3-legged cores and high quality, grain oriented silicon steel; core steel is precision cut and stacked for reduced noise and losses; cores clamped with heavy steel brackets. -- Coil windings have high quality copper magnet wire; Class 220° C insulation is utilized throughout the coil winding process; coil is impregnated and baked in Polyester resin varnish. -- Complete with: -- Substantial cooling ducts for effective cooling. -- NEMA 3R rated Heavy Gauge steel enclosure w/ventilation openings; sprinkler proof. -- UL & CSA approved.

REX MFG. 75 KVA RC75H1-J, 460/600 Three-Phase Auto TransformerSpecifications & Features: -- 75 KVA Auto-ventilated "dry type", 3-phase Auto Transformer. -- 460 Volt primary, 575/600 Volt secondary. -- Manufactured with 3-legged cores and high quality, grain oriented silicon steel; core steel is precision cut and stacked for reduced noise and losses; cores clamped with heavy steel brackets. -- The 75-460/600 Transformer coil windings have high quality copper magnet wire; Class 220° C insulation is utilized throughout the coil winding process; coil is impregnated and baked in Polyester resin varnish. -- Complete with: -- Substantial cooling ducts for effective cooling. -- NEMA 1 rated Heavy Gauge steel enclosure w/ventilation openings. -- UL & CSA approved. -- Includes: -- Delivery anywhere in the Continental USA.

REX MFG. 75 KVA RC75C2-F/N 220/380 Three-Phase Auto TransformerSpecifications & Features: -- 75 KVA Auto-ventilated "dry type", 3-phase Auto Transformer. -- 220 Volt primary, 380 Volt secondary. -- Manufactured with 3-legged cores and high quality, grain oriented silicon steel; core steel is precision cut and stacked for reduced noise and losses; cores clamped with heavy steel brackets. -- The 75-460/600 Transformer coil windings have high quality copper magnet wire; Class 220° C insulation is utilized througout the coil winding process; coil is impregnated and baked in Polyester resin varnish. -- Complete with: -- Substantial cooling ducts for effective cooling. -- NEMA 3R rated Heavy Gauge steel enclosure w/ventilation openings; sprinkler proof. -- UL & CSA approved. -- Includes: -- Delivery anywhere in the Continental USA.

REX MFG. 30-208/600 Auto TransformerSpecifications & Features: -- 30 KVA Auto-ventilated "dry type", 3-phase Auto Transformer; 208 Volt primary, 600 Volt secondary. -- Manufactured with 3-legged cores and high quality, grain oriented silicon steel; core steel is precision cut and stacked for reduced noise and losses; cores clamped with heavy steel brackets.Complete with: -- Coil windings with high quality copper magnet wire; -- Class 220° C insulation is utilized througout the coil winding process; -- Coil is impregnated and baked in Polyester resin varnish; substantial cooling ducts for effective cooling.Includes: -- NEMA 3R Indoor, sprinkler proof steel enclosure; -- UL & CSA approval; delivery anywhere in the Continental USA.

REYNOLDS - PF-622, ...Paper Bale BreakerSpecifications: -- Main motors: (2) 20 HP -- Conveyor motor: 1/5 HPEquipped with: -- (2) Rotors with adjustable bearing rails for adjustable height. -- Heavy-Duty piano hinge conveyor belt. -- (3) Rows of steel pads welded to the underneath. -- Replaceable teeth and hinged access door.

$8,750

ROBINSON - EF/T, ...36" Band Resaw Solid Heavy-Duty Vertical Resaw Equipped with: -- 3-Phase Electric Motor. -- 36" Dia. balanced steel wheels. -- 4" Max. band width capability provides feed speeds up to 100 FPM. Complete with: -- Large work surface for the most demanding jobs

ROBUST SD 70 Low Noise Vertical Wood Waste GrinderBasic machine features: -- BOVER_BASIC intelligent control system -- Power set (electric motor, reduction gear, and belt transmission) -- Vertical hopper -- Hydraulic pressure unit -- Robust and adjustable -- Hardened knives with four cutting edges with an extended service life -- Hardened cleaning knives -- Hardened cutting racks -- HARDOX sieve -- The motor start-up is controlled by the star/triangle systemTechnical Specifications: -- Main motor 30 kW (40 HP) -- Top Opening: 1445 mm × 1345mm ( 56.8" X 53") -- Rotor working length: 650 mm -- Rotor diameter: 270 mm -- Number of knives: 28 -- Screen hole diameter 10 - 50 mm -- Production capacity: 3 - 5 Cubic meter -- Weight : 1,750 Kg (3,850 Lbs) -- OAL 1973 mm X 1548 mm (77.6" X 61")

ROBUST SD 60E Low Noise Vertical GrinderFeatures: -- One-piece machined cutterhead without welding for increased accuracy in knife fastening. -- The inserts can be used on their four (4) sides, which reduces operating and tooling costs. -- Overload protection. -- Several dimensions of HARDOX Screen available according to your requisitions.Technical Specifications: -- Motor (18.5KW) - 25CV/600V/60C/3Ph -- Top opening 946 mm x 567 mm (37" X 22.3") -- Cutterhead diameter 222 mm -- Cutterhead speed 80 à 120 RPM -- Quantity of TCT tips 14 ( + 2 latéral) -- Productiion capacity 3 à 4 m3/hour The capacity varies according to the dimensions of the grill, the type of wood and its humidity rate . -- Rear screen dimensions of holes 10 à 30 mm -- Dust hood 160 mm -- Machine dimensions 1881(L) x 1115(W) x 1670(H) (70" X 44" X 65.7")

ROBUST SD 45 Vertical Low Noise Grinder; The model SD 45 is characterized by low power consumption, high productivity, and ease to use.Features: -- Universal use (diverse wood, particle boards, veneer, MDF plates, cardboard boxes, plastics, etc.); -- Completely automatic operation -- The engine start-up is controlled by the star/triangle system -- Hardened knives with four cutting edges with an extended service life -- The crushing unit without any mechanical obstacles that could cause stopping -- The HARDOX sieve -- Simple installation, plug-in and start-up -- Economic use of energy -- Extremely quiet operation -- Simple and minimum maintenanceTechnical Specifications: -- Motor: 20 HP (15 kW) -- Rotor diameter: 150 mm -- Rotor speed 140 RPM 140 -- Number of knives: ) 17 (15 + 2) -- Top opening 640 mm x 430 mm ( 25.2" X 17") -- Dust extraction size 152 mm diameter -- Weight 950 Kg (2090 Lbs) -- Screen with holes available from 10 to 50 mm (comes standard with 12 mm screen) -- Production capacity: Approx. 0,5 - 1,5 Cubic meters per minute