704-288-1904

Carolina Machinery Sales (CMS) works in the sawmill, pallet and woodworking industries. In addition to the buying and selling of used equipment, we work as brokers and take in machines on consignment. Give us a call today!

971 Results Found

704-288-1904

Call for Price

Call for Price

Frog Mill 4-axis CNC Foam Carving Router Cuts 3D carvings up to 4' diameter and 8' length 26" stroke and 16.5" clearance under gantry Complete with Frog Scanner and Frog Skin Coating System

Call for Price

4300mm x 1920mm x 80mm work area 4.4 KW 3450 RPM motor 300mm blade with 30mm arbor 14'1" rip cut 6'3"cross cut 220/440 volt 3 phase

Call for Price

Stromab Stromab TR350 Up Cut Saw 4 HP Motor (230v/3ph) Variable Feed Speed This was a demo machine. Ready to ship!

Call for Price

Stromab WS1 Cutoff Saw Thru feed system with defecting o cutting preset sizes - NO optimizing! Operator can mark the board with crayon. Demo unit with low hours!

Call for Price

Call for Price

Superfici Flat Line Will be removed from service by the end of January 2024. Still under power.

Call for Price

Superfici Finishing Line 1 x 0000 GENERAL FEATURES OF OFFER Coatings : Universal Drying results vary according to the coating. Workpiece Dimensions (Approx.): Min. - max. length: 300 mm (12") - 2440 mm (8') Min. - max. width: 25 mm (1") - 1300 mm (51", 4' nominal) Min. - max. thickness: 3 mm (1/8") - 80 mm (3-1/8") Min. - max. weight: XX kg - XX kg TO BE ADVISED MACHINE SPECIFICATIONS: Passline Height : 900 mm Operating side: RH, as viewed from inlet of line. LH available. Speeds: Mechanical speed : 2-6 m/min (6.5 - 19.5 fpm). Others available. Electrics: Sprayer is explosion proof. All other machines and all control cabinets are not explosion proof and must be placed outside any hazardous area. Voltage: 480 V / 3 Ph / 60 Hz (To be confirmed). Manufactured with UL norms components. Compressed air : 6 bars (90 PSI). See individual machine descriptions for consumption. Thermal connection - electric coils. These general features supersede the individual machine specifications in the event of any disagreement. MACHINE SPECIFICATIONS: 1 1 x 040201 AUTOMATIC SPRAYING MACHINE "COMPACT SPRAY Plus / R" With combined lacquer recovery system. Central belt conveyor in the spray area in special material, to work with lacquers and stains, and a patented combined lacquer recovery system for recovery and cleaning of the conveyor. Technical data: - Belt conveyor overall width 1700 mm - Infeed roller conveyor length 890 mm - Outfeed roller conveyor length 595 mm - Total machine length 3385 mm 1 x 040200 GENERAL DESCRIPTION The automatic through-feed spraying machine mod. "COMPACT SPRAY Plus" consists of: Infeed and outfeed driven roller conveyor system. Central belt conveyor in the spray area. The conveyor system can be in the following two options: - code 040201: with conveyor belt in special material, to work with lacquers and stains, and a patented combined lacquer recovery system for recovery and cleaning of the conveyor. The recovery system is mounted on trolley and extractable from the machine to make cleaning operations easier ; Lacquer application system consisting of a reciprocator with double arm driven by brushless motor and sliding on a high precision prismatic guide. The two arms are equipped with guns holder supporting up to max four guns each with two lacquer circuits (with possibility to install a third circuit). Based on the type of product as well as the grammage to be applied, it is possible to use three different types of guns (not included in the supply): - low pressure guns - airmix guns - airless guns Booth, in welded and painted steel framework, with glass sidewalls opening on both sides. The booth is also equipped with an inspection window on the work piece infeed side as well as an illuminated wall on the workpiece outfeed side. The pressurization system consists of two air intake blowing fans combined with a pre-filtering system, allowing easy access for inspection, as well as a filtering roof inside the

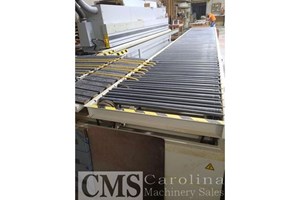

This system is no longer needed by the seller. It is still under power and available for inspection. This was pulled off production about a year ago and they were running about a 1,000 pallets on a full 8 hour shift with the machine. - 15' Powered infeed roller - High speed pallet dispenser - 1-Man push button control - (4) High speed pallet stackers with stop gates and transfers - Outfeed gravity rolls from each stacker - Stack eject gravity rollers 480V, 3 phase 60amp power - This can be inspected under power Monday - Friday from 8AM to 4PM, call now to set up an inspection!

Call for Price

Capacities: 11” minimum length 98” maximum length 1” minimum width 32” maximum width 5/8” minimum thickness 3” maximum thickness Includes glue conveyor Model 300194-300198

Call for Price

Capacities: 11” minimum length 98” maximum length 1” minimum width 32” maximum width 5/8” minimum thickness 3” maximum thickness with a conversed glue spreader(model 30J)

Call for Price

Call for Price

CMS represents Big on Dry (BOD) Thermo Wood Kilns in the USA. This system is another on elf our customers in the USA who is producing mostly poplar and oak decking. Big on Dry has improved the Thermo-Modification process with their THERMOWOOD (THW) line and provides complete "turn key" systems. The PLC control systems allow programming for a wide variety off wood applications. This allows the same systems to work with very delicate wood that is hard to treat to thicker wood that will be used for outdoor products. The THW system can also be used as a conventional kiln with steam. Basic systems include: - Kiln completely built with stainless steel and aluminum - Initial humidy of 10-15% is reduced to 5-6% - Loading options: Side or Trolley - Heating options: Gas or Wood Burner - Humidification: Combined Spraying System

Call for Price

Thermwood C42 CNC Router (2) 5'x5' Tables It has 2 large routers, 4 smaller routers, and 2 aggregate heads in the turret Travainni Vacuum Pump Note from Seller: Includes two shaper heads that are not mounted into the turret and one pneumatic drill head that is not mounted into the turret. I also have one seat of Microvellum cabinetry program that I will transfer to you along with the purchase.

Call for Price

Call for Price

Call for Price

Tidland 470 Sander This system was used in a particle board plant that has been closed around 10 years.

Call for Price

- Automated push feed saw system for fast and accurate cutting of wood and plastic - Adjustable cutting envelope so you can set the envelope to the needed width of the material you are cutting, whether single piece or pack - Tigersaw 1000's Dynamic Optimization software give you the best yield by determining the optimal cutting order from your parts list - Value based optimizing allows the operator to value items in a cut list individually - Accuracy: +/- .012" - Push capacity: 90 lbs.(on flat tables) - Cutting envelope with 450 mm blade: 1" x 16" up to 5" x 6" - Cutting envelope with 500 blade: 1" x 16" up to 6" x 6" - Maximum clearance length for loading: 12' - Material feeds right to left - 24" wide x 18' long flat infeed table - 24" wide x 12' long roller outfeed table - Complete guarding of the saw blade area, safety interlocked guard door and saw blade door (neither can be opened while running) - Saw motor: 10 hp - Dust collection requirements: 600 cfm (4" dust port) - Air requirements: 85 psi (water and oil free air) - Electrical: 15 full load amps on 460 volt

Call for Price

Automated push feed saw system for fast and accurate cutting of wood and plastic Adjustable cutting envelope so you can set the envelope to the needed width of the material you are cutting, whether single piece or pack Tigersaw 1000's Dynamic Optimization software give you the best yield by determining the optimal cutting order from your parts list (Will cut the mark) Value based optimizing allows the operator to value items in a cut list individually Download parts files to Tigersaw 1000, comes with TigerLink 6 (Tigerstop's cut list downloading software) Accuracy: +/- .012" Push capacity: 90 lbs.(on flat tables) Cutting envelope with 450 mm blade: 1" x 16" up to 5" x 6" Cutting envelope with 500 blade: 1" x 16" up to 6" x 6" Maximum clearance length for loading: 12' Material feeds right to left 24" wide x 18' long flat infeed table 24" wide x 12' long roller outfeed table Complete guarding of the saw blade area, safety interlocked guard door and saw blade door (neither can be opened while running) Saw motor: 10 hp Dust collection requirements: 600 cfm (4" dust port) Air requirements: 85 psi (water and oil free air) Electrical: 15 full load amps on 460 volt INCLUDES: Tablet package: TigerTouch software loaded onto a Surface Pro tablet. Includes downloading software (DNLD), Dynamic optimization software (OPT), and TigerSET software (SET). Label printer